Grinding head with online electrolytic dressing function

A grinding head and function technology, applied in the direction of manufacturing tools, grinding machine parts, grinding/polishing equipment, etc. Processing requirements and other issues, to achieve the effect of improving grinding conditions, improving continuity and maintaining grinding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

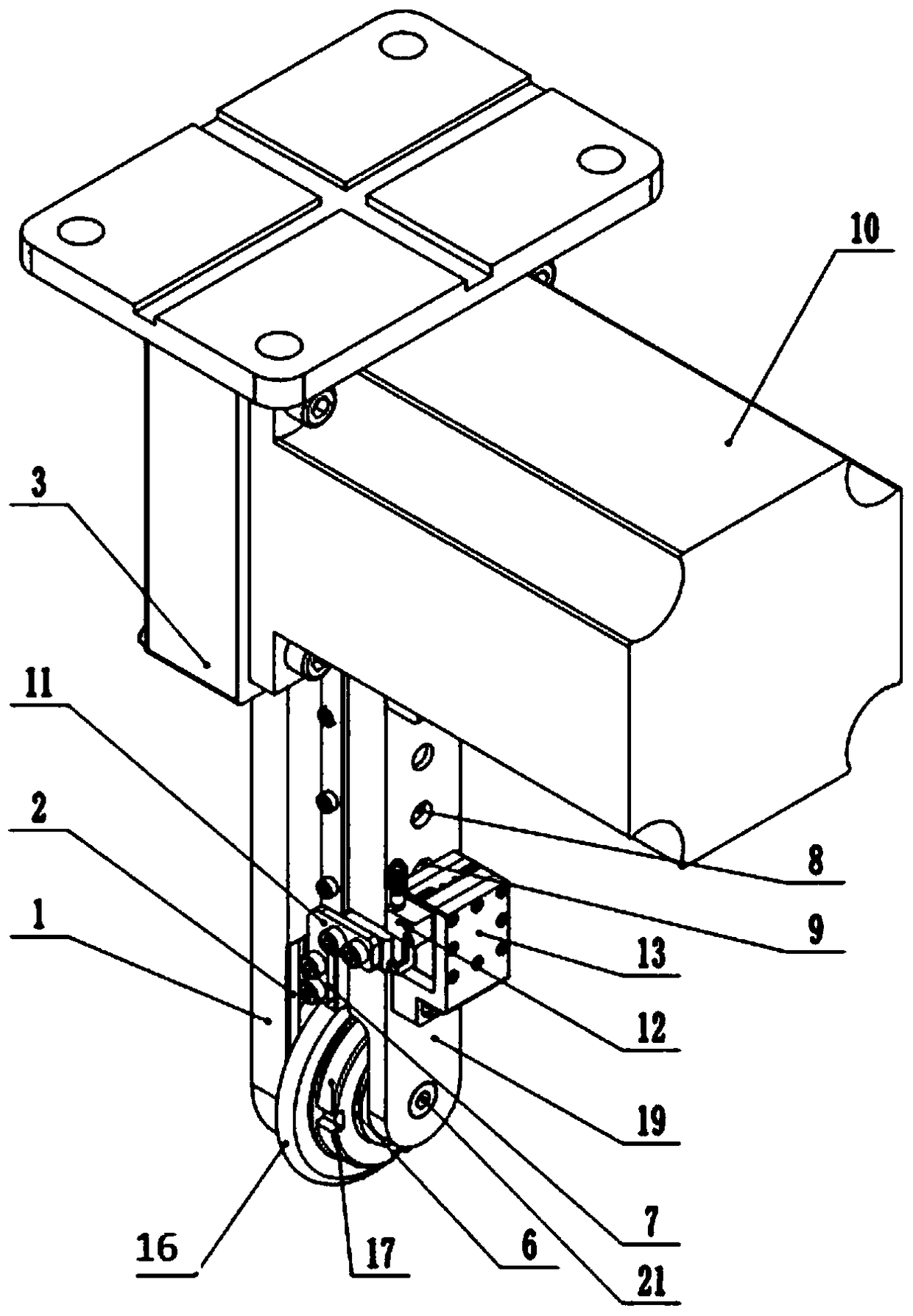

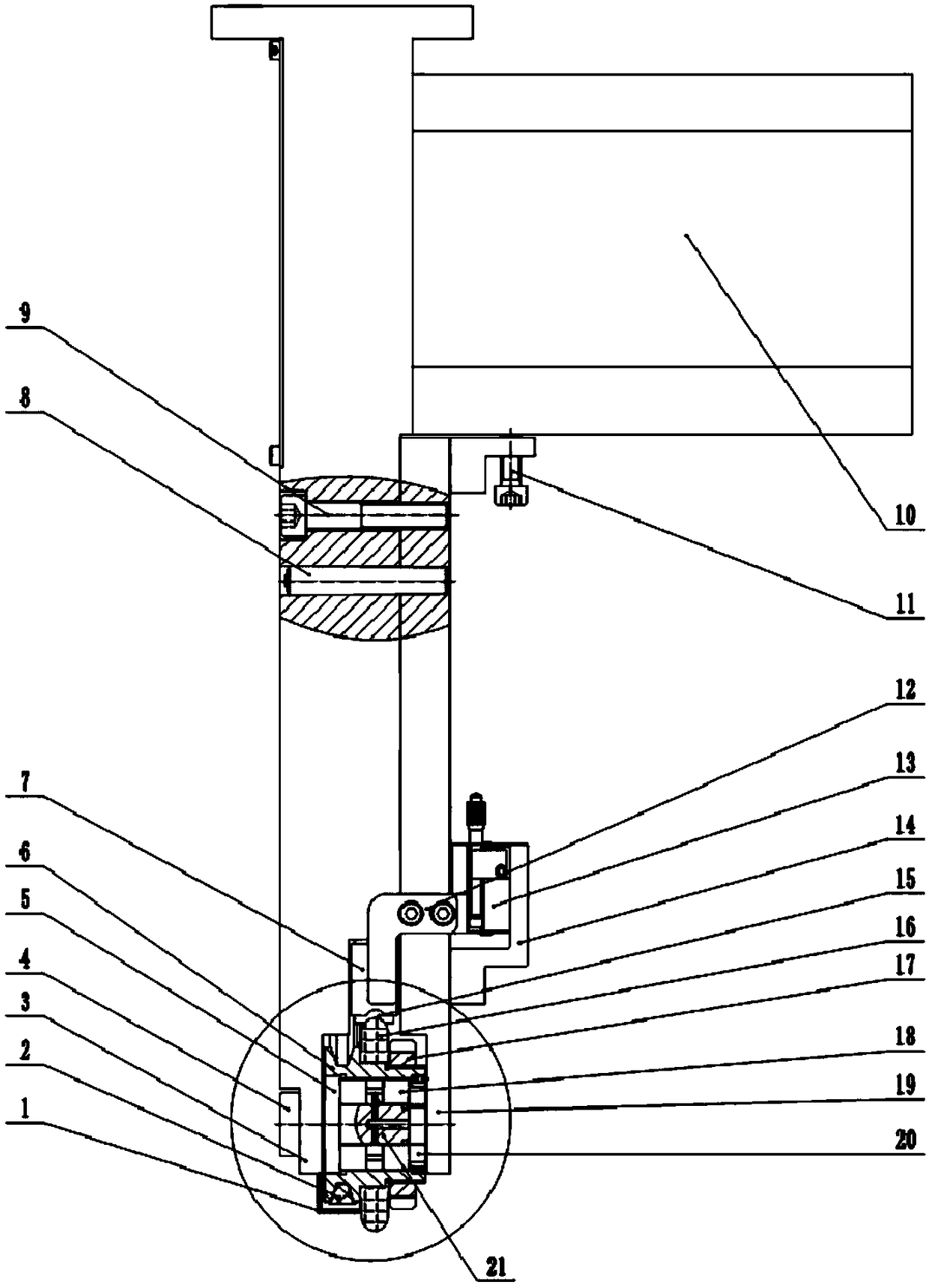

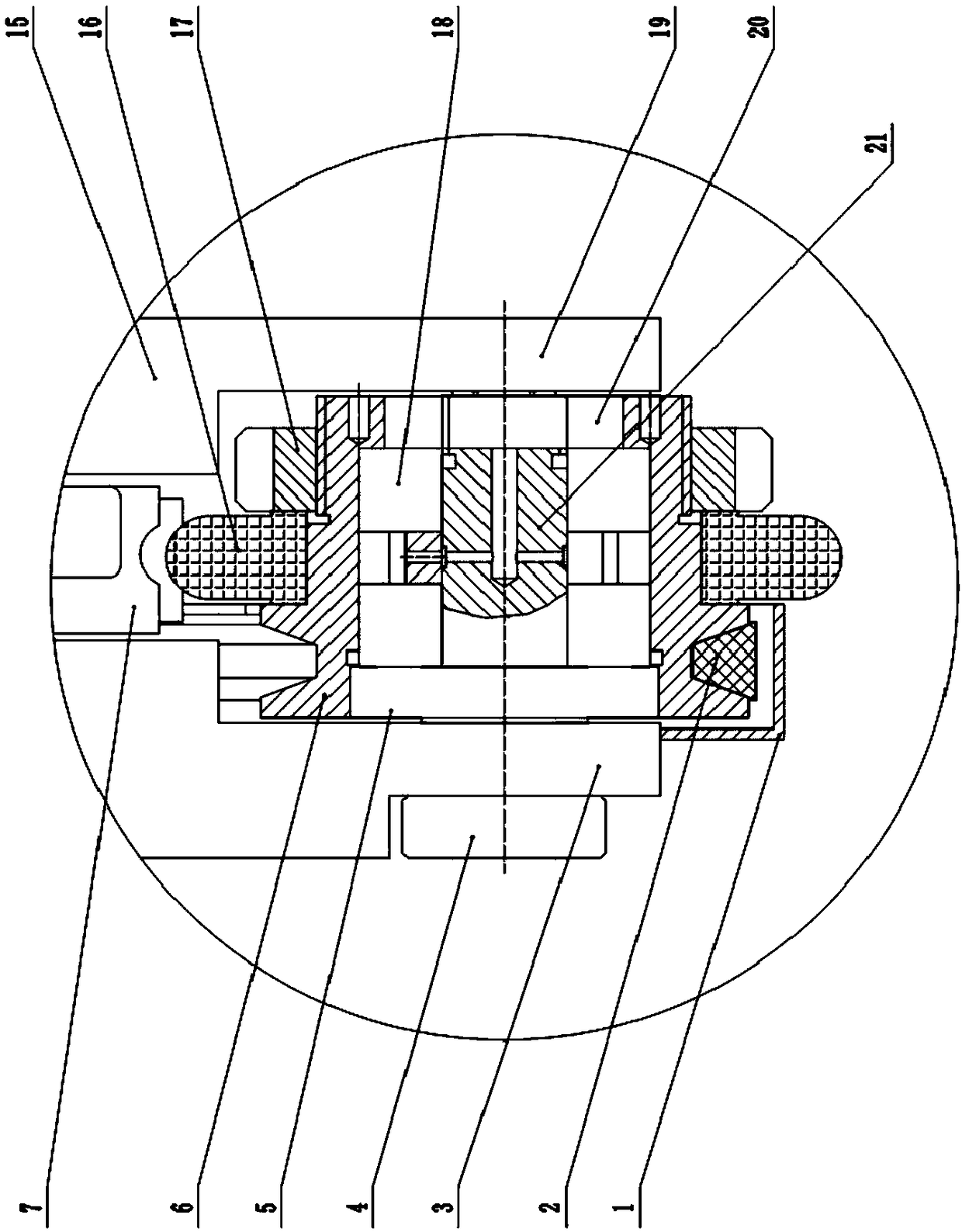

Image

Examples

Embodiment 1

[0038] Such as Figure 6 As shown, when grinding the thin-walled stainless steel spherical shell 22 parts at high speed, the sample cutting is first carried out. After several weeks of cutting, there is clogged grinding debris in the grinding wheel 16. The differential head on 13 continuously adjusts the gap between the copper shoe 15 and the grinding wheel 16, and observes the electrolytic removal of grinding debris in the grinding wheel 16, so as to find a better distance between the copper shoe 15 and the grinding wheel 16. After adjusting the distance, carry out Grinding process is carried out according to the predetermined trajectory. During the processing, observe the clogging of grinding debris on the grinding wheel 16. If the clogging of grinding debris increases, the copper shoe 15 has electrolytic removal, corrosion, etc. during processing, and then readjust the copper shoe 15. With the distance between the emery wheel 16, continue processing, after the processing is...

Embodiment 2

[0040] Such as Figure 7 As shown, the difference from Embodiment 1 is that the electrolytic grinding tank device of online electrolytic grinding debris is used to grind the outer spherical surface of the thin-walled stainless steel spherical shell 22 parts, and the described device is fixed on the external machine tool during the grinding process. And it is close to the outer spherical surface of the workpiece and revolves around the center of the sphere to feed. The thin-walled stainless steel spherical shell 22 always rotates around its axis. Combined with the high-speed rotation of the grinding wheel 16, a continuous and dense grinding track is formed on the surface of the workpiece. The revolution of the device The feed can realize the grinding of the entire outer spherical surface. The processing and operation are the same as the internal grinding. First, the sample is cut for trial cutting. After a few weeks of cutting, there is clogged grinding debris in the grinding wh...

Embodiment 3

[0042] Such as Figure 8 As shown, for the non-conductive grinding wheel 16, the electrode 23 with a special structure is designed, the positive pole and the negative pole are distributed alternately, there is an insulating material between the positive pole and the negative pole, and the pulse power is connected to control the change between the positive and negative poles. If there is grinding debris blocking the grinding wheel 16 during processing, when the positive and negative poles are connected through the grinding debris, the grinding debris will be electrolyzed; the removal of the clogged grinding debris will be completed; when the pulse power supply continuously changes the positive and negative poles on the electrode, the entire The clogged grinding debris in the grinding wheel 16 is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com