A kind of preparation method of nanometer graphite-based abrasive material

A technology of nano-graphite and abrasive materials, which is applied in the field of preparation of nano-graphite-based abrasive materials, can solve problems such as high thermal expansion coefficient, difficult to further improve grinding performance, and affect the use effect, so as to achieve high processing accuracy, maintain grinding performance, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

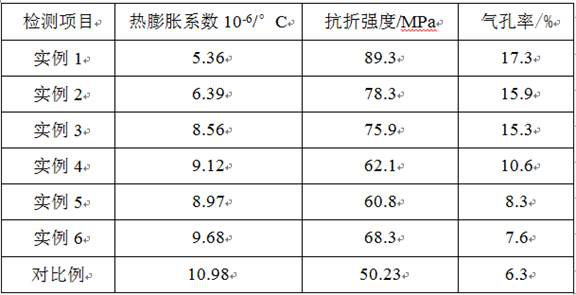

Examples

example 1

[0021]According to the mass ratio of 1:15, mix nano-graphite and absolute ethanol into No. 1 beaker, and move No. 1 beaker into an ultrasonic disperser. Add polyvinylpyrrolidone with 0.4 times the mass of nano-graphite to the mixture, and continue to ultrasonically disperse at an ultrasonic frequency of 60kHz for 40min, then move the No. , stirred and mixed at a constant temperature for 4 hours to obtain a nano-graphite dispersion; pour the precursor and absolute ethanol into the No. 2 beaker according to the volume ratio of 1:7, and move the No. 2 beaker into an ultrasonic disperser, and the ultrasonic frequency is 50kHz. and ultrasonically mixed for 45 minutes to obtain the precursor dilution; in parts by weight, 80 parts of nano-graphite dispersion, 100 parts of precursor dilution, 20 parts of 60% ethanol solution by mass fraction, and 5 parts of sodium fluoride , 5 parts of nano-iron powder, first pour the nano-graphite dispersion, sodium fluoride, and nano-iron powder int...

example 2

[0023] According to the mass ratio of 1:15, mix the nano-diamond powder and absolute ethanol into the No. 1 beaker, and move the No. 1 beaker into the ultrasonic disperser. Add polyvinylpyrrolidone with 0.4 times the mass of nano-diamond powder into the beaker, continue ultrasonic dispersion at 60kHz ultrasonic frequency for 40min, then move No. Stirring and mixing at constant temperature for 4 hours under the same conditions to obtain a nano-diamond powder dispersion; pour the precursor and absolute ethanol into the No. 2 beaker at a volume ratio of 1:7, and move the No. 2 beaker into an ultrasonic disperser, and Under the condition of frequency of 50kHz, ultrasonic mixing for 45min, the precursor dilution was obtained; in parts by weight, 80 parts of nano-diamond powder dispersion, 100 parts of precursor dilution, 20 parts of ethanol solution with a mass fraction of 60%, 5 parts of sodium fluoride, 5 parts of nano-iron powder, first pour the nano-diamond powder dispersion, s...

example 3

[0025] According to the mass ratio of 1:15, mix nano-graphite and absolute ethanol into No. 1 beaker, and move No. 1 beaker into an ultrasonic disperser. Add polyvinylpyrrolidone with 0.4 times the mass of nano-graphite to the mixture, and continue to ultrasonically disperse at an ultrasonic frequency of 60kHz for 40min, then move the No. , stirred and mixed at a constant temperature for 4 hours to obtain a nano-graphite dispersion; pour tetrabutyl titanate and absolute ethanol into a No. 2 beaker at a volume ratio of 1:7, and move the No. 2 beaker into an ultrasonic disperser, Under the condition of 50kHz, ultrasonically mix for 45min to obtain tetrabutyl titanate dilution; in parts by weight, take 80 parts of nano-graphite dispersion, 100 parts of tetrabutyl titanate dilution, 20 parts by mass fraction of 60% of ethanol solution, 5 parts of sodium fluoride, and 5 parts of nano-iron powder. First, pour the nano-graphite dispersion, sodium fluoride, and nano-iron powder into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com