Electrochemical discharge energizing micro-grinding method for silicon-based material micro part

A technology of silicon-based materials and tiny parts, applied in the field of micro-grinding, can solve the problems of difficult and efficient melting of workpiece materials and low processing efficiency, and achieve the effects of eliminating processing damage, improving processing efficiency, and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described through specific examples below in conjunction with the accompanying drawings.

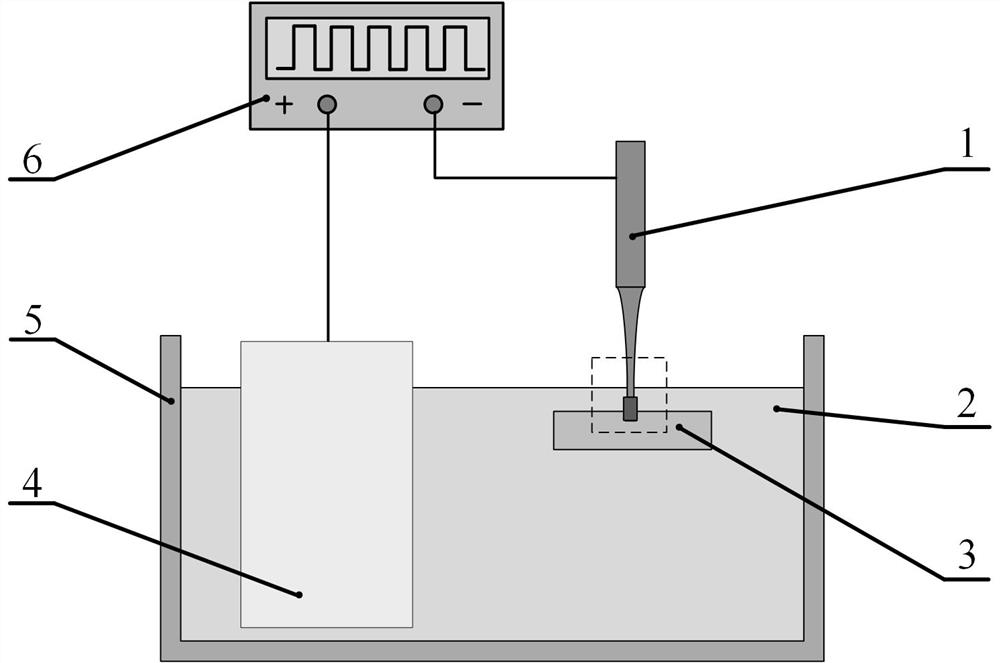

[0022] Such as figure 2 As shown, an electrochemical discharge energized micro-grinding method for tiny parts of silicon-based materials includes the following steps.

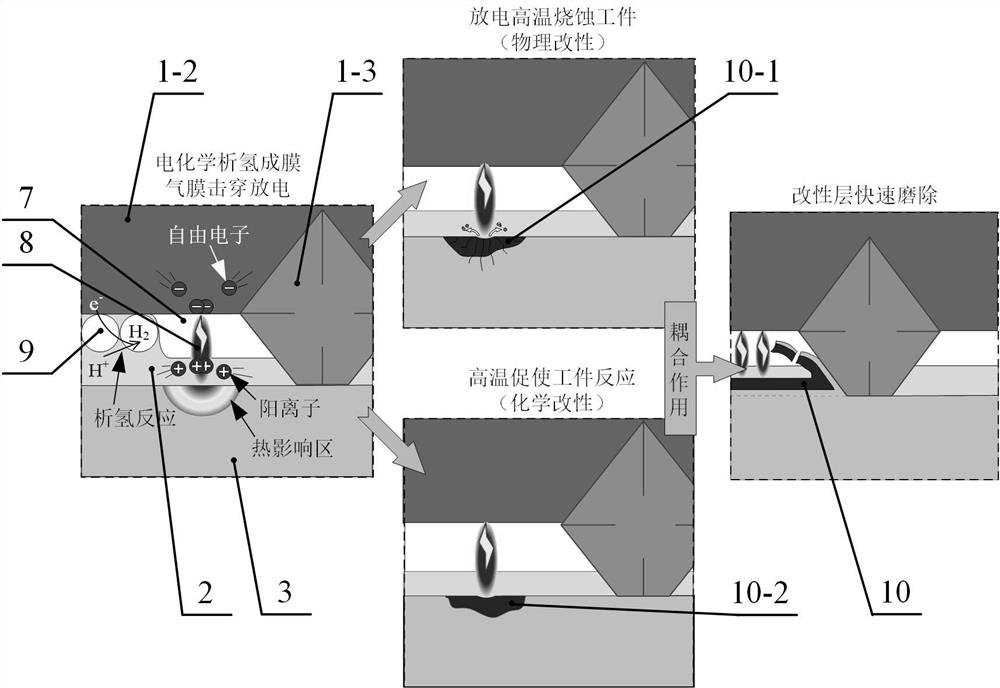

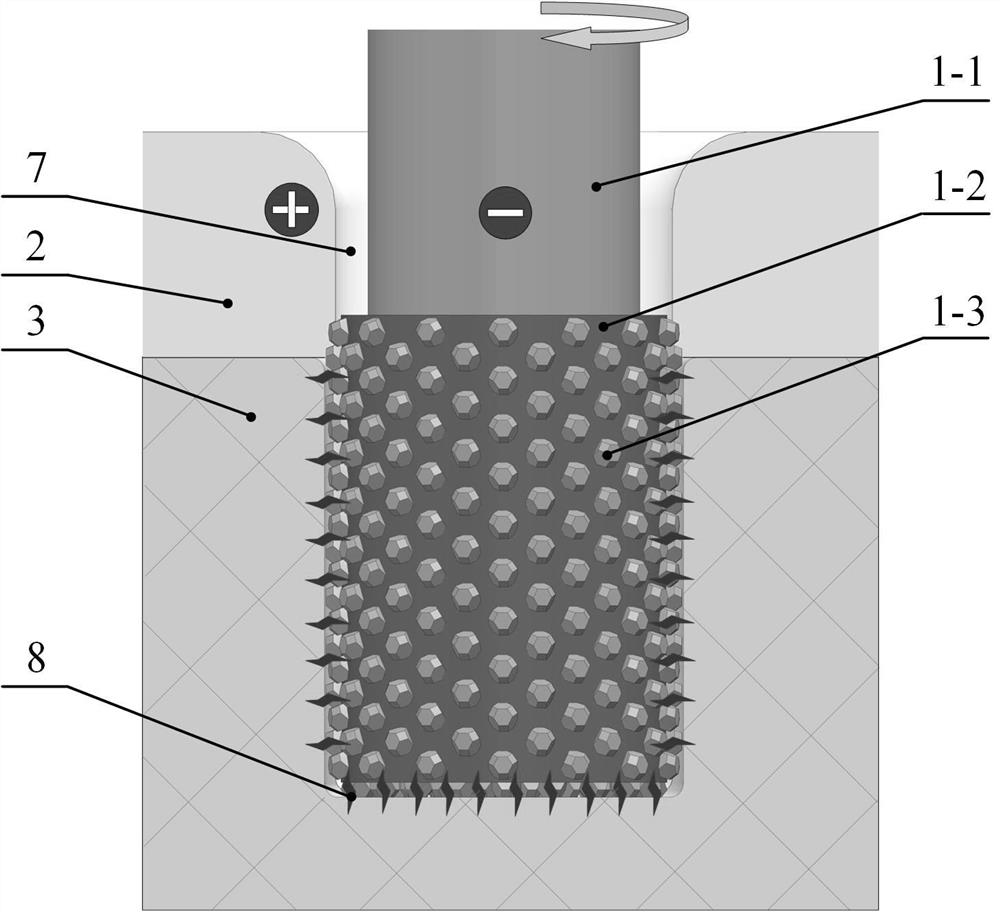

[0023] Step 1. Electrochemical reaction hydrogen evolution film formation: Among the electrical parameters of the pulsed DC power supply (6), the pulse width is 60 μs, the duty cycle is 0.2, and the peak voltage is 40 V; when the current of the pulsed DC power supply (6) passes through the loop , the microabrasive tool (1) undergoes electrochemical hydrogen evolution reaction in the grinding fluid (2), and the H in the grinding fluid (2) + Electrons are obtained from the cathode to generate hydrogen bubbles (9) and attach to the outer circumference of the micro-abrasive tool (1), and multiple hydrogen bubbles (9) fuse to form an insulating gas film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com