Space-adjustable smashing device for micro powder production

A crushing device and adjustable technology, applied in grain processing, etc., can solve the problems of unsuitable micro-powder crushing, high manufacturing cost, cumbersome operation, etc., and achieve the effect of simple structure, low production cost and improved screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

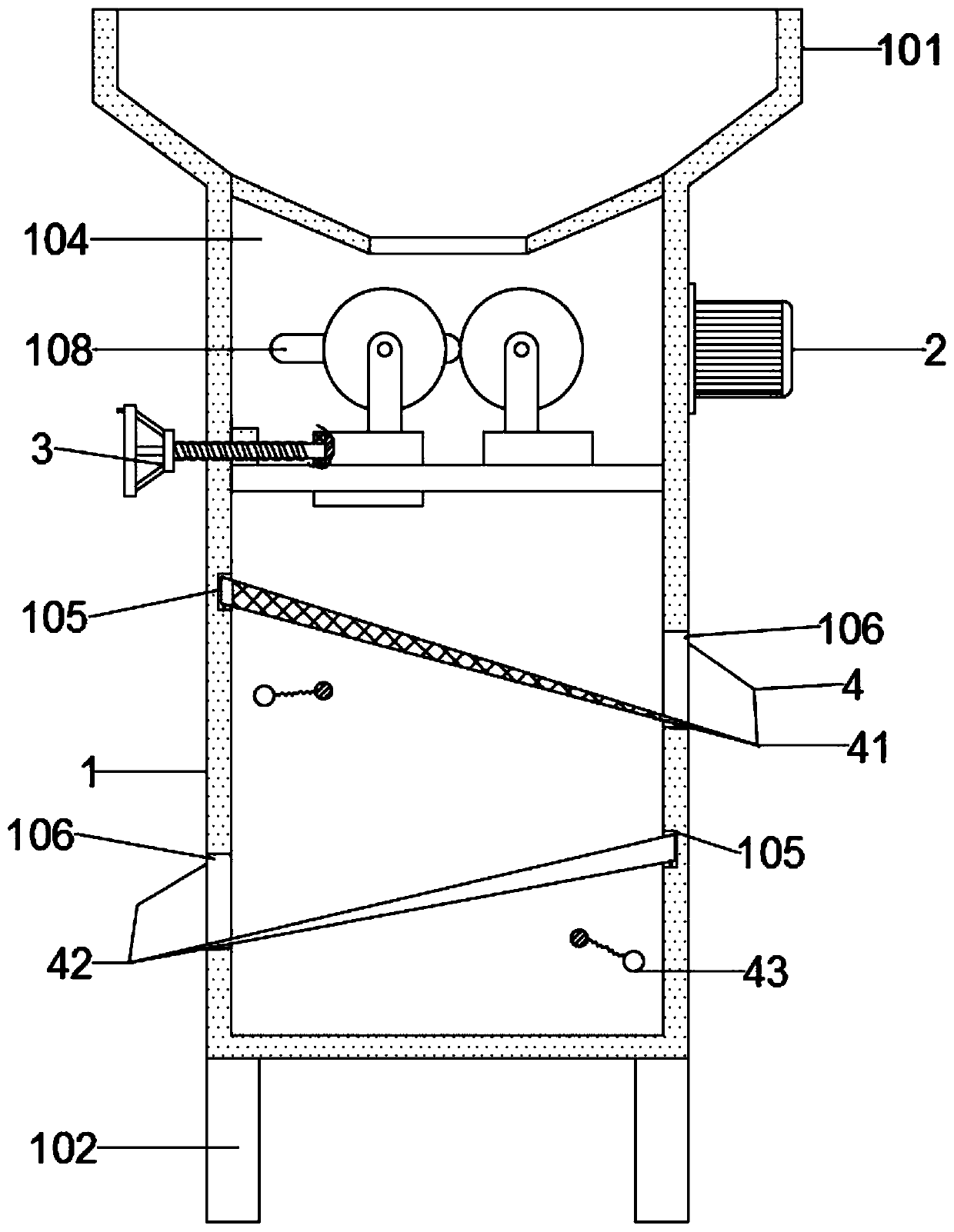

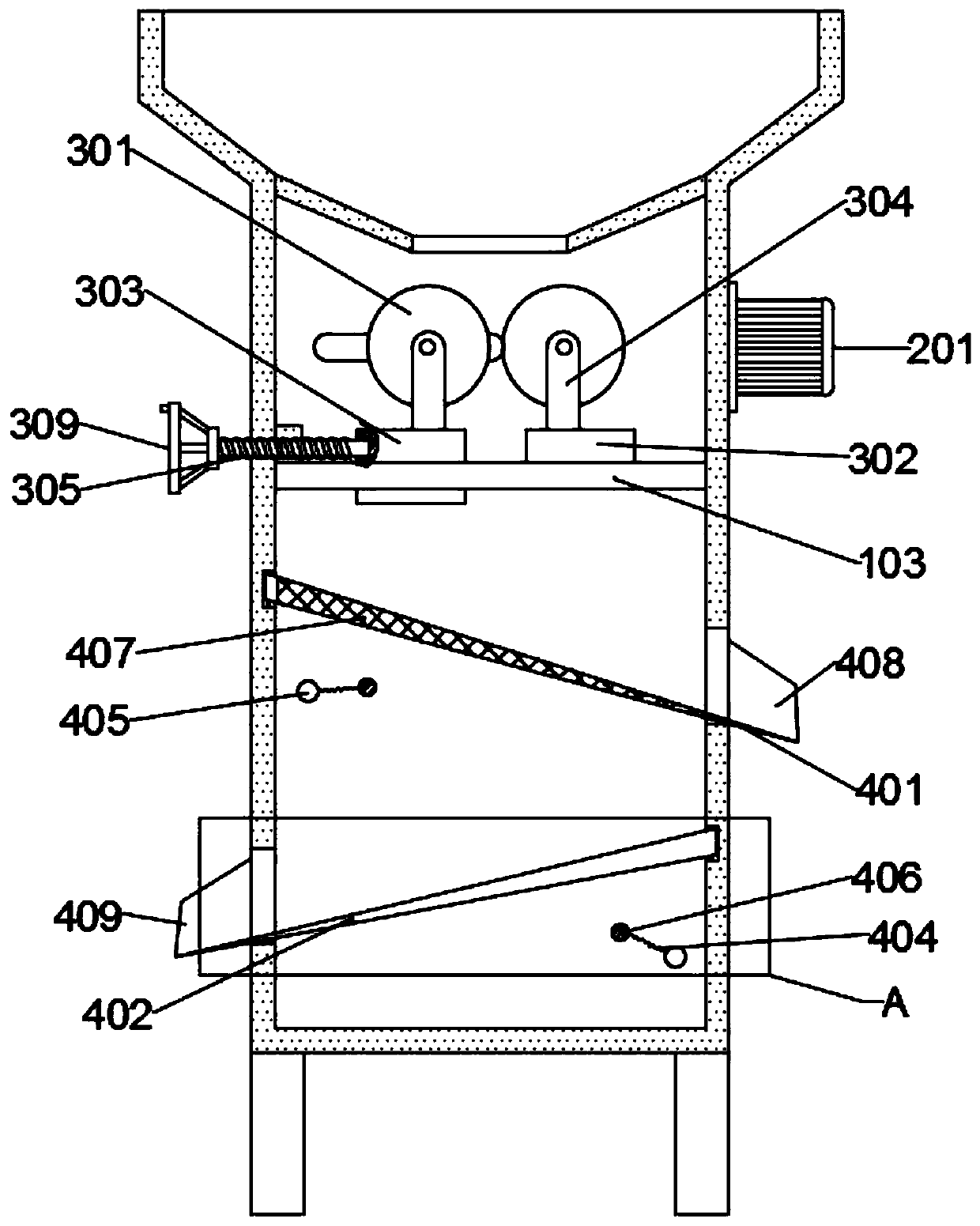

[0028] see figure 1 with figure 2 , a pulverizing device for fine powder production with adjustable spacing, including a pulverizing frame 1, a transmission mechanism 2, a pulverizing mechanism 3 and a screening mechanism 4; Supporting feet 102; the middle part of the cavity of the crushing frame 1 is fixed with a horizontal middle partition 103; the middle and rear side of the top of the middle partition 103 is fixed with a vertical isolation plate 104; the rear of the isolation plate 104 The side is the transmission mechanism 2, the front side is the crushing mechanism 3, and the right side of the isolation plate 104 is provided with a long hole 108 through the front and rear; the crushing mechanism 3 and the transmission mechanism 2 are directly below the screening mechanism 4.

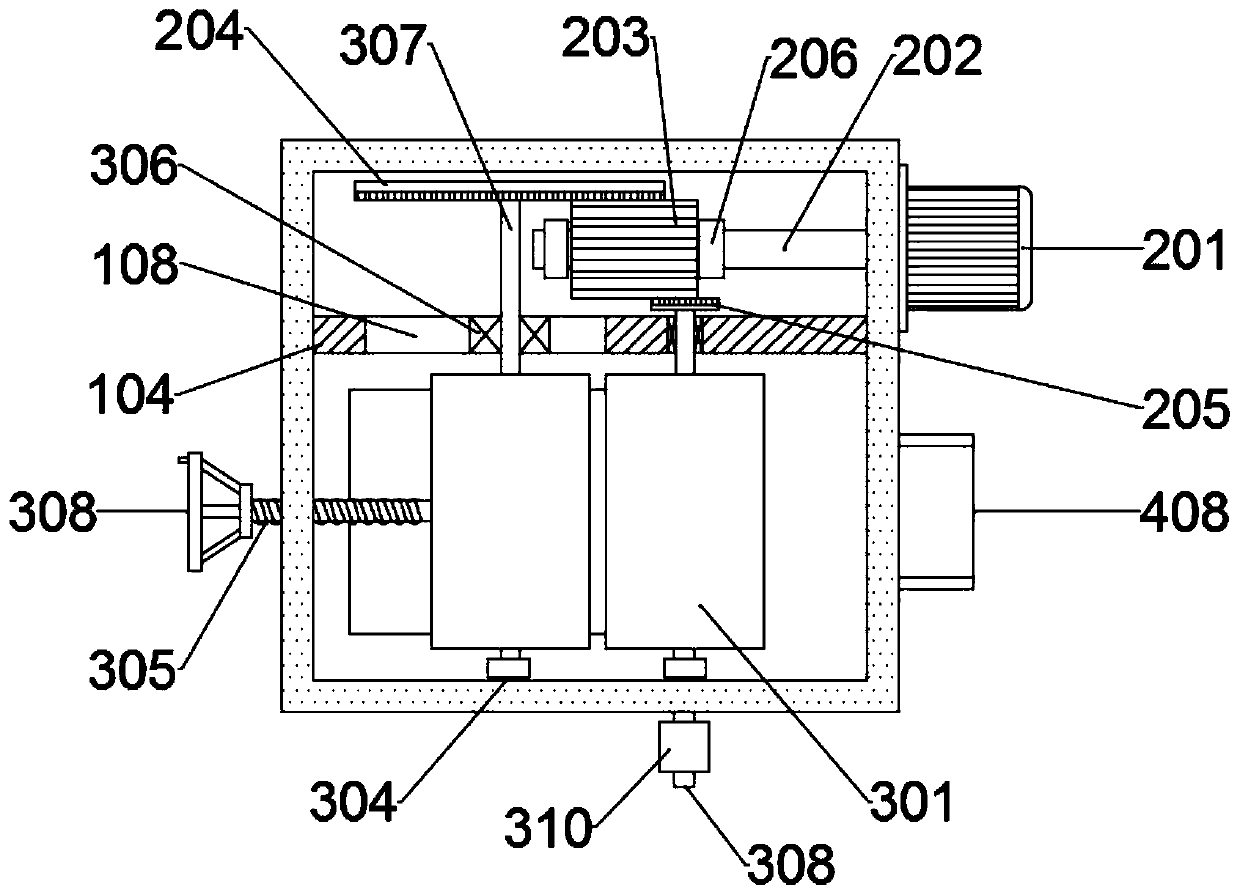

[0029] see figure 1 , figure 2 with image 3 Specifically, the transmission mechanism 2 includes a motor 201, a rotating shaft 202, a long gear 203, a first end gear 204 and a second end gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com