Gypsum raw material stirring apparatus for medical orthopedics department

A mixing device and gypsum technology, which is applied in the field of medical appliances, can solve the problem of not being able to distribute gypsum raw materials according to equal weight, and achieve high processing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

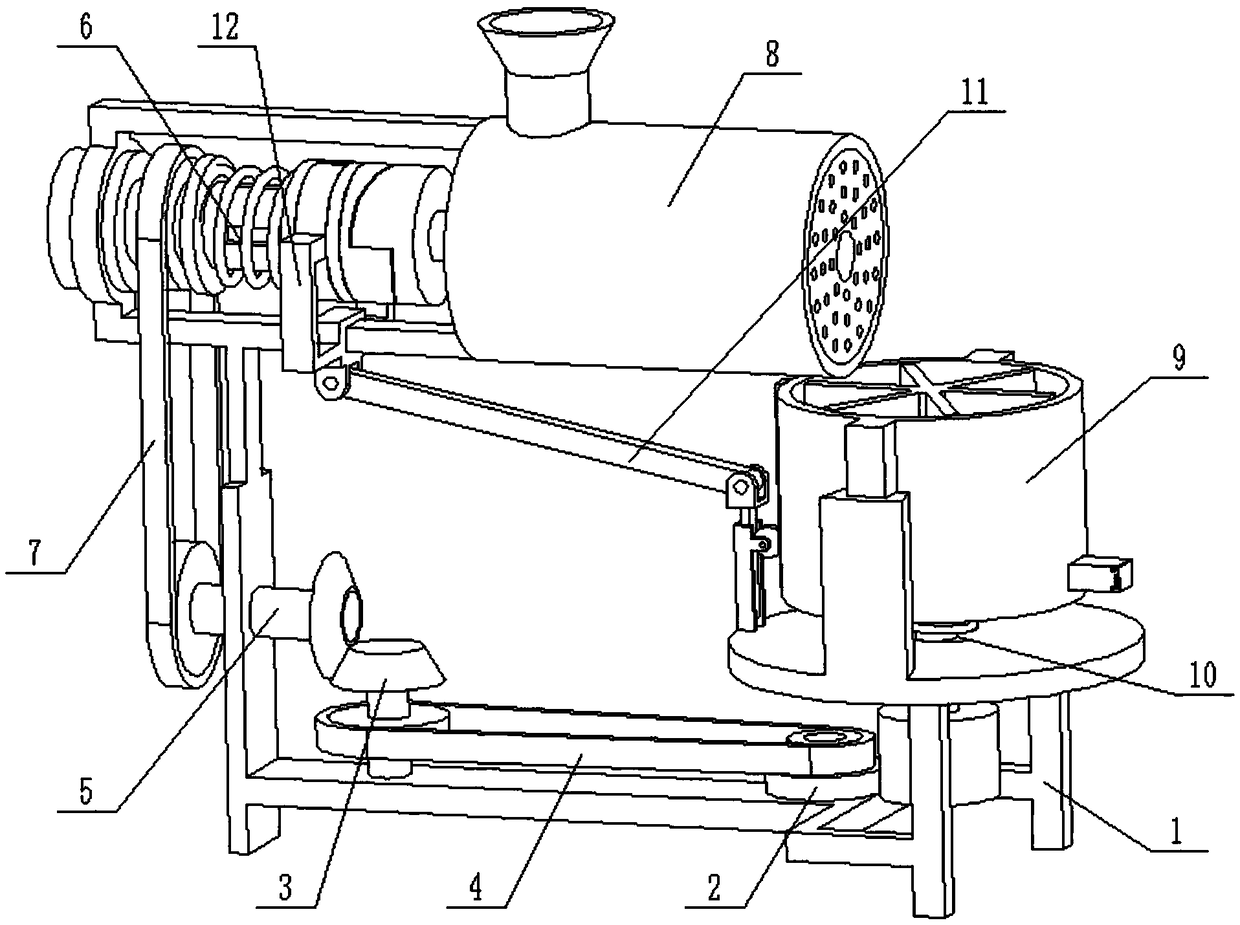

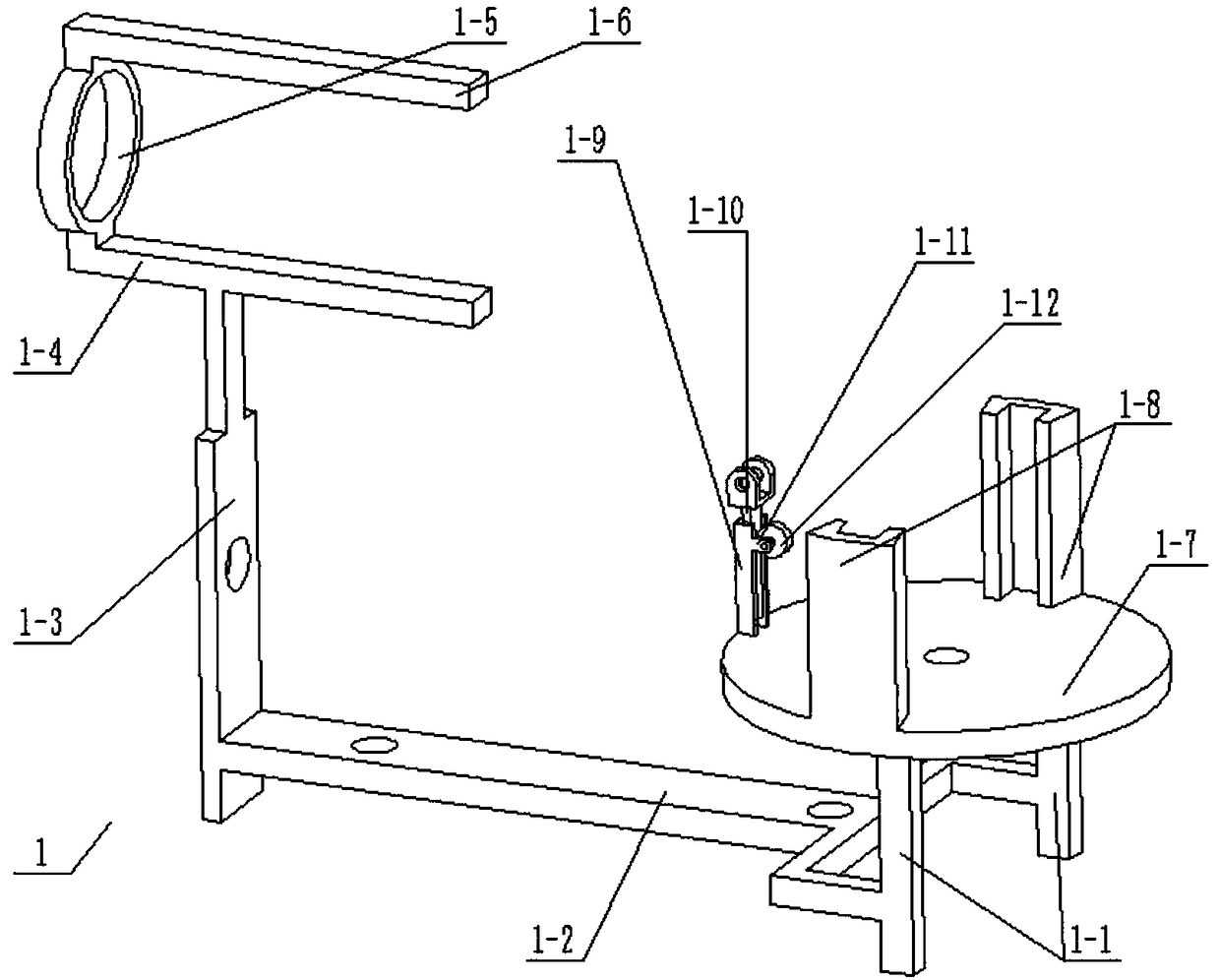

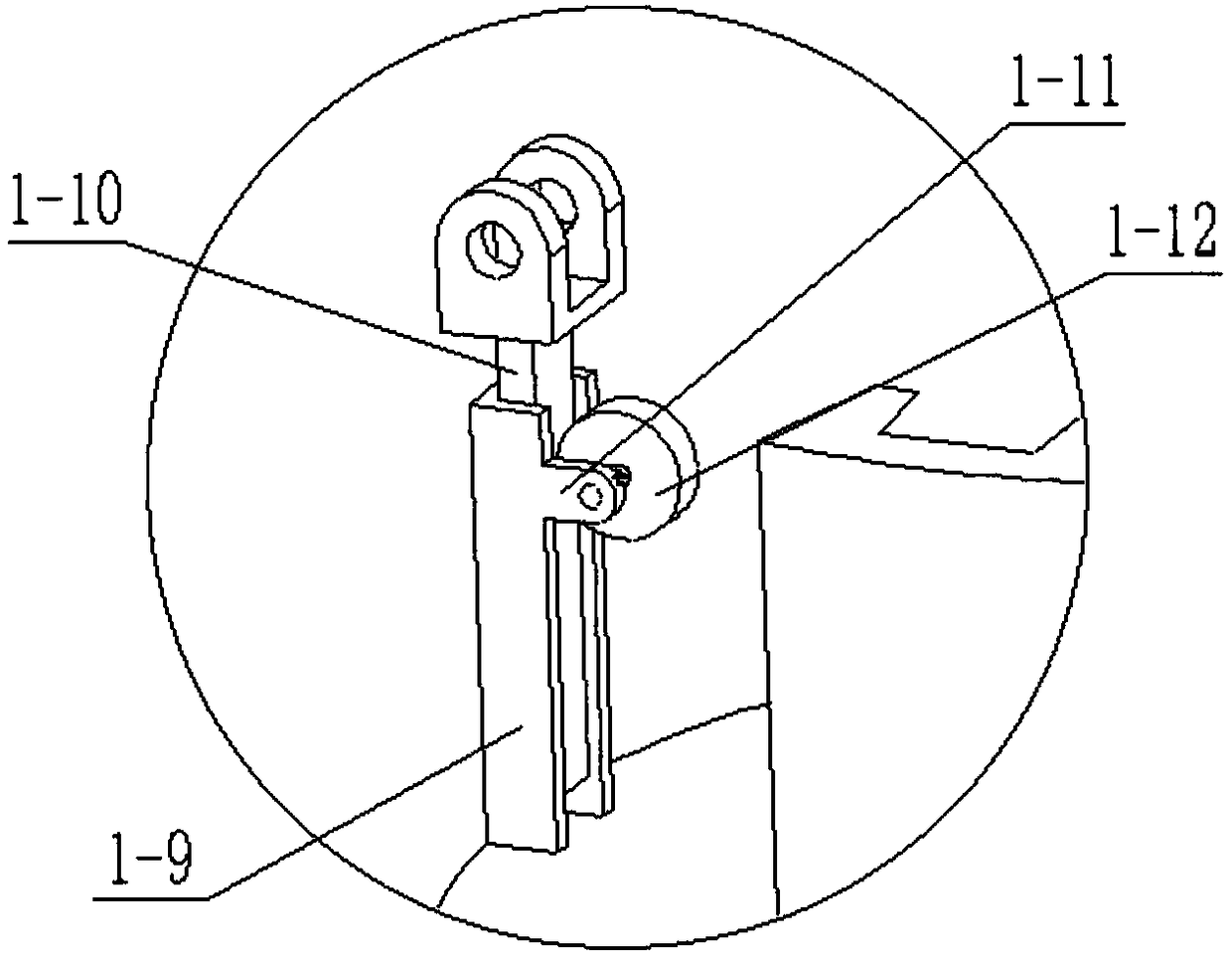

[0039] Combine below Figure 1-15 Describe this embodiment, a gypsum raw material mixing device for medical orthopedics, including a support frame 1, a transmission device 2, a conveying device 3, a conveying belt 4, a linkage device 5, a power unit 6, a linkage belt 7, a crushing device 8, and a stirring device 9. Compression spring 10, hinge rod 11 and power control member 12. The support frame 1 includes a support rod 1-1, a horizontal plate 1-2, a vertical plate 1-3, a lower rod 1-4, and a motor base 1- 5. The upper rod 1-6, the disc seat 1-7 and the U-shaped sliding seat 1-8, the left ends of the two support rods 1-1 are fixedly connected with the horizontal plate 1-2, and the left end of the horizontal plate 1-2 is fixedly connected There are vertical boards 1-3, the left ends of the lower rods 1-4 and upper rods 1-6 are fixedly connected with motor bases 1-5, and the lower rods 1-4 are fixedly connected with the upper ends of the vertical boards 1-3; two support rods 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com