Friction lever driving air static pressure guide rail

A gas static pressure and friction rod technology, which is applied in the direction of grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as high dependence on experience, inconvenient operation, and uncertainty in trimming accuracy, and achieve The effect of high rigidity, easy operation and good sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

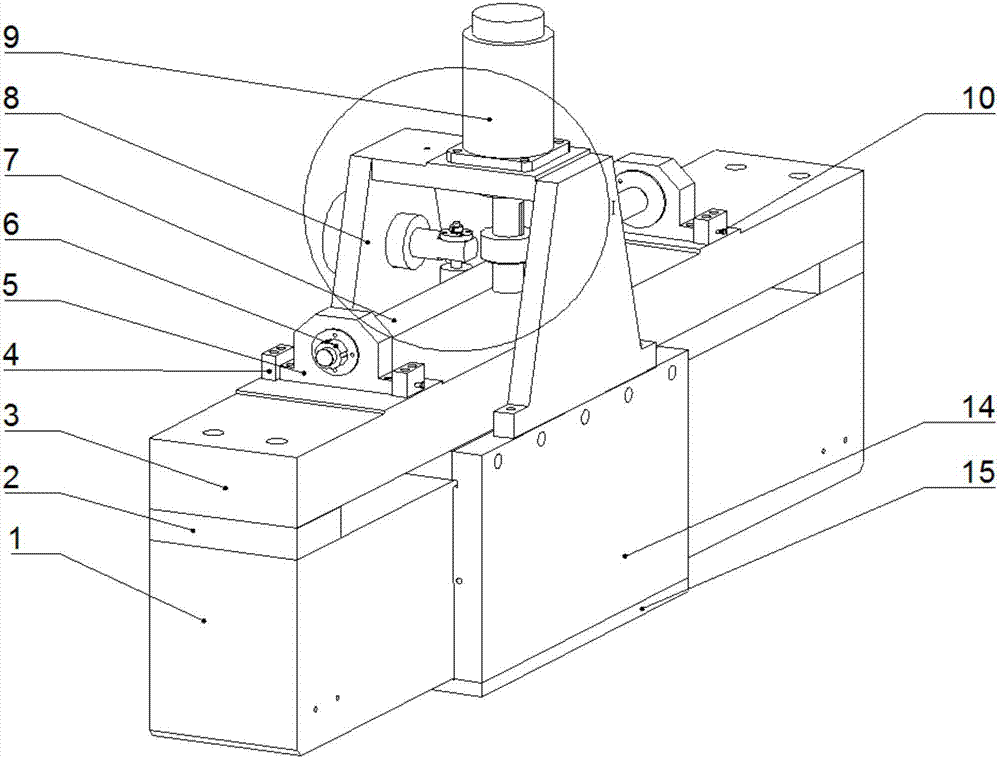

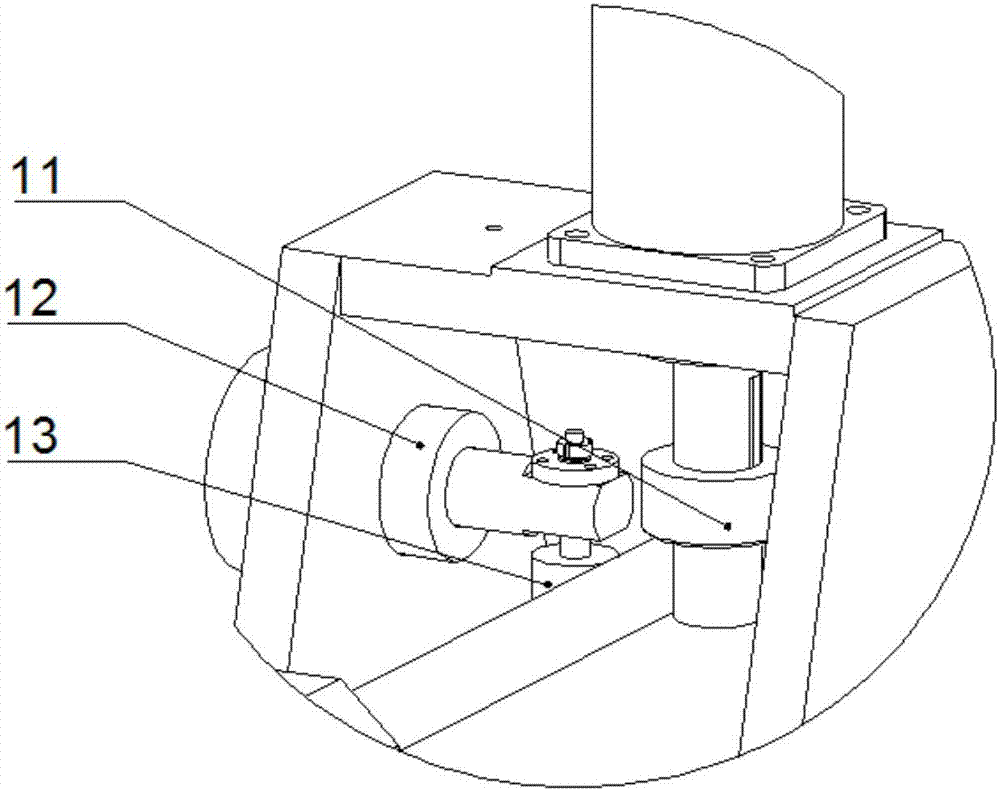

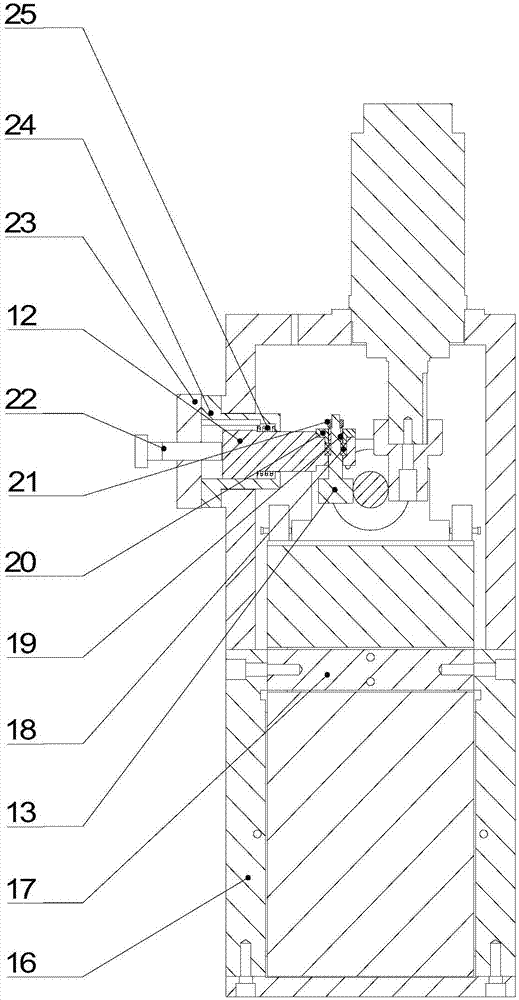

[0027] A friction rod-driven gas static pressure guide rail of the present invention, as a gas static pressure component suitable for precision trimming, has the characteristics of high precision, good precision retention, high rigidity, and high trimming efficiency, and can further improve the precision and efficiency of polishing processing . By adopting the structural mode combining the friction rod drive and the gas static pressure guide rail movement, the former has the characteristics of high precision, high efficiency, micro-feed, and no gap in transmission, while the latter has the characteristics of no friction, no vibration, no pollution, and high precision. , Error homogenization and other characteristics, the combination mechanism can realize the high-precision operation of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com