Patents

Literature

34 results about "Born rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Born rigidity is a concept in special relativity. It is one answer to the question of what, in special relativity, corresponds to the rigid body of non-relativistic classical mechanics. The concept was introduced by Max Born (1909), who gave a detailed description of the case of constant proper acceleration which he called hyperbolic motion. When subsequent authors such as Paul Ehrenfest (1909) tried to incorporate rotational motions as well, it became clear that Born rigidity is a very restrictive sense of rigidity, leading to the Herglotz-Noether theorem, according to which there are severe restrictions on rotational Born rigid motions. It was formulated by Gustav Herglotz (1909, who classified all forms of rotational motions) and in a less general way by Fritz Noether (1909). As a result, Born (1910) and others gave alternative, less restrictive definitions of rigidity.

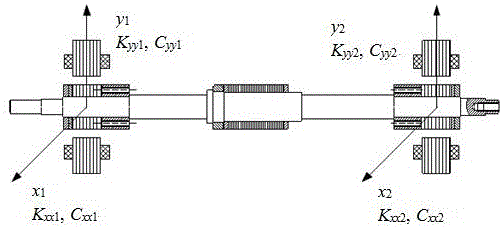

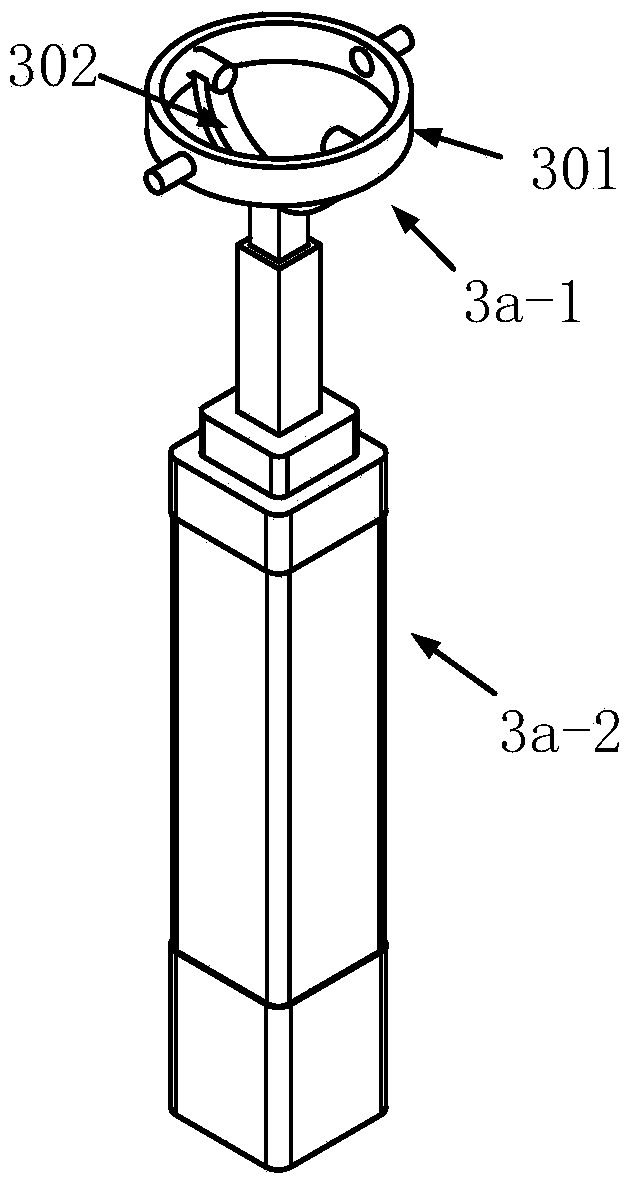

Rotor system dynamic balance excitation identification method

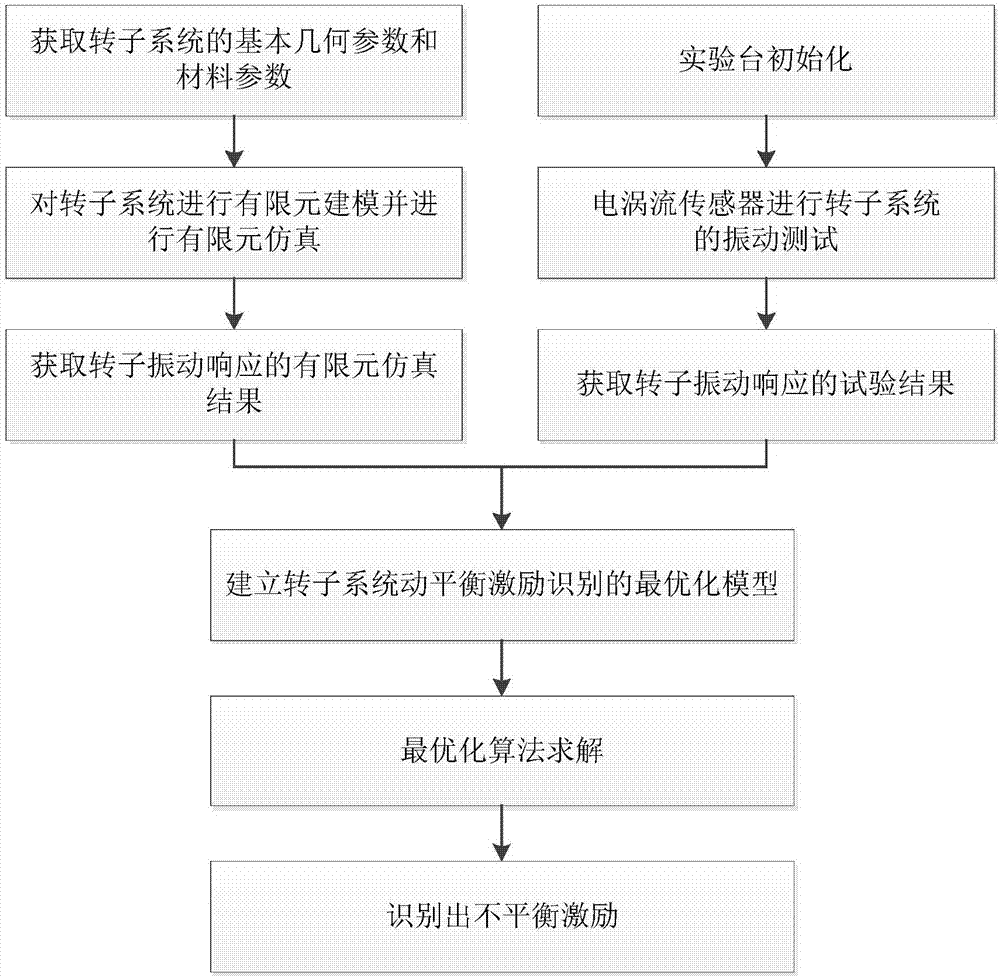

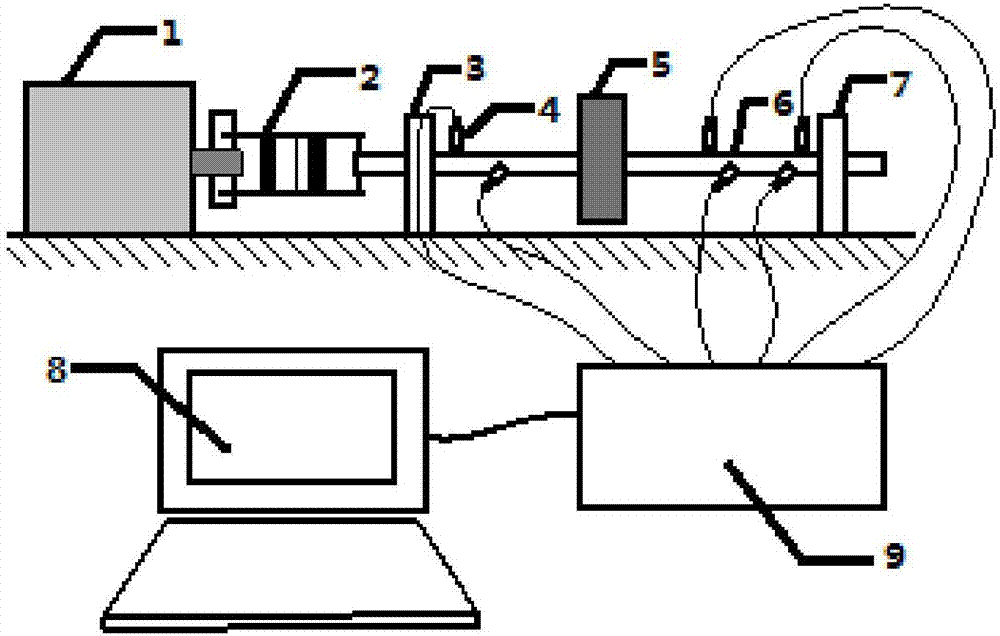

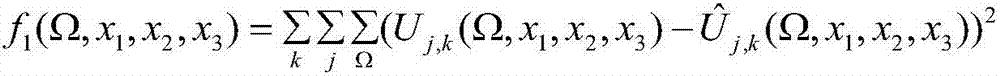

ActiveCN107389267AOvercome cumbersomeLow costStatic/dynamic balance measurementElasticity measurementElectricityElement model

A rotor system dynamic balance excitation identification method is disclosed. The method is characterized by carrying out experiment determination; collecting output of an eddy current sensor on a rotating shaft and acquiring an actual measurement value of a rotor vibration response; when a motor stops rotating, collecting a geometrical parameter and a material parameter of a rotor system and establishing a finite element model of the rotor system; through finite element simulation, acquiring a simulation value of the rotor vibration response; setting a rotor system dynamic balance excitation identification target function and an optimization model; and using an optimization algorithm to carry out iteration solution and acquiring an initial imbalance amount, bearing rigidity and a damping parameter of the rotor system. By using the method, a simulation result and an experiment result are optimized; based on parts of experiment data, through rotor system dynamic balance excitation possessing good robustness and identification precision, effective identification is performed; the method can be easily applied to actual engineering; and an application is less limited by an equipment result and a test condition.

Owner:HARBIN ENG UNIV

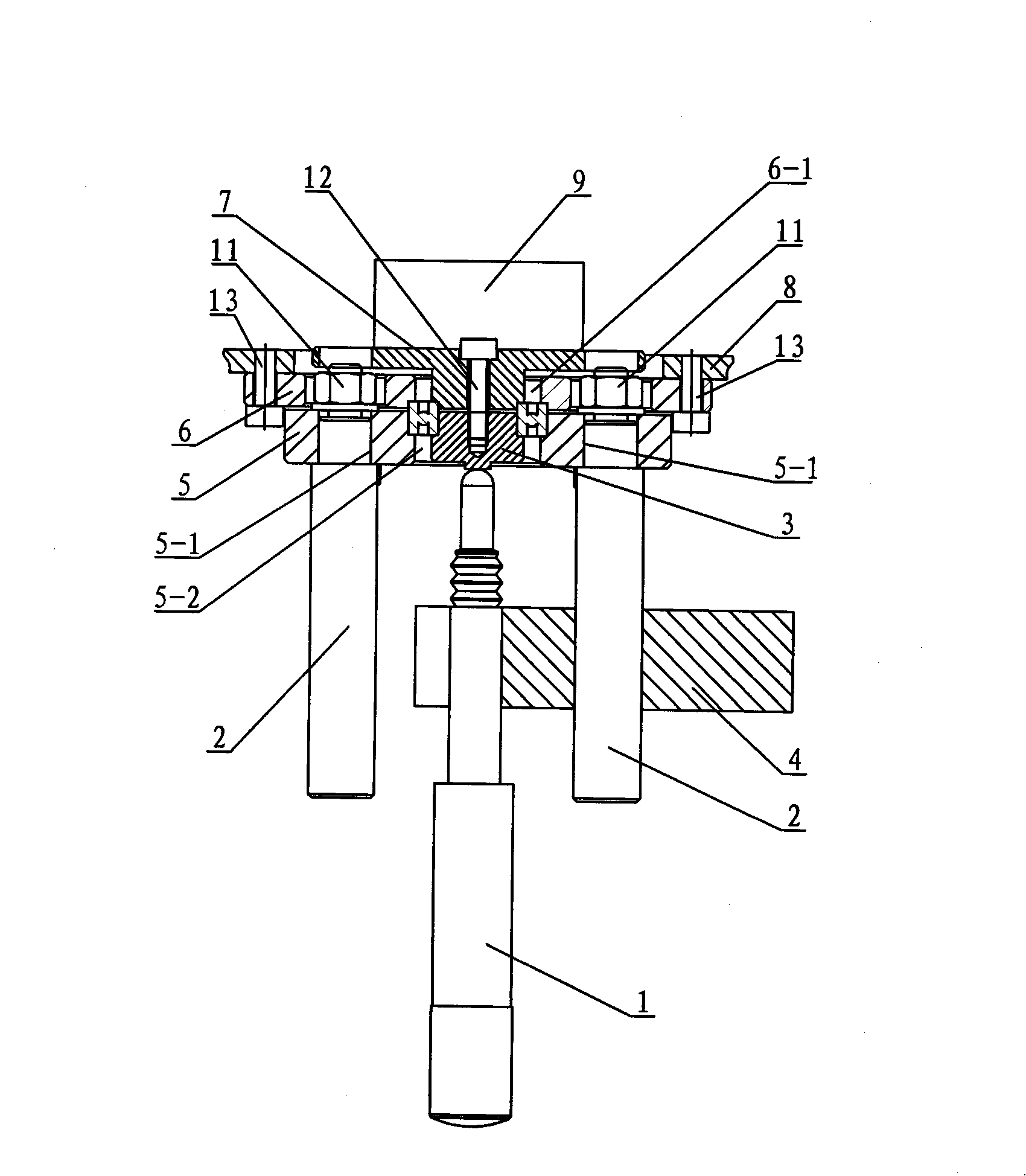

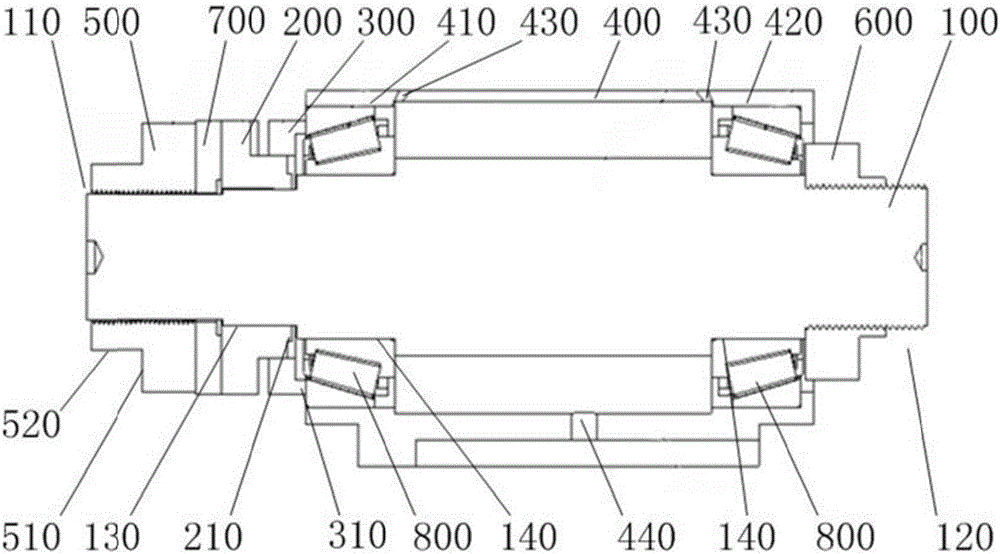

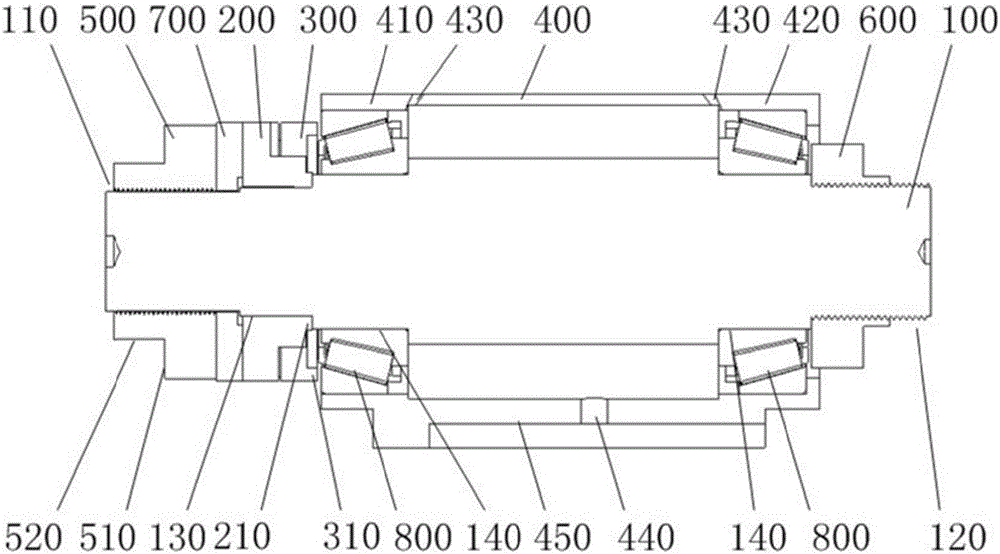

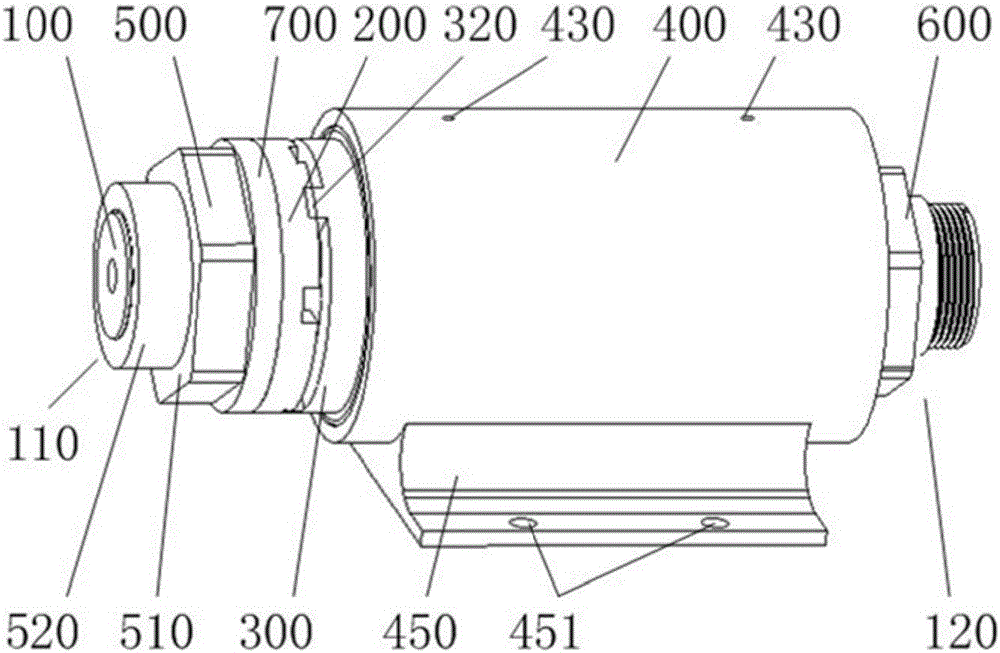

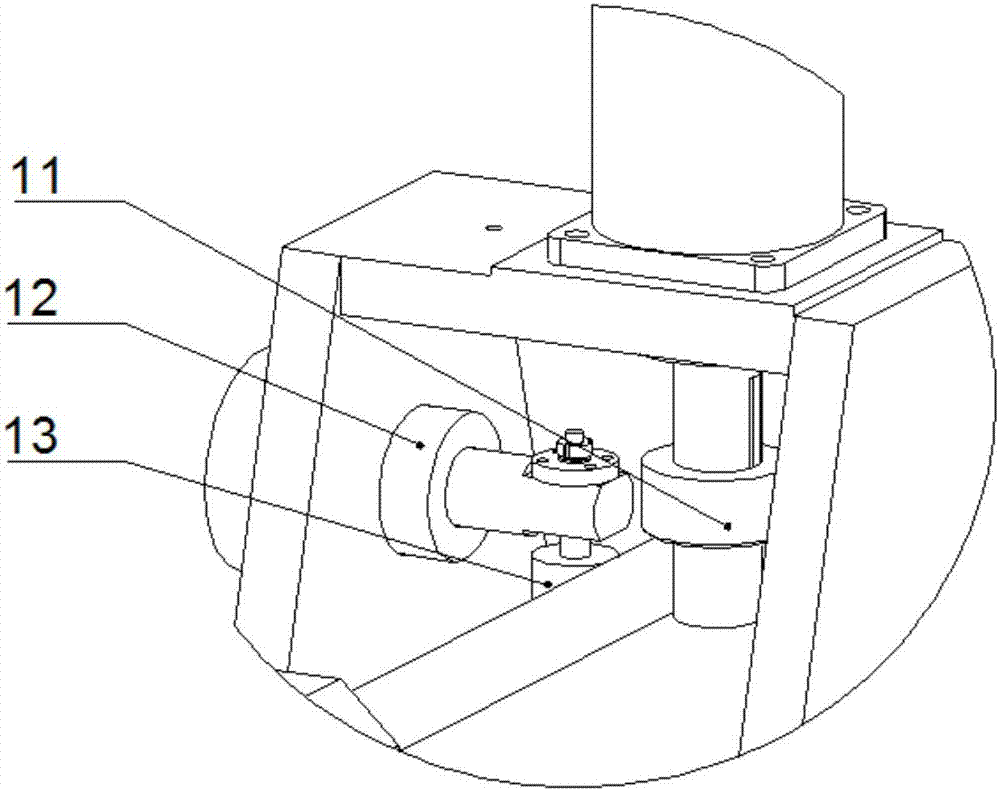

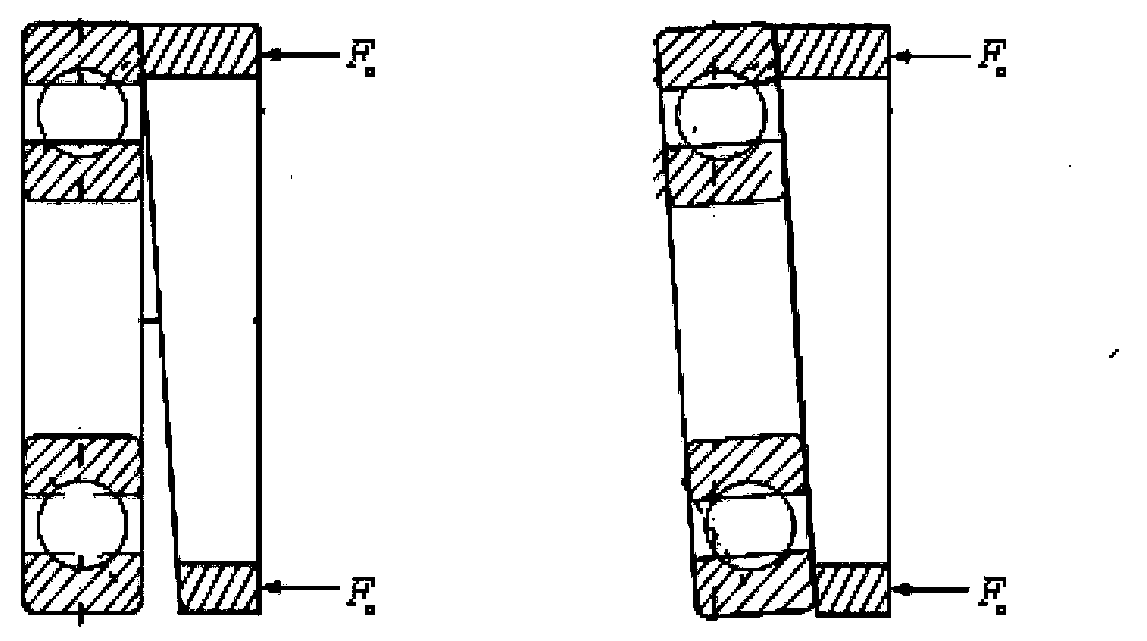

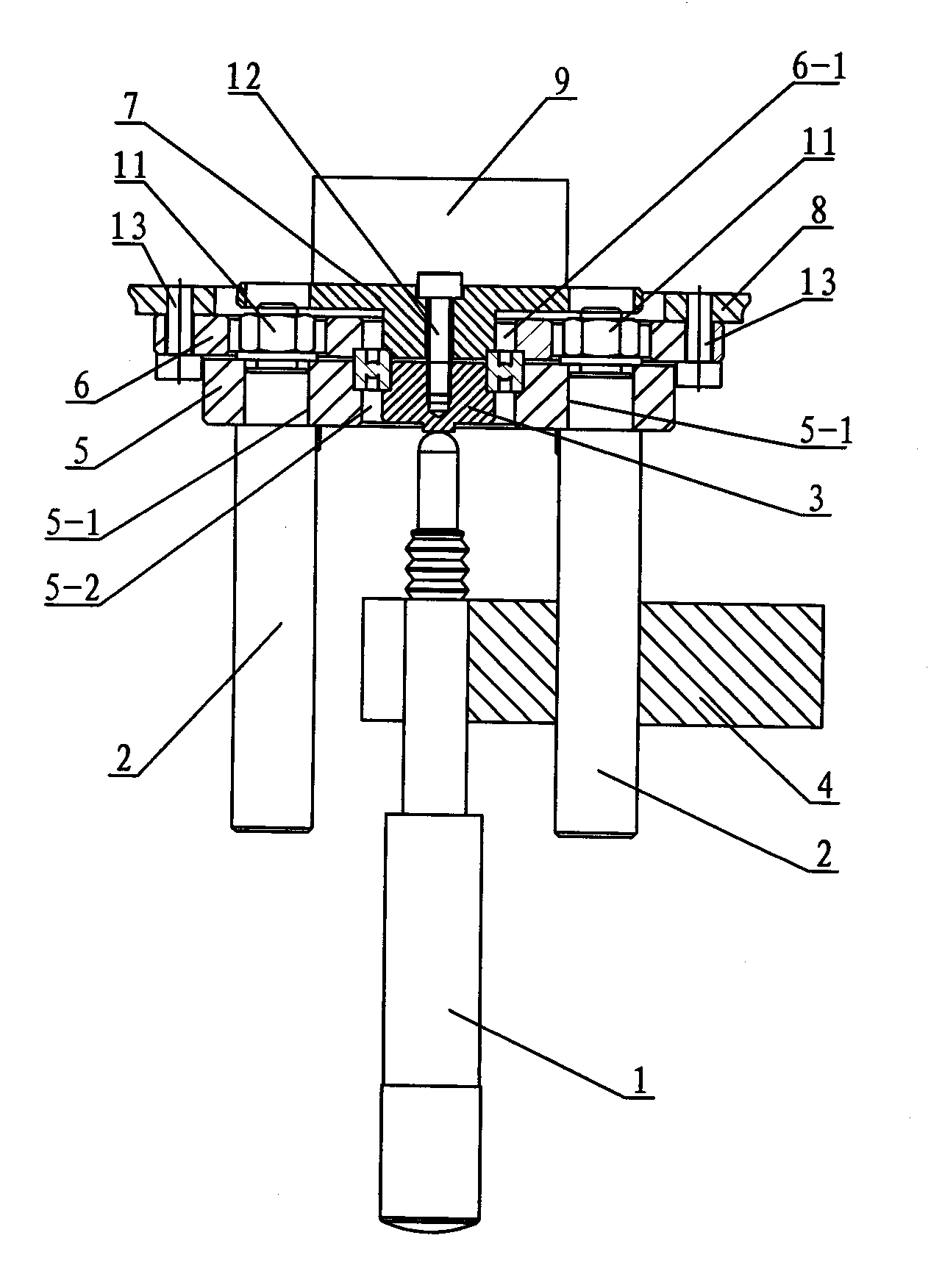

Bearing rigidity test device

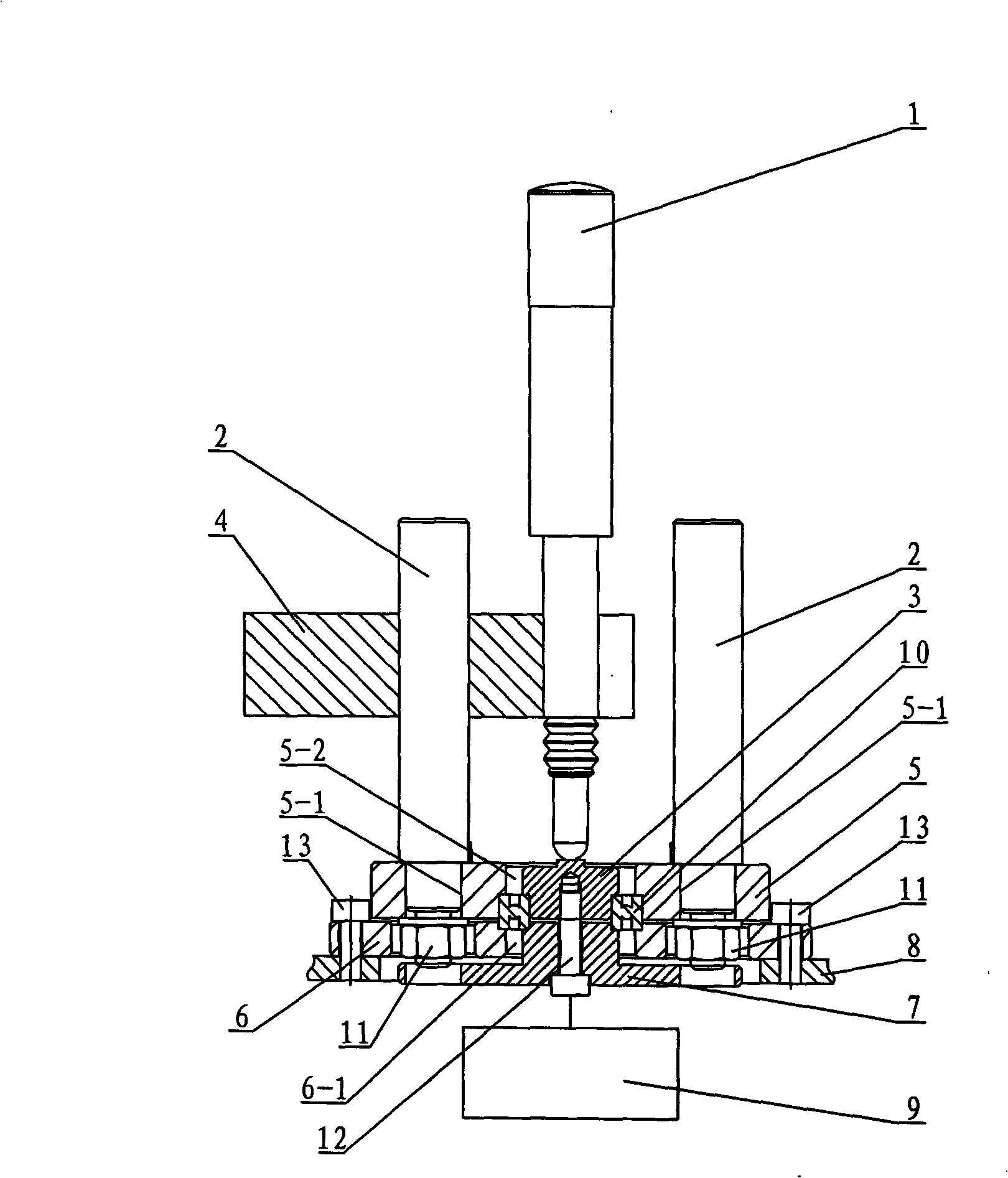

InactiveCN101354314ASimple structureEasy to operateMachine bearings testingInsertion stentEngineering

The invention relates to a bearing stiffness testing device, aiming at solving the problems of complex structure, inconvenient operation and high requirements on the surrounding environment of the existing bearing stiffness testing device. Ends of two studdles of the invention are respectively arranged at two studdle holes; an inner ring briquette is arranged in a central hole; one end of a connecting stent is positioned at any one studdle and an inductance probe is installed at the other end of the connecting stent; the probe end of the inductance probe is pressed on the center of a contact surface corresponding to the inner ring briquette; a connecting plate is connected with a bearing seat in a detachable manner through a first connecting piece, a flange is positioned in the central hole of the connecting plate and connected with the inner ring briquette in a detachable manner through a second connecting piece and a weight is connected with the flange. The testing device of the invention fixes the inner ring and the outer ring of the bearing to be tested respectively, loads on the inner ring to obtain the position deviation of the inner ring and the outer ring of the bearing under different load, thereby obtaining bearing stiffness index; in addition, the testing device has simple structure, convenient operation and relatively low requirements on the surrounding environment.

Owner:HARBIN INST OF TECH

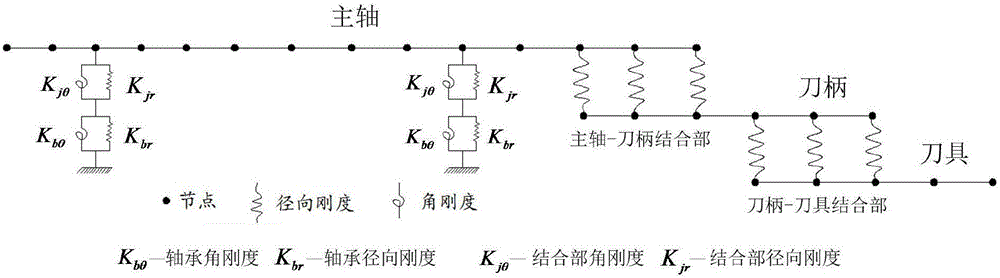

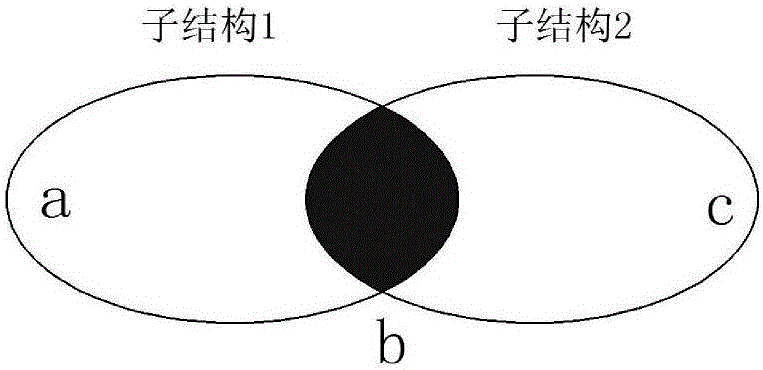

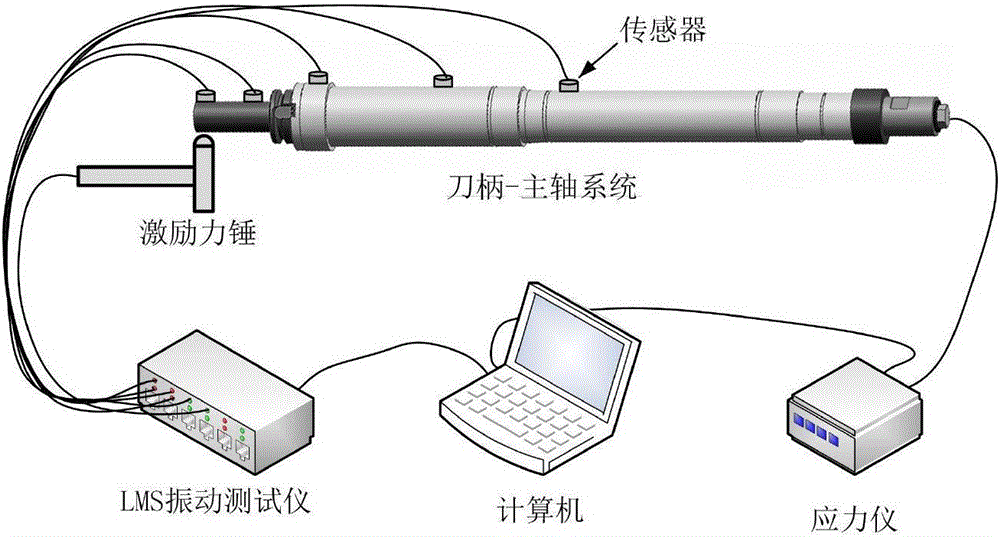

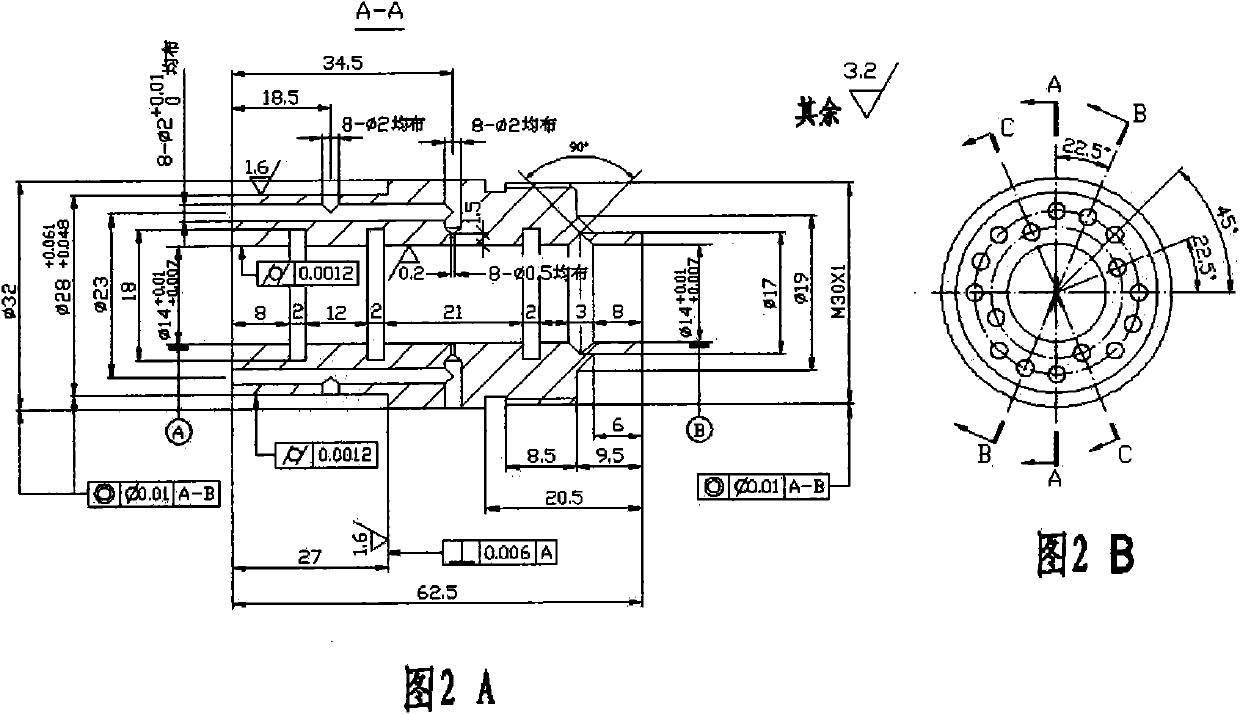

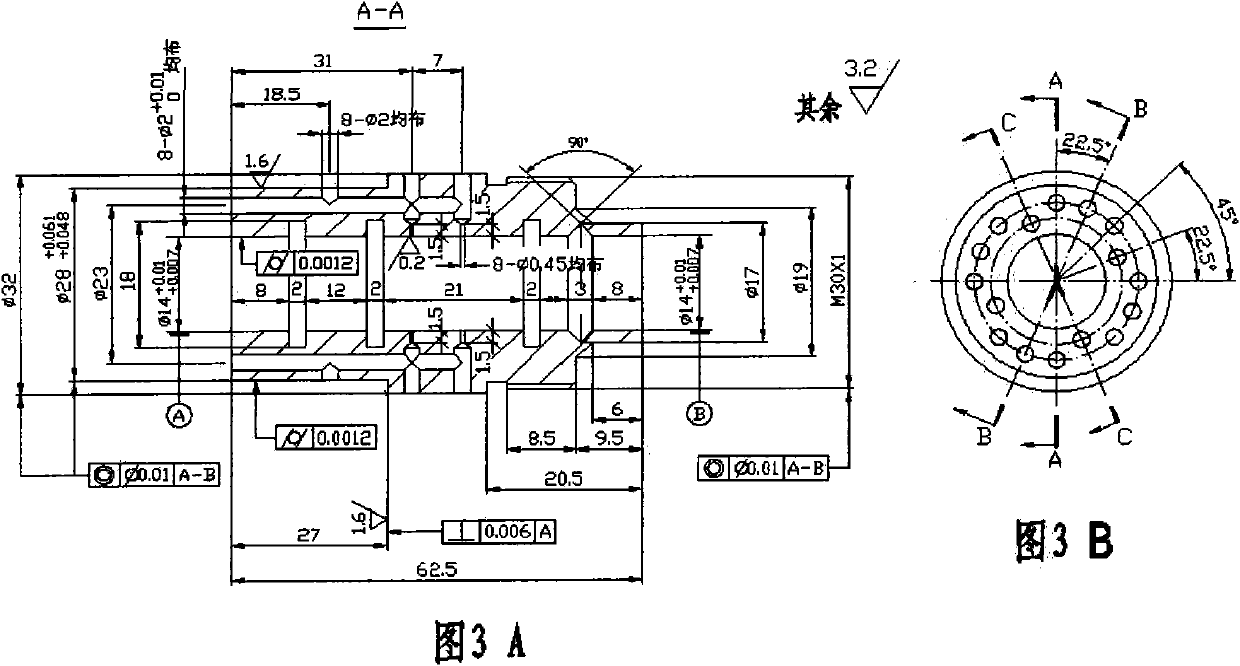

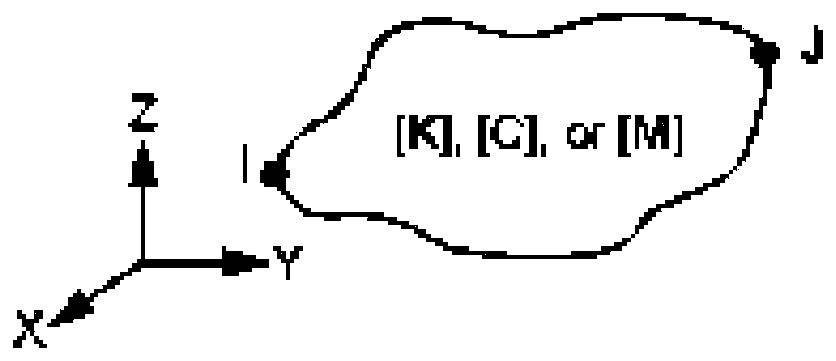

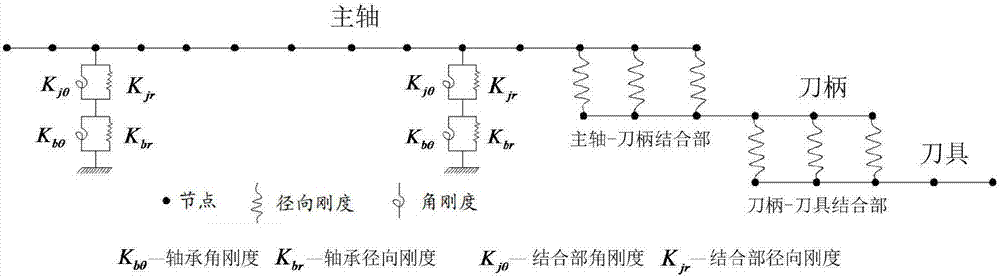

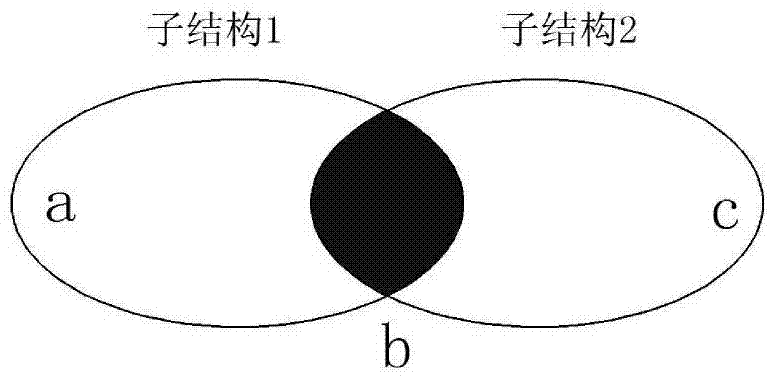

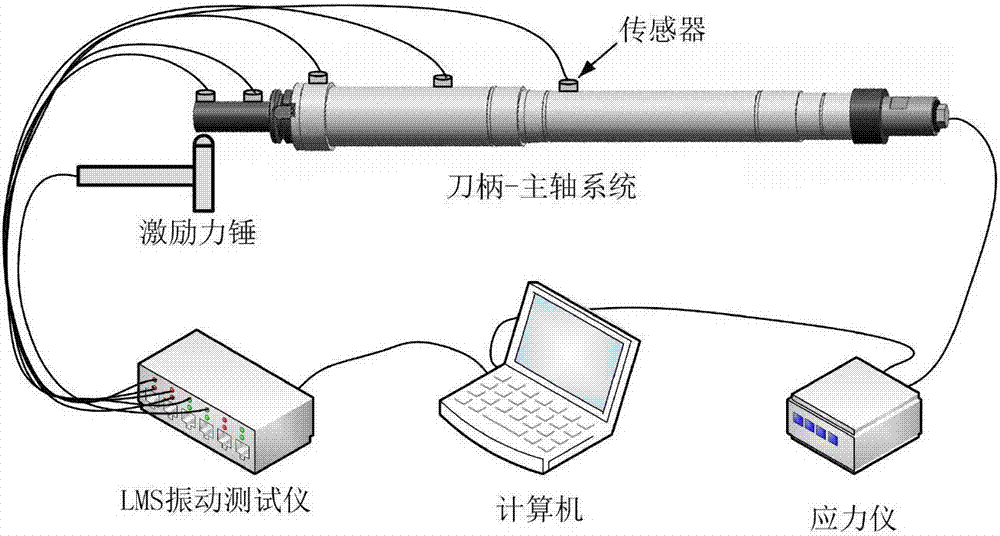

Electric main shaft system modeling method taking features of combination portions into consideration

The invention discloses an electric main shaft system modeling method taking features of combination portions into consideration. According to the method, first of all, based on a frequency response function method, the rigidity of the combination portion of an electric main shaft system is identified by use of a hammering experiment, then a finite element model of a main shaft-handle-cutter system is established through the mode of adding and deleting a transition unit at the tail end of a main shaft and a handle, and finally, bearing rigidity, and a rigidity matrix of a main shaft-bearing combination portion and a rigidity matrix of a main shaft-handle-cutter combination portion which are obtained through identification are added to the rigidity matrix of the electric main shaft system so that a complete electric main shaft system kinetic equation is obtained. According to the invention, the rigidity of the combination portions are identified by use of an experiment method, and a theoretical model of the electric main shaft system is established with the influences of the combination portions are taken into consideration, so that the influence rules of the rotating speed, the bearing rigidity, the rigidity of each combination portion and the like for the dynamic features of the electric main shaft system can be simultaneously analyzed. The method can provide guidance for design and application of an electric main shaft and also provides a theoretical basis for prediction of the cutting stability of the electric main shaft system.

Owner:BEIJING UNIV OF TECH

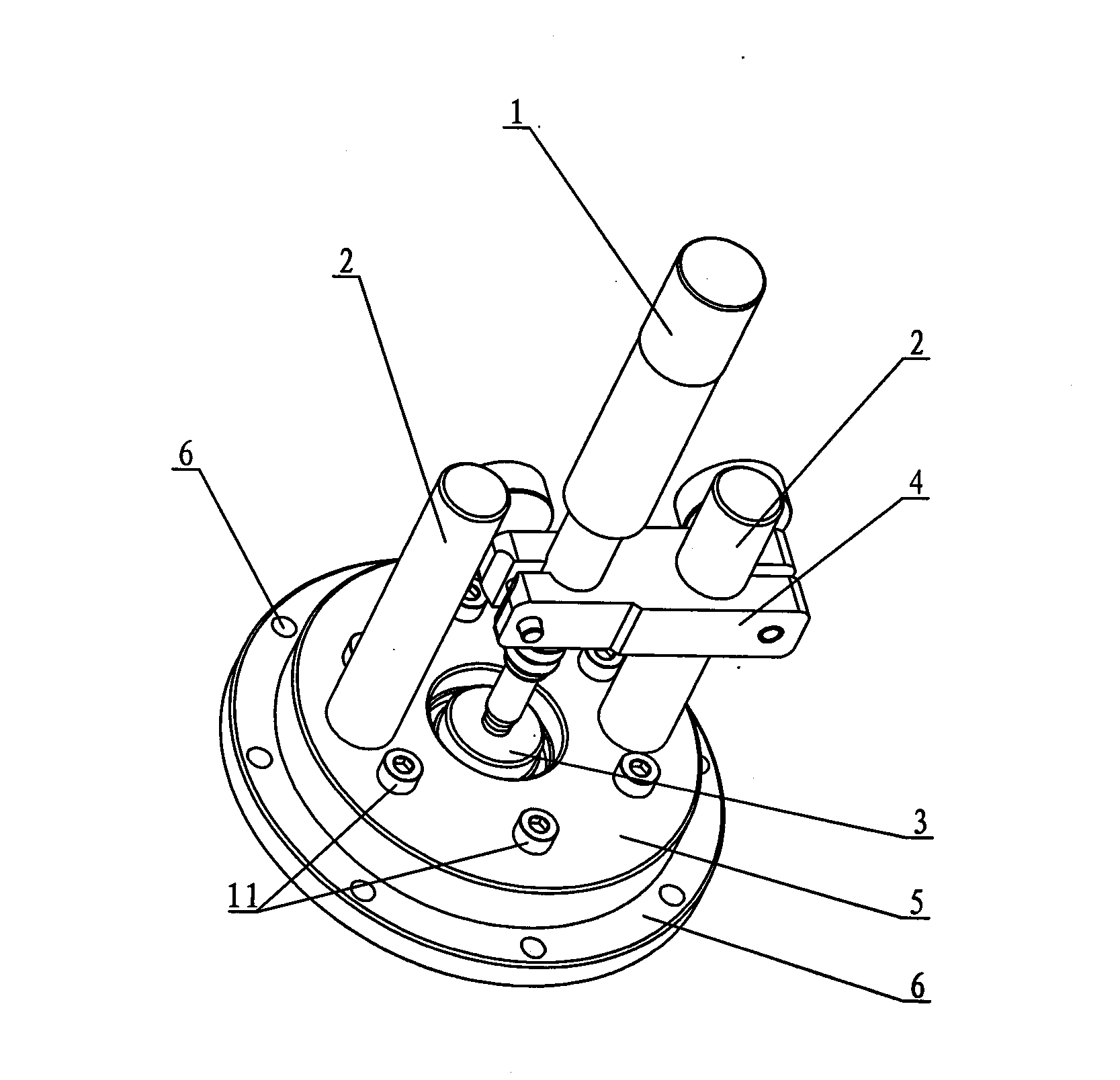

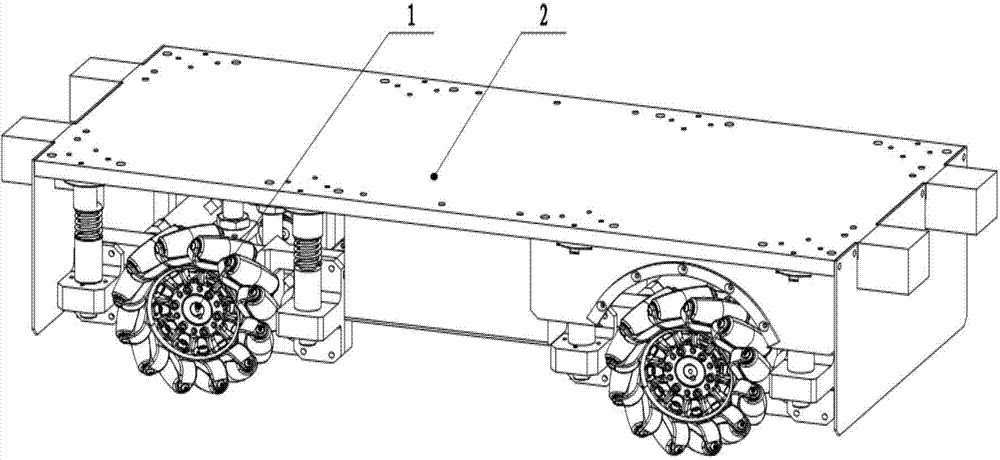

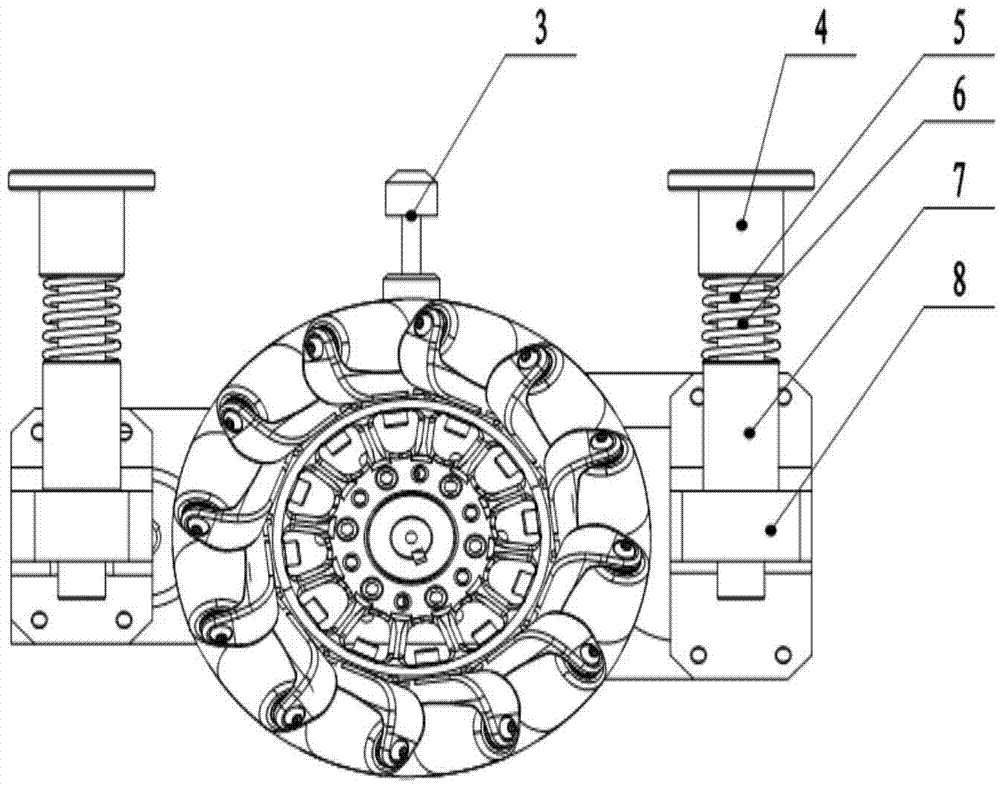

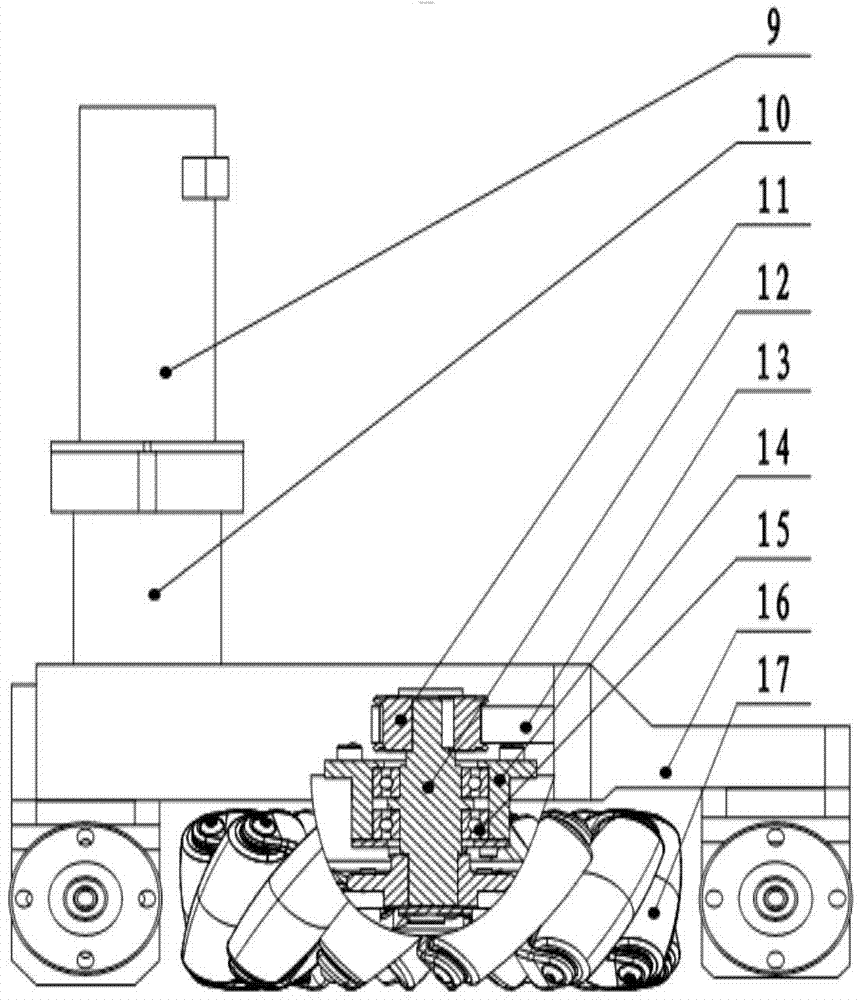

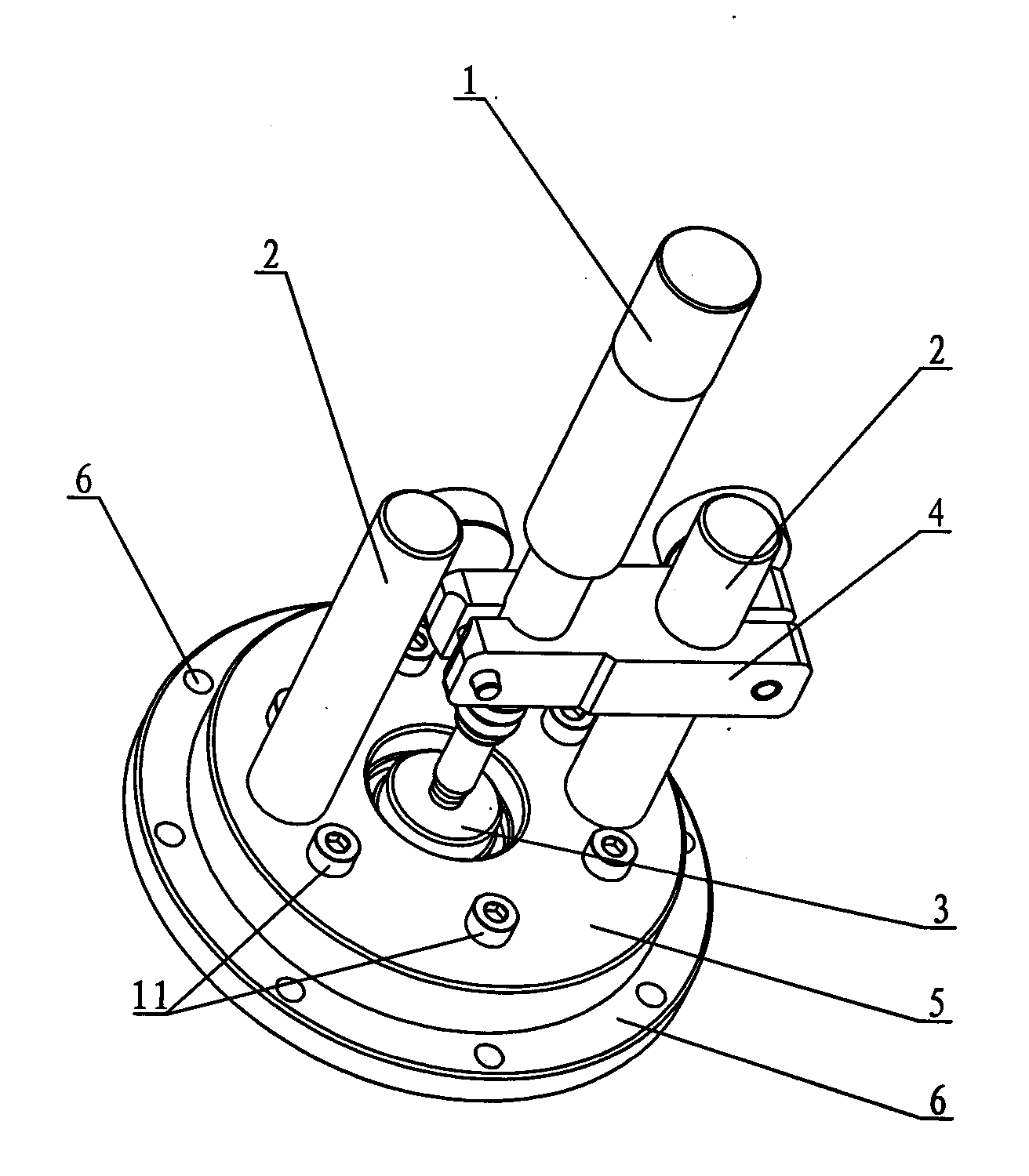

Independent suspension mechanism of intelligent Mecanum wheel movement platform

InactiveCN104494382AGuaranteed uptimeImprove bearing rigidityMotor depositionResilient suspensionsTerrainEngineering

The invention relates to an independent suspension mechanism of an intelligent Mecanum wheel movement platform. The independent suspension mechanism is arranged below the movement platform and on the radial side of a Mecanum wheel and comprises a feed rod, a linear bearing, springs, a feed rod flange and an installation frame, wherein one end of the feed rod is connected with the movement platform through the feed rod flange, the other end of the feed rod is connected to the installation frame through a feed rod seat, the feed rod penetrates the linear bearing to be connected with the feed rod seat, and the springs sleeve the feed rod and are arranged between the feed rod flange and the linear bearing respectively. According to the independent suspension mechanism of the intelligent Mecanum wheel movement platform, advantages of the independent suspension mechanism and the Mecanum wheel movement platform are organically combined, the platform is stably operated, a high adaptive capability to uneven terrains and a high obstacle crossing capability are achieved, and the platform is good in bearing rigidity.

Owner:LIAONING XINHAI HONGYE AVIATION TECH CO LTD

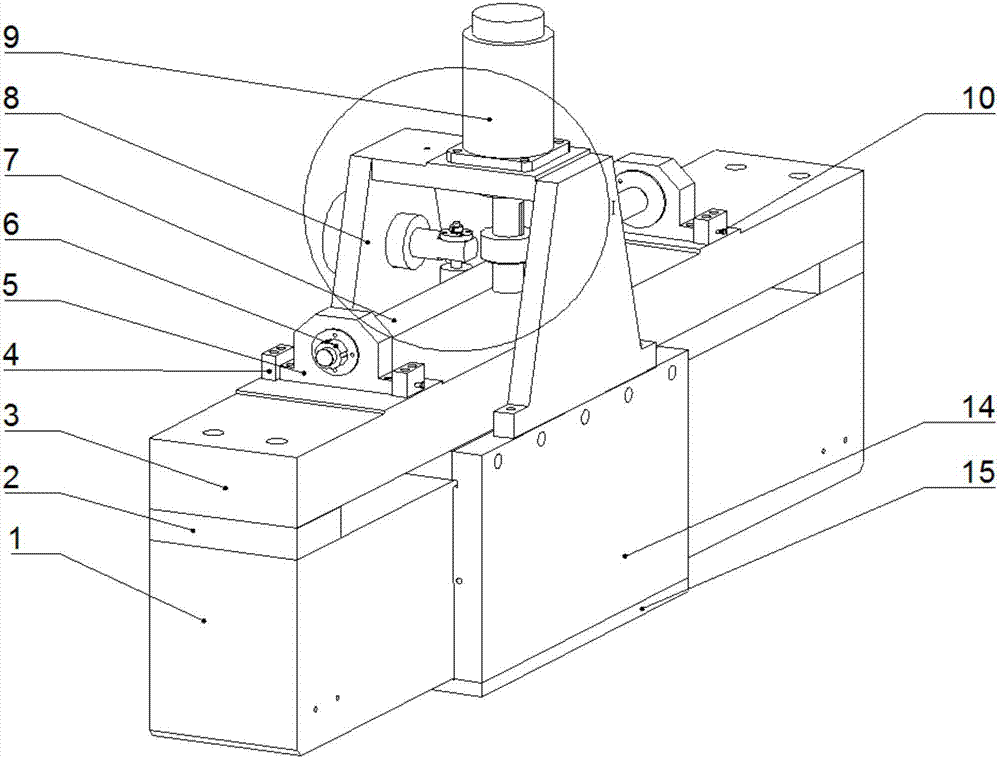

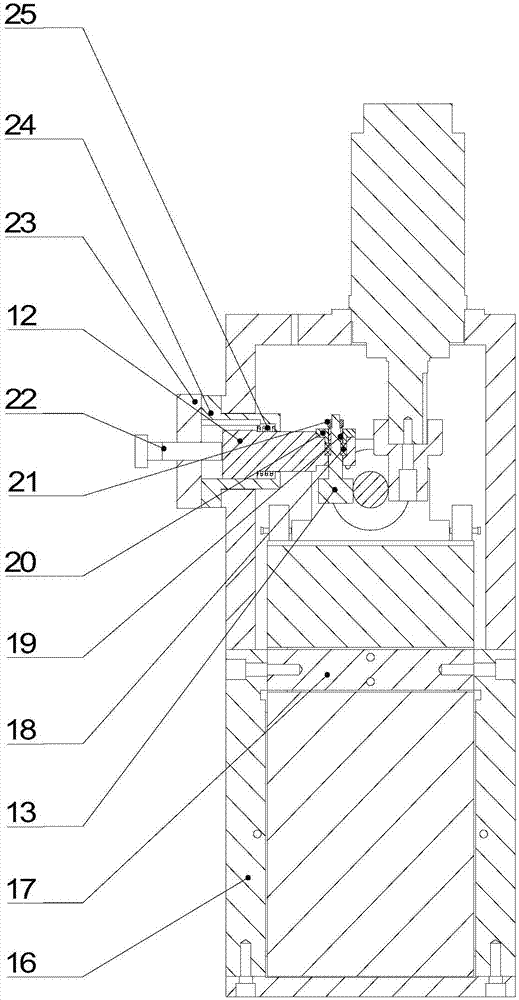

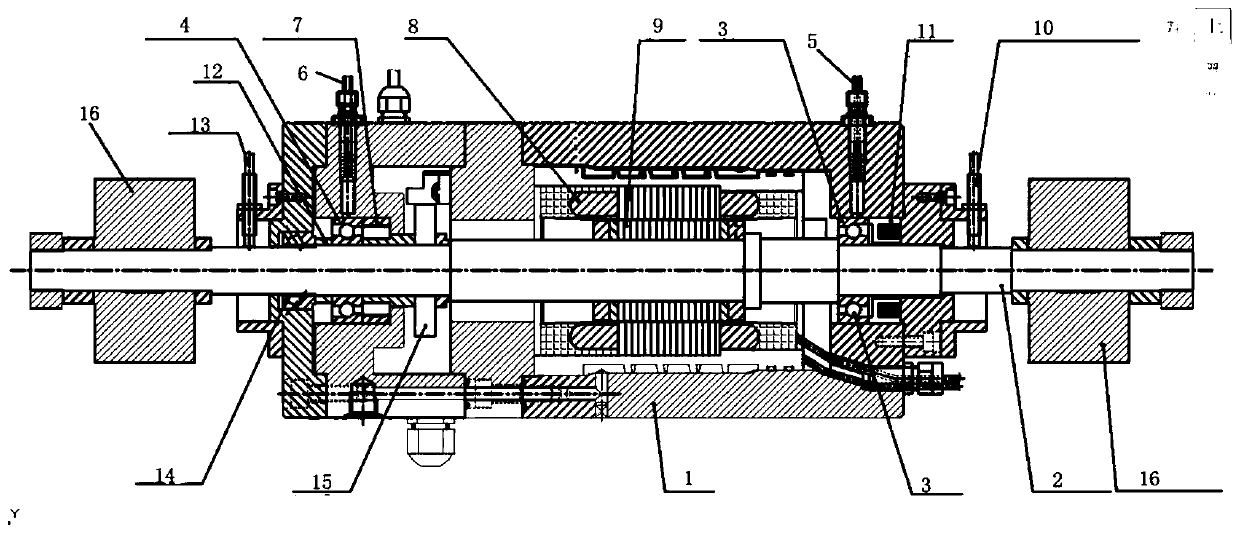

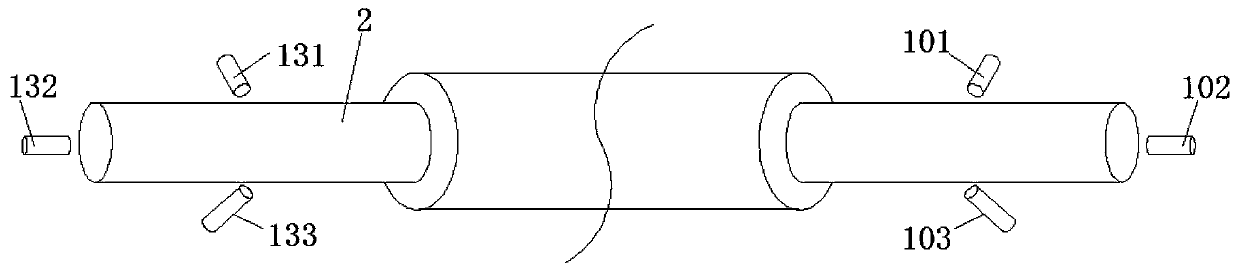

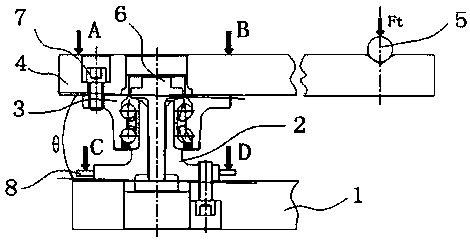

Comprehensive measurement device and method for bearing rigidity and starting friction torque

ActiveCN106525424AAchieve stiffnessAchieve frictionMachine bearings testingForce sensorsFriction torqueMeasurement device

The invention discloses a comprehensive measurement device for bearing rigidity and starting friction torque, including a driving shaft, an inner axial pressure conduction block, an outer axial pressure conduction block, a pressure sensor and locking nuts. The driving shaft comprises a first step, a second step which is used for clamping a bearing, a testing end and a fastening end, and the testing end and the fastening end are provided with outer threads. The inner axial pressure conduction block is sleeved on the first step and is provided with a groove. The outer axial pressure conduction block is provided with a projection cooperated with the groove. The pressure sensor is sleeved on the driving shaft, and the end surface of the pressure sensor is adhered to the end surface of the inner axial pressure conduction block. The locking nuts are fixedly connected at two ends of the driving shaft respectively. The comprehensive measurement device for bearing rigidity and starting friction torque obtains the pretightening force, rigidity and starting friction torque of a single bearing or bearings in pair with one measurement device.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

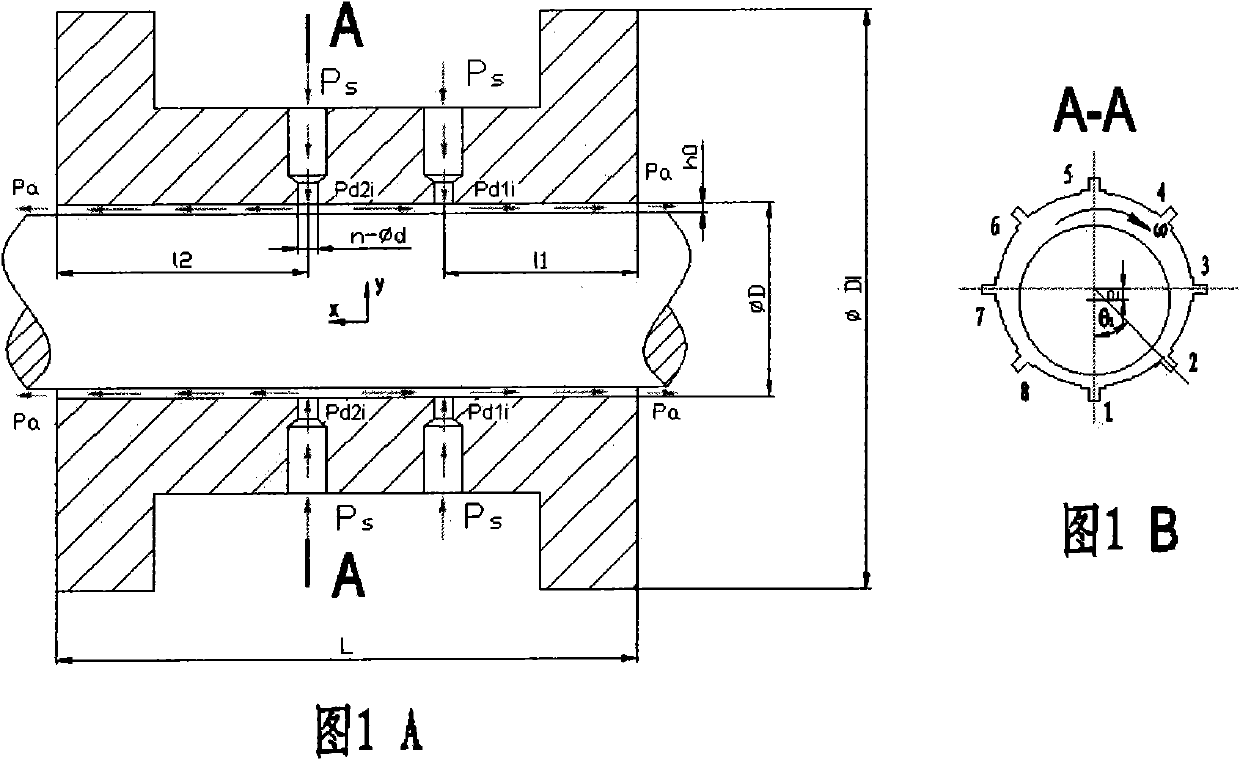

Method for designing optimal static parameter of radial static pressure gas bearing of turbine expansion engine

InactiveCN101673318AHigh precisionMachines/enginesEngine componentsBorn rigidityDifferential equation

The invention relates to a method for designing optimal static parameters of a radial static pressure gas bearing of a turbine expansion engine, comprising the following steps: decomposing a journal bearing into a plurality of equivalent slits, listing a differential equation of gas movement, obtaining an equation about bearing capacity coefficient CW, bearing rigidity coefficient KW, total flow Mand the total frictional power loss FT based on the differential equation, and obtaining the optimal static parameters for a radial throttling hole static pressure gas bearing of the turbine expansion engine on the condition of different eccentricity ratios obtained through the equation of the bearing capacity coefficient CW, bearing rigidity coefficient KW, total flow M and the total frictionalpower loss FT. The invention can obtain four performance parameters reflecting the radial throttling hole static pressure gas bearing realized by calculation of one program, therefore, the determinedoptimal static parameters has high precision in engineering application and can be used for designing the radial throttling hole static pressure gas bearing of the turbine expansion engine with high rotation speed and special usage.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

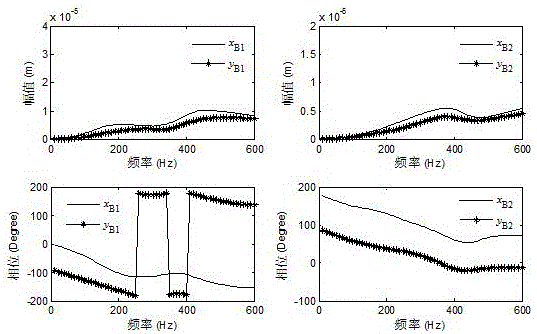

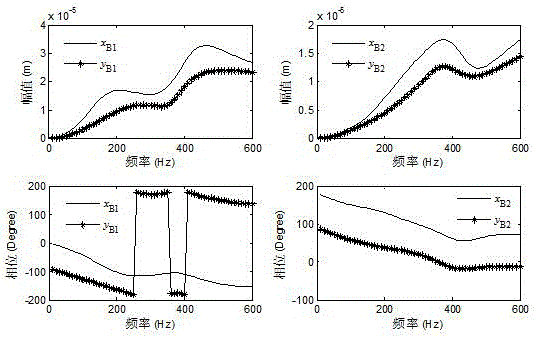

Flexible magnetic levitation bearing rotator rigidity damping identification method

The invention discloses a flexible magnetic levitation bearing rotary rigidity damping identification method, and belongs to the technical field of magnetic levitation bearing dynamic feature identification. The method comprises the following steps: firstly, acquiring two groups of independent magnetic levitation bearing rotor system rotation responses, namely, responses added with unbalance masses and responses not added with any unbalance mass; acquiring amplitude and phase data of two groups of independent responses by first-order Fourier series fitting; subtracting corresponding amplitude and phase data from the two groups of responses to eliminate interference force influence in the rotating process of a magnetic levitation bearing rotor subsystem; calculating amplitude and phase data from which the interference force influence is eliminated through a matrix inverse transformation recognition algorithm to obtain a magnetic levitation bearing rigidity damping dynamic feature. Compared with the prior art, the method has the advantages of high resolving accuracy and high interference resistance, is suitable for rigidity rotors below a bending critical rotation speed, and is suitable for flexible rotors over a bending critical rotation speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

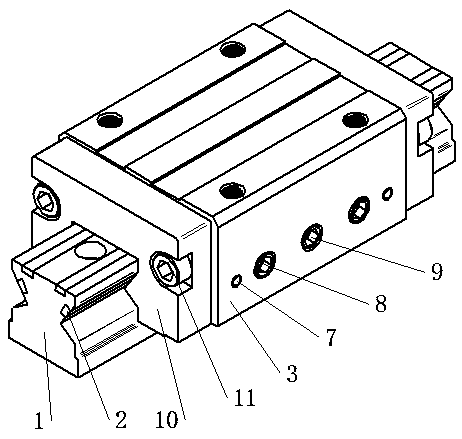

Vertically used direct drive precise air lubricated hydrostatic guide pair

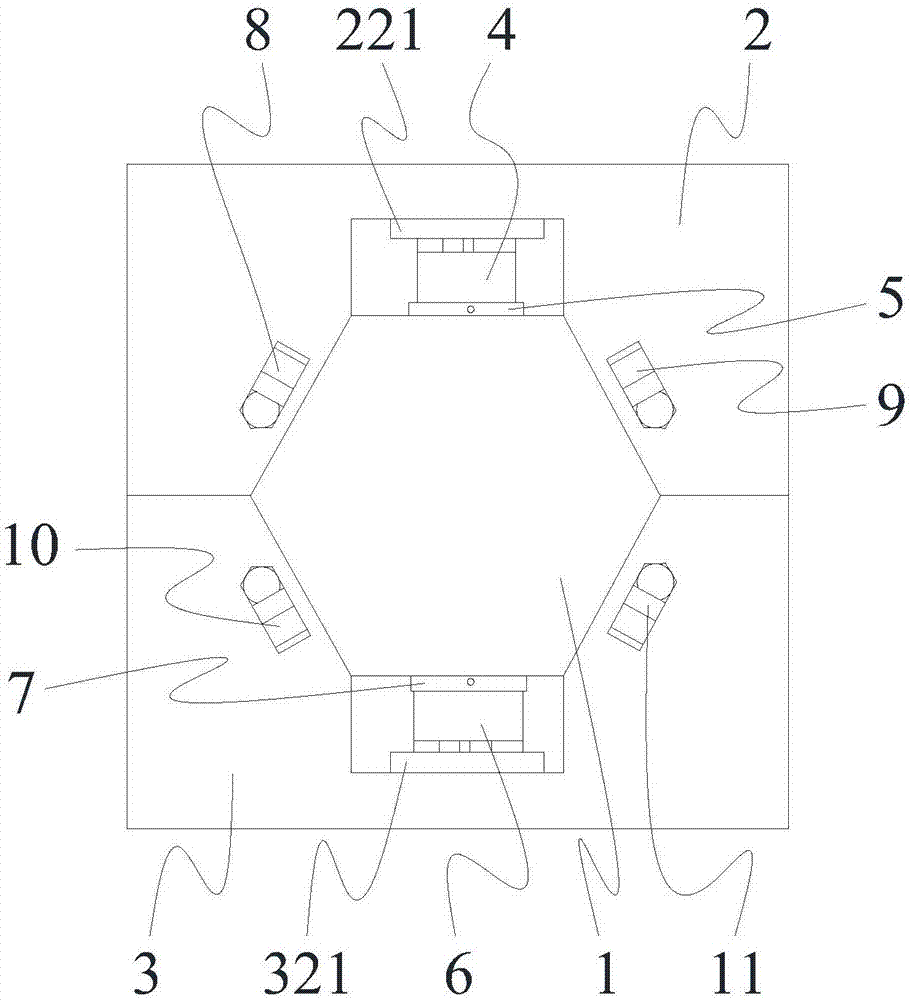

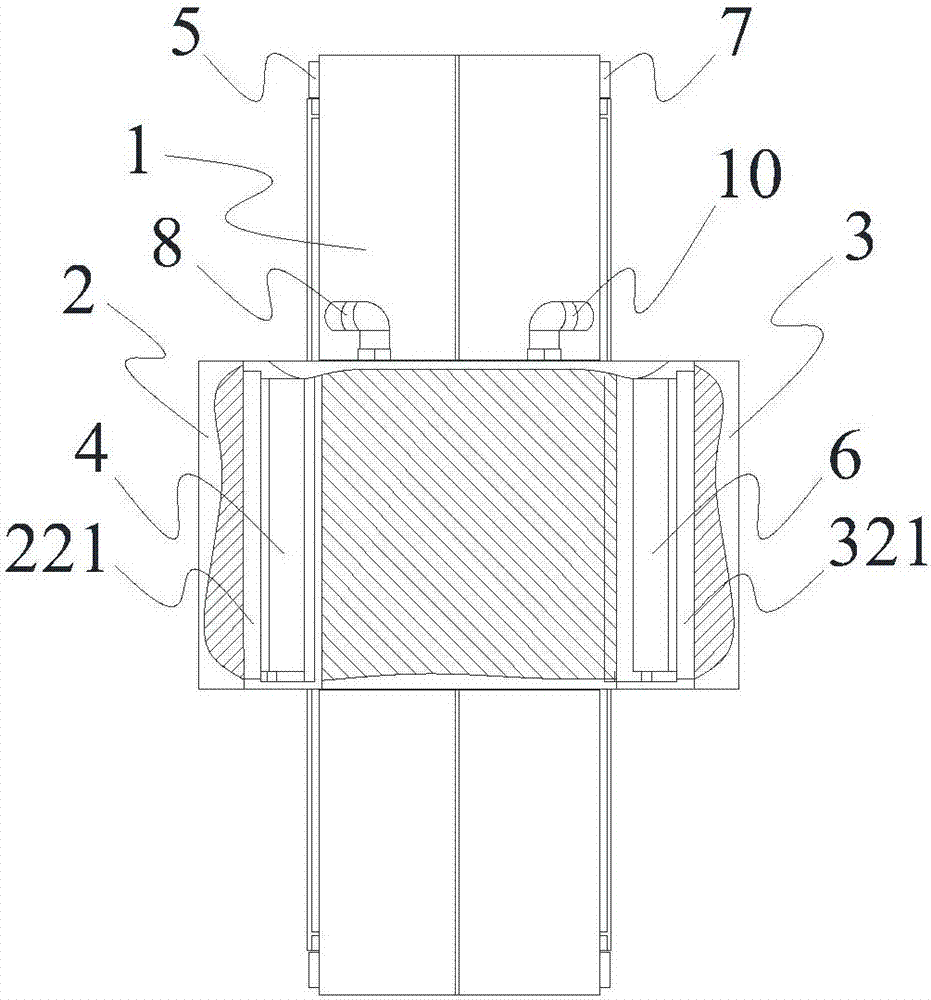

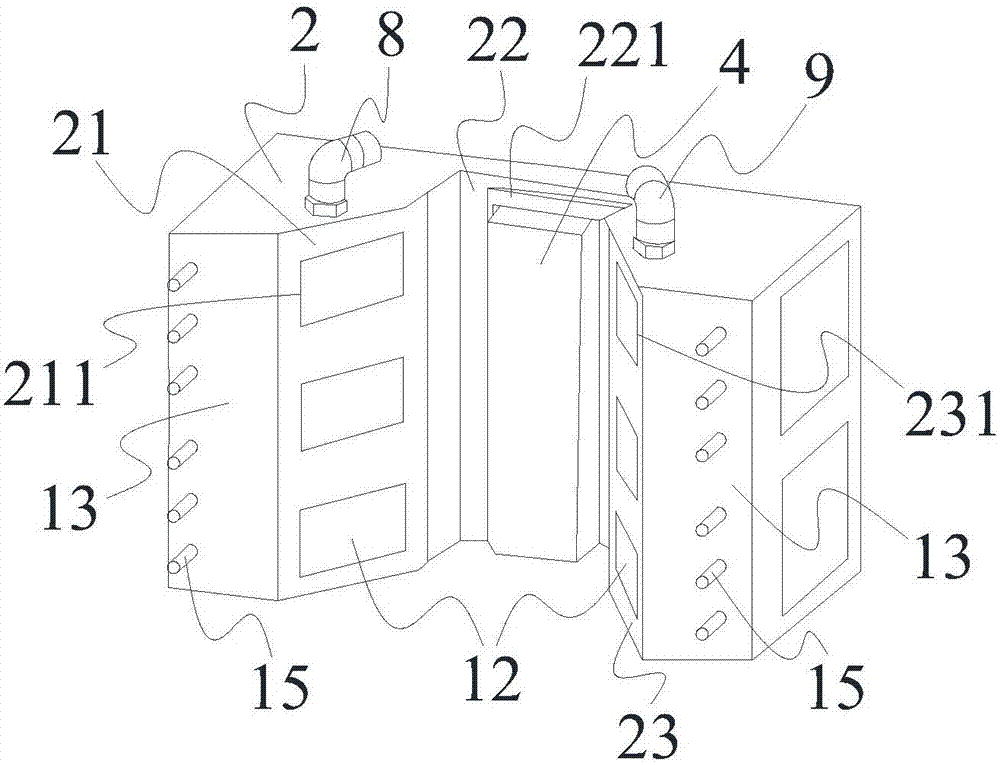

InactiveCN107044486AAchieving a symmetrical layoutEnsure support rigidityGas cushion bearingsLinear motorBorn rigidity

The invention discloses a vertically used direct drive precise air lubricated hydrostatic guide pair which comprises a guide base in a regular hexagonal prism shape, a slide carriage capable of sliding along the guide base, a first linear motor and a second linear motor. The first linear motor and the second linear motor are mounted between the guide base and the slide carriage. The inner wall section of the slide carriage is a hexagon. A hexagonal section square pillow serves as the guide base. The hexagonal air lubricated hydrostatic guide pair adopts four faces as the bearing faces, symmetrical arrangement of the bearing faces is achieved, high movement straightness and structural rigidity and high movement positioning and repeating precision can be achieved, and deformation caused by temperature fluctuation is minimized; the four faces are adopted as the air lubricated hydrostatic bearing faces, the other two symmetrical side wall faces are separately provided with the linear motors, and symmetrical layout of guide pair bearing and driving is achieved; and bearing rigidity of the guide pair is ensured by adoption of a porous restrictor, the structure has the characteristics of high precision and good symmetry, and the guide pair is particularly suitable for vertical using conditions.

Owner:中原工学院信息商务学院

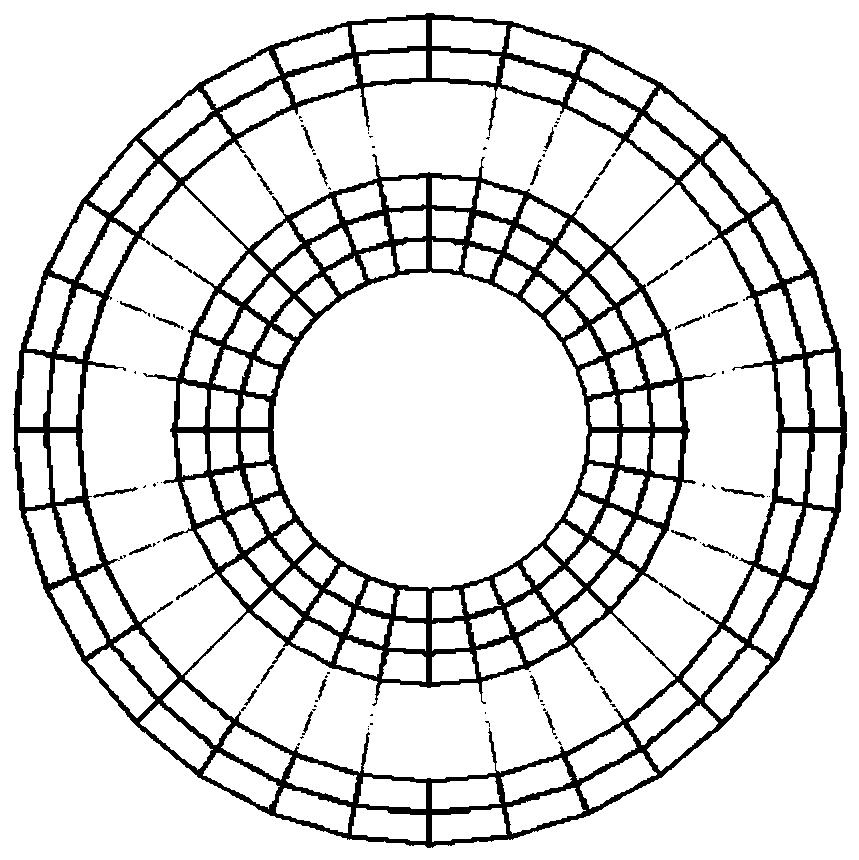

Sliding bearing rigidity recognition method based on mill vibration mode parameters

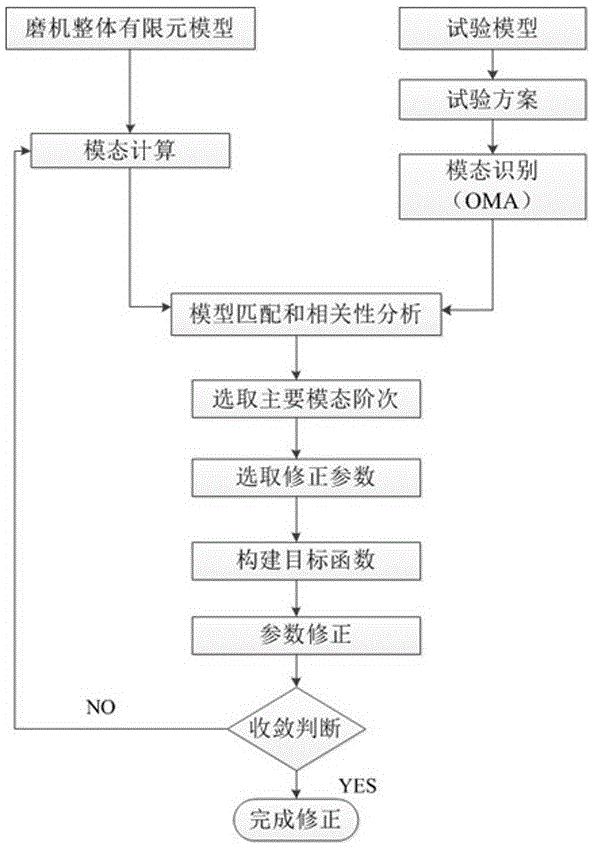

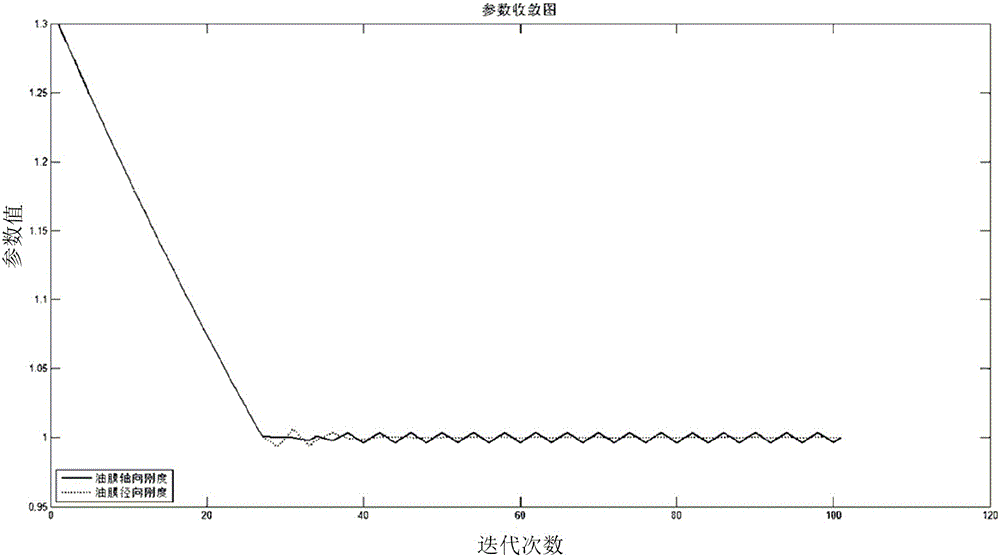

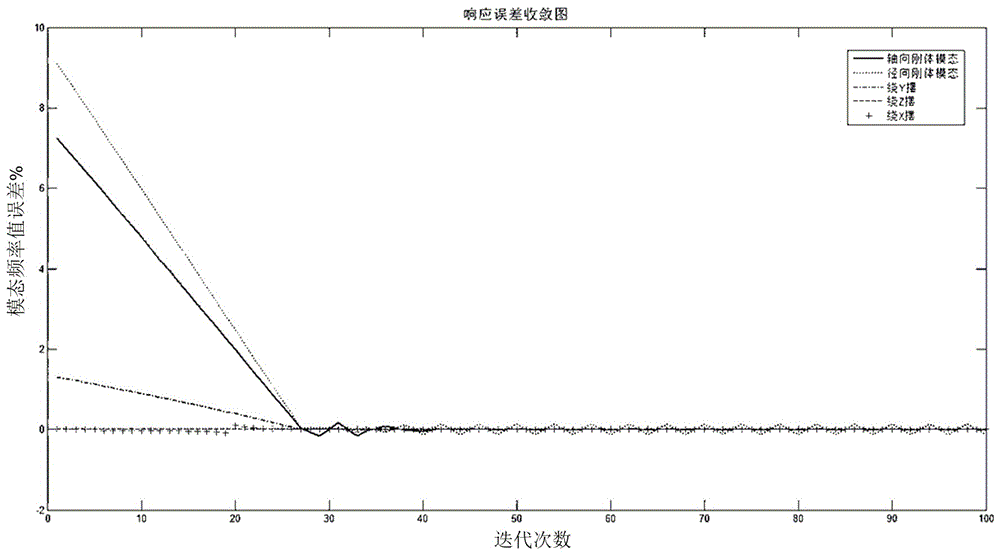

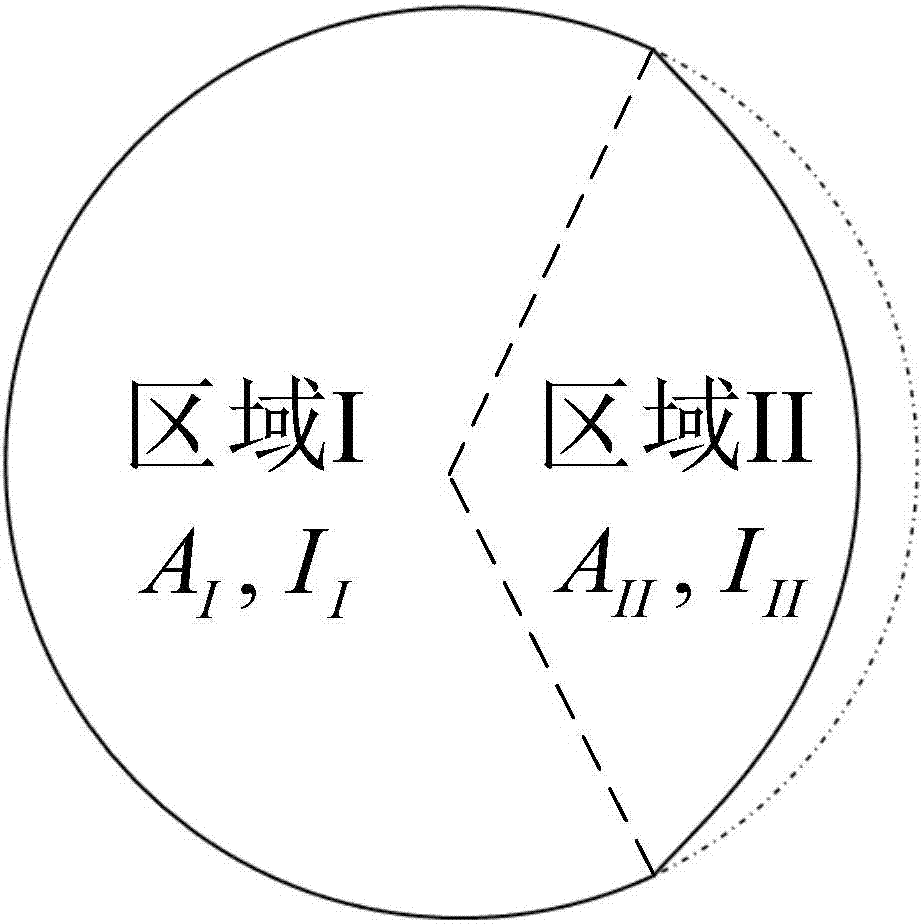

InactiveCN106354955AImprove computing efficiencyHigh precisionDesign optimisation/simulationSpecial data processing applicationsElement modelConfidence factor

The invention discloses a sliding bearing rigidity recognition method based on mill vibration mode parameters. The method comprises the specific steps of 1, building a mill full finite element model; 2, designing a testing scheme; 3, utilizing operational modal analysis for recognizing modal parameters; 4, calculating a modal confidence factor analysis correlation; 5, selecting and calculating a modal confidence factor larger than 0.7, and adopting an axial rigid body modal, a radial rigid body modal and the like as main modals to be recognized; 6, selecting sliding bearing rigidity as parameters to be recognized; 7, constructing a target function; 8, performing iterative optimization, wherein the overall calculation efficiency and model precision of a mill can be improved through the recognition method, so that the model is closer to the actual structure, and due to accurate oil film rigidity recognition, later model-based response calculation, prediction and damage recognition are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

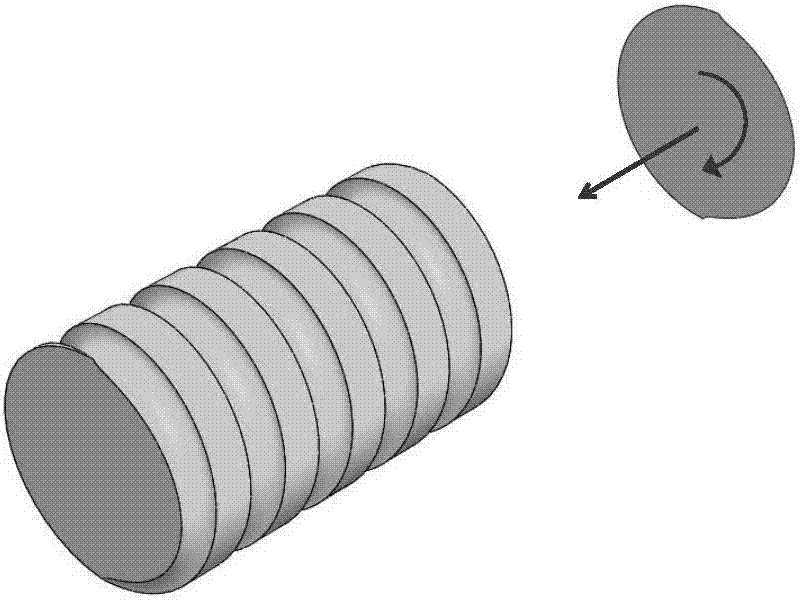

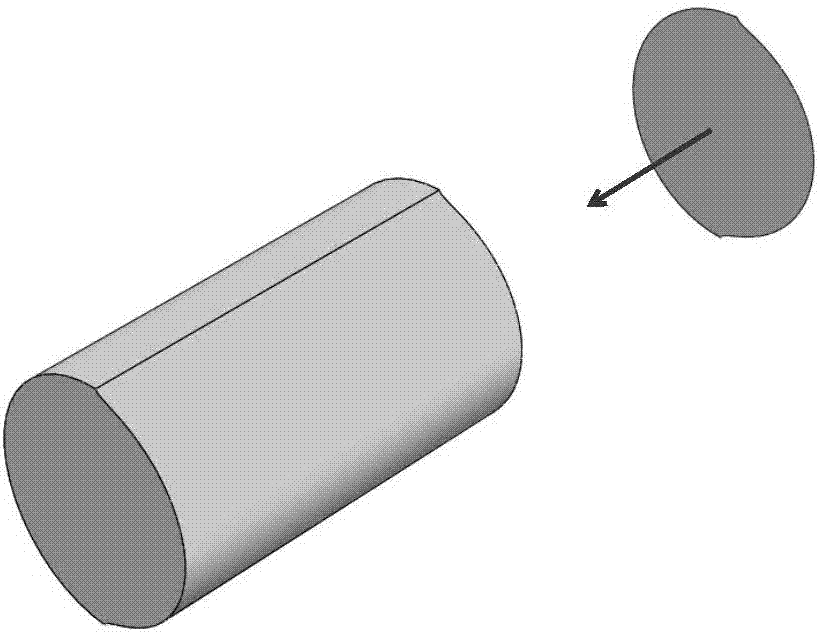

Calculation method for equivalent torsional, tensile and flexural stiffness of ball screw

InactiveCN107092737AThe result is accurateImprove applicabilityDesign optimisation/simulationSpecial data processing applicationsBall screwEngineering

The invention relates to a calculation method for equivalent torsional, tensile and flexural stiffness of a ball screw. The method comprises the steps of firstly inspecting a single-start screw and calculating torsional, tensile and flexural stiffness of a uniform beam with the same section as the screw; fitting a size effect coefficient by introducing a two-dimensional lognormal distribution probability density function, and in combination with the stiffness of the uniform beam, finally obtaining equivalent torsional, tensile and flexural stiffness of the single-start screw; and finally introducing a stiffness reduction quantity, and through superposition principle popularization, obtaining equivalent torsional, tensile and flexural stiffness of a ball screw with any start number or a hollow ball screw. Compared with international and other methods, the calculation method considers the influence of all screw parameters, including the outer diameter, the inner diameter, the ball diameter, the screw lead and the start number, on the stiffness; and the calculation method is more accurate in calculation and wider in applicability, and provides a research basis for feed system control, dynamics, thermotics and installation consistency research of the ball screw.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

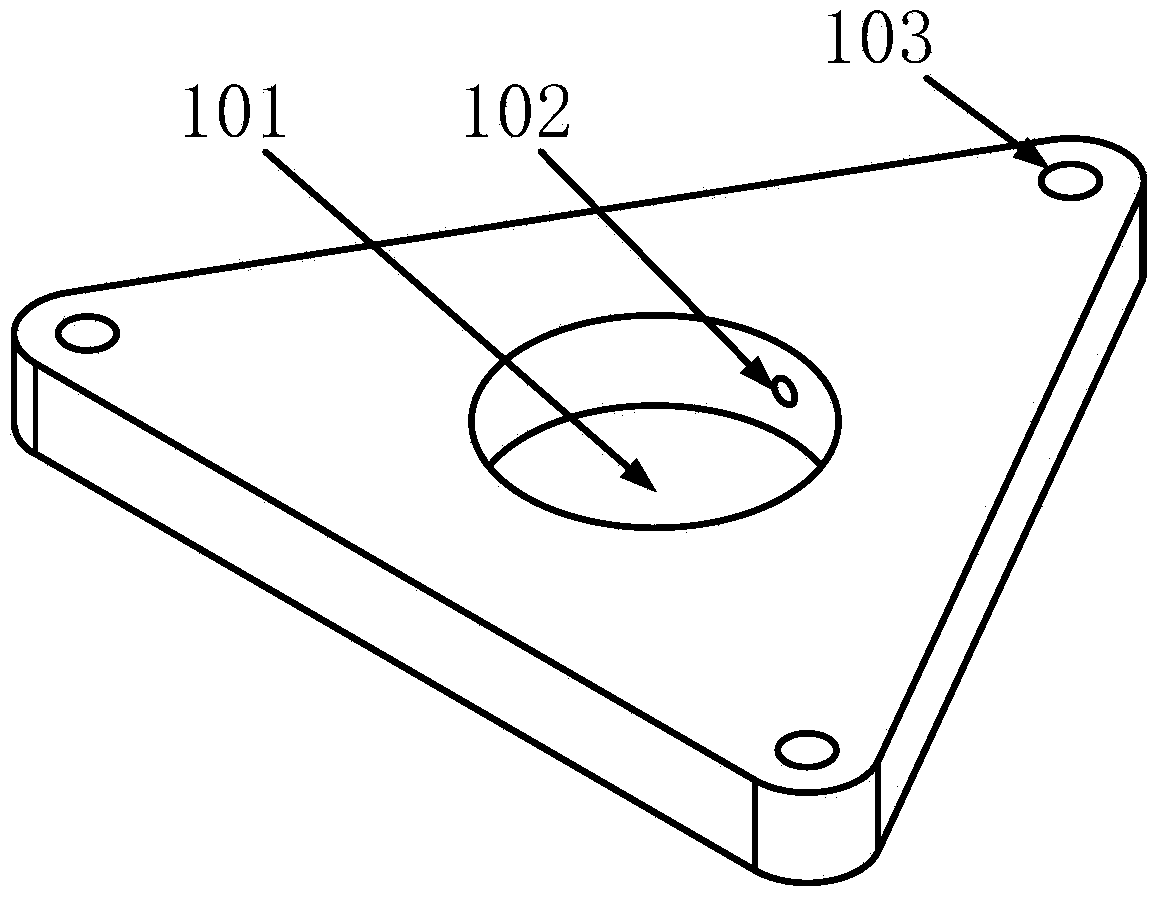

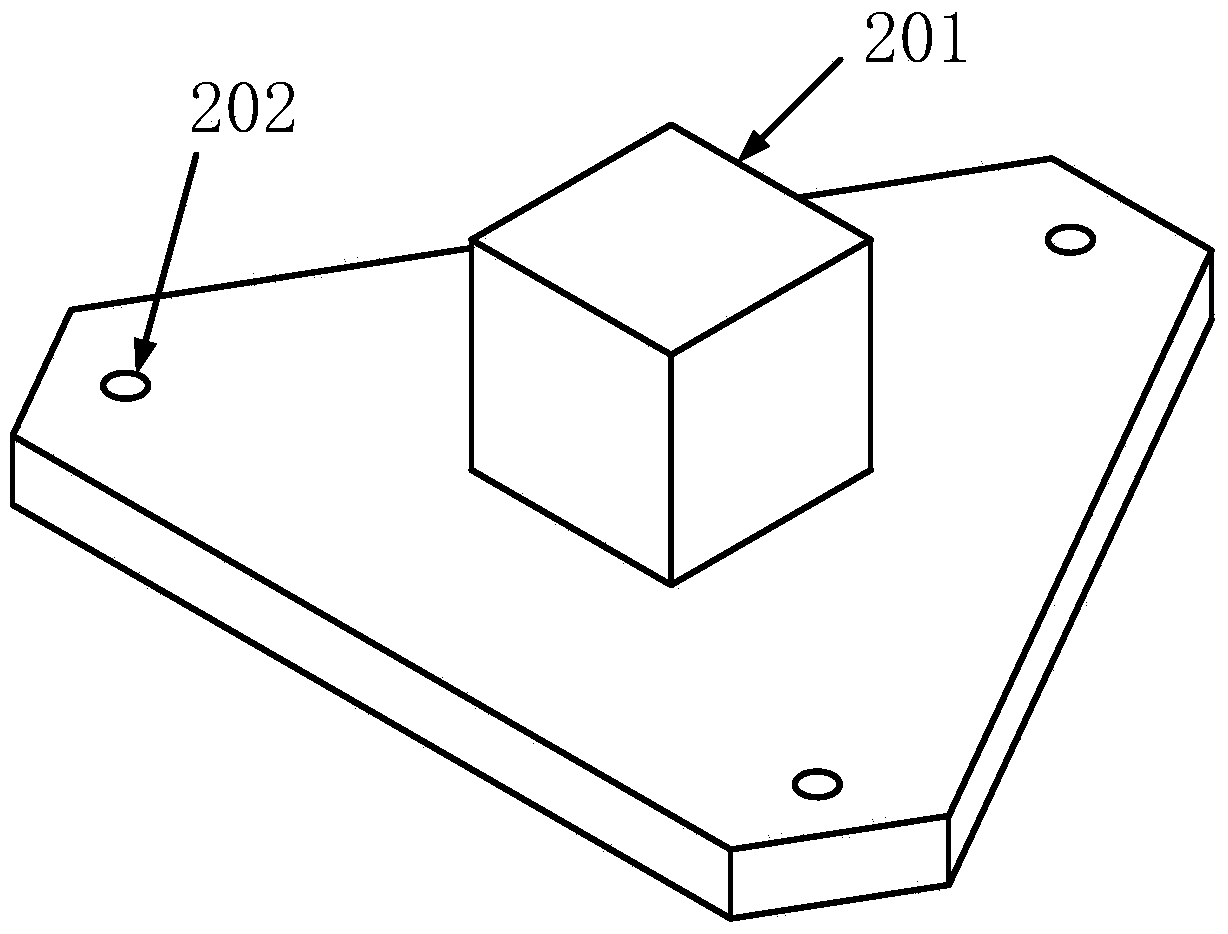

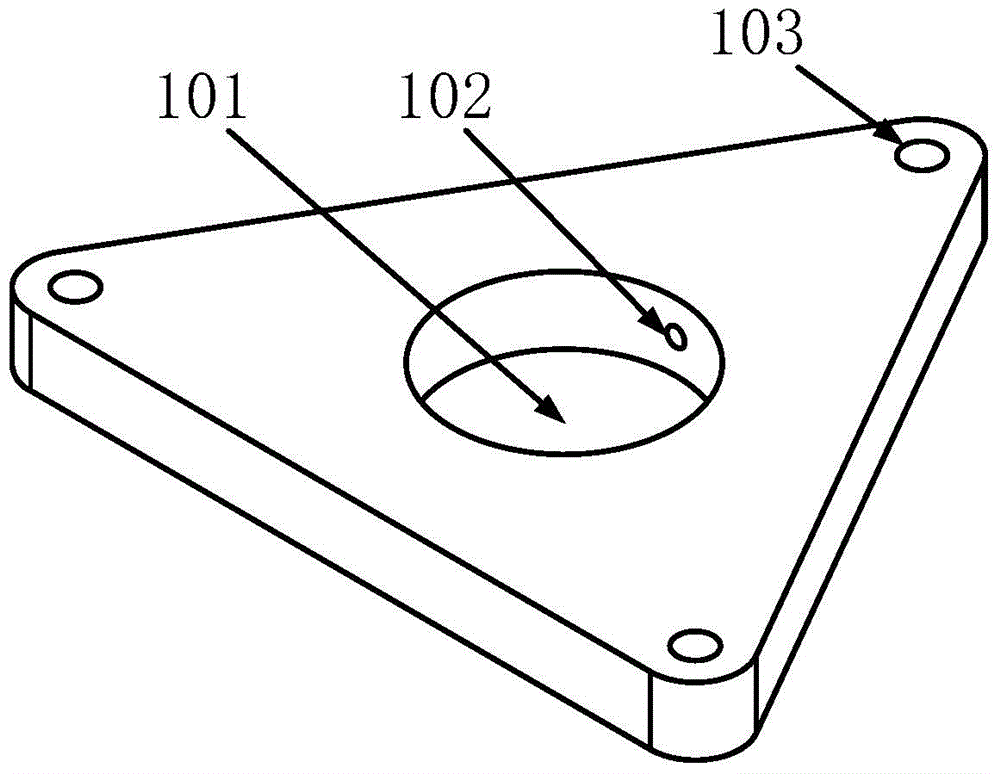

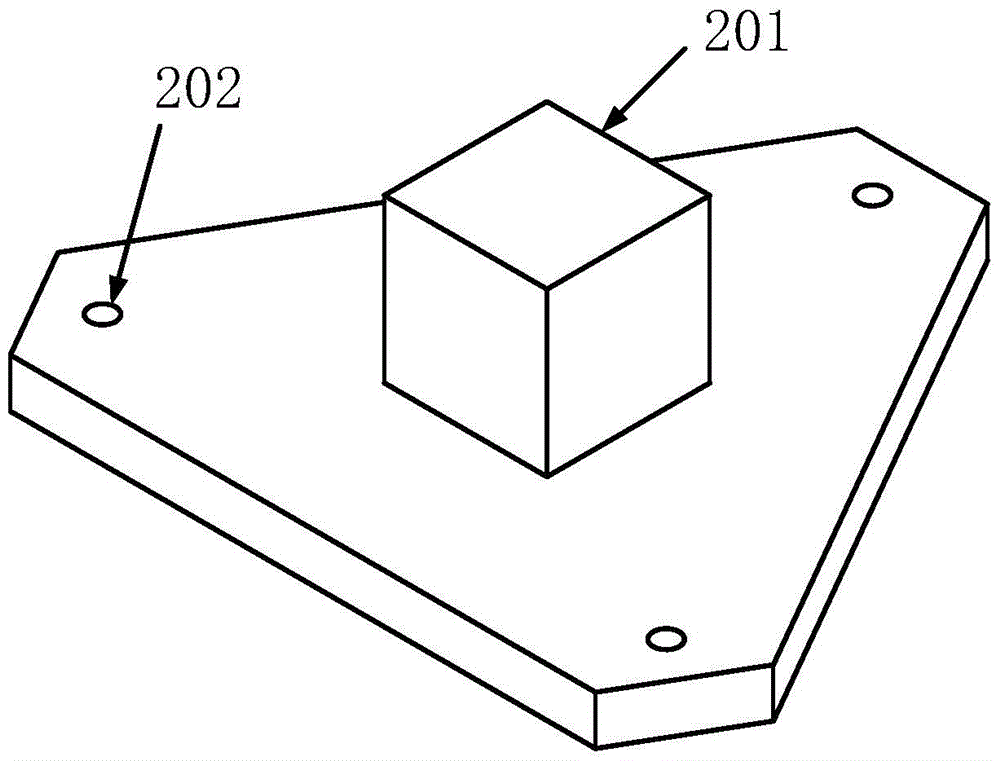

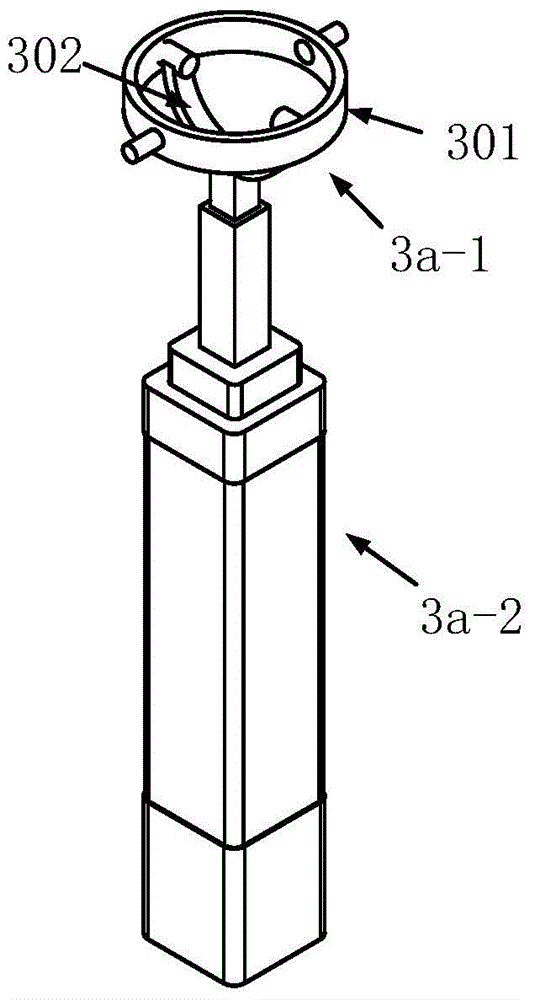

Composite load simulator for achieving multidimensional pure bending moment and tensile pressure

InactiveCN103884373ALarge working spaceWide range of stiffnessMeasurement devicesPure bendingBorn rigidity

The invention discloses a composite load simulator for achieving multidimensional pure bending moment and tensile pressure. The composite load simulator can achieve pure bending moment loading, tensile pressure loading and pure bending moment and tensile pressure composite loading in any direction. The simulator comprises a moving platform, a fixed base and moving branch chains. The moving platform is fixedly connected with a loaded test piece, and the moving branch chains comprise the central moving branch chain and the uniformly-distributed moving branch chains, wherein the uniformly-distributed moving branch chains are of six different structures. The uniformly-distributed moving branch chains of the different structures, the central moving branch chain, the fixed base and the moving platform can form six kinds of different bending moment-tensile pressure composite load simulator structures. The composite load simulator has the advantages that the composite load simulator can achieve multidimensional pure bending moment load output and can output composite loads of the bending moment and the tensile pressure; due to the fact that the branch chains exist, the structure has high bearing rigidity, decoupling can be achieved through output of the tensile pressure and the bending moment, and the composite load simulator is convenient to control, simple to manufacture and convenient to install.

Owner:BEIHANG UNIV

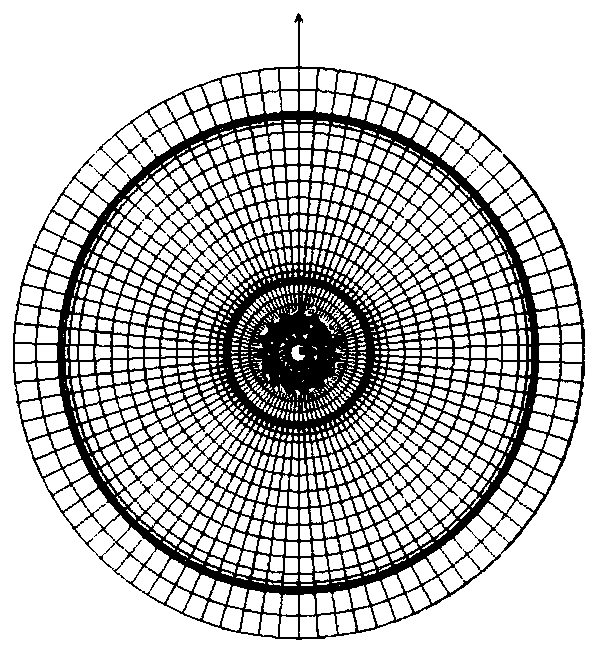

Constant-pressure pre-tightening angular contact bearing rigidity numerical correction method considering vibration influence

ActiveCN110399628ASmall amount of calculationGuaranteed calculation accuracySustainable transportationSpecial data processing applicationsElement modelEngineering

The invention discloses a constant-pressure pre-tightening angular contact bearing rigidity numerical correction method considering vibration influence. The method comprises the following steps: 1, constructing a finite element model of a rotor system; 2, constructing an angular contact bearing simplified model; 3, solving a bearing load-rigidity curve, and assigning an initial value to rigidity;4, carrying out modal shape trial calculation on the rotor system containing the bearing equivalent spring model; and 5, carrying out bearing rigidity iterative correction considering the vibration load. A two-dimensional equivalent spring model is constructed by using Matrix27 in ANSYS software, so that the calculation amount of carrying out overall numerical simulation of the rotor system is reduced on the premise of ensuring the calculation precision. When the spring rigidity is corrected, the vibration mode characteristics of a target structure are combined, main factors influencing the bearing rigidity are comprehensively considered, and the influence of steady-state vibration and pre-tightening force on the bearing rigidity is emphatically inspected. A macroscopic rotor system and amicroscopic bearing mechanical analysis model can be effectively communicated, and a large number of application requirements exist in actual work.

Owner:中国人民解放军军事科学院评估论证研究中心

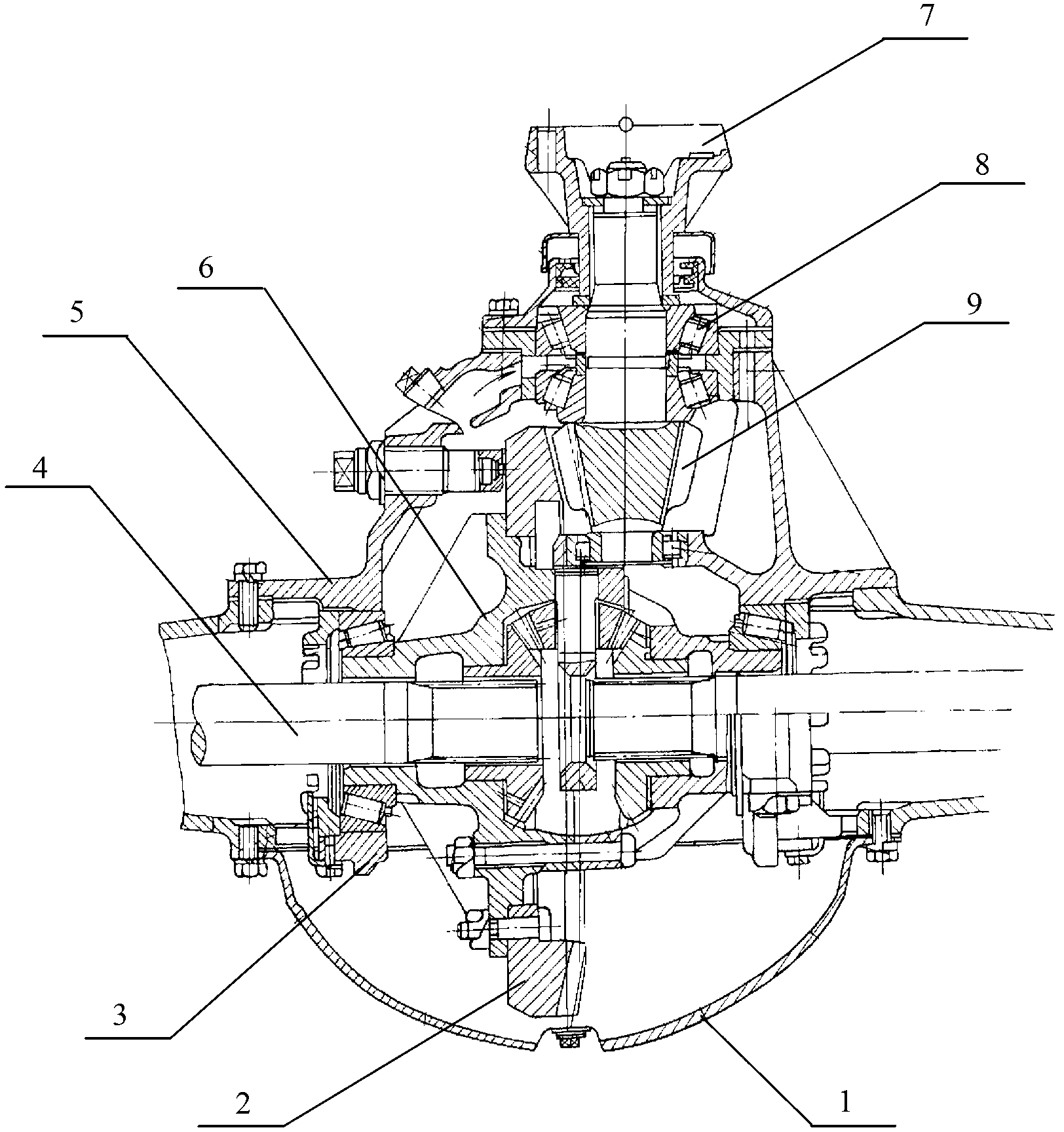

Bearing rigidity test system of bevel gear of automobile driving axle assembly

ActiveCN103018040ARealize automatic collectionAchieving processing powerMachine gearing/transmission testingCar drivingMeasurement point

A bearing rigidity test system of a bevel gear of an automobile driving axle assembly comprises a displacement sensor connected with a concentrator connected with a computer. A trigger switch unit is connected with the computer configured with test software. Reading of the displacement sensor is transferred to the computer under control of the test software, the trigger switch element is arranged on a casing, and a corresponding protrusion block is arranged on a driven bevel gear. When the protruding block rotates to the position of the trigger switch element, the trigger switch element transmits signals to the computer, and the test software automatically records reading of the displacement sensor. The test software records displacement at all displacement measuring points each time the system is triggered. Therefore, the bearing rigidity test system achieves automatic measurement of displacement data, ensures that displacement of all the displacement measurement points can be recorded when the driven bevel gear is located at the identical position relative to the casing. The bearing rigidity test system is reliable in accuracy and low in cost.

Owner:TSINGHUA UNIV +1

Friction lever driving air static pressure guide rail

InactiveCN107042445AIncrease stiffnessLoad largeGrinding carriagesOptical surface grinding machinesBall screwEngineering

The invention relates to a friction lever driving air static pressure guide rail, belongs to the technical field of machine tool equipment units and components, and has the benefits as follows: 1, an upper cross beam and a lower cross beam are adopted for forming a double-cross beam structure, so that the rectangular air static pressure guide rail is high in motion accuracy, frictionless, free from pollution; a back pressure structural design is adopted, an aerostatic guide rail mover is utilized to be arranged on the lower cross beam in a sleeving manner, so that an aerostatic back pressure area is formed between the upper surface of the aerostatic guide rail mover and the upper cross beam, and the load-bearing rigidity of the aerostatic guide rail is improved; besides, with the adoption of the friction lever driving structure, the advantages of high precision, micro-feeding and no transmission clearance are achieved, and the friction lever driving air static pressure guide rail is more economic and practical compared with the driving method adopting a linear motor or ball screw; 2, the aerostatic guide rail mover of the air static pressure guide rail adopts a porous restriction material, thereby being high in rigidity, high in the load-bearing capacity and high in precision, and capable of ensuring a good sliding effect while meeting the back pressure requirements; 3, by adopting a pre-tightening mechanism comprising a puller bolt and a preloaded spring for pre-tightening a pre-tightening friction wheel, the operation is convenient, the pre-tightening effect is good, and the stepless regulation on the pre-tightening force can be realized.

Owner:XI AN JIAOTONG UNIV

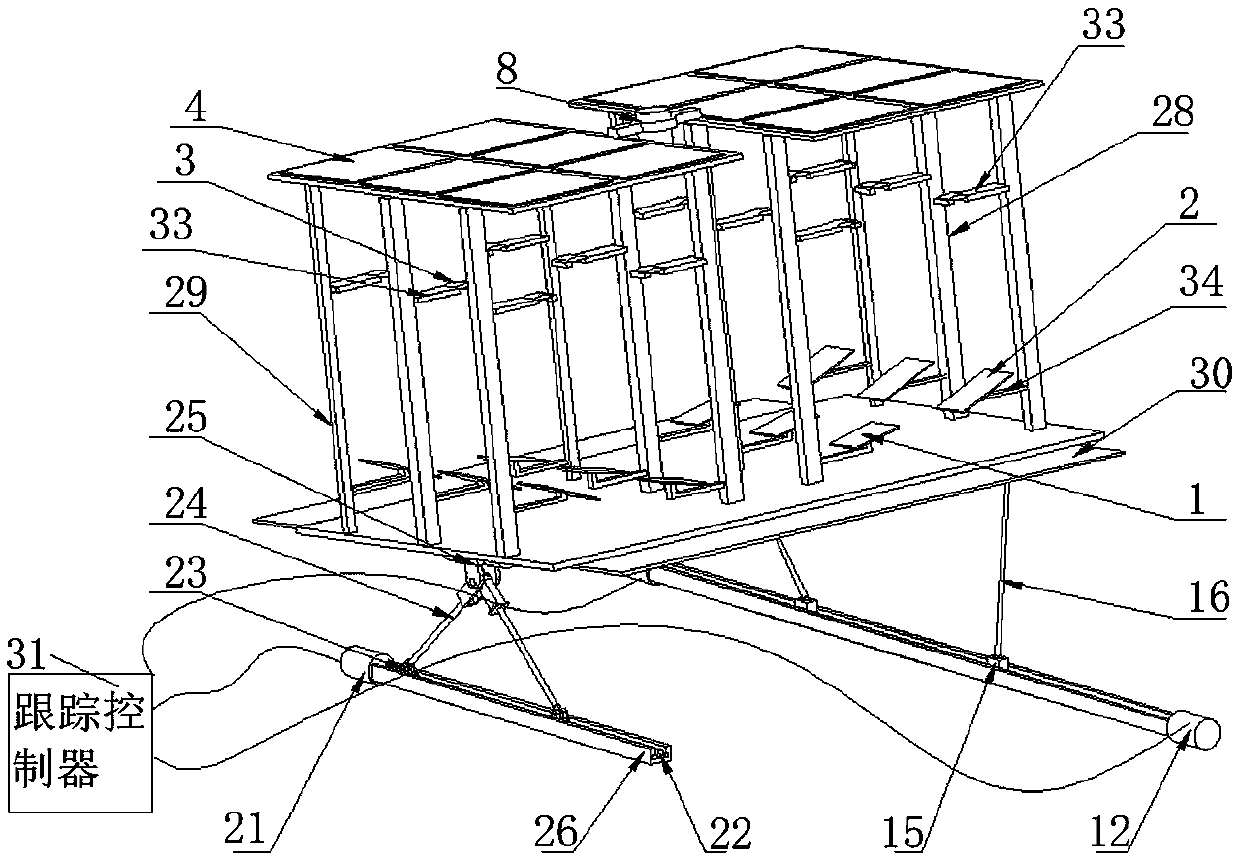

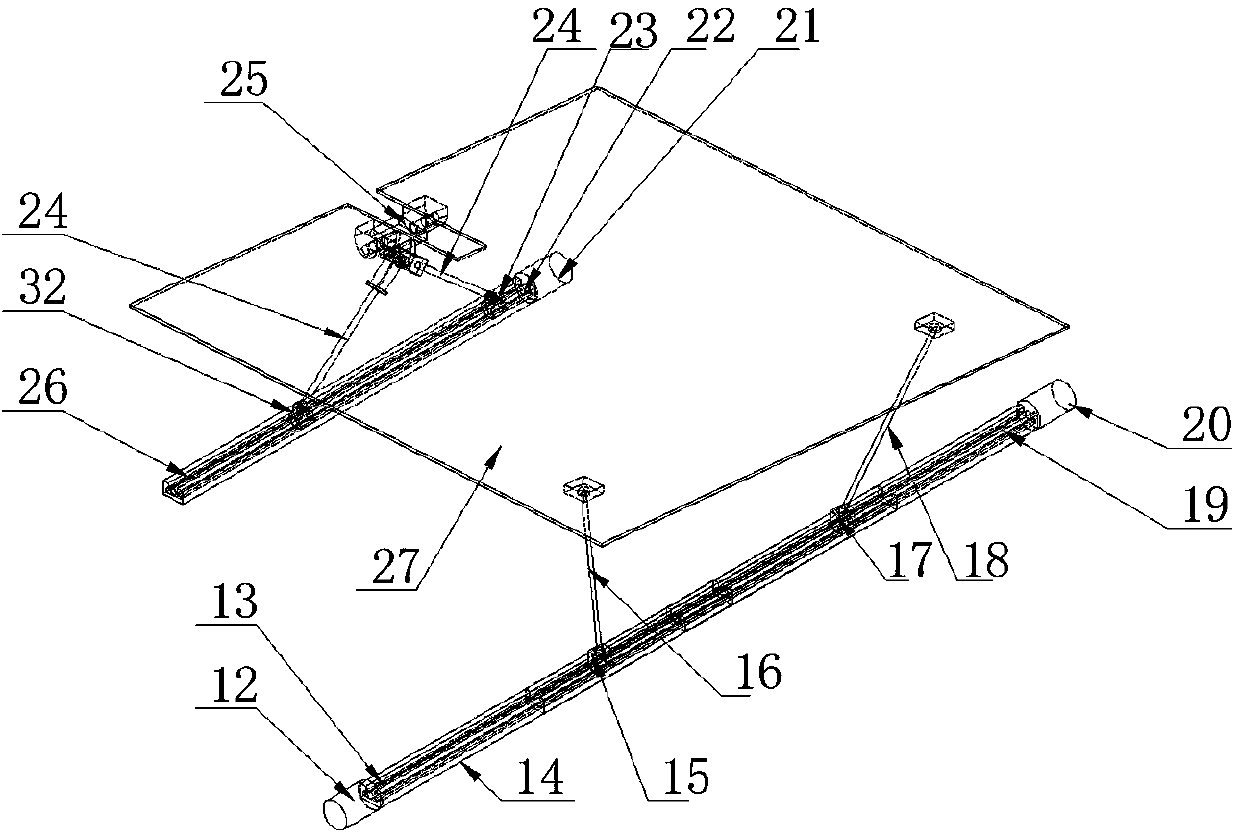

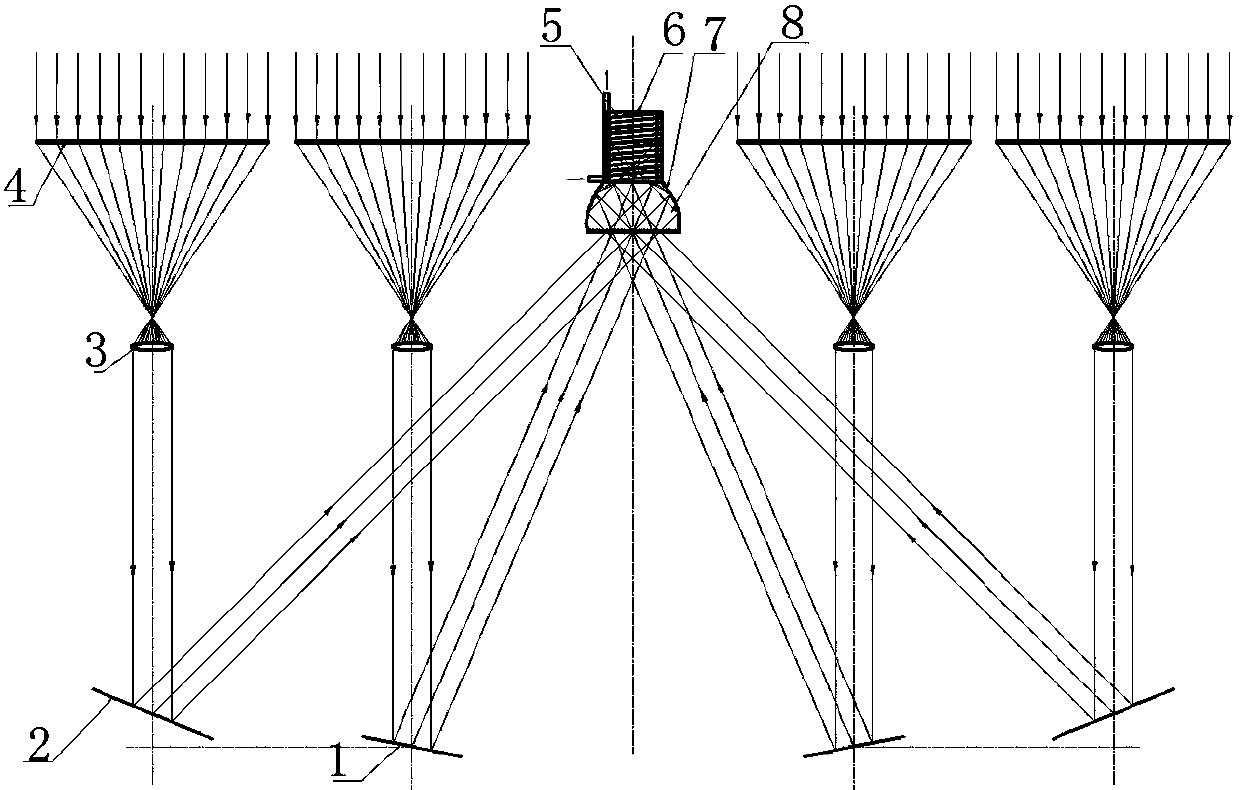

Dual-axis tracking multiple Fresnel lens integrated solar concentrating heat collection system

PendingCN110186206AReduce manufacturing costReduce installation costsSolar heating energySolar heat collector controllersFresnel lensCollection system

The invention discloses a dual-axis tracking multiple Fresnel lens integrated solar concentrating heat collection system. The system comprises a condenser, a dual-axis tracking platform, a heat absorber and a tracking controller, wherein the condenser comprises a fixing frame, a plurality of Fresnel lenses and reflector elements. The Fresnel lenses and the heat absorber are fixed on the fixing frame; the Fresnel lenses directly face the sun; one reflector element is arranged below each Fresnel lens; the reflector elements are capable of reflecting sunlight focused by the Fresnel lenses to theheat absorber; the fixing frame is fixedly arranged on the dual-axis tracking platform; and a dual-axis tracker of the dual-axis tracking platform is connected with the tracking controller. The systemis simple in structure, low in cost and good in bearing rigidity; the application of small area of the Fresnel lenses to the high-power solar concentrating heat collection system is achieved; and moreover, dual-axis tracking of the condenser is achieved by adopting parallel connected link mechanisms, so that the manufacturing and installation cost of the solar concentrating heat collection systemis further reduced.

Owner:HUNAN UNIV OF SCI & TECH

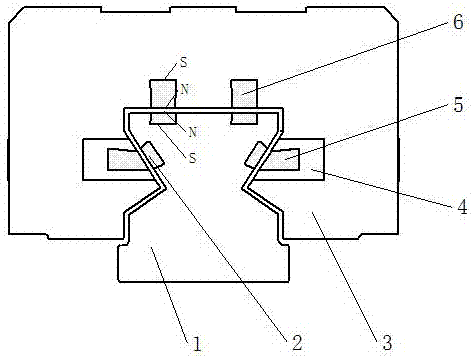

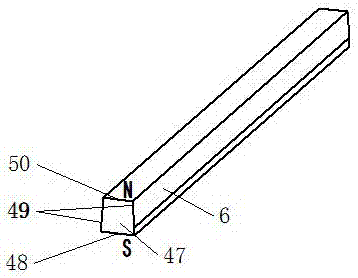

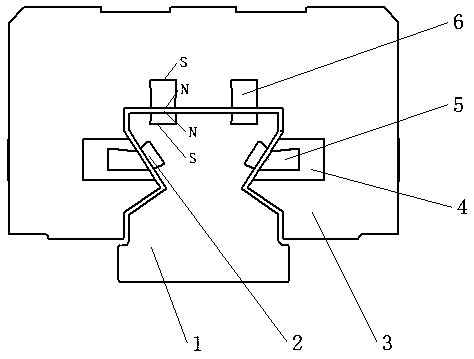

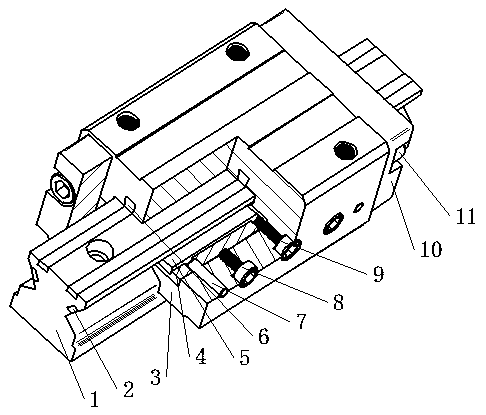

Permanent magnet repulsion type magnetic suspension linear guide rail

ActiveCN107420425ANo mechanical contact, with no mechanical wearNo mechanical wearMagnetic bearingsMagnetic holding devicesMechanical wearEngineering

The invention relates to a permanent magnet repulsion type magnetic suspension linear guide rail and belongs to the technical field of transmission engineering components. The permanent magnet repulsion type magnetic suspension linear guide rail comprises a guide rail, guide rail magnetic strips, a sliding block body, an adjusting block, a lateral sliding body magnetic stripe, an upper sliding block body magnetic stripe, guide pin shafts, an adjusting screw, a locking screw, side plates and side plate screws. According to the permanent magnet repulsion type magnetic suspension linear guide rail, the four pairs of permanent magnet repulsion type magnetic suspension magnet set magnetic strips are correspondingly mounted on the guide rail and the sliding block body, the repulsion acting directions of two pairs of magnetic suspension magnet sets are the up-down directions, the repulsion acting directions of the two pairs of magnetic suspension magnet sets are the left-right internally-inclined directions, and the stable repulsion magnetic suspension structure is formed; and gaps between the magnetic strips of the two pairs of magnetic suspension magnet sets on the two inclined side faces can be adjusted. According to the permanent magnet repulsion type magnetic suspension linear guide rail, the guide rail is in non-mechanical contact with the sliding block body by the adoption of the permanent magnet repulsion magnetic suspension, and the guide rail has the beneficial effects of being free of mechanical wear and free of lubricating and can be applied to a precision machine. The guide rail has the beneficial effects of being good in repulsion suspension stability, high in antijamming capability, adjustable in bearing rigidity, good in applicability, compact and simple in structure and easy to apply and popularize.

Owner:KUNMING UNIV OF SCI & TECH

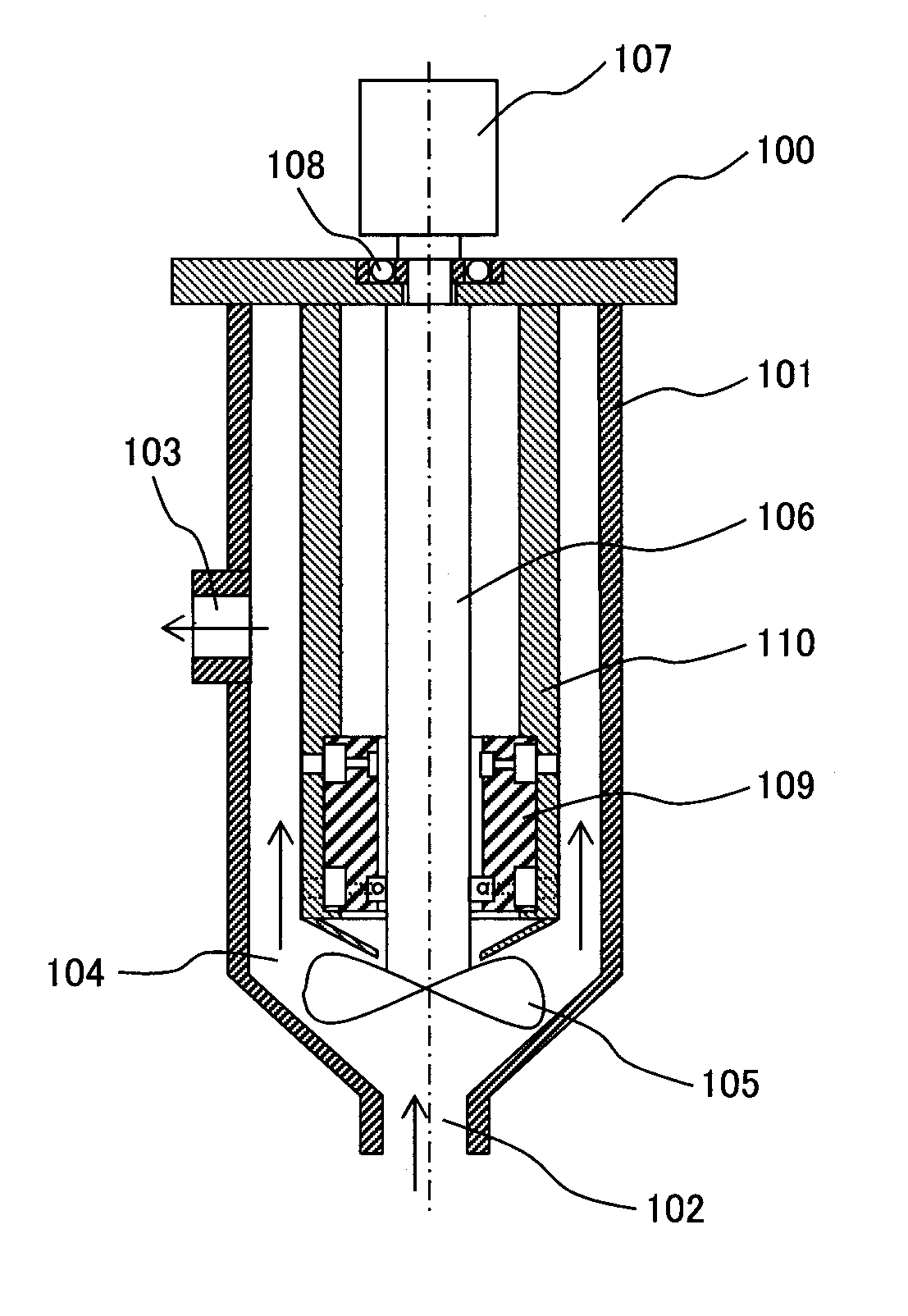

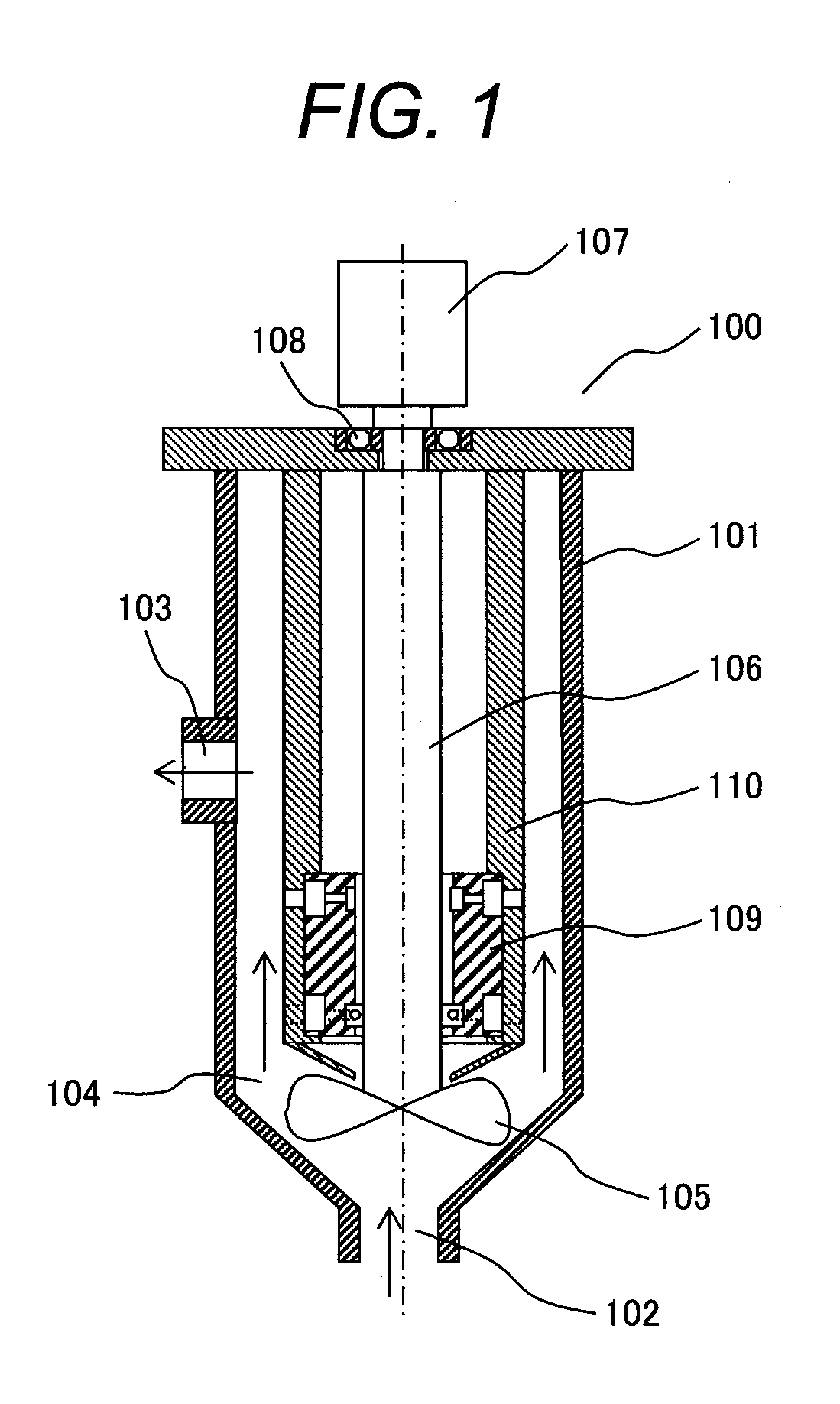

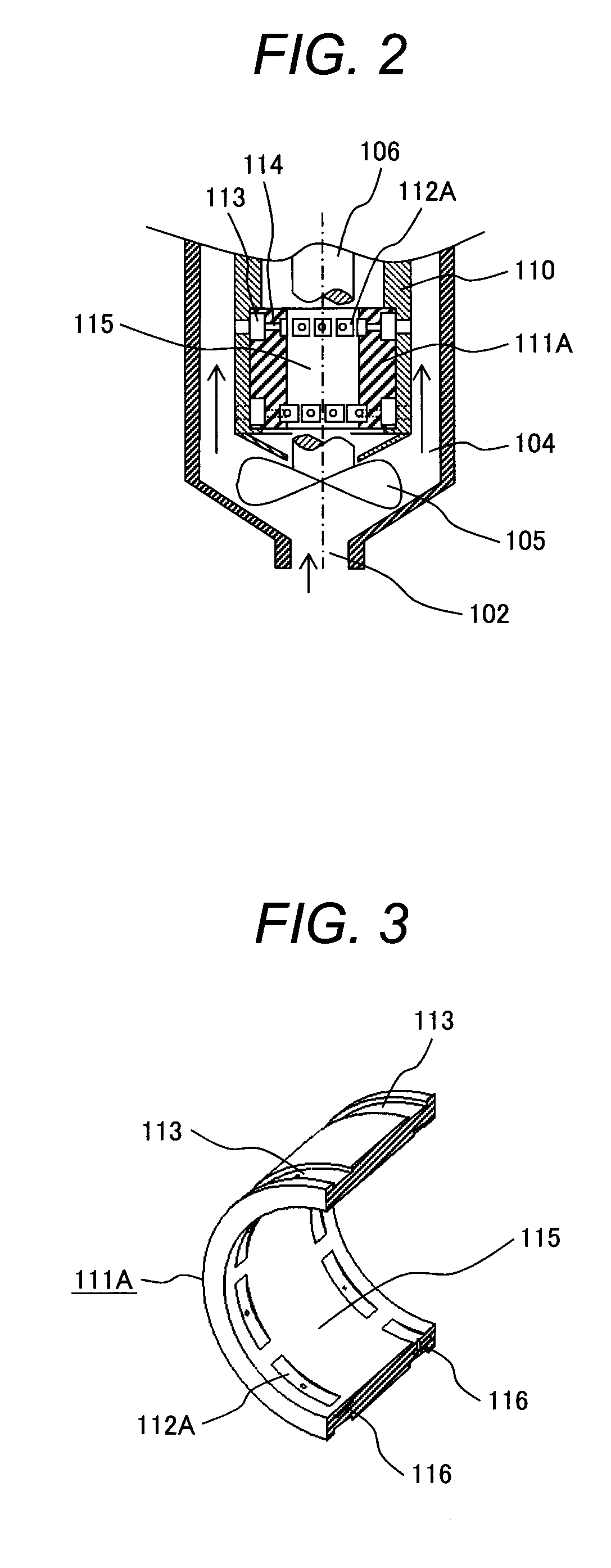

Sliding Bearing and Pump Device Using the Same

InactiveUS20130149142A1High pressureImprove rendering capabilitiesPump componentsShaftsCarrying capacityHydrostatic pressure

In a sliding bearing, load carrying capacity and bearing rigidity is increased without increasing a size of the bearing and the pressure of the fluid. The sliding bearing comprises a cylindrical-shaped sleeve supporting a rotatable shaft via fluid, and hydrostatic pressure pockets provided in the inner periphery of the sleeve. The hydrostatic pressure pockets constitute a plurality of rows of circumferentially disposed hydrostatic pressure pockets via orifices. At least one of the hydrostatic pressure pocket rows is arranged adjacently to each of both end portions of the inner periphery of the sleeve. And a circular cylindrical inner peripheral surface region without the hydrostatic pressure pockets is provided at a center portion of the sleeve. A width of the circular cylindrical inner peripheral surface region provided in the axial direction of the shaft is made wider than a sum of widths of the hydrostatic pressure pocket rows.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

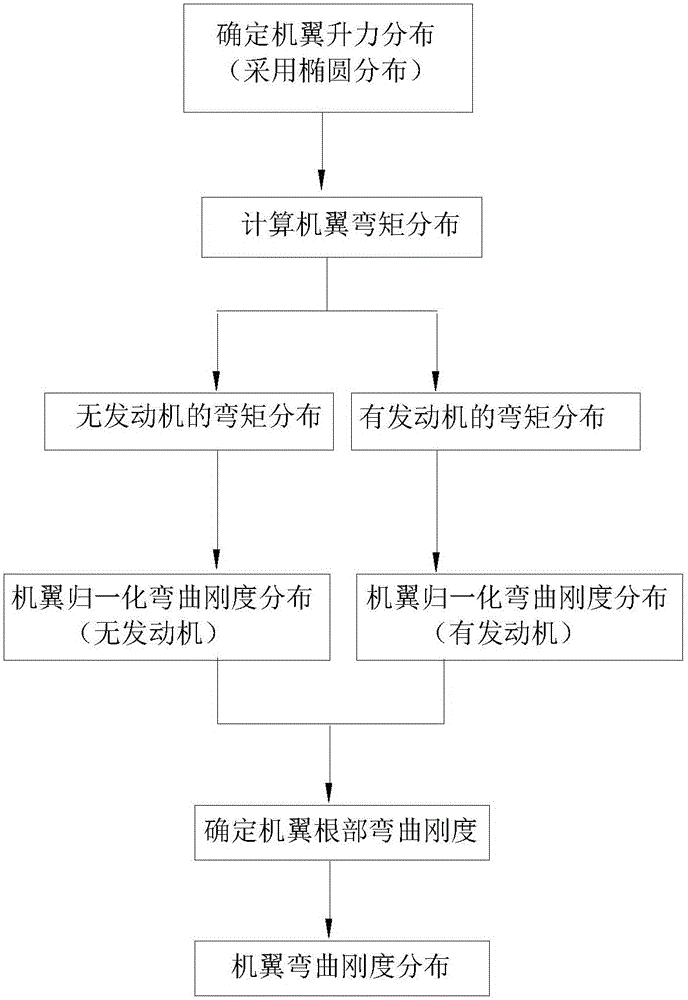

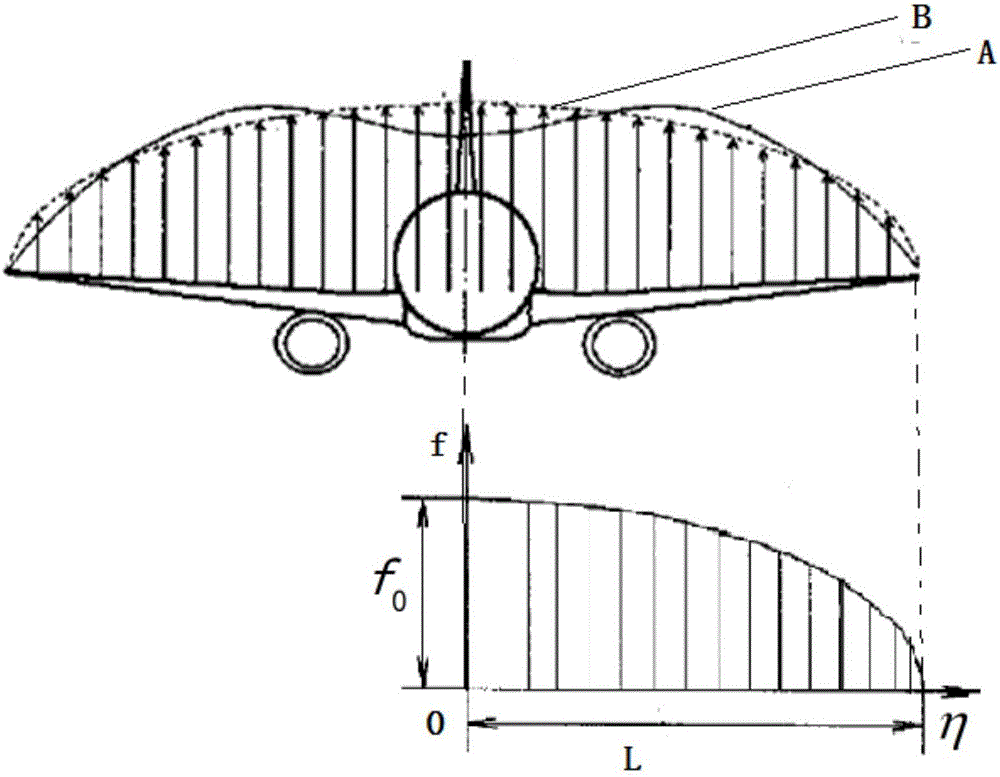

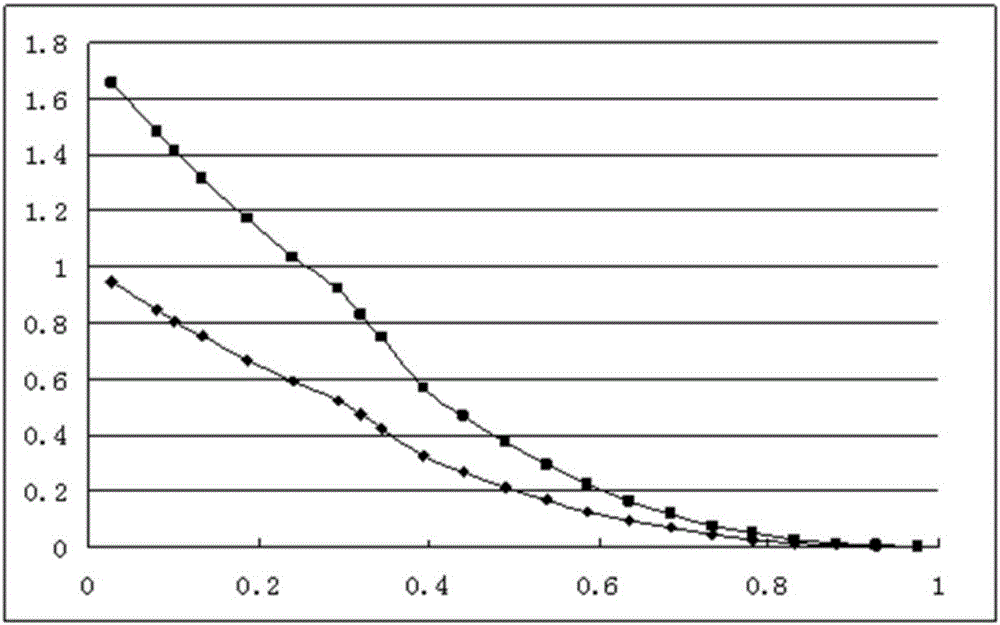

Calculation method for wing bending rigidity distribution

InactiveCN105975707AStiffness distribution quickly obtainedGeometric CADSpecial data processing applicationsAeroelasticityWingspan

The invention relates to a calculation method for wing bending rigidity distribution and belongs to the field of aeroelasticity. The method comprises the steps that firstly, the lift force distribution of a wing is equivalent to the oval lifting force distribution, and a distribution function of the wing lifting force along wingspan under the equivalent condition is acquired; secondly, a bending moment expression of any position on the wingspan of the wing is acquired according to the distribution function of the wing lift force along the wingspan; then, with the bending rigidity of a position on the root part of the wing being a reference, the normalization bending rigidity distribution of the wing along the wingspan is acquired, and the bending rigidity of the root part of the wing is calculated; finally, the actual bending rigidity distribution of the wing along the wingspan is acquired according to the normalization bending rigidity distribution of the wing along the wingspan and the bending rigidity of the root part of the wing. The calculation method for the wing bending rigidity distribution is applicable to the later period and the primary design stage of a wing concept design, and under the situation that design conditions are not sufficient, the rigidity distribution of the wing can be quickly acquired through the method.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Test platform and method of nonparallelism of space ring on coupling influence rule of main shaft thermal structure

InactiveCN110132593ASimple structureThe principle of the test is clearMachine bearings testingThermal deformationEngineering

The invention discloses a test platform and method of nonparallelism of a space ring on coupling influence rule of a main shaft thermal structure. A main shaft is arranged in an outer shell, fixing ofthe main shaft in the outer shell is achieved by a front support piece and a rear support piece, the main shaft is provided with a front displacement sensor group and a rear displacement sensor grouprelative to an extension segment of the outer shell, and a front temperature sensor and a rear temperature sensor are arranged on surfaces of the front support piece and the rear support piece. The test platform has the advantages the working condition of a high-speed main shaft is truly simulated, the thermal deformation change of the space ring having a parallelism error on the main shaft, thetemperature rising of a main shaft system and heat generation data of a bearing can be truly reflected, the influence of the parallelism error of the space ring on the main shaft deformation, the temperature rising of the main shaft system and the temperature change of the bearing is simulated by a test method under conditions of fixed rotational speed and variable rotational speed, and an important theoretical support effect is achieved for analysis of bearing rigidity change.

Owner:CHONGQING UNIV

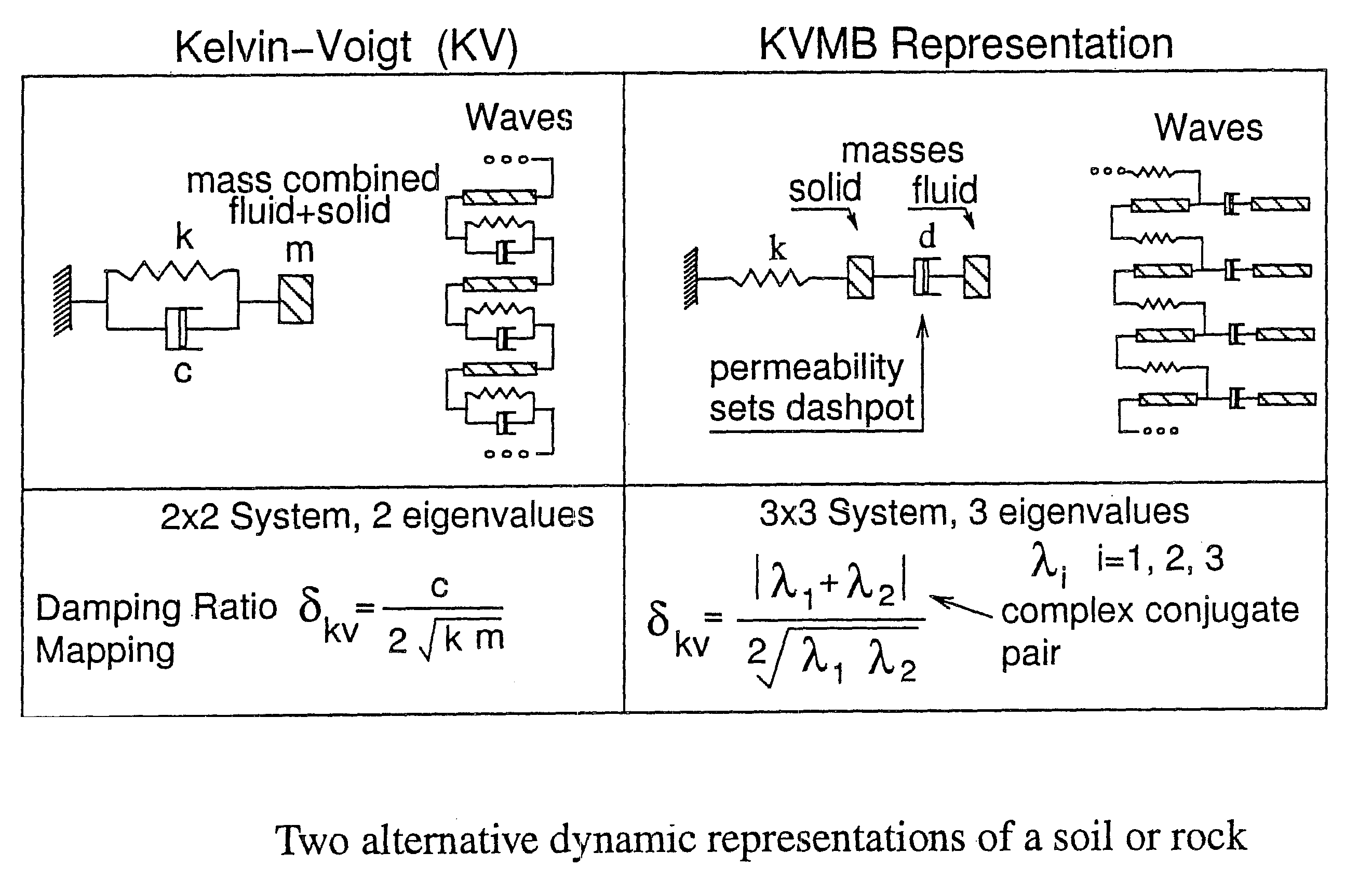

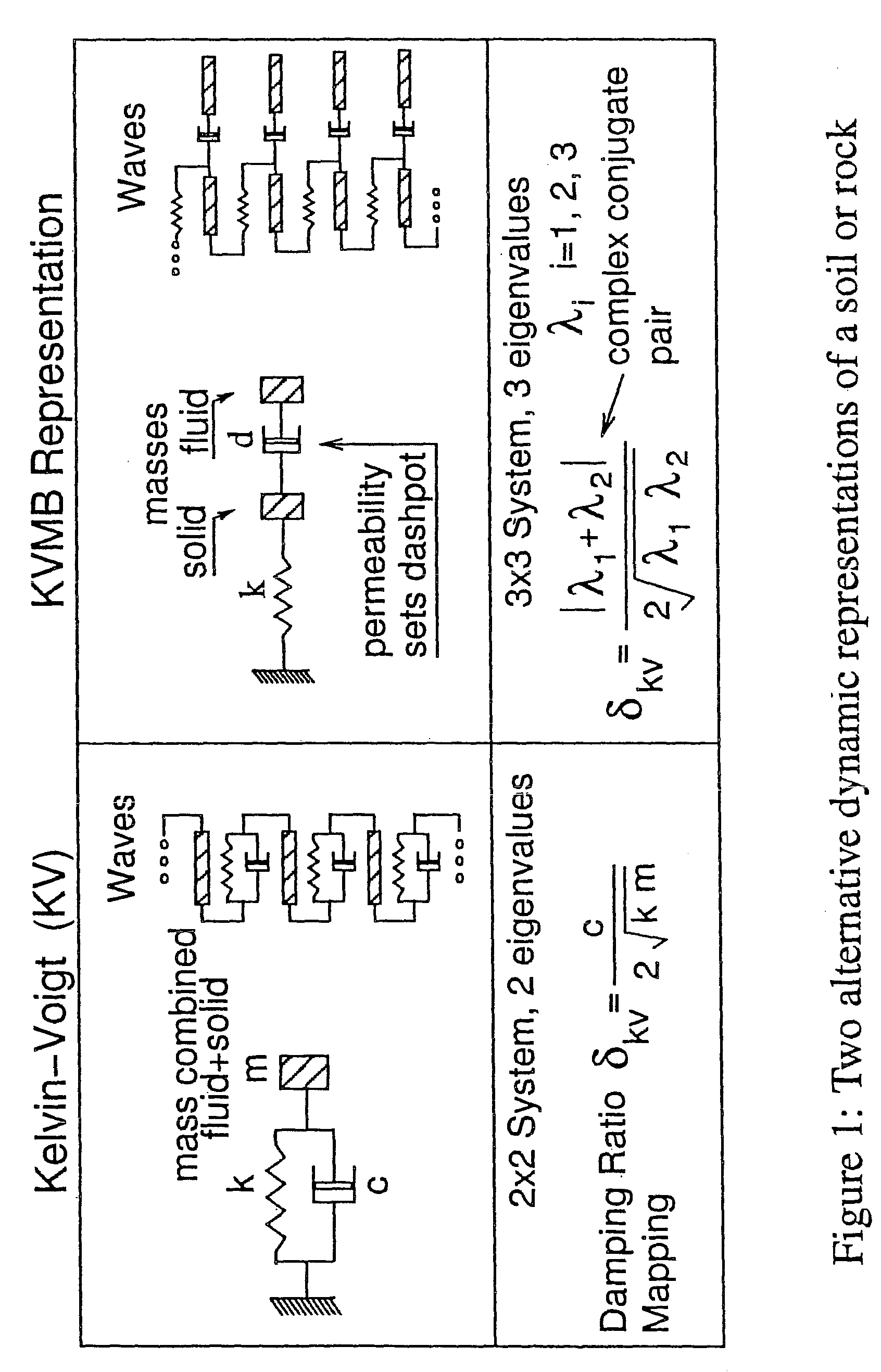

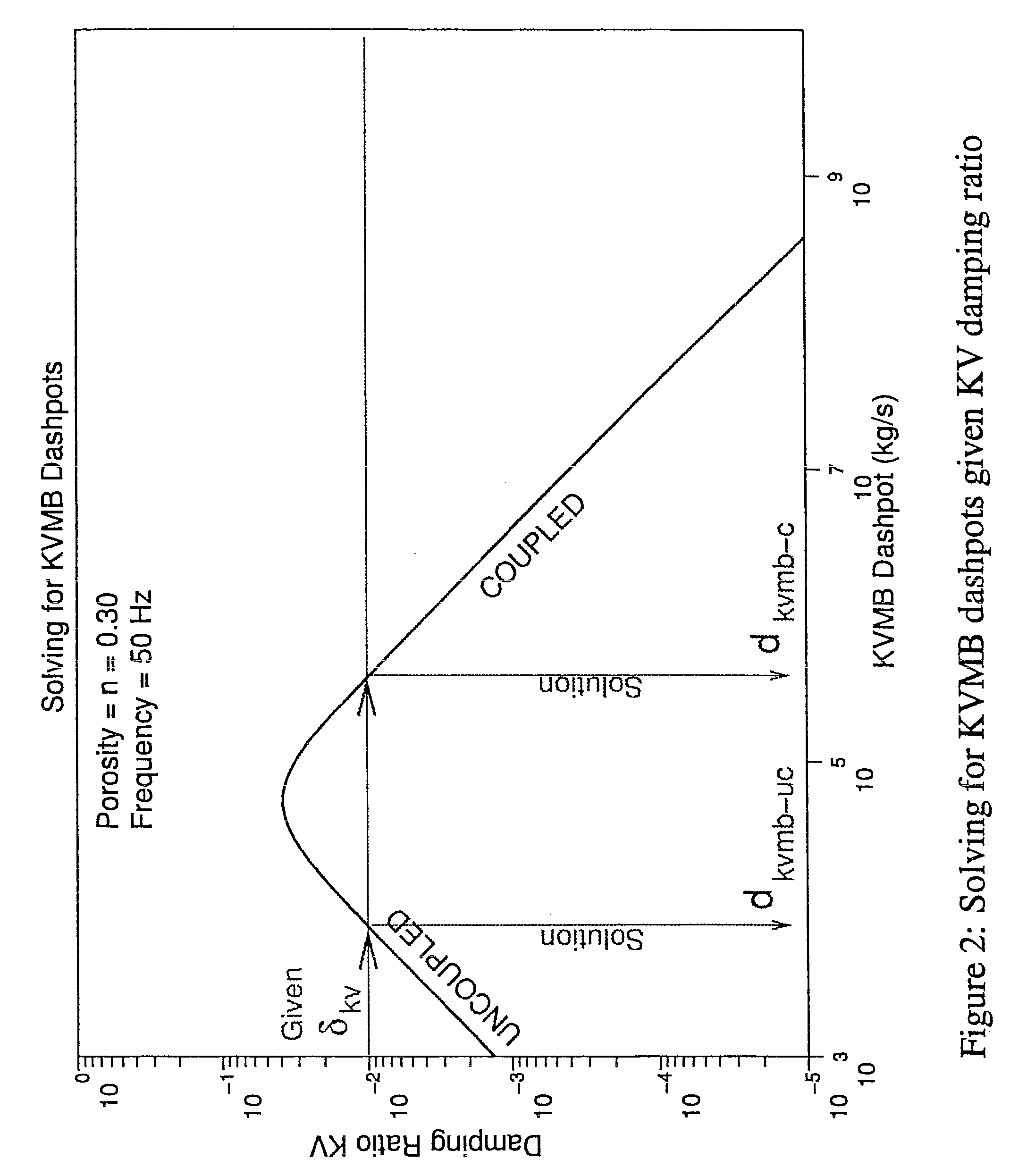

Determination of permeability from damping

InactiveUS7930926B2Permeability/surface area analysisBorehole/well accessoriesInertial effectPorosity

Permeability of a fluid through a saturated material is determined by measuring the dynamic response of that saturated material to shaking vibrations and / or shear wave propagation, and then mapping the dynamic response (preferably, viscoelastic stiffness and damping properties) to an invented model (called “KVMB”) that yields the property of permeability. The preferred embodiments may use shear waves, inertial effects, and / or transmission effects, but preferably not compression, to force fluids through the pores. The mapping preferably predicts two possible mappings to permeability, coupled and uncoupled. The preferred methods are both internally consistent and directly related to known laws of physics rather than dependent on empirical calibrations. In use, for example, one may use a porosity log (conventional neutron or sonic) and recordings of SH-waves to obtain damping ratio, followed by locating of the damping ratio on a KVMB map that depends on porosity, and choosing of one of the two possible permeabilities indicated by the mapping, wherein the best choice is typically the largely coupled case.

Owner:BOISE STATE UNIVERSITY

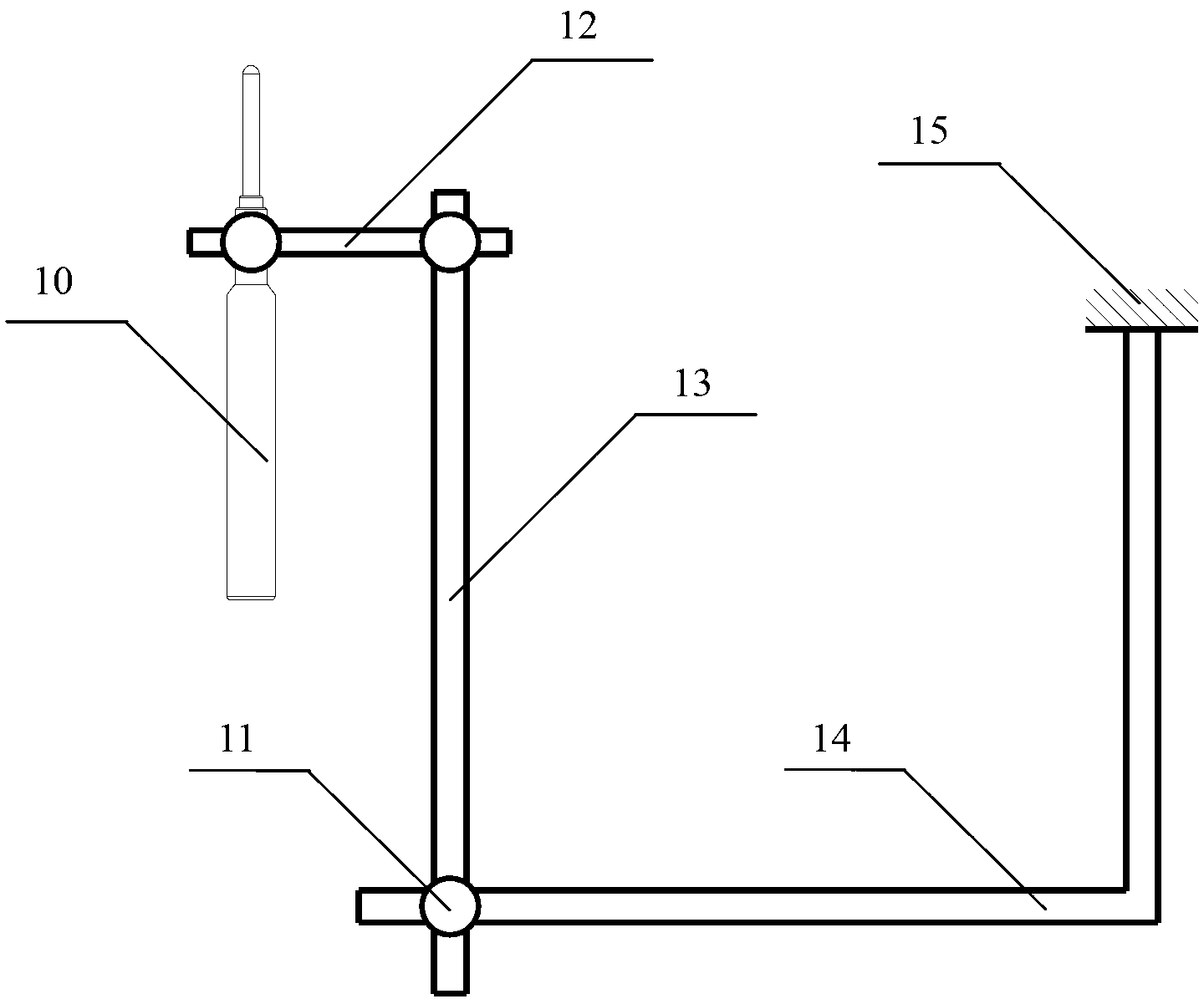

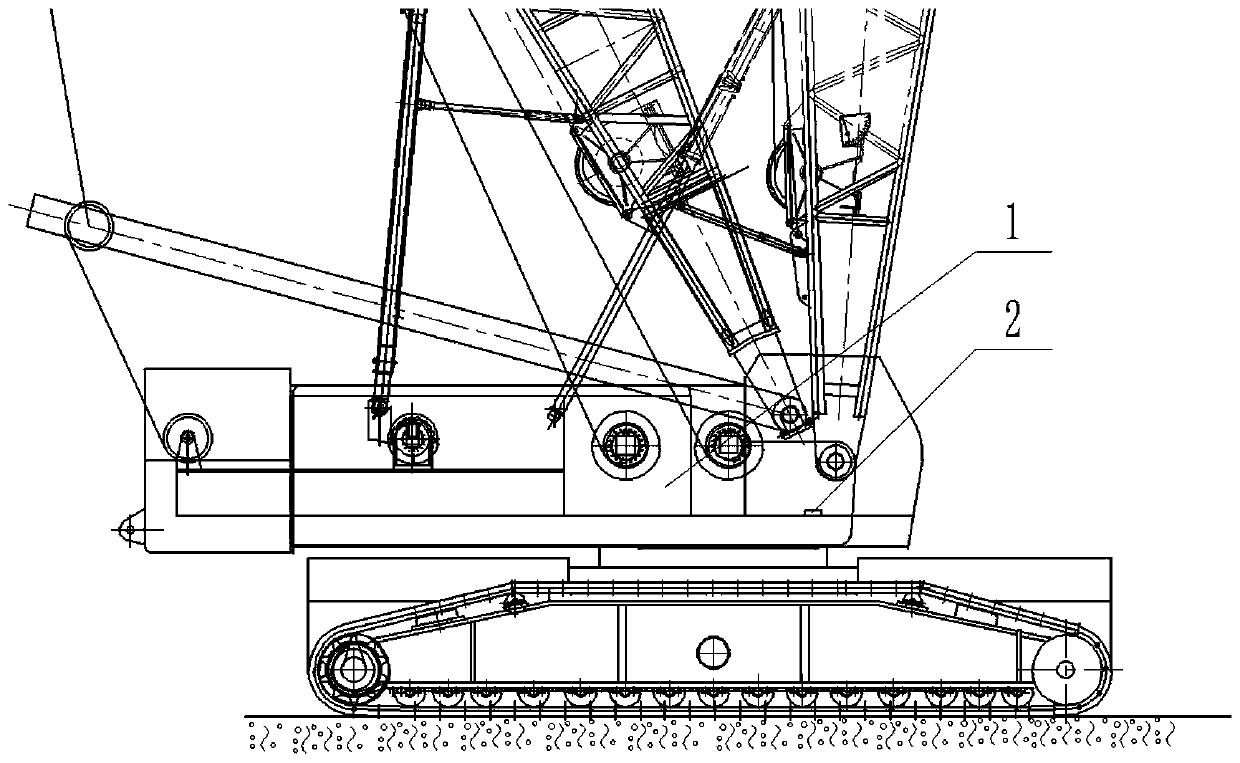

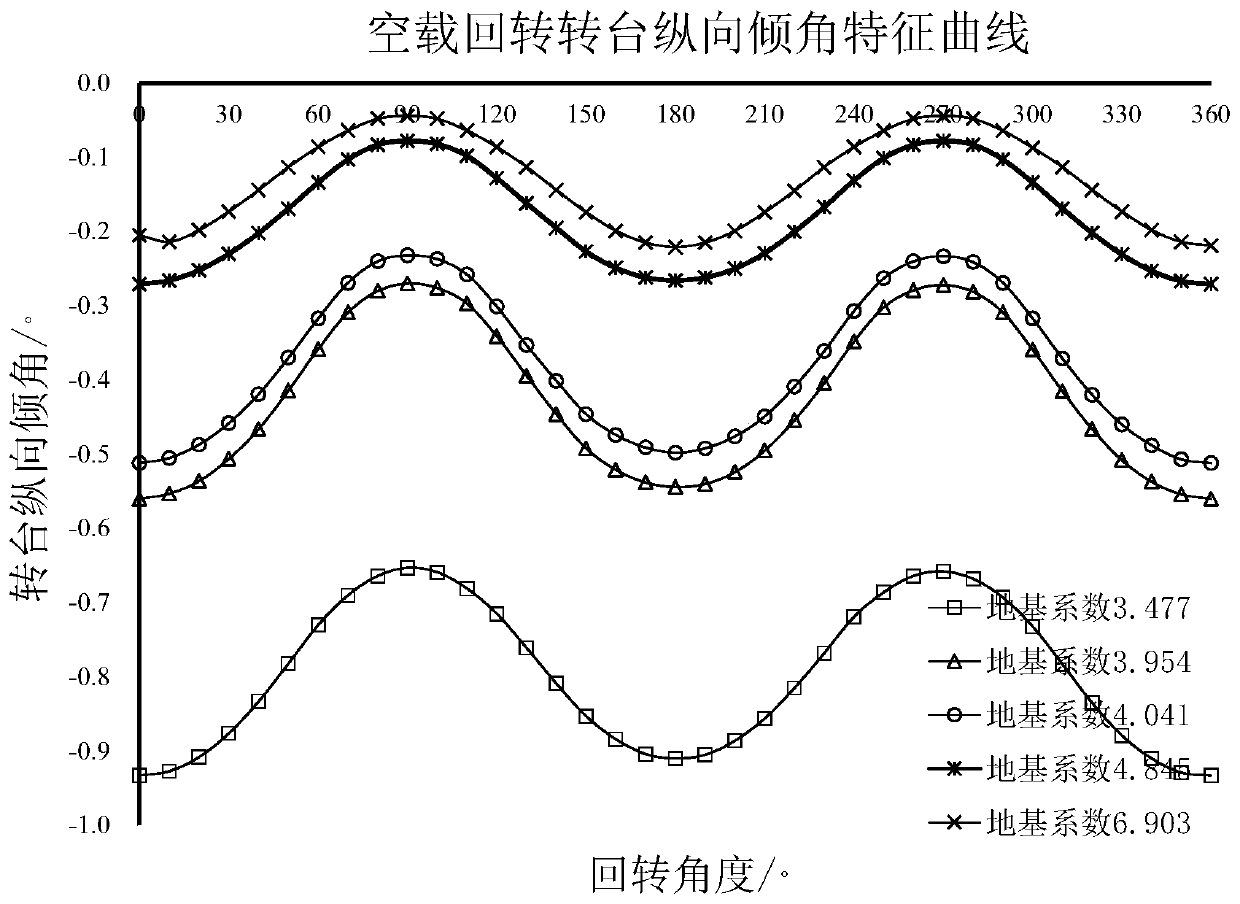

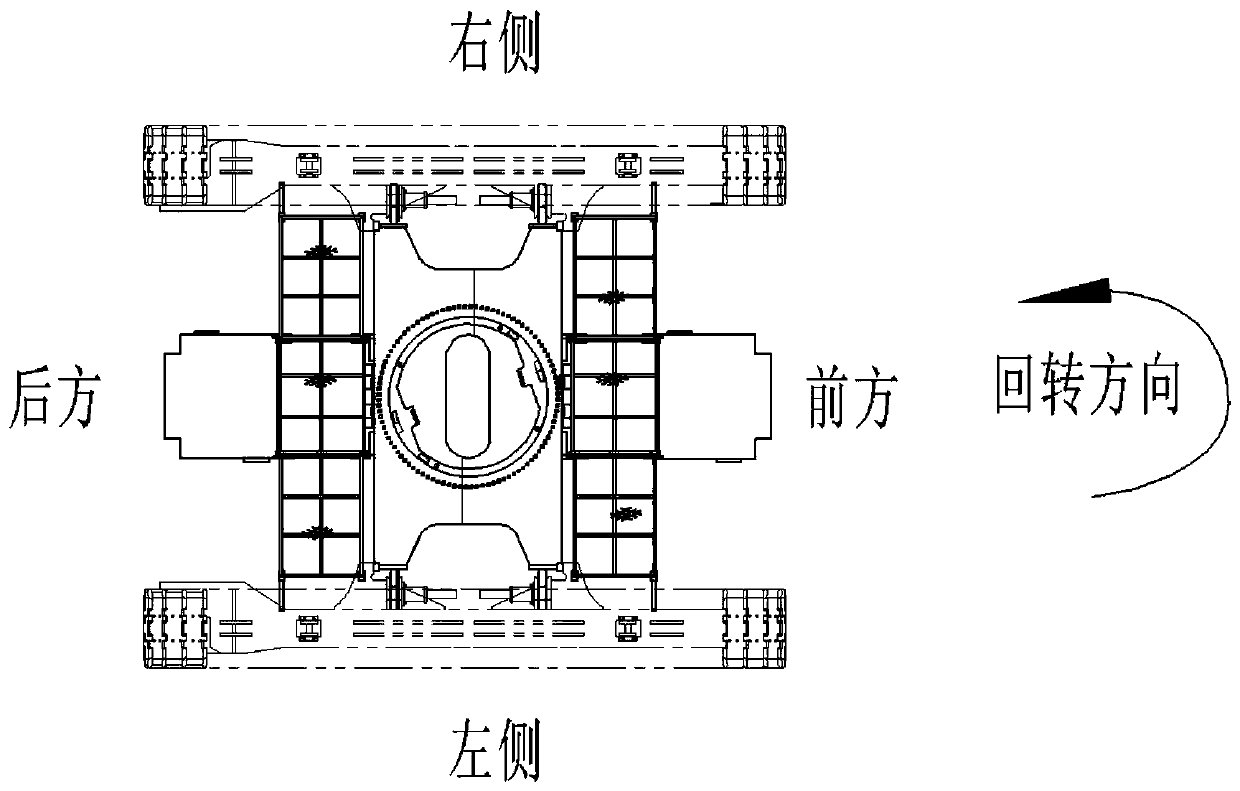

Method for on-line detecting bearing rigidity of foundation of track crane

The invention belongs to the technical field of track cranes, and provides a method for on-line detecting bearing rigidity of a foundation of the track crane. An inclination sensor is mounted on a rotary table of the track crane; the longitudinal inclinations of the rotary table when the unloaded track crane rotates to 0 degree, 90 degrees, 180 degrees and 270 degrees are measured by the inclination sensor; a longitudinal inclination change curve of the rotating of the rotary table of the unloaded track crane under different foundation coefficient conditions, obtained through simulation of thecrane is combined, so that the spot foundation coefficient and ground levelness are obtained through an interpolation method; and according to the obtained spot data, a track crane load form under anideal state is amended by the interpolation method, so as to obtain the track crane load form guaranteeing the operation safety, and then the safe operation of the track crane is guided. The whole process is automatically performed by a vehicle-mounted PLC, so that the operation is convenient.

Owner:DALIAN UNIV OF TECH

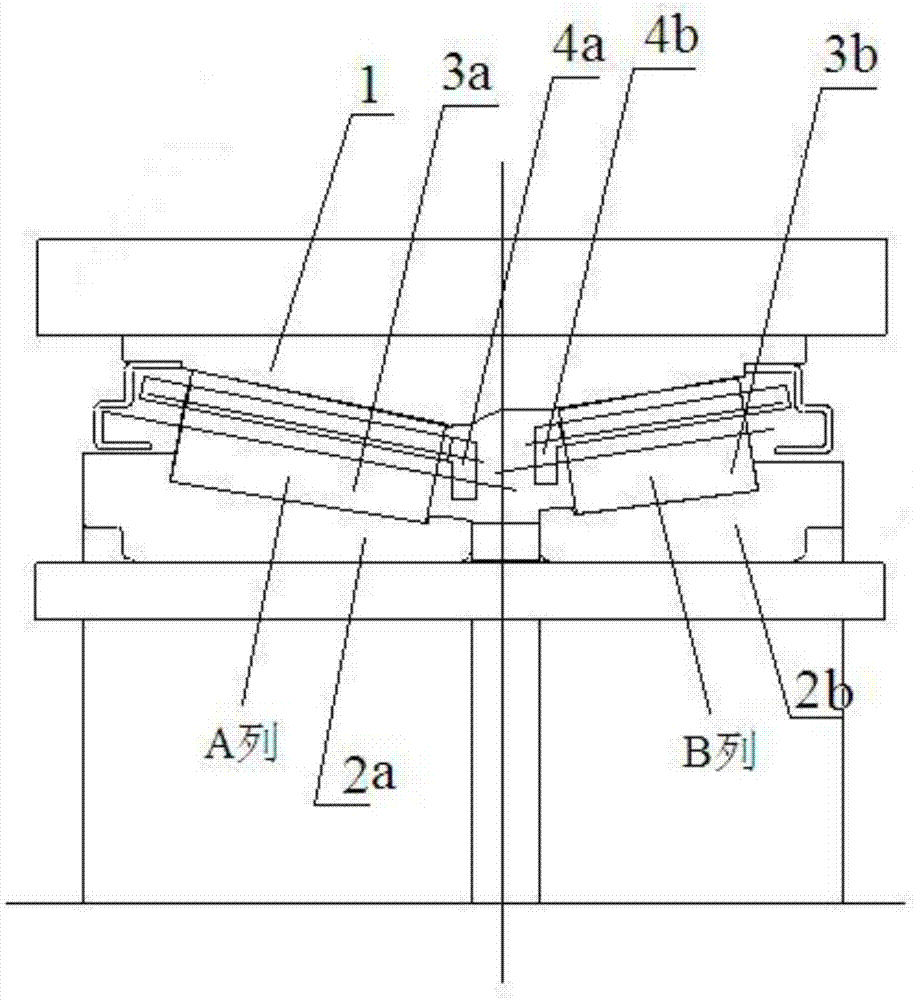

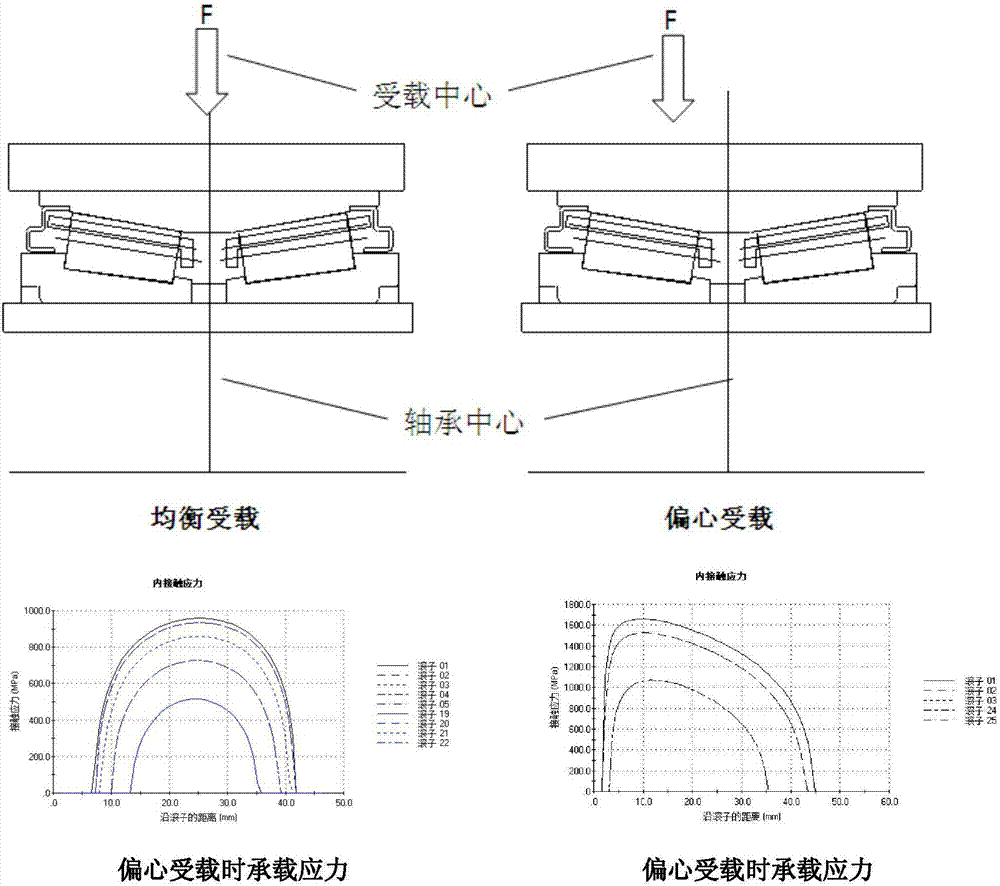

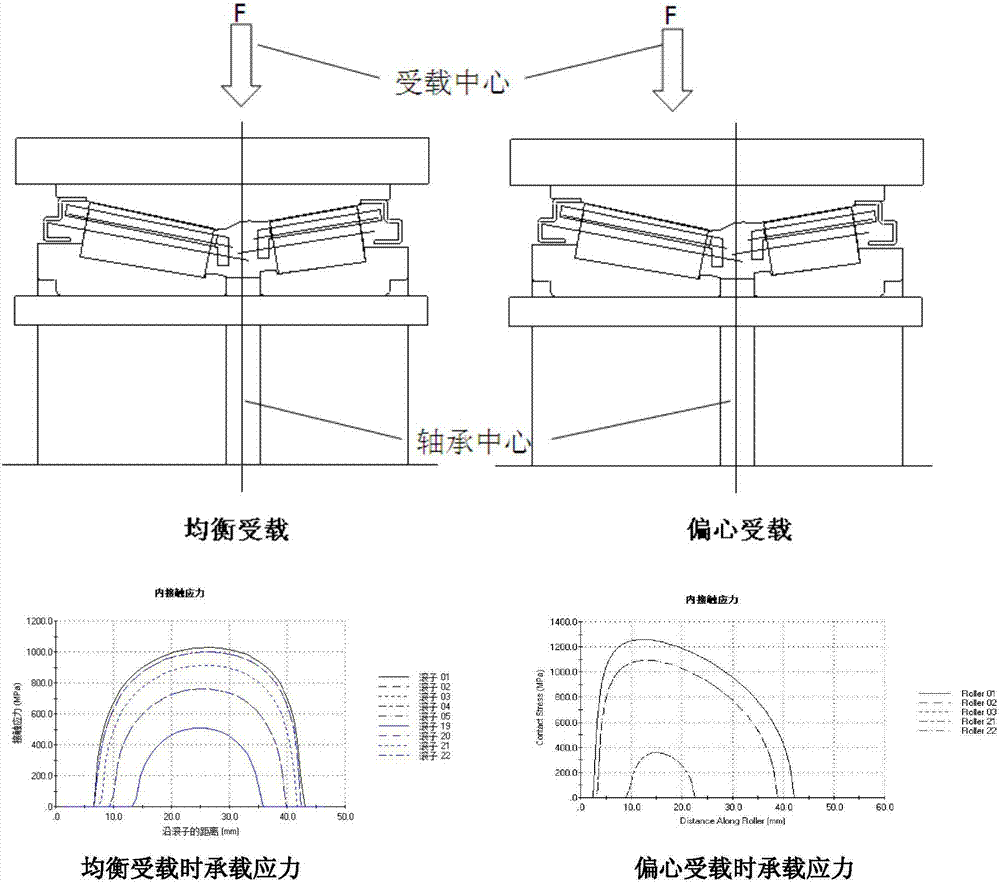

Double-row tapered roller bearing capable of bearing non-balance loads

InactiveCN107975537AReduce stress concentrationExtended service lifeRolling contact bearingsBearing componentsStress concentrationNon symmetric

The invention relates to the technical field of bearing machining, in particular to a double-row tapered roller bearing capable of bearing non-balance loads. The bearing is of a non-symmetric structure, design parameters of the row A and the row B of the bearing are different, the number of the A row of rollers is larger than the number of the B row of rollers, the length of the A row of rollers is larger than that of the B row of rollers, and the diameter of the A row of rollers is smaller than that of the B row of rollers. The bearing contact stress and bearing rigidity of the A row can be obviously improved, when the bearing bears eccentric loads and overturning moment generated by the non-balance load effect, the bearing can effectively reduce the bearing stress concentration condition, and the service life of the bearing is prolonged. The bearing centre of the bearing is not the centre of the bearing, and therefore the bearing can bear certain eccentric loads and overturning moment, the stress concentrated condition of the bearing is reduced, and the service life of the bearing is prolonged.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

A permanent magnetic repulsion type magnetic levitation linear guide

ActiveCN107420425BNo mechanical wearNo lubricationMagnetic bearingsMagnetic holding devicesMechanical wearEngineering

Owner:KUNMING UNIV OF SCI & TECH

A Composite Load Simulator Realizing Multidimensional Pure Bending Moment and Tensile Compression

InactiveCN103884373BLarge working spaceWide range of stiffnessMeasurement devicesEngineeringBorn rigidity

The invention discloses a composite load simulator for achieving multidimensional pure bending moment and tensile pressure. The composite load simulator can achieve pure bending moment loading, tensile pressure loading and pure bending moment and tensile pressure composite loading in any direction. The simulator comprises a moving platform, a fixed base and moving branch chains. The moving platform is fixedly connected with a loaded test piece, and the moving branch chains comprise the central moving branch chain and the uniformly-distributed moving branch chains, wherein the uniformly-distributed moving branch chains are of six different structures. The uniformly-distributed moving branch chains of the different structures, the central moving branch chain, the fixed base and the moving platform can form six kinds of different bending moment-tensile pressure composite load simulator structures. The composite load simulator has the advantages that the composite load simulator can achieve multidimensional pure bending moment load output and can output composite loads of the bending moment and the tensile pressure; due to the fact that the branch chains exist, the structure has high bearing rigidity, decoupling can be achieved through output of the tensile pressure and the bending moment, and the composite load simulator is convenient to control, simple to manufacture and convenient to install.

Owner:BEIHANG UNIV

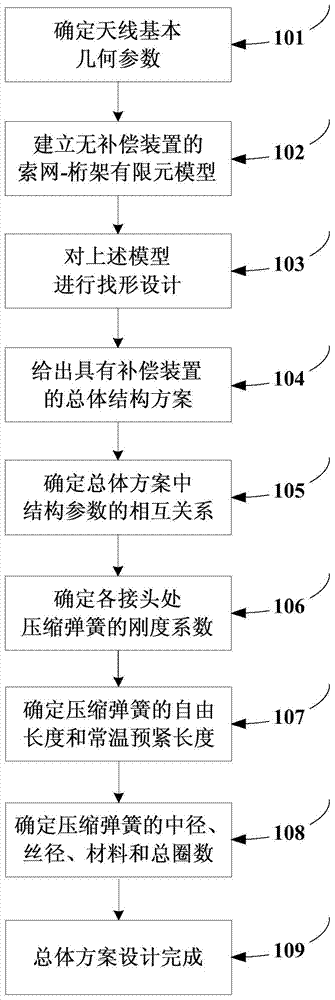

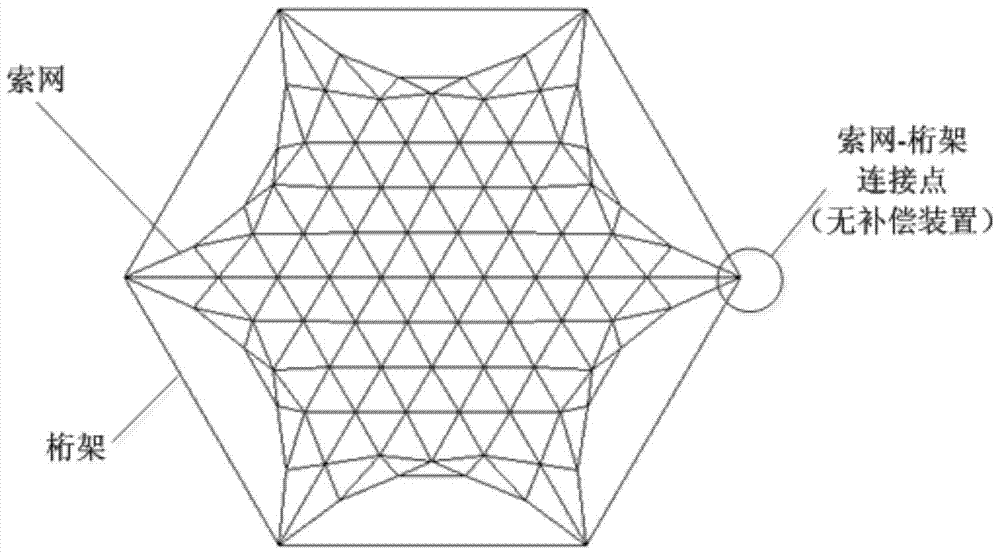

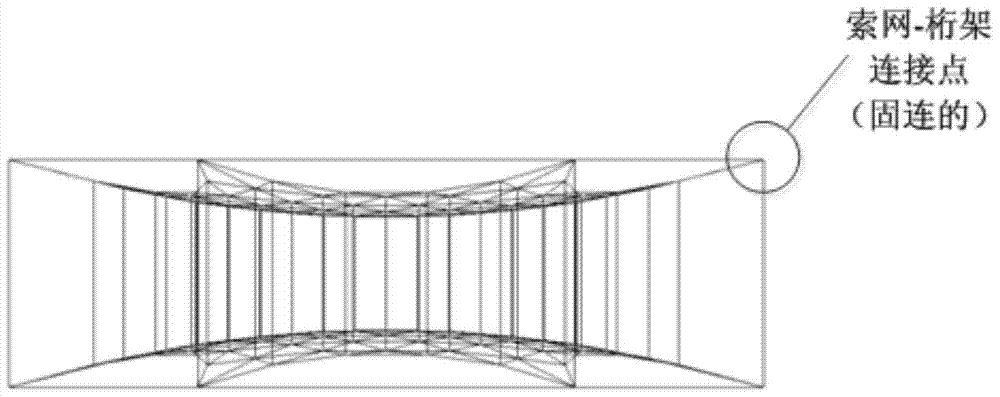

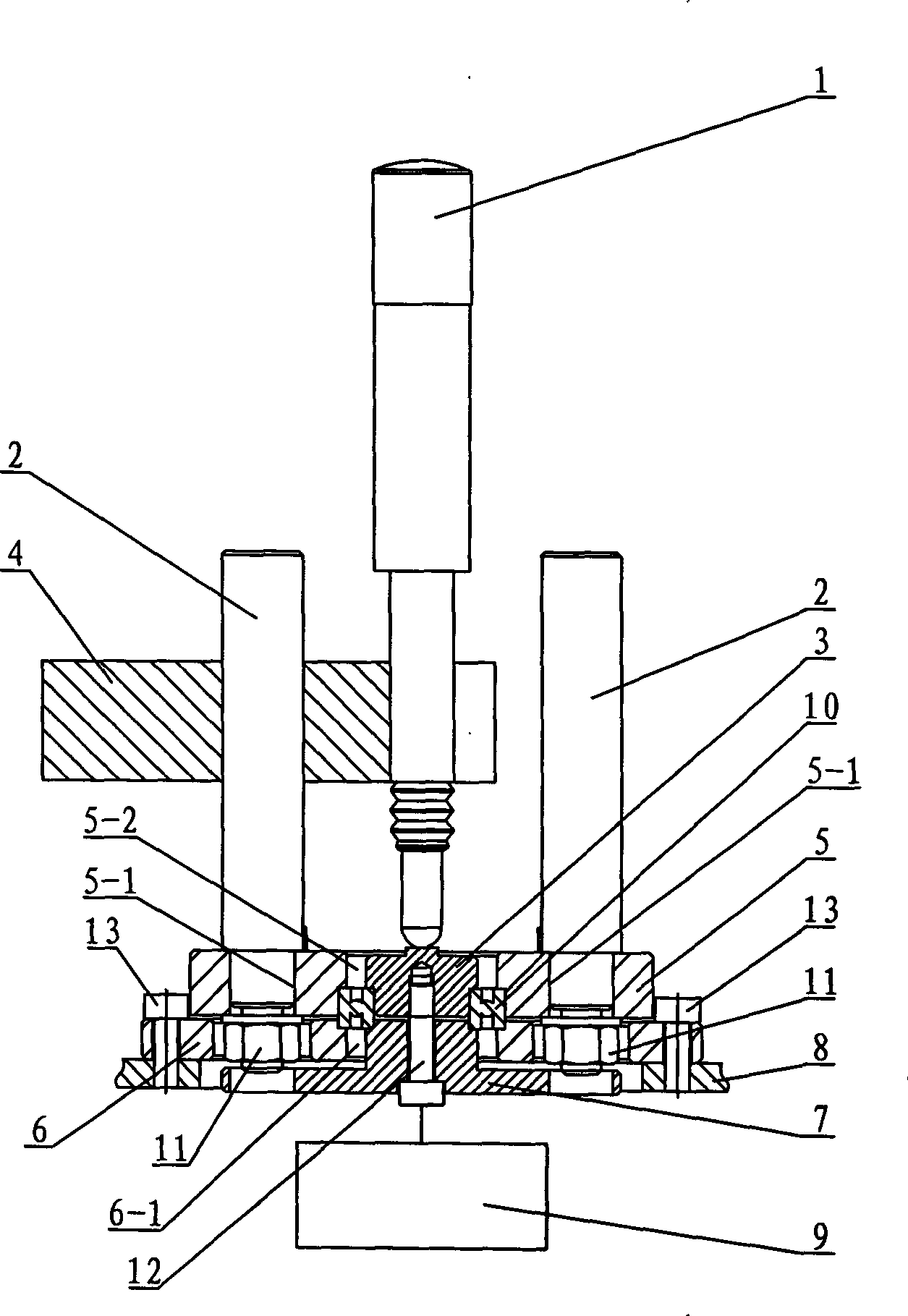

A method for preventing thermal relaxation of surrounding truss-type deployable antenna wire nets

InactiveCN104795640BGood compensationSimple structureAntenna supports/mountingsSpecial data processing applicationsEngineeringRail network

The invention discloses a method for preventing heat-induced relaxation of a peripheral truss-type expandable antenna wire net. In this method, a compression spring device is installed at each truss joint of the existing peripheral truss deployable antenna, so that it can adaptively compensate the tension change of the cable net caused by the thermal load on orbit. In the new design scheme, the stiffness coefficient, free elongation length, compensation margin and other structural parameters of the compression spring can be obtained through reasonable thermal simulation analysis.

Owner:XIDIAN UNIV

Method for designing optimal static parameter of radial static pressure gas bearing of turbine expansion engine

The invention relates to a method for designing optimal static parameters of a radial static pressure gas bearing of a turbine expansion engine, comprising the following steps: decomposing a journal bearing into a plurality of equivalent slits, listing a differential equation of gas movement, obtaining an equation about bearing capacity coefficient CW, bearing rigidity coefficient KW, total flow M and the total frictional power loss FT based on the differential equation, and obtaining the optimal static parameters for a radial throttling hole static pressure gas bearing of the turbine expansion engine on the condition of different eccentricity ratios obtained through the equation of the bearing capacity coefficient CW, bearing rigidity coefficient KW, total flow M and the total frictional power loss FT. The invention can obtain four performance parameters reflecting the radial throttling hole static pressure gas bearing realized by calculation of one program, therefore, the determined optimal static parameters has high precision in engineering application and can be used for designing the radial throttling hole static pressure gas bearing of the turbine expansion engine with high rotation speed and special usage.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Bearing rigidity test device

InactiveCN101354314BSimple structureEasy to operateMachine bearings testingInsertion stentEngineering

The invention relates to a bearing stiffness testing device, aiming at solving the problems of complex structure, inconvenient operation and high requirements on the surrounding environment of the existing bearing stiffness testing device. Ends of two studdles of the invention are respectively arranged at two studdle holes; an inner ring briquette is arranged in a central hole; one end of a connecting stent is positioned at any one studdle and an inductance probe is installed at the other end of the connecting stent; the probe end of the inductance probe is pressed on the center of a contact surface corresponding to the inner ring briquette; a connecting plate is connected with a bearing seat in a detachable manner through a first connecting piece, a flange is positioned in the central hole of the connecting plate and connected with the inner ring briquette in a detachable manner through a second connecting piece and a weight is connected with the flange. The testing device of the invention fixes the inner ring and the outer ring of the bearing to be tested respectively, loads on the inner ring to obtain the position deviation of the inner ring and the outer ring of the bearing under different load, thereby obtaining bearing stiffness index; in addition, the testing device has simple structure, convenient operation and relatively low requirements on the surrounding environment.

Owner:HARBIN INST OF TECH

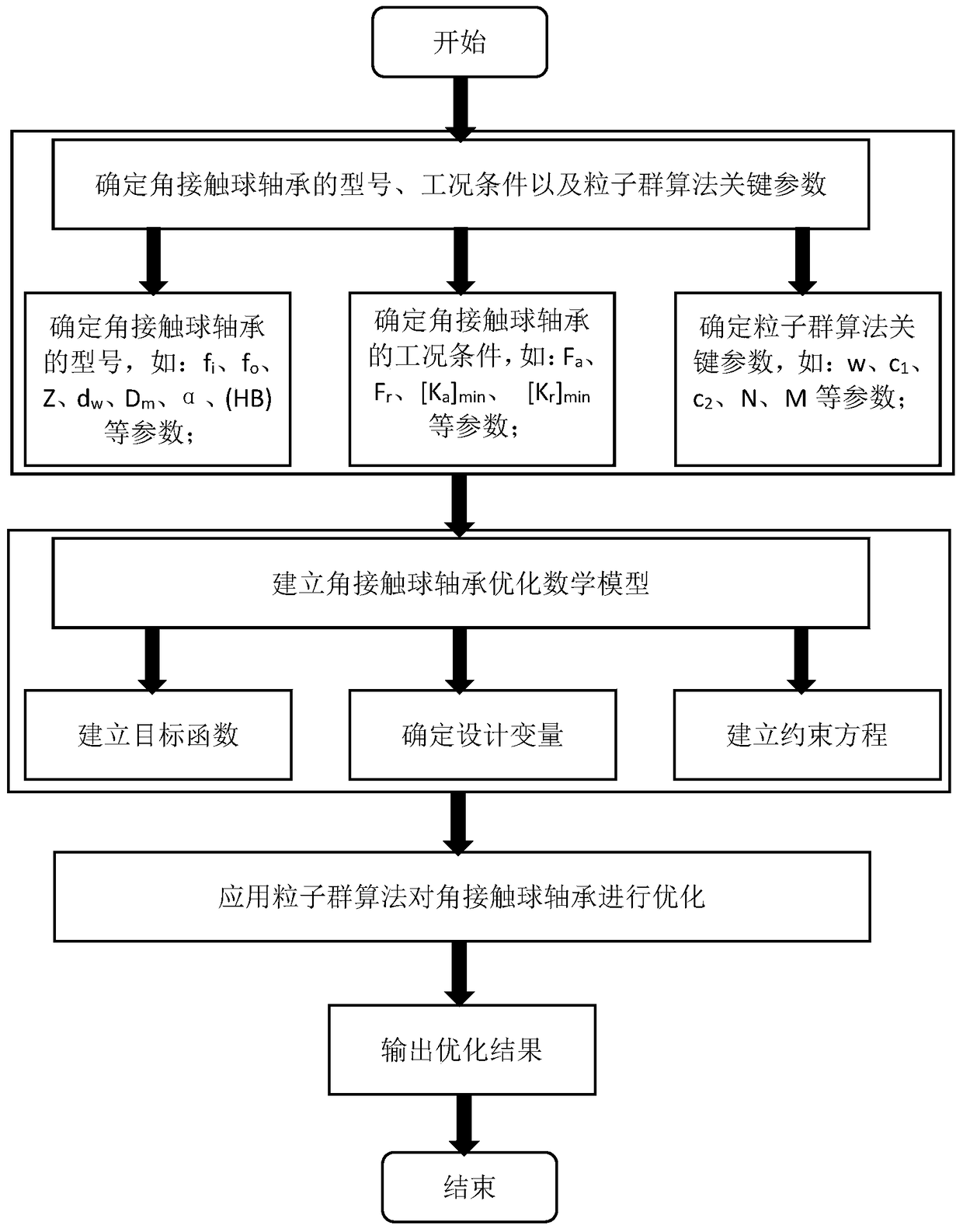

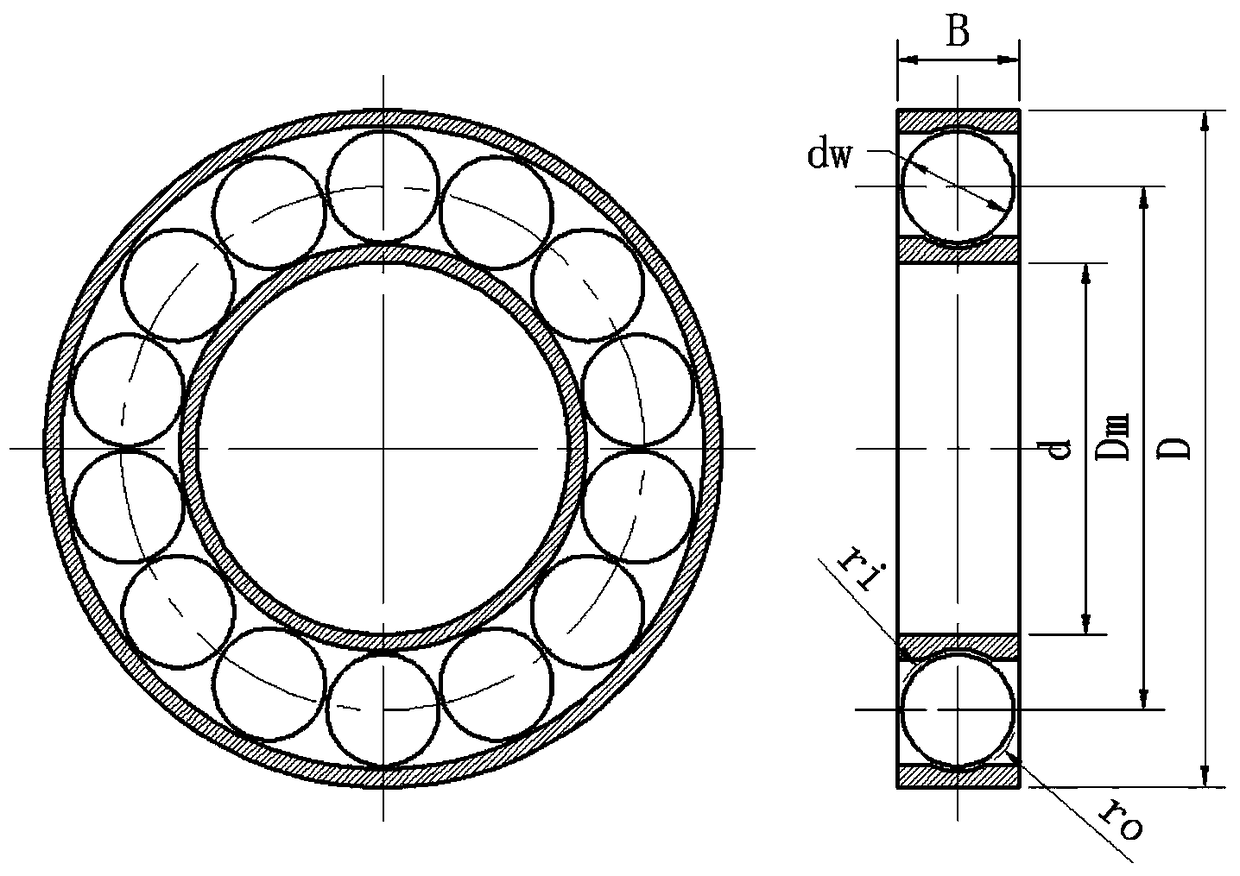

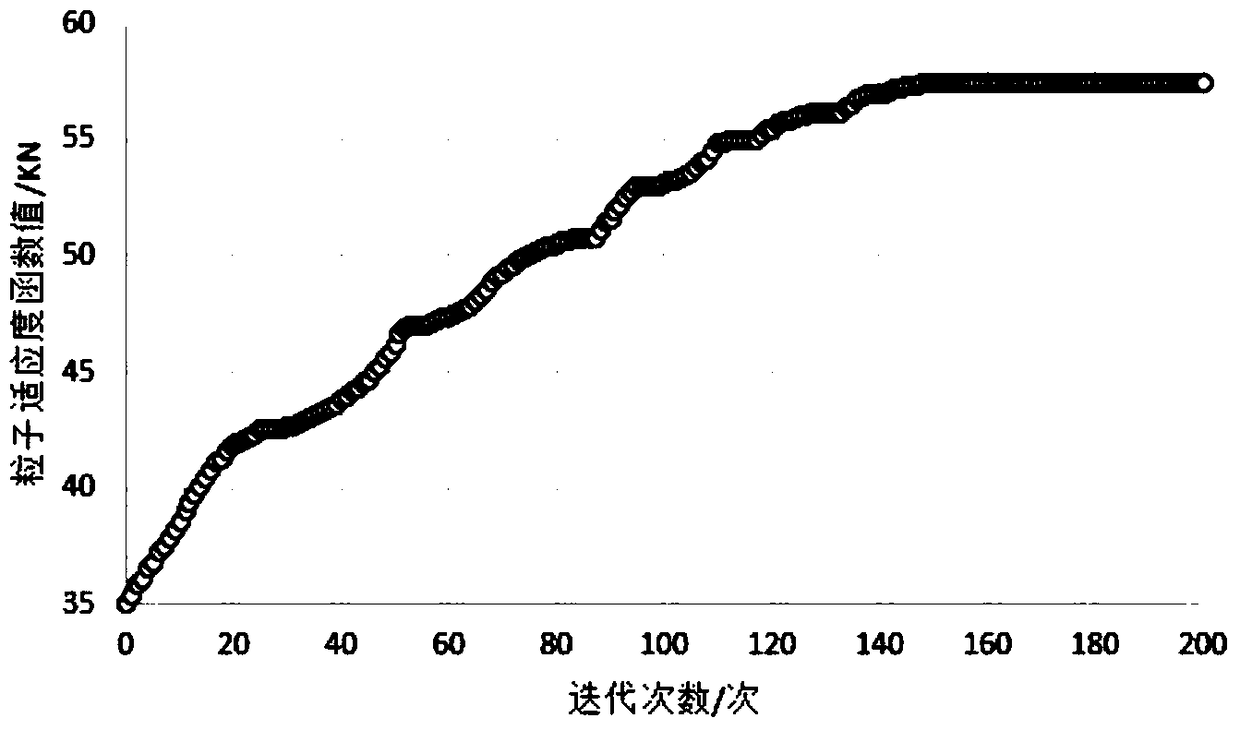

An Optimal Design Method for Angular Contact Ball Bearings Based on Particle Swarm Optimization

ActiveCN105426630BExtend your lifeImprove accuracyBiological modelsSpecial data processing applicationsBall bearingMathematical model

The invention discloses an angular contact ball bearing optimum design method based on particle swarm optimization. According to the method, the basic parameters and working condition of a bearing are determined firstly, then an optimum design mathematical model is established with the service life of the angular contact ball bearing as the optimization objective, bearing inner and outer roller way curvature radius coefficients fi and fo, ball number Z, ball diameter dw and bearing pitch circle diameter Dm as design variables, and bearing rigidity requirement, ball contact strength requirement and bearing size requirement as constrain conditions, and finally the optimum solutions of the five design variables of the bearing are obtained by optimizing the angular contact ball bearing based on particle swarm optimization. By applying particle swarm optimization to optimum design of the angular contact ball bearing, the service life of the bearing is prolonged to the maximum on the premise that the rigidity of the bearing is high enough. The method has the advantages of being high in accuracy, high in reliability, high in computing speed and the like and is a practical and effective angular contact ball bearing optimum design method.

Owner:BEIJING UNIV OF TECH

A Modeling Method of Electric Spindle System Considering the Characteristics of Joint

The invention discloses an electric main shaft system modeling method taking features of combination portions into consideration. According to the method, first of all, based on a frequency response function method, the rigidity of the combination portion of an electric main shaft system is identified by use of a hammering experiment, then a finite element model of a main shaft-handle-cutter system is established through the mode of adding and deleting a transition unit at the tail end of a main shaft and a handle, and finally, bearing rigidity, and a rigidity matrix of a main shaft-bearing combination portion and a rigidity matrix of a main shaft-handle-cutter combination portion which are obtained through identification are added to the rigidity matrix of the electric main shaft system so that a complete electric main shaft system kinetic equation is obtained. According to the invention, the rigidity of the combination portions are identified by use of an experiment method, and a theoretical model of the electric main shaft system is established with the influences of the combination portions are taken into consideration, so that the influence rules of the rotating speed, the bearing rigidity, the rigidity of each combination portion and the like for the dynamic features of the electric main shaft system can be simultaneously analyzed. The method can provide guidance for design and application of an electric main shaft and also provides a theoretical basis for prediction of the cutting stability of the electric main shaft system.

Owner:BEIJING UNIV OF TECH

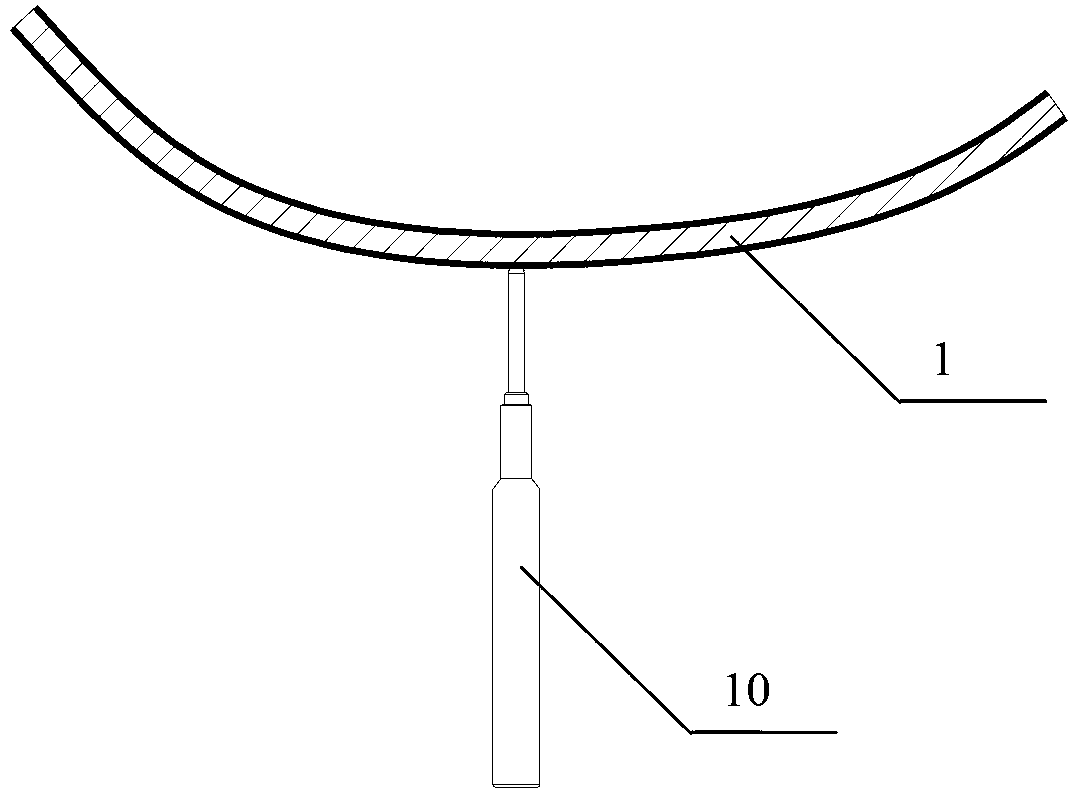

Hub bearing rigidity measuring device and method

InactiveCN109540428AReasonable structural designEasy to operateMachine bearings testingElasticity measurementMeasurement pointEngineering

The invention relates to bearing measurement technologies, especially to a professional automobile hub bearing rigidity measuring device and method. The device is characterized in that a pressing piece and a support piece in parallel with the pressing piece are designed, the inner ring of a hub bearing is fixed to the support piece in the direction vertical to the pressing piece and the support piece, a space sufficiently high for accommodating the wheel hub as well as the deformation after pressurization of the hub is arranged between the pressing piece and the support piece, each of the pressing piece and the support piece within the maximal hub circumference of the hub bearing is provided with two measurement points, a pressurizing point is arranged in the position whose distance to thecenter of the hub bearing equals the radius of a wheel, data variables after pressurizing are obtained from four measurement points, the deformation angle of the wheel hub in the bearing state is calculated, and the rigidity of the hub bearing is then calculated.

Owner:汉十知识产权服务(十堰)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com