Method for on-line detecting bearing rigidity of foundation of track crane

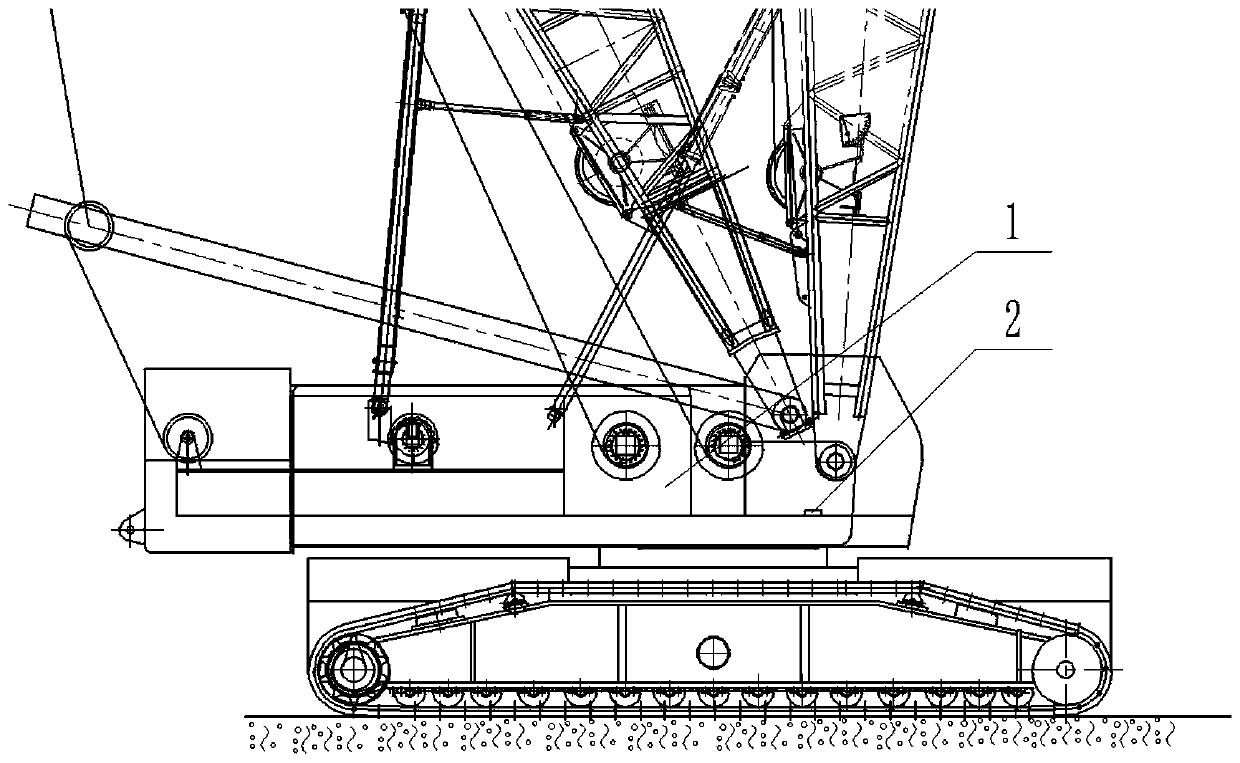

The technology of a crawler crane and a detection method is applied in the directions of cranes, load hanging elements, transportation and packaging, etc., which can solve the problems of crane strength or tipping accidents, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

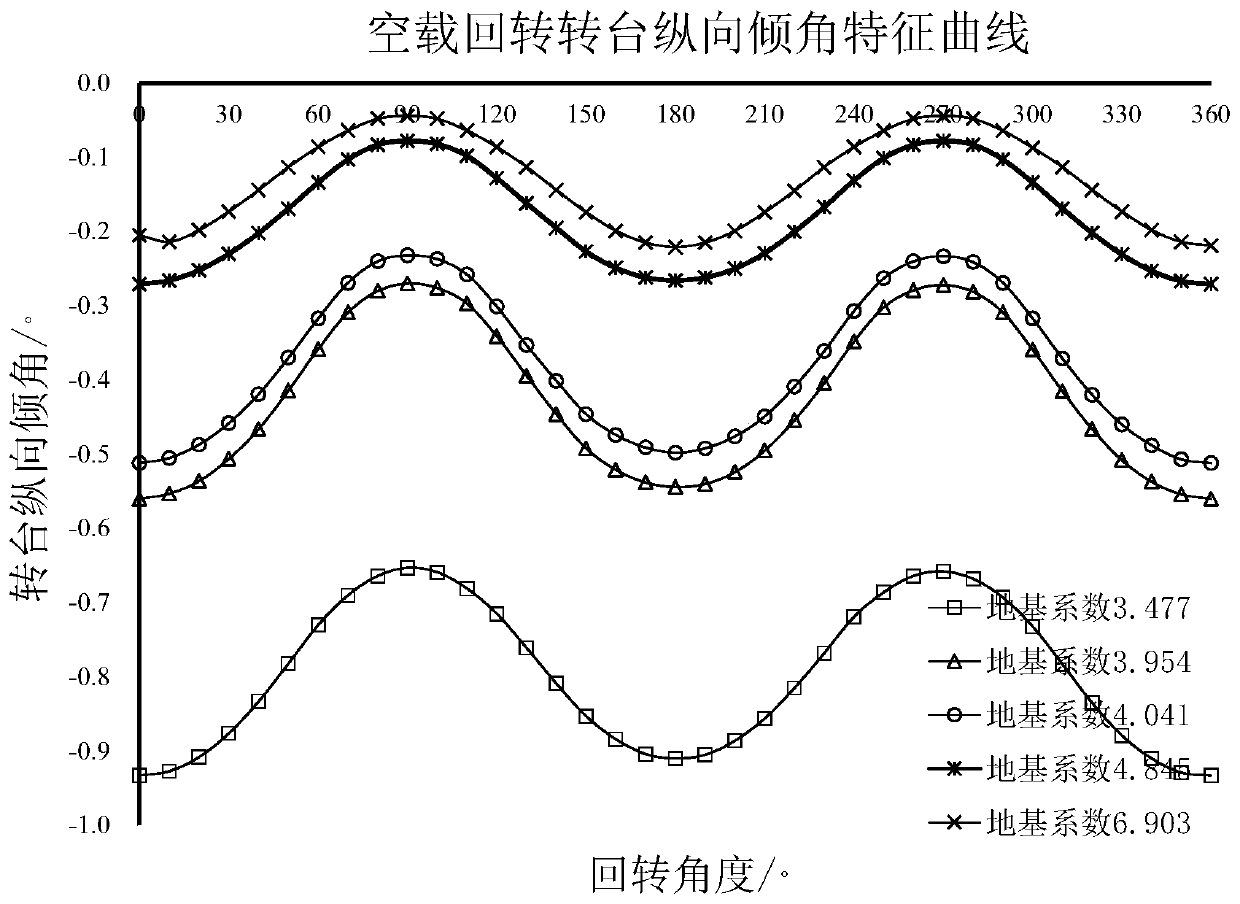

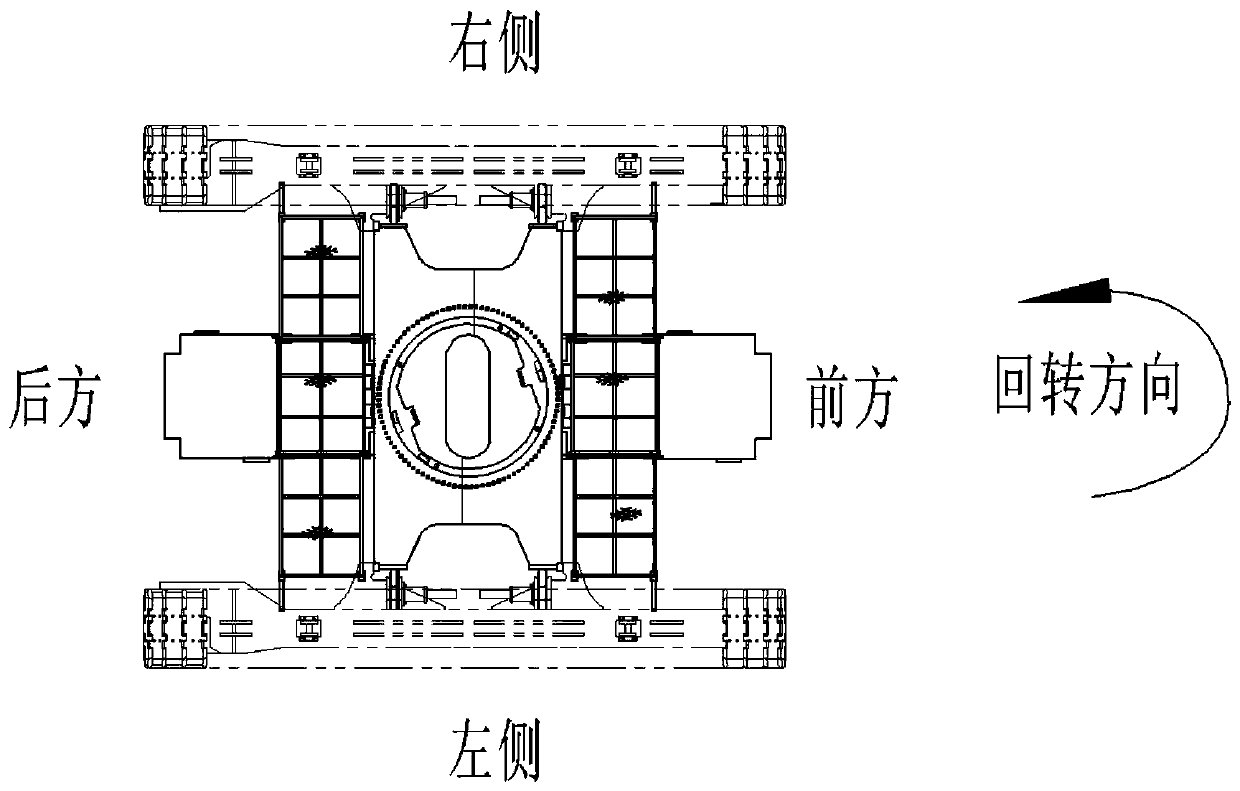

[0028] The present invention uses an inclination sensor installed on the turntable to automatically acquire online the longitudinal inclination angle of the turntable when the turntable is located at 0°, 90°, 180° and 270°. The foundation coefficient and ground levelness of the job site are automatically calculated through the characteristic curve of the longitudinal inclination angle of the turntable of the crawler crane stored in the PLC control system and the algorithm of the bearing stiffness of the foundation. Using the crawler crane load tables with different foundation coefficients and ground levelness stored in the PLC control system, the corrected crawler crane load table under the working conditions of the job site is automatically calculated. Provide necessary references for the safe operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com