Bearing rigidity test system of bevel gear of automobile driving axle assembly

A drive axle assembly and support rigidity technology, which is applied in the direction of machine gear/transmission mechanism testing, measuring devices, instruments, etc., can solve the problems of inconvenient adjustment of installation position, small measuring range, high cost, etc., and achieve low test labor intensity and low cost , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

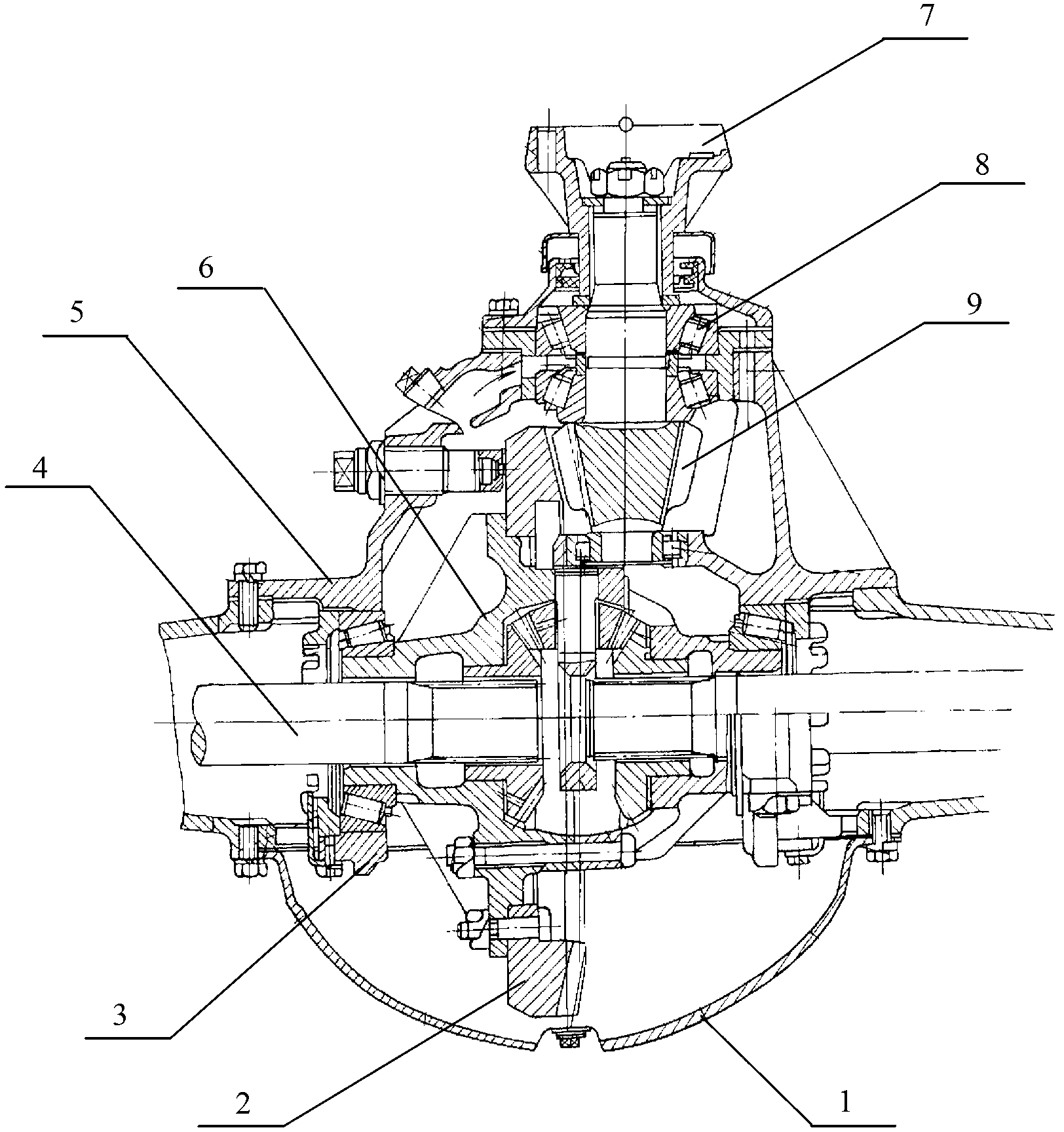

[0026] figure 1 It is a structural diagram of a certain type of drive axle assembly, and it is an example of a test object of this test system. Depend on figure 1 It can be seen that the drive axle assembly mainly includes axle housing 1, driven bevel gear 2, differential bearing seat 3, half shaft 4, main reducer housing 5, differential 6, fork flange 7, tapered roller bearing 8. Active bevel gear 9 and other components. The axle housing 1 and the main reducer housing 5 are collectively referred to as the housing. During the rigidity test of the bevel gear support of the automobile drive axle assembly, the torque is input from the fork flange 7, the driving bevel gear 9 and the driven bevel gear 2 rotate at a certain speed, and the displacement of the relevant measuring points is measured in X, Y, Z The displacement of the driving bevel gear 9 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com