Hub bearing rigidity measuring device and method

A technology of wheel hub bearing and measuring device, which is applied in the direction of measuring device, mechanical bearing test, elasticity test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

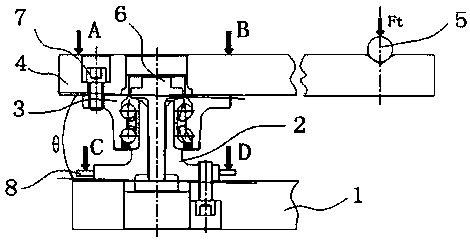

[0013] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0014] Referring to Fig. 1, this embodiment assumes that the hub unit consisting of hub 2, hub bearing 3 and fastening shaft pin 6 is fixed on the base 1, and the outer hub of the hub bearing 3 is fixed on the pressure plate 4 through four fixing bolts 7, Set a steel ball positioning groove on the pressure plate 4 which is one wheel radius away from the hub bearing 3, and place the pressed steel ball 5 in the steel ball positioning groove. By replacing the bottom plate and pressure plate, the measurement requirements of different types of hub bearings can be met.

[0015] Two measuring platforms 8 are arranged on the flange plate-shaped base at the lower part of the hub 2 of the hub unit, and the measuring platforms 8 are arranged on the hub 2 at the part of the maximum outer diameter from the bearing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com