Patents

Literature

107results about How to "Achieve friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

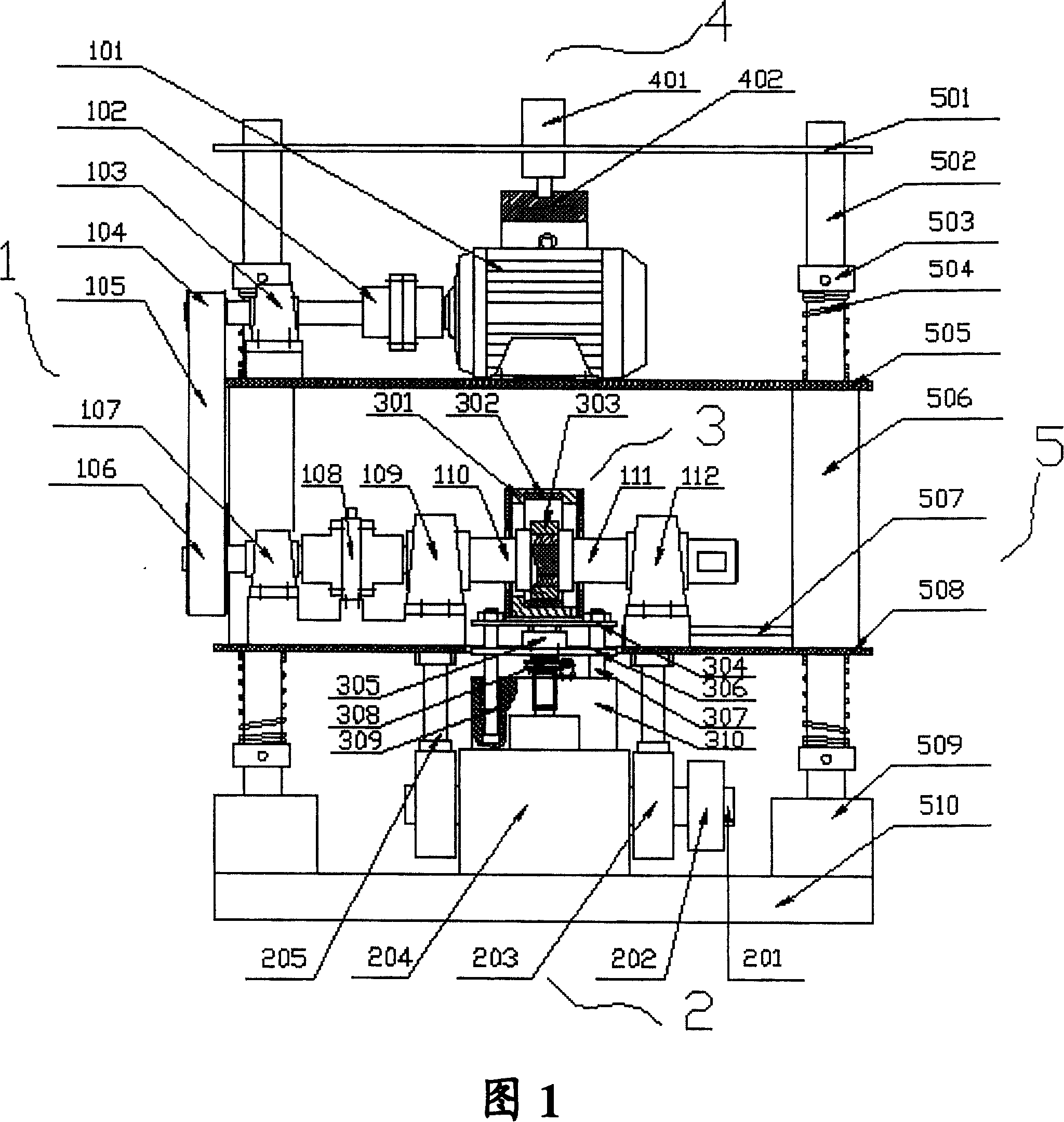

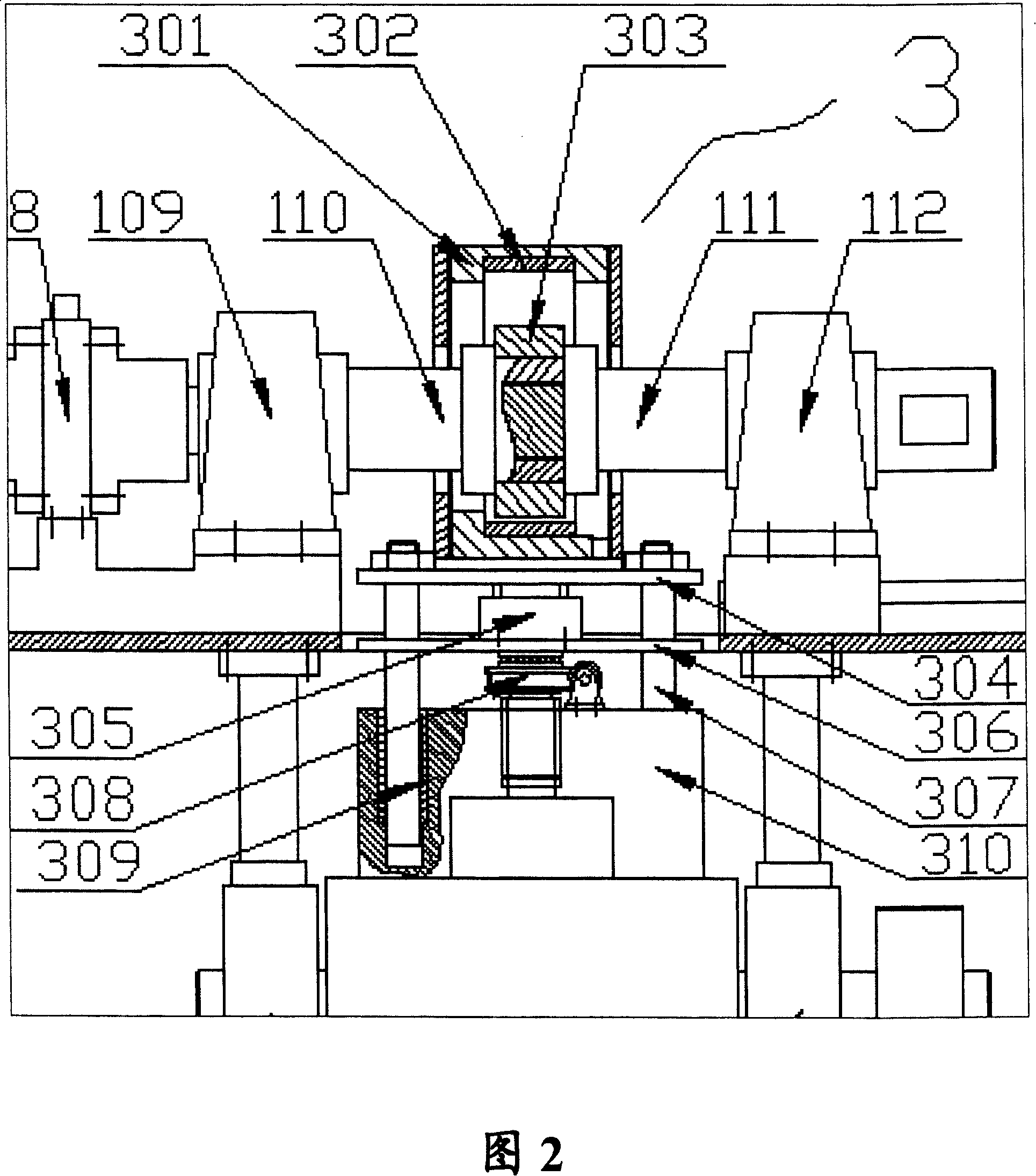

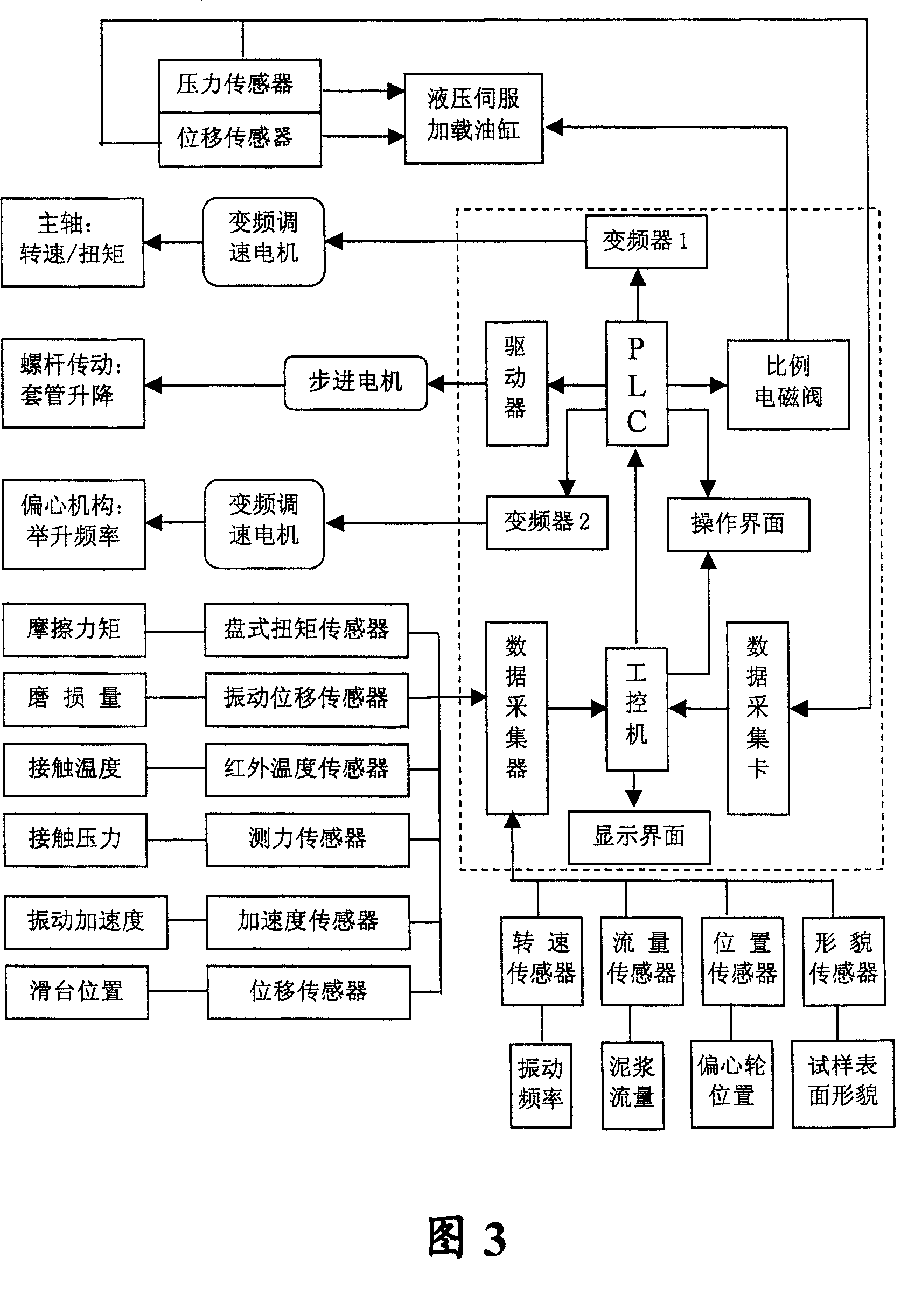

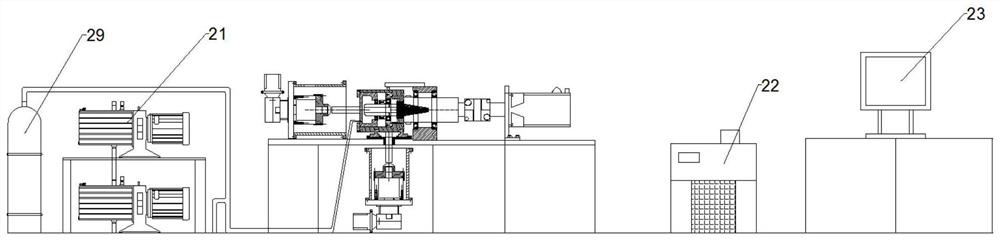

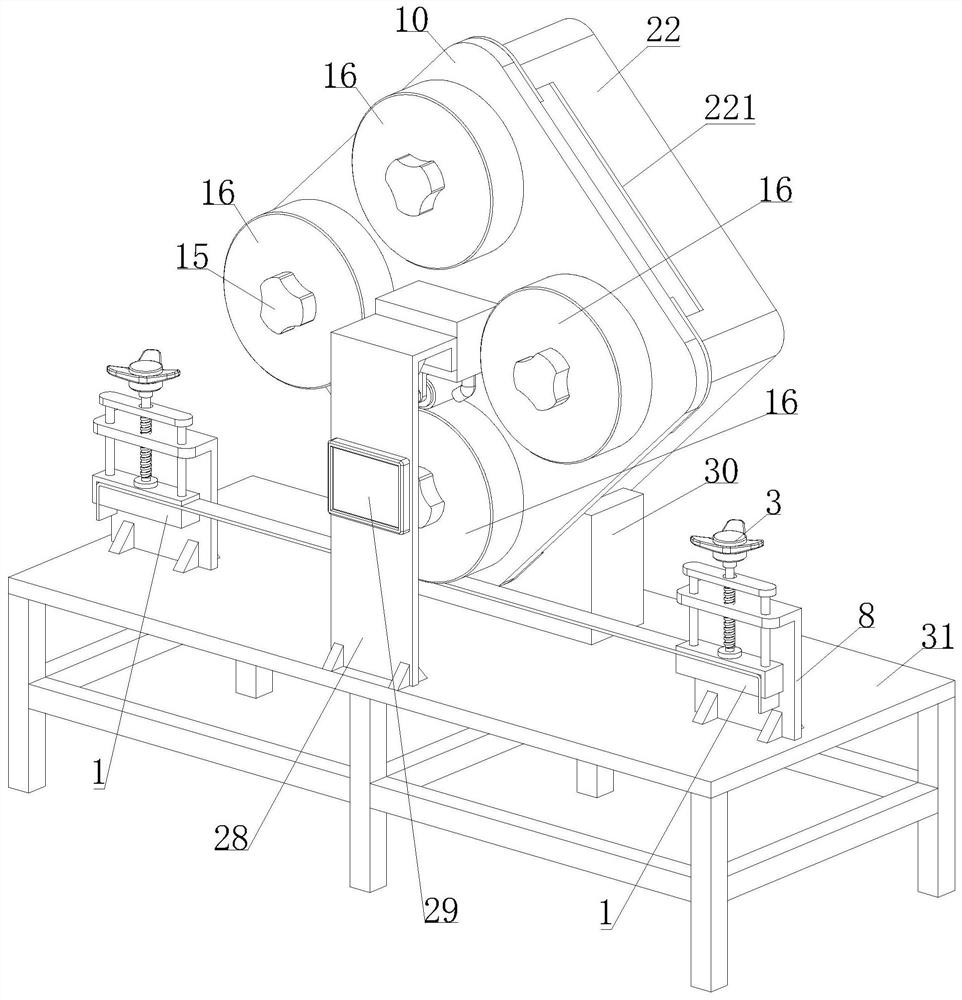

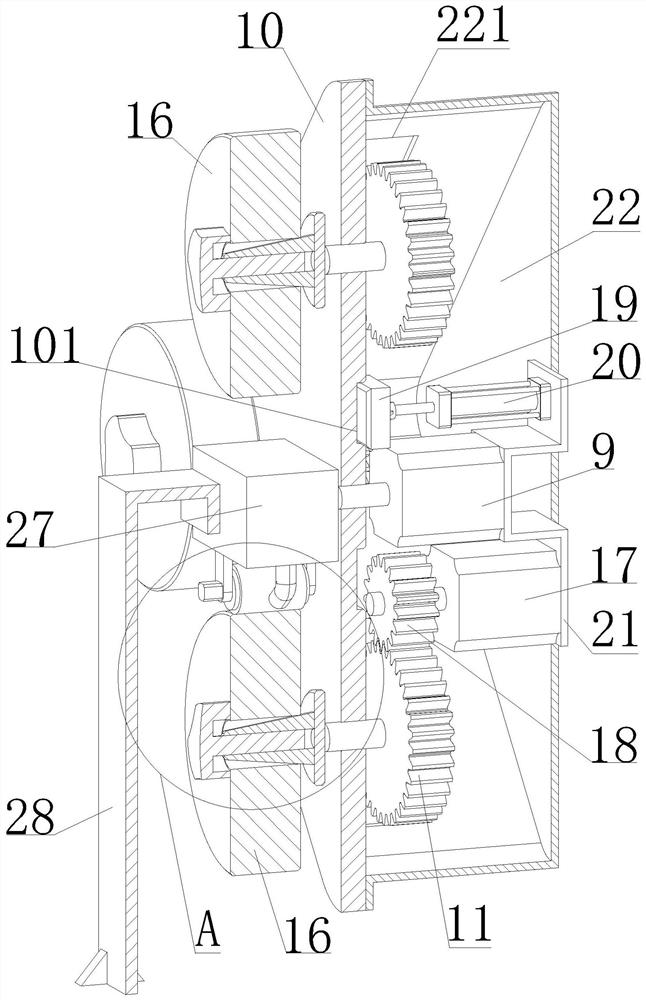

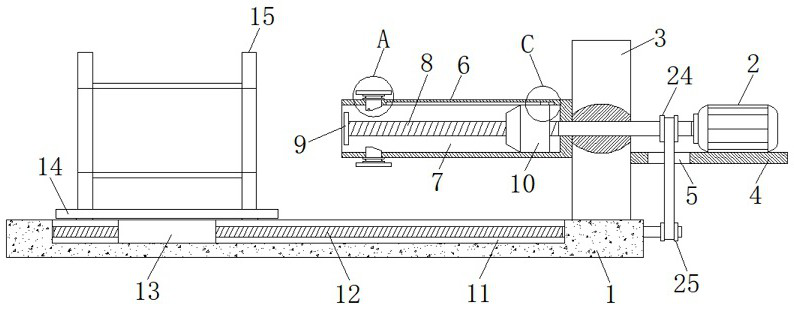

Sliding desk type casing tube abrasion testing machine

InactiveCN101153835AAchieve frictionEnable wear studiesStructural/machines measurementInvestigating abrasion/wear resistanceDrive shaftPetroleum

The invention is a sliding way sleeve abrasion testing machine, which comprises a transmission system, an excitation system, a clamping system and a rack. A first test piece is fixed and clamped on a rotating transmission shaft of the transmission system; a second test piece is arranged corresponding to the first test piece on the clamping system and the transmission system drives the first test piece to rotate around the axis. The rack is provided with at least one sliding platform and the transmission system is arranged on the sliding platform. The excitation system can drive the sliding platform to vibrate up and down to drive the first test piece to impulse the second test piece while rotating. The testing machine overcomes the disadvantage of the prior abrasion testing machine which is incapable of satisfying the requirement on studying the impulse and sliding composite abrasion test between petroleum the drilling rod and the sleeve under the conditions of circulating medium and can perform systematic investigation on the impulse and sliding composite abrasion of various materials of large dimension between the petroleum the drilling rod and the sleeve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

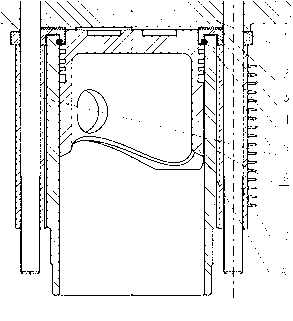

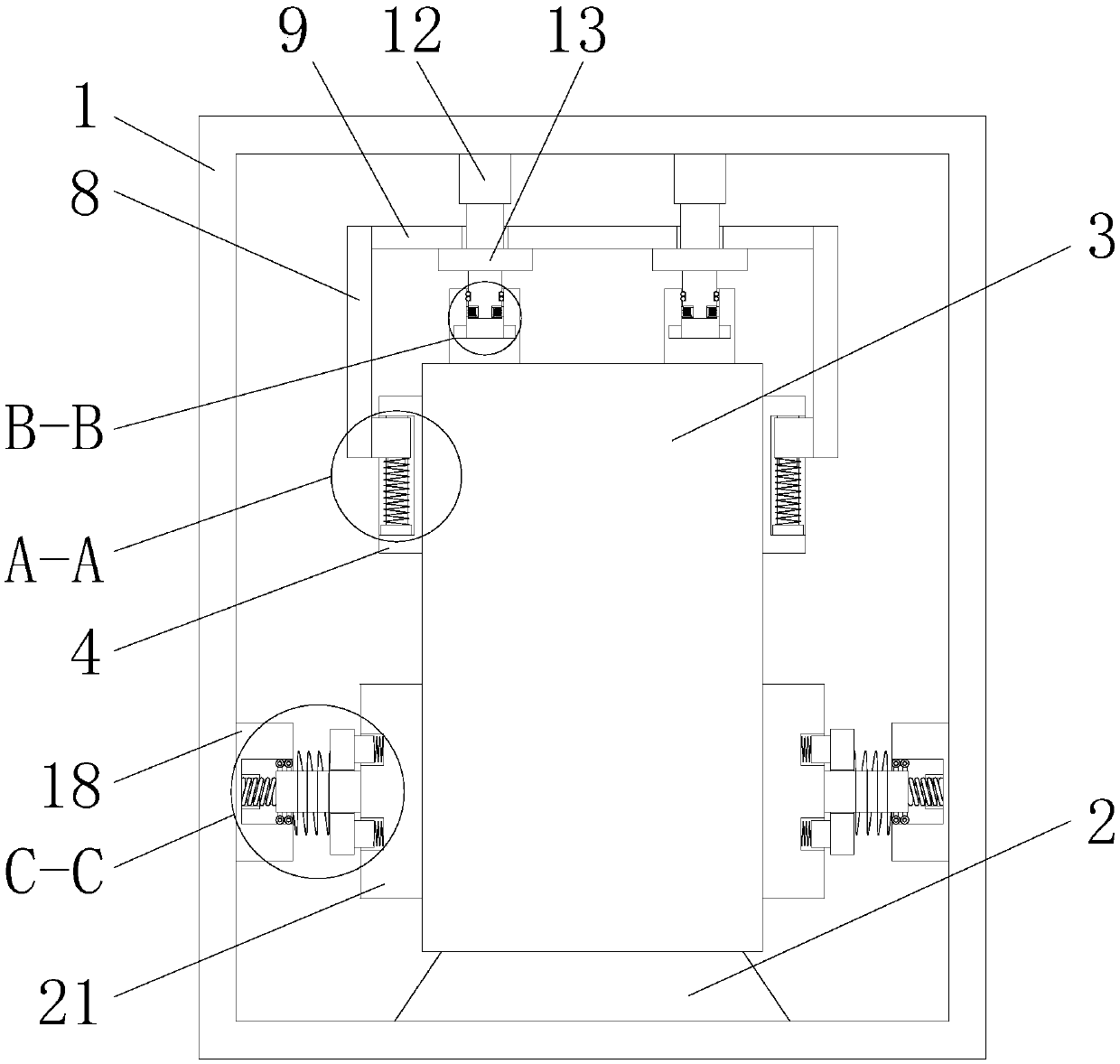

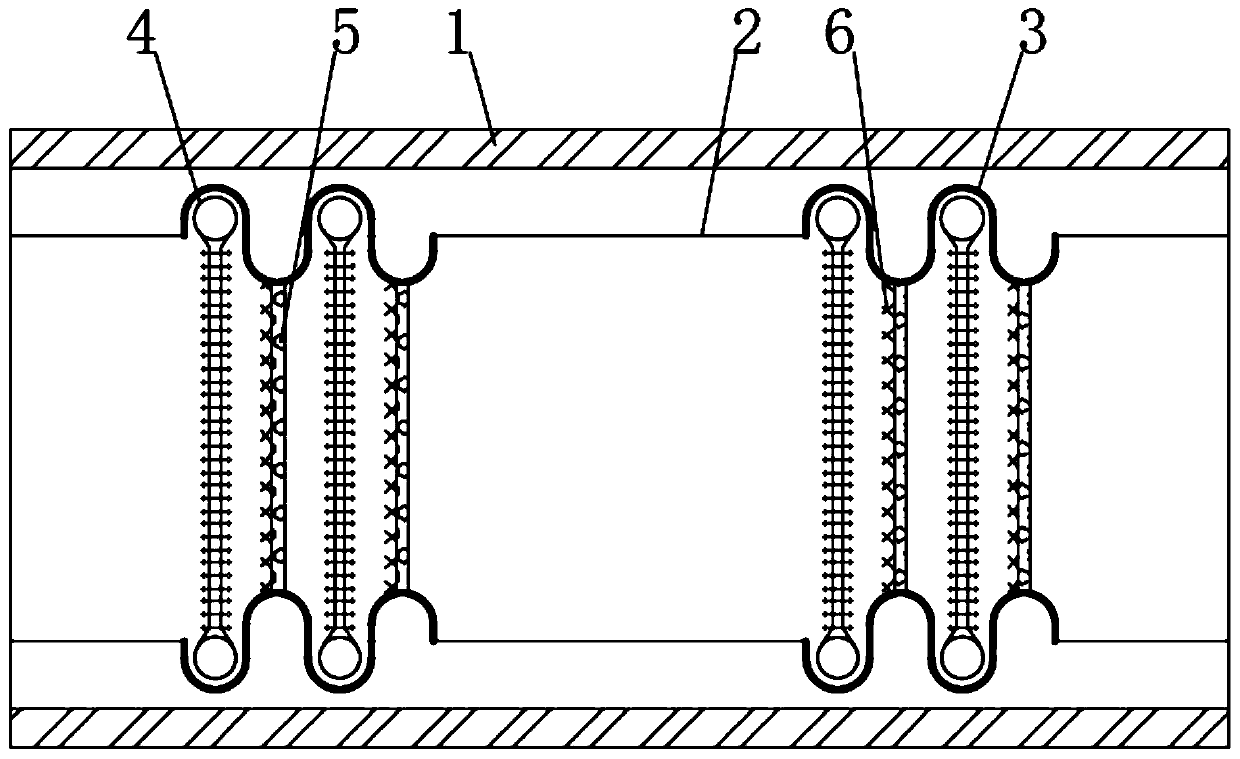

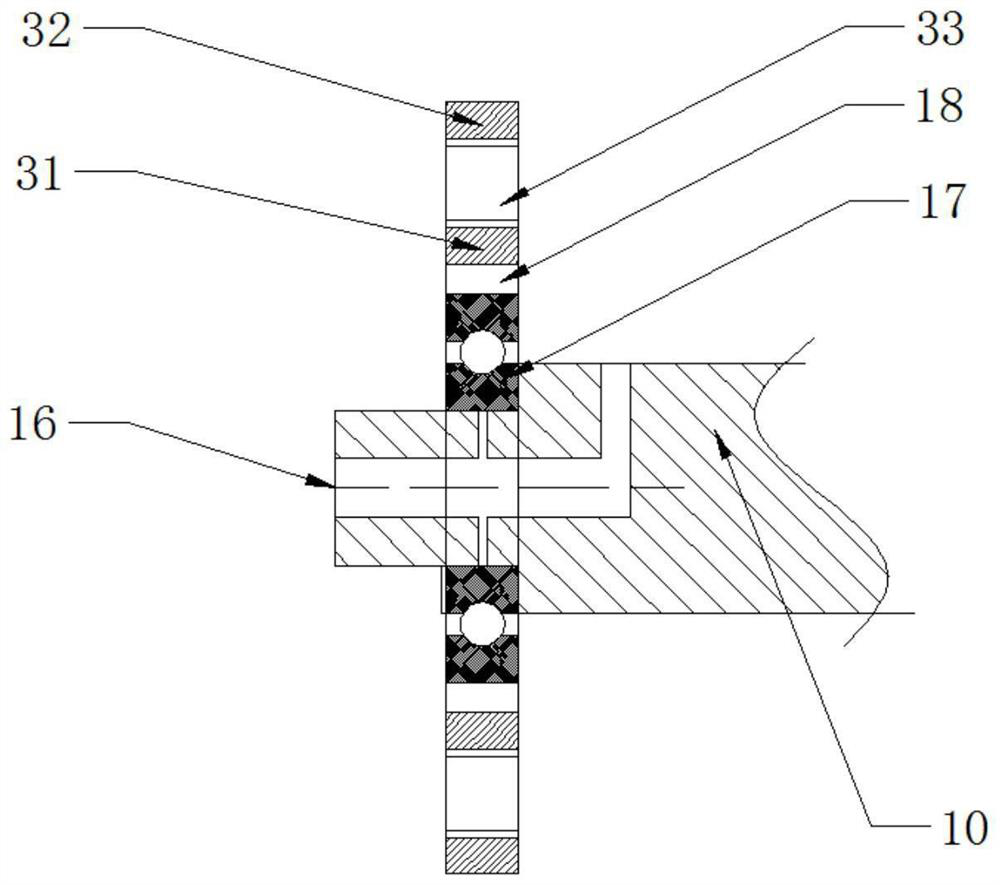

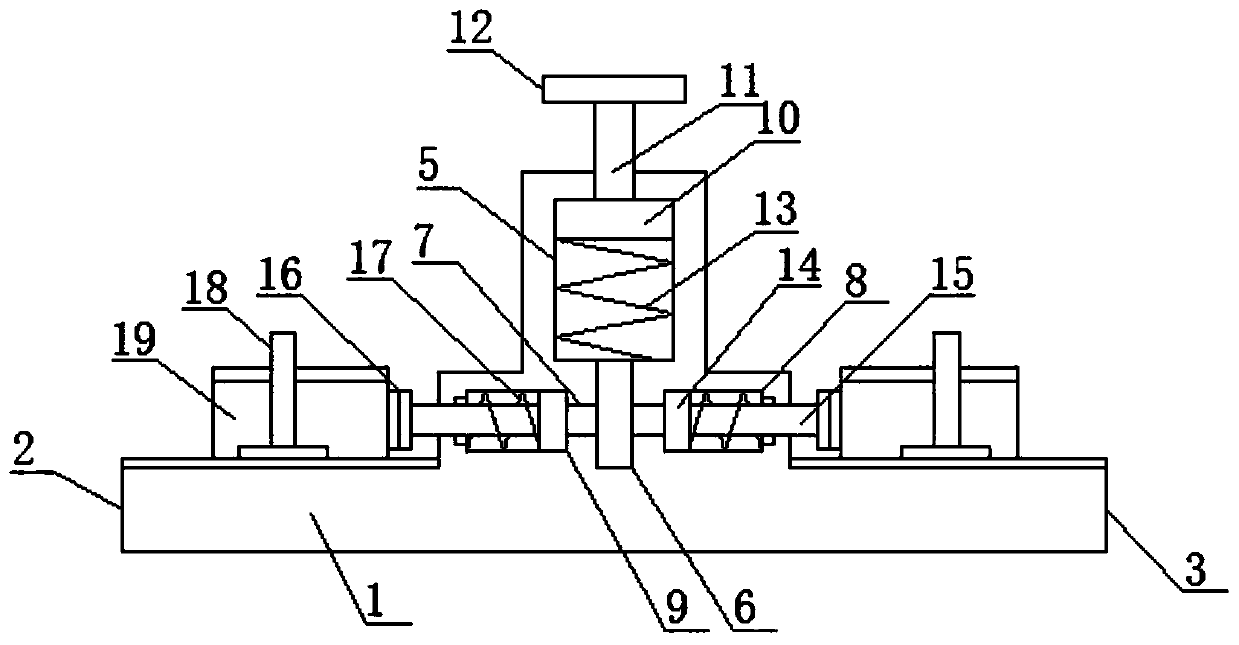

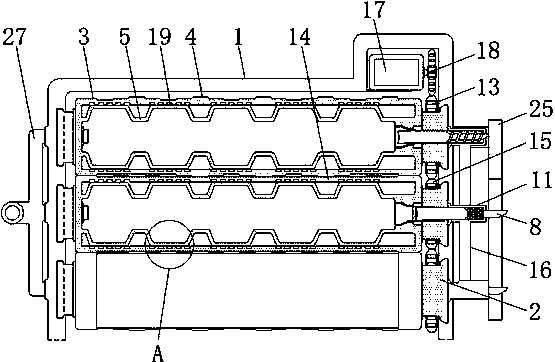

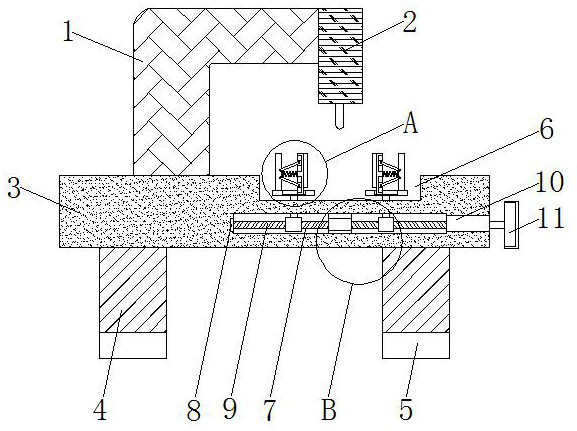

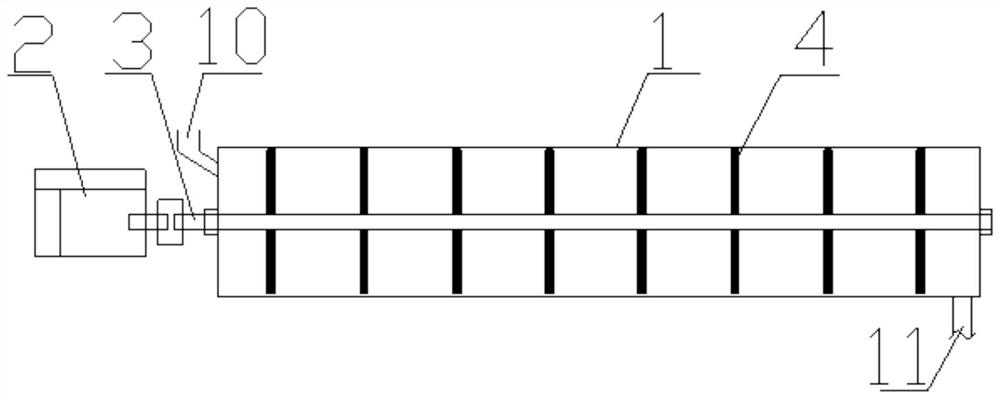

Floating cylinder liner mechanism for friction test of cylinder liner and piston in ignition state

InactiveCN103293005ASimple structureReduce in quantityInternal-combustion engine testingPistonEmbedded system

The invention relates to a floating cylinder liner mechanism for a friction test of a cylinder liner and a piston in an ignition state. The lower end of an embedded cylinder cover (1) is connected with the upper ends of embedded intermediates (3) through upper embedded seam allowances (9), sealing copper pads (2) are connected between the embedded cylinder cover (1) and the embedded intermediates (3), the embedded intermediates (3) are provided with the upper embedded seam allowances (9) and step embedded grooves (10), and the step embedded grooves (10) of the embedded intermediates (3) are connected with the cylinder liner (6), cylinder cover bolts (7) are sequentially connected with the embedded cylinder cover (1), the embedded intermediates (3) and same-height support guide barrels (5), the piston (8) is arranged in the cylinder liner (6), and a pressure sensor is arranged between the cylinder liner (6) and a machine body. The floating cylinder liner mechanism can accurately and reliably realize floating of the cylinder liner (6) of a diesel engine in the ignition state and provide power supports for test and research of typical friction pair power consumption of a piston group of the cylinder liner.

Owner:NO 70 INST OF CHINA NORTH IND GRP

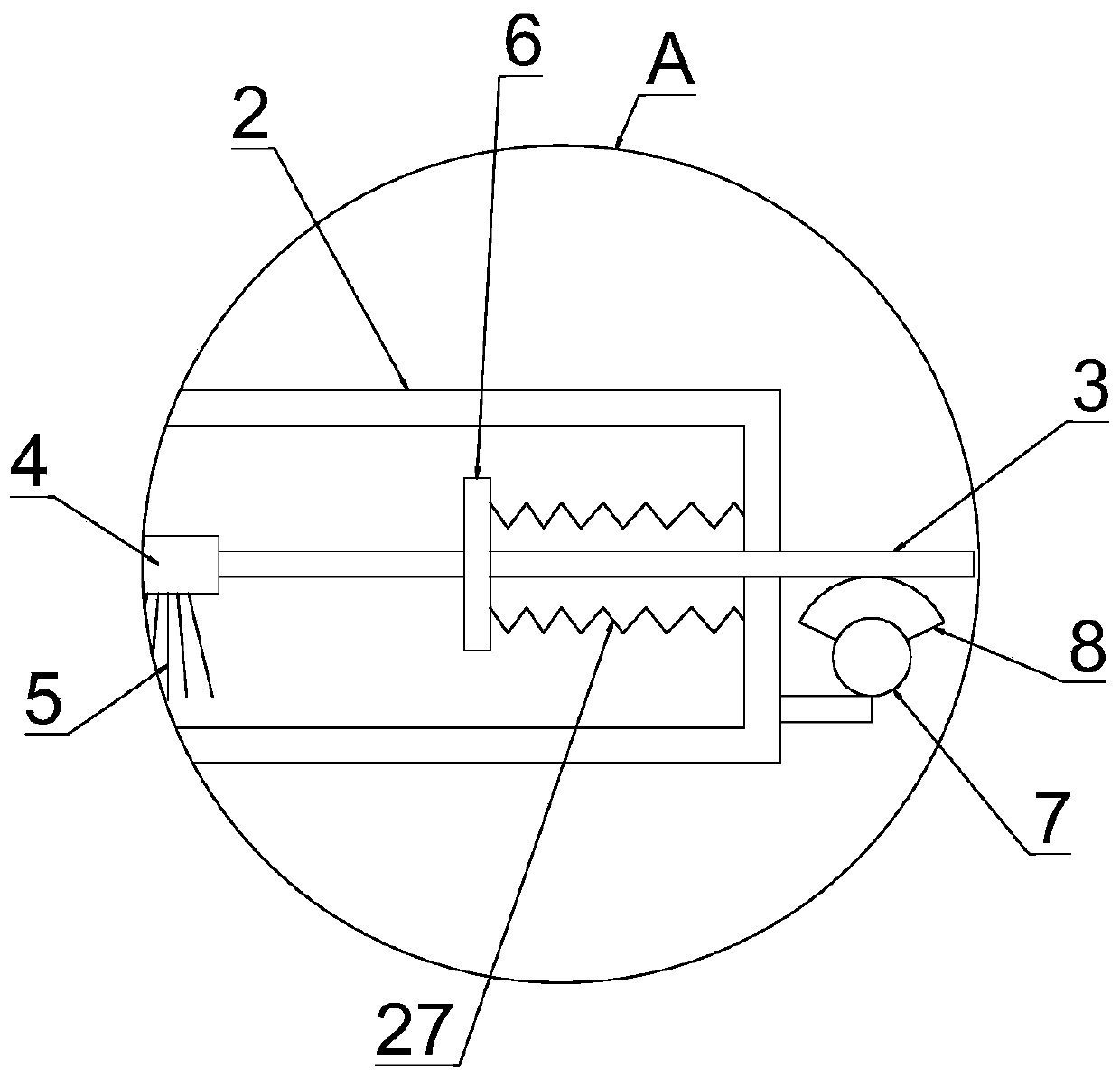

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

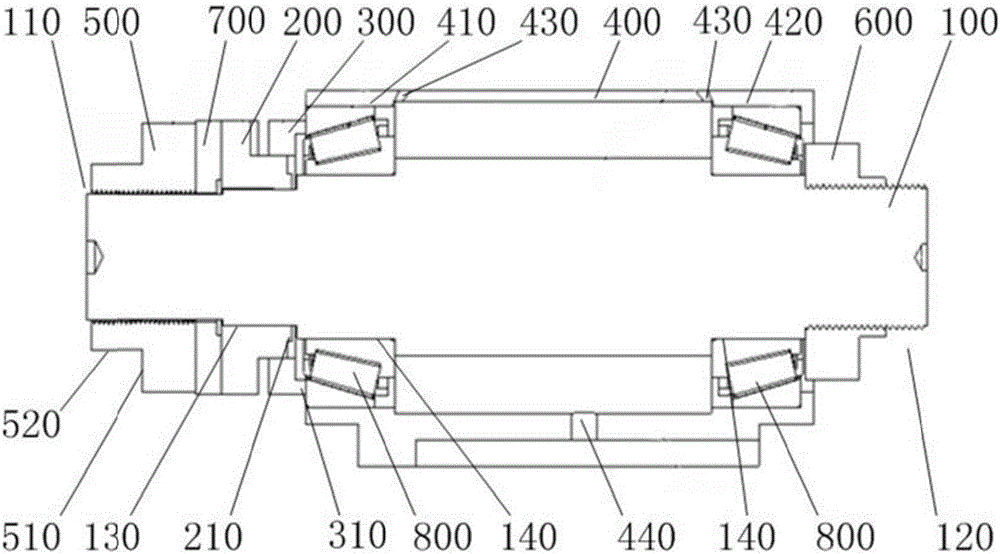

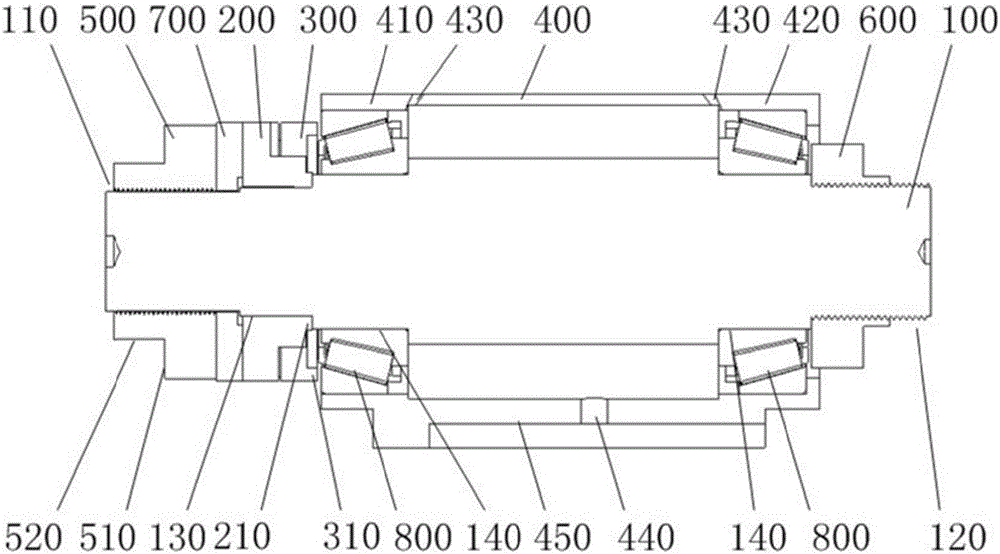

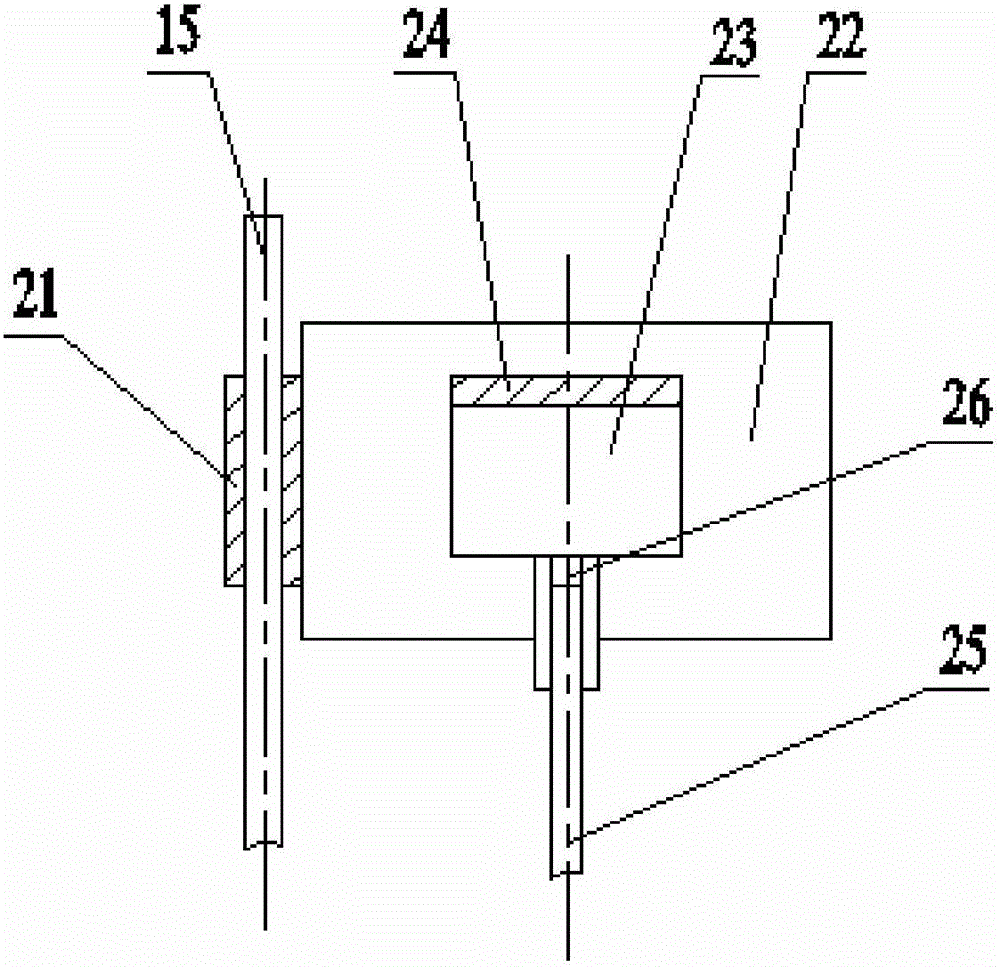

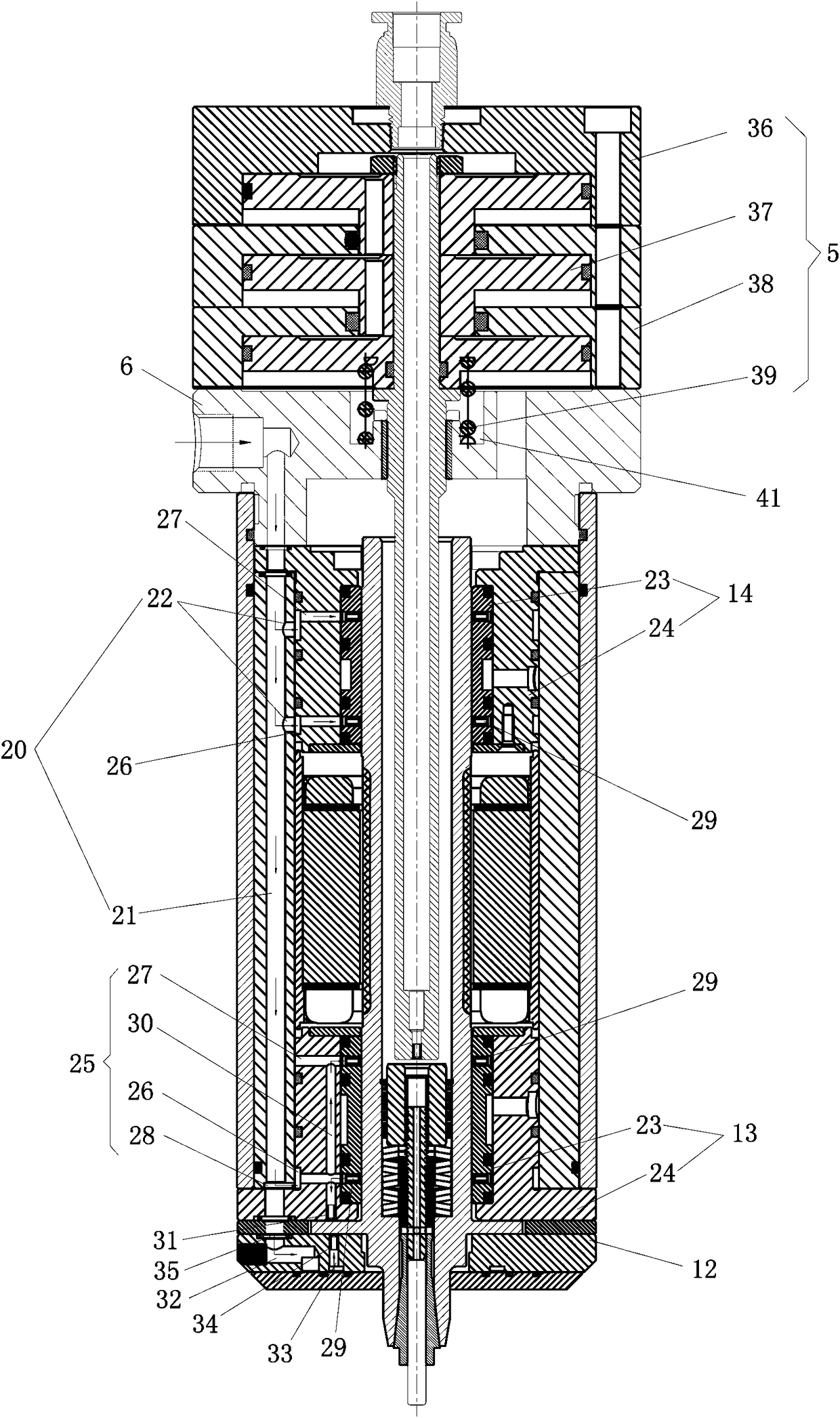

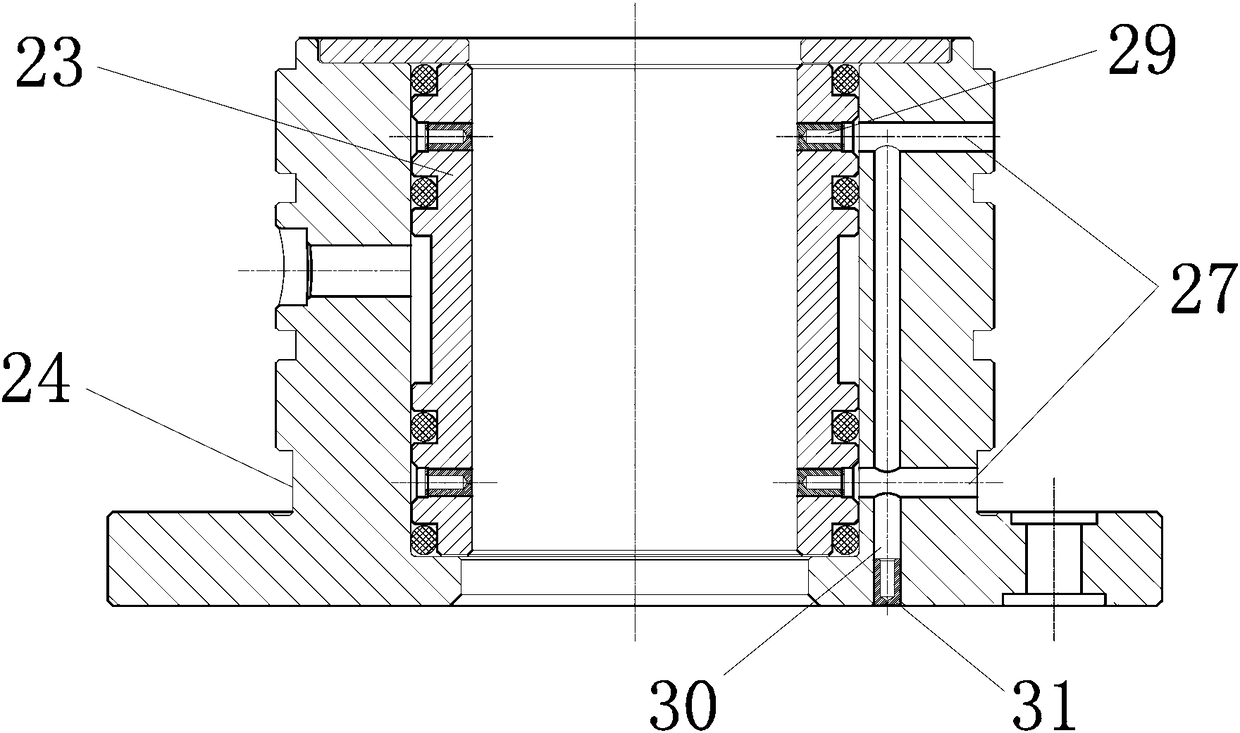

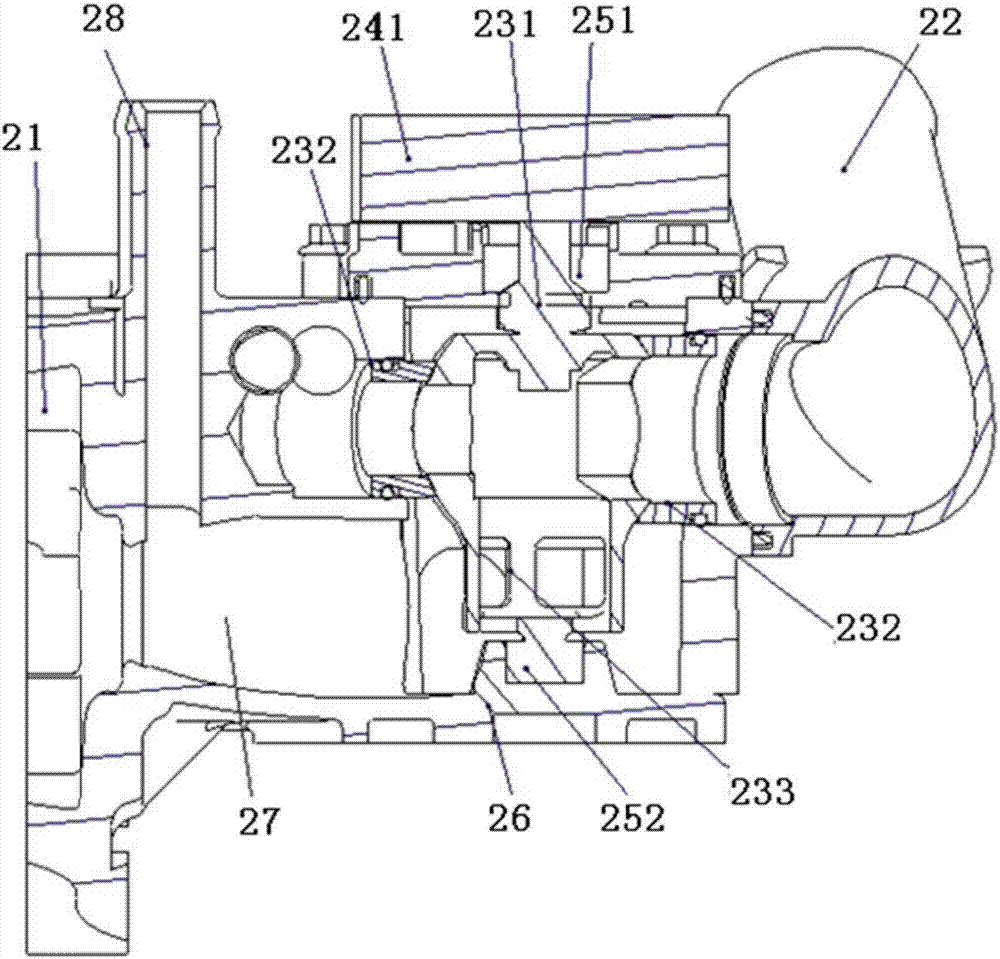

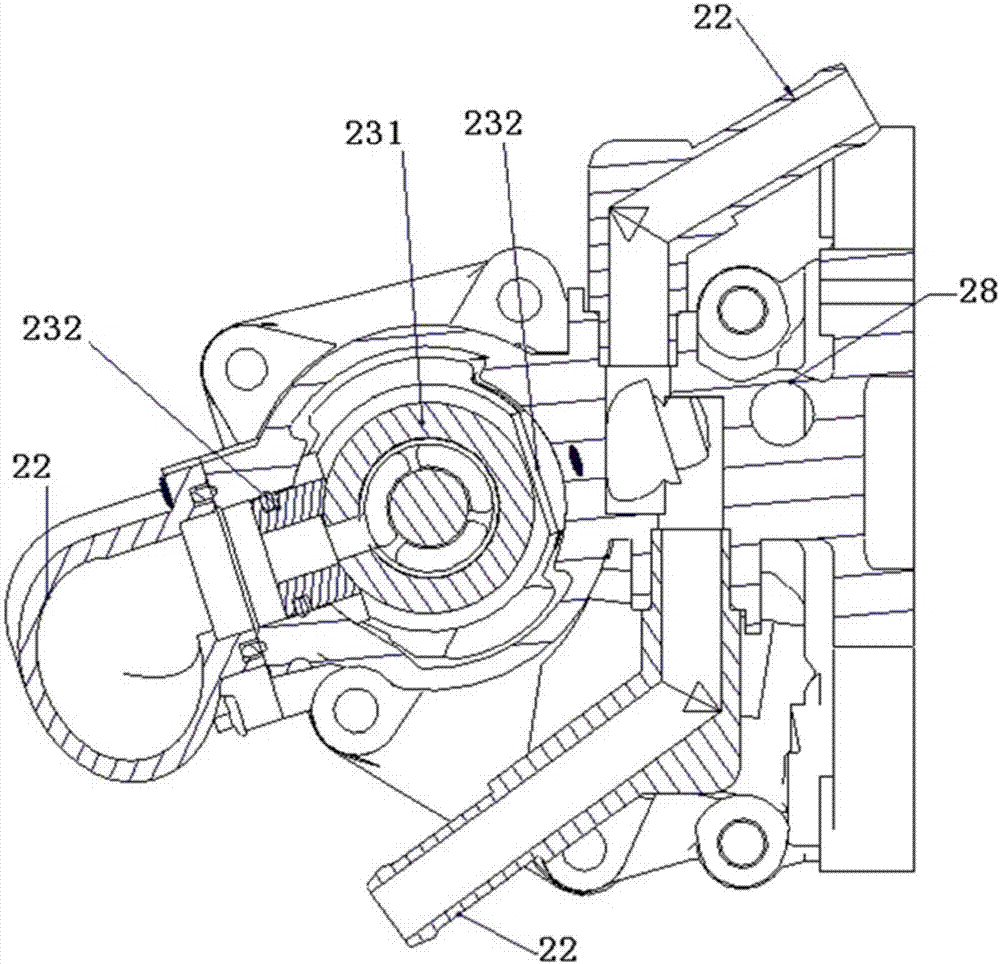

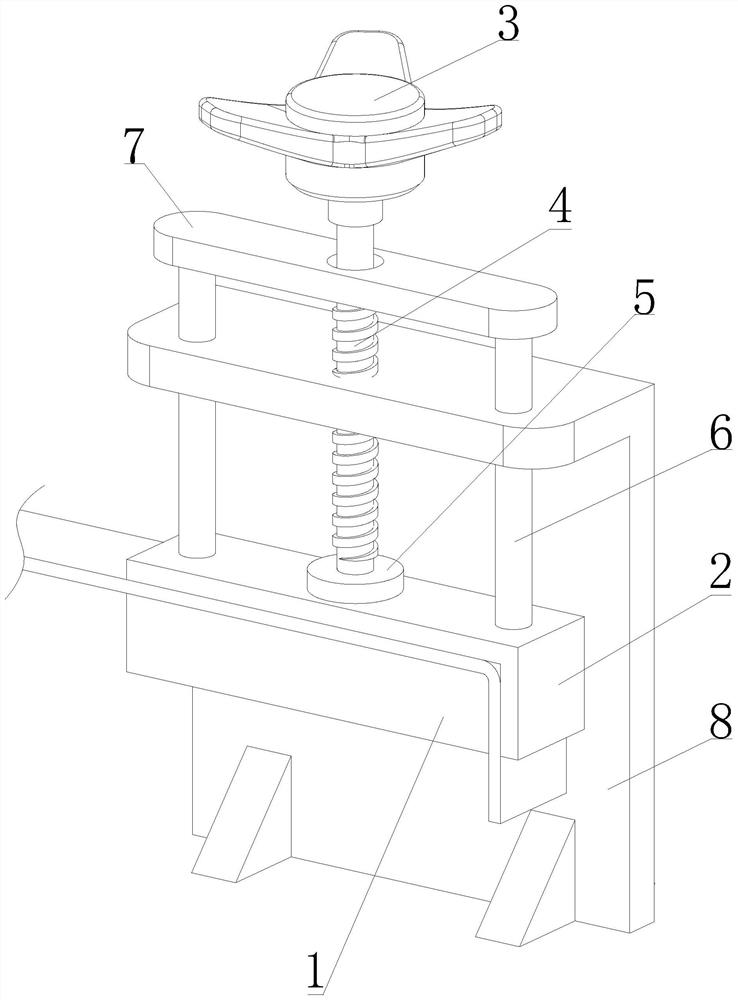

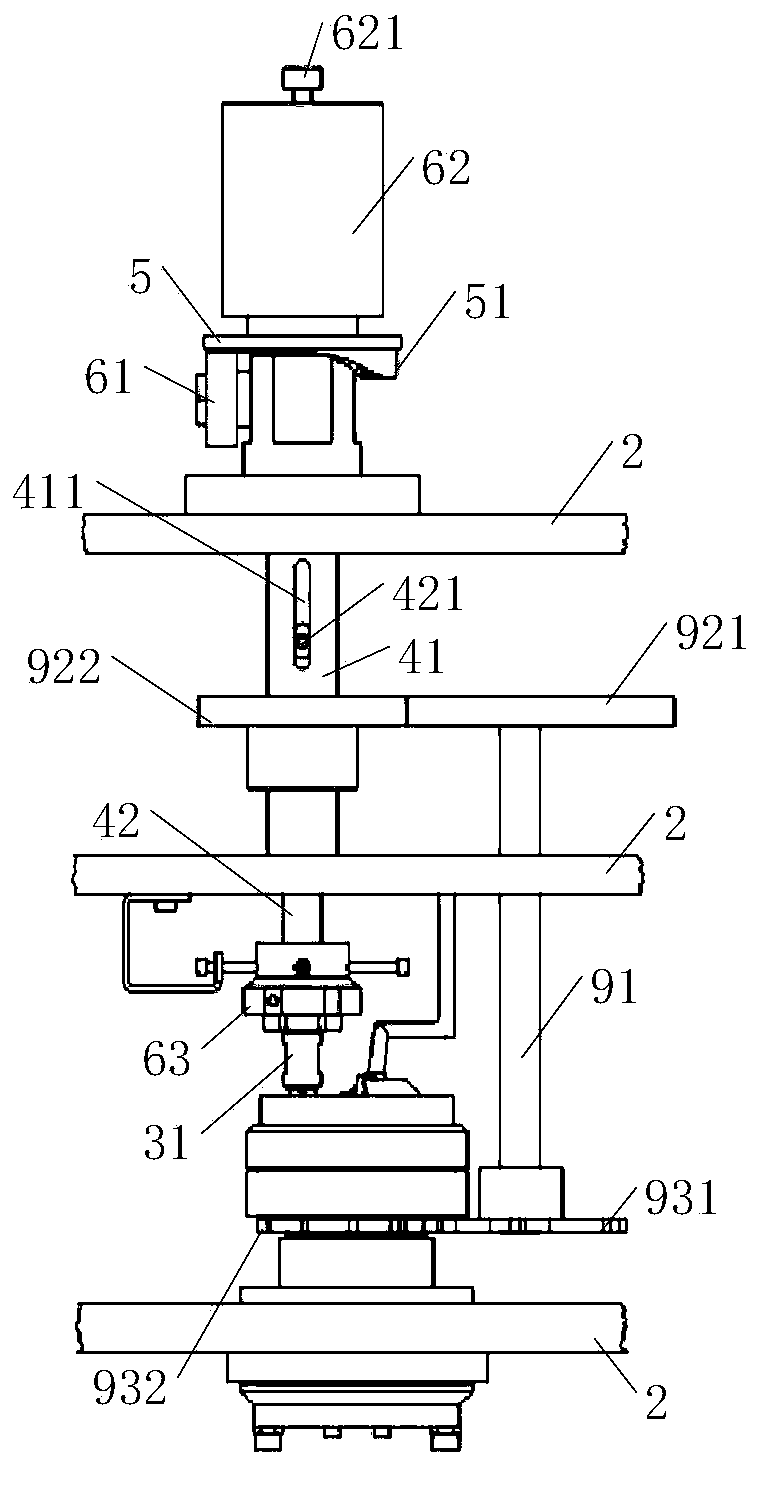

Comprehensive measurement device and method for bearing rigidity and starting friction torque

ActiveCN106525424AAchieve stiffnessAchieve frictionMachine bearings testingForce sensorsFriction torqueMeasurement device

The invention discloses a comprehensive measurement device for bearing rigidity and starting friction torque, including a driving shaft, an inner axial pressure conduction block, an outer axial pressure conduction block, a pressure sensor and locking nuts. The driving shaft comprises a first step, a second step which is used for clamping a bearing, a testing end and a fastening end, and the testing end and the fastening end are provided with outer threads. The inner axial pressure conduction block is sleeved on the first step and is provided with a groove. The outer axial pressure conduction block is provided with a projection cooperated with the groove. The pressure sensor is sleeved on the driving shaft, and the end surface of the pressure sensor is adhered to the end surface of the inner axial pressure conduction block. The locking nuts are fixedly connected at two ends of the driving shaft respectively. The comprehensive measurement device for bearing rigidity and starting friction torque obtains the pretightening force, rigidity and starting friction torque of a single bearing or bearings in pair with one measurement device.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

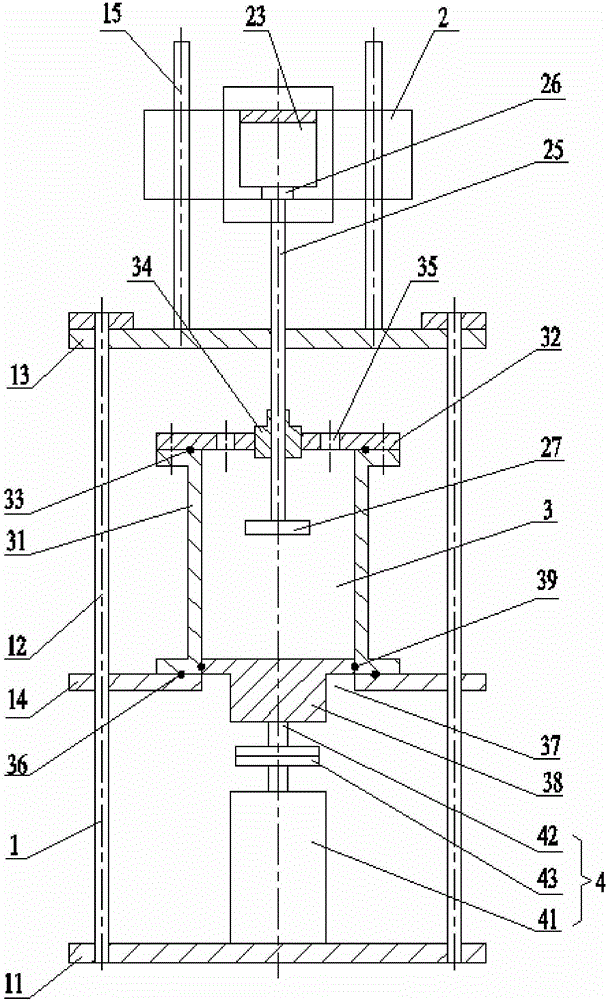

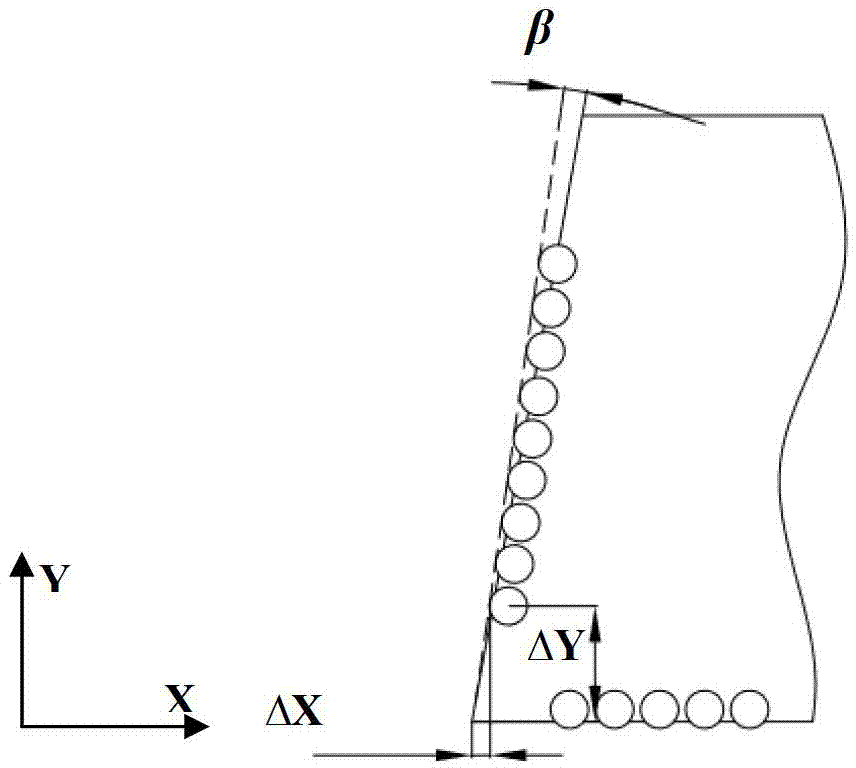

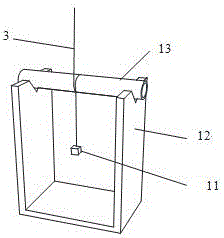

Indoor measuring device for friction between soil mass and structure and use method of measuring device

The invention relates to a measuring device for friction between a soil mass and works and a use method of the measuring device. The measuring device comprises a main frame, a soil sample chamber, a shearing mechanism and a loading mechanism, wherein the soil sample chamber, the shearing mechanism and the loading mechanism are arranged in the main frame; an operating table is mounted at the middle part of the main frame, the soil sample chamber is placed on the operating table, the bottom of the soil sample chamber is sealed through a piston, the shearing mechanism is mounted at the top of a side upright rod, the bottom of the shearing mechanism is connected with a force transfer lever, a torque sensor is arranged between the force transfer lever and the shearing mechanism, a metallic disc is fixed at the bottom of the force transfer lever and enters the soil mass in the soil sample chamber, the loading mechanism comprises a lifting stepping motor, an output shaft of the lifting stepping motor is connected to the piston through a connecting member, a weighing sensor is arranged between the piston and the connecting member, and the weighing sensor and the torque sensor are used for separately acquiring a normal force applied to the soil mass and the shearing force of a surface, in contact with the metallic disc, of the soil mass in a testing process, so as to calculate a load borne by the soil mass, the friction between the soil mass and the metallic disc and a corresponding relationship between the soil mass and the metallic disc.

Owner:SHENYANG JIANZHU UNIVERSITY

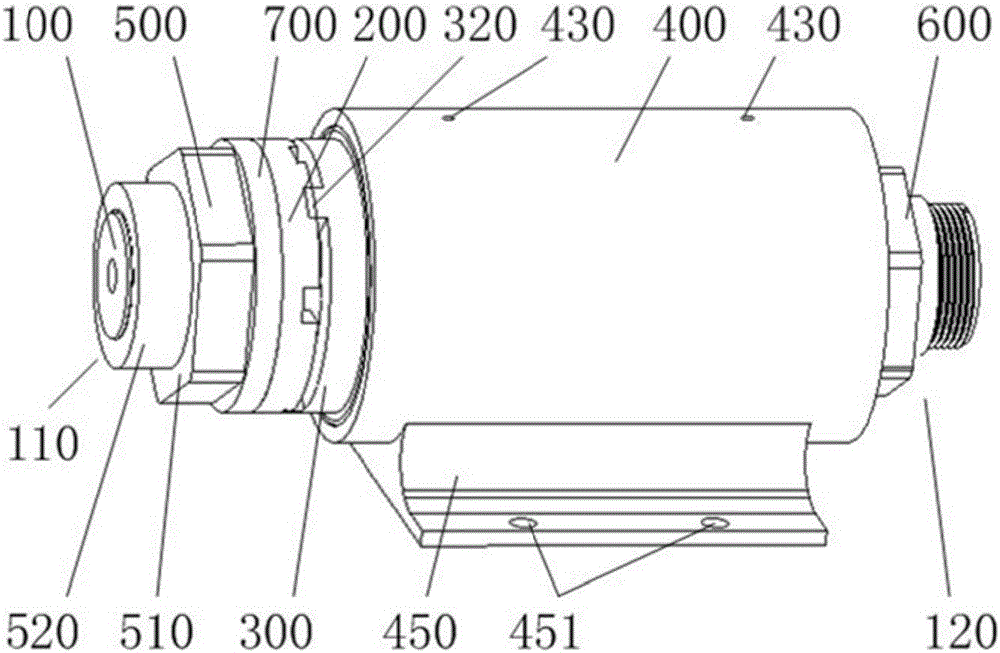

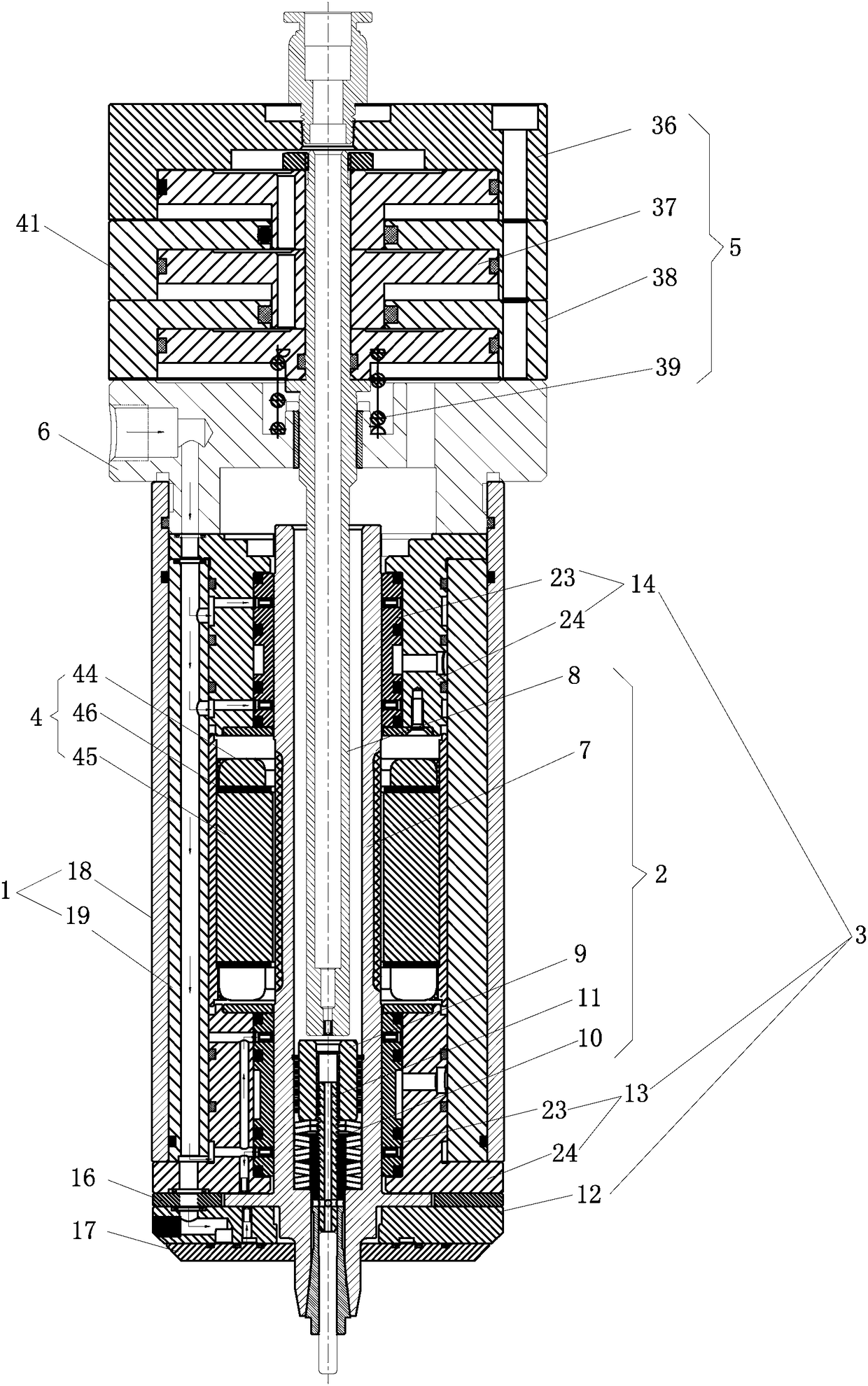

High-precision and low-energy-consumption high-speed air floating type electric spindle

PendingCN108817421AImprove machining accuracyHigh precisionLarge fixed membersGrip forceElectric machinery

The invention relates to a high-precision and low-energy-consumption high-speed air floating type electric spindle. The high-precision and low-energy-consumption high-speed air floating type electricspindle comprises a body mechanism, a rotor mechanism, a bearing mechanism, a stator mechanism, an air cylinder mechanism and a rear base mechanism. The rotor mechanism comprises a shaft core, an ejector rod, a pull rod, a spring assembly and a chuck. The chuck is connected with the pull rod through a screw. The bearing mechanism comprises a thrust bearing, a front bearing assembly and a rear bearing assembly. The shaft core is provided with an extension part connected with the thrust bearing. A thrust clearance ring is arranged between the thrust bearing and the front bearing assembly. The thrust bearing is provided with a dustproof mechanism. The high-precision and low-energy-consumption high-speed air floating type electric spindle has the beneficial effects that a composite bearing inner sleeve is embedded in an air hydrostatic bearing of the air floating spindle, abrasion resistance is good, self-lubricating and self-centering can be conducted, and friction with the shaft core iseffectively avoided; an efficient circulation water cooling channel is adopted, and higher CPK precision and rotation speed are achieved; a reasonable damping plug is embedded in the bearing, air consumption is greatly reduced, and cost is saved; and the excellent motor torque and tool gripping force are achieved, and high adaptability and practicability are achieved.

Owner:岳阳市显隆电机有限公司

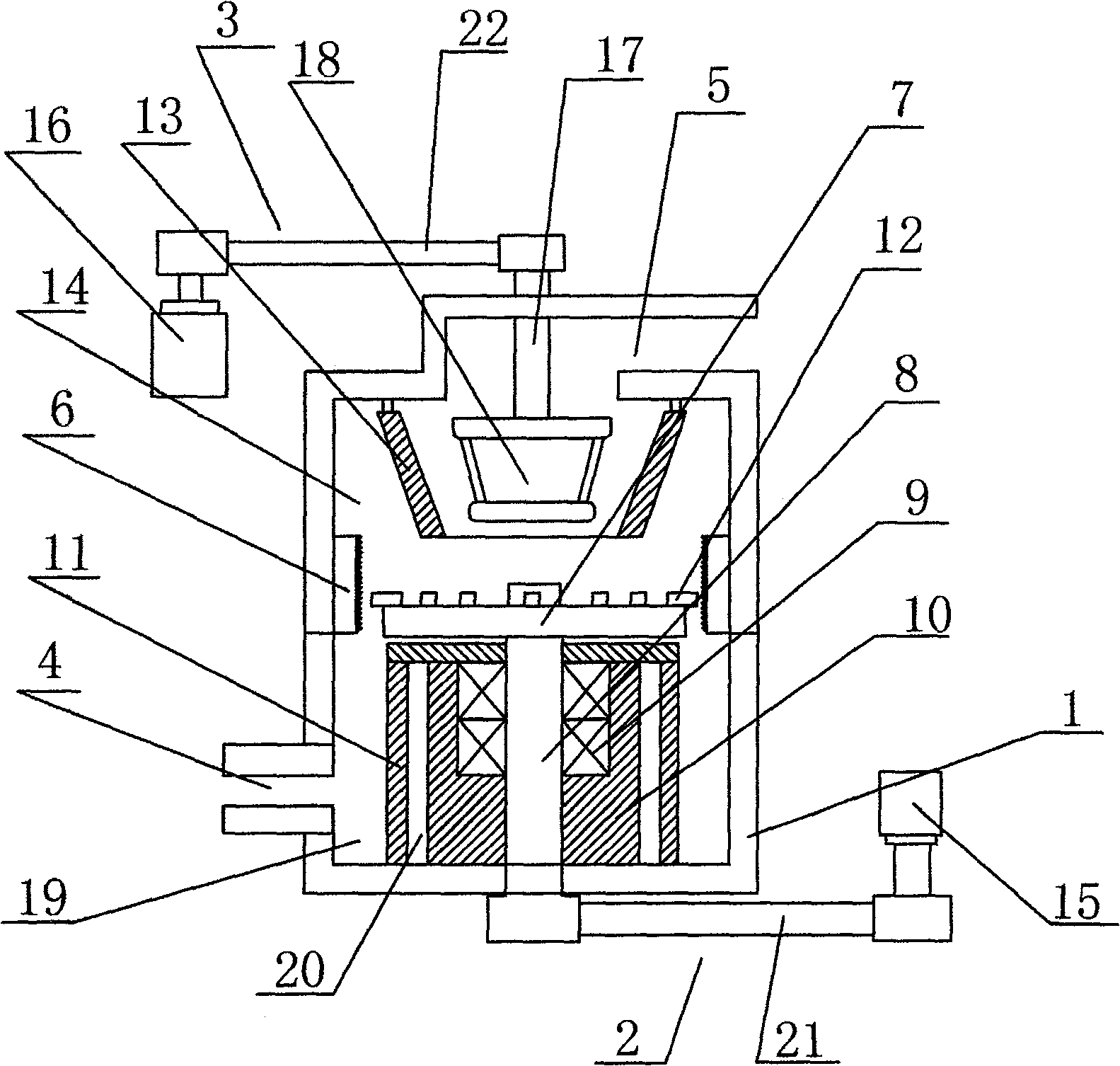

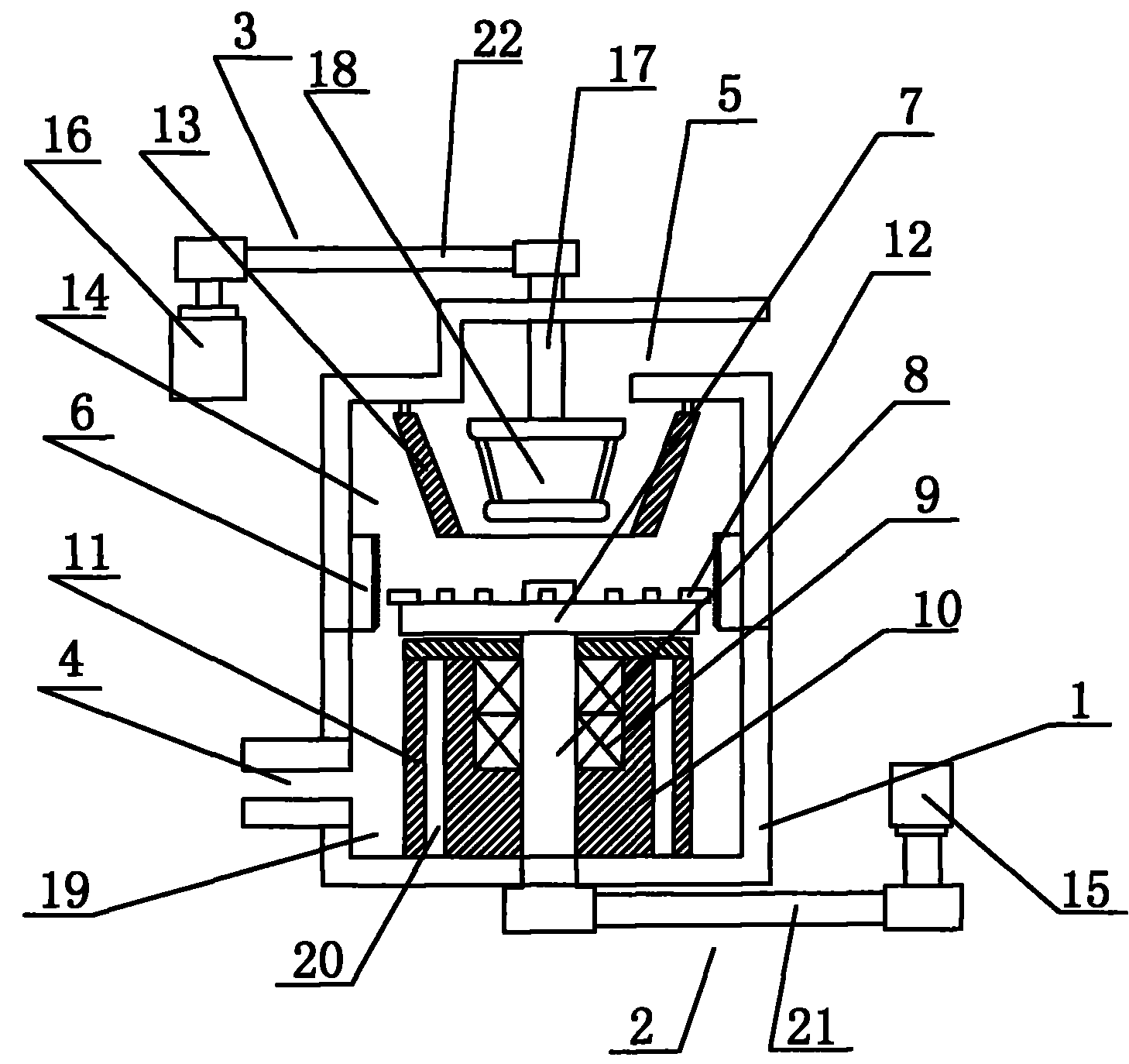

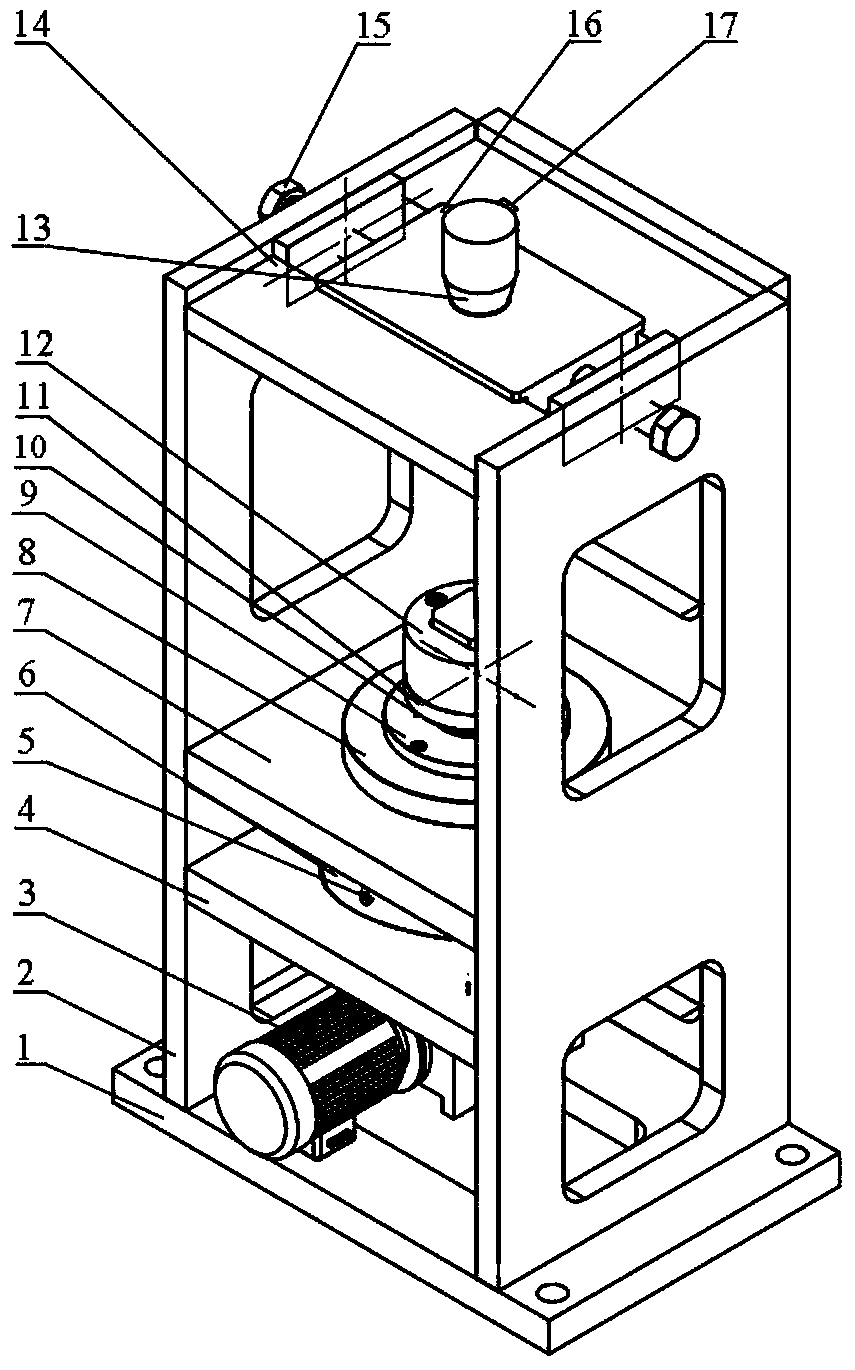

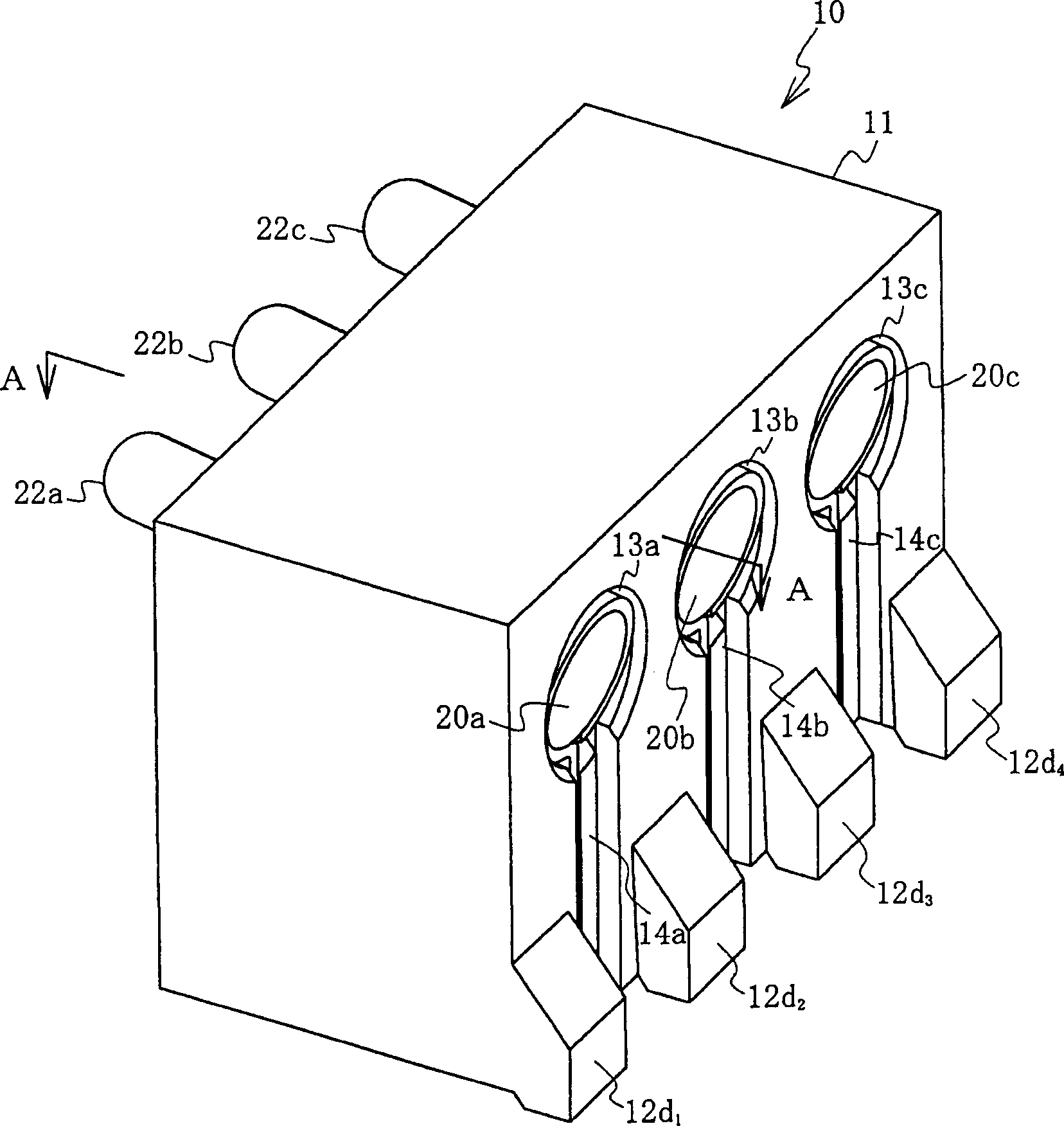

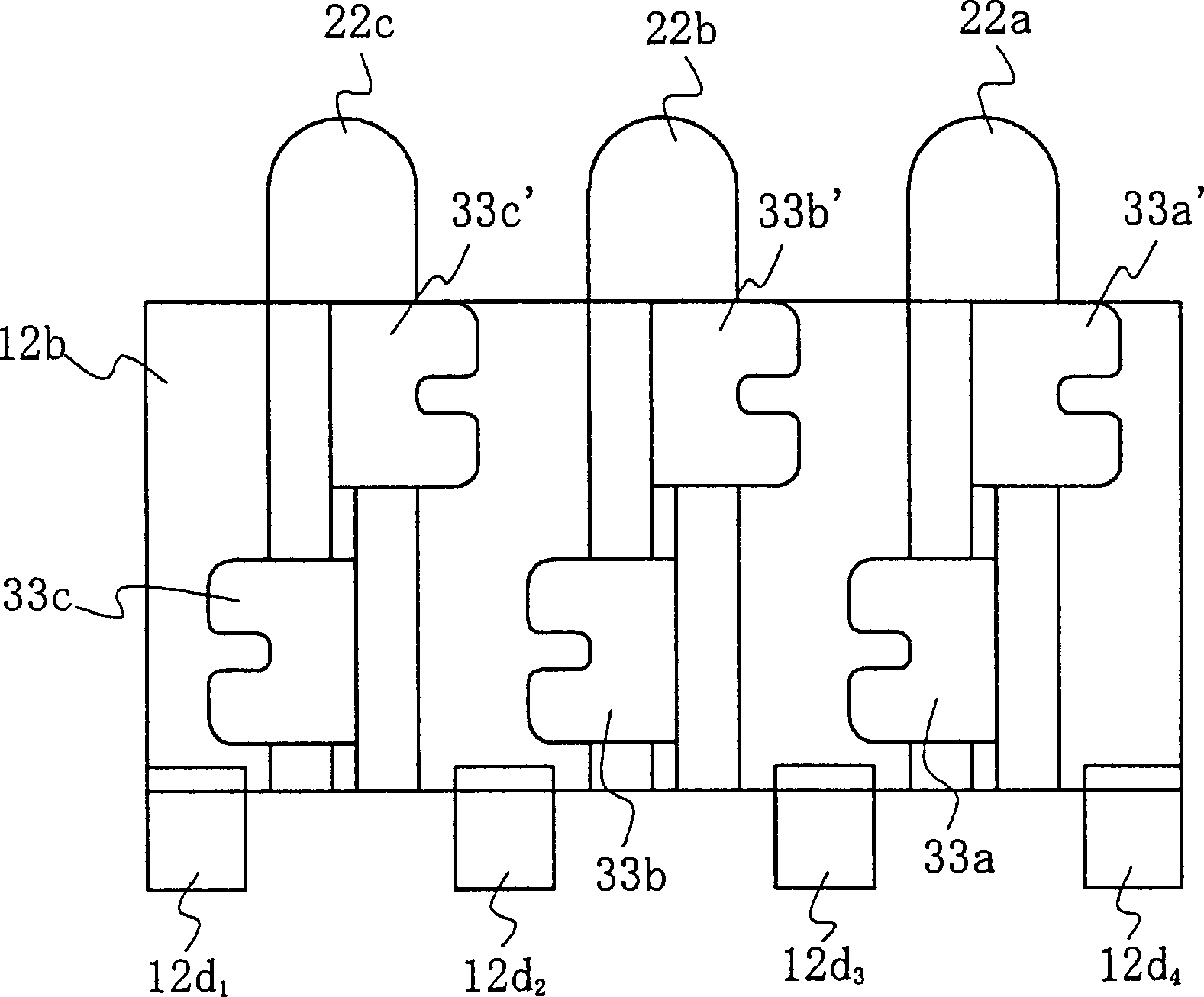

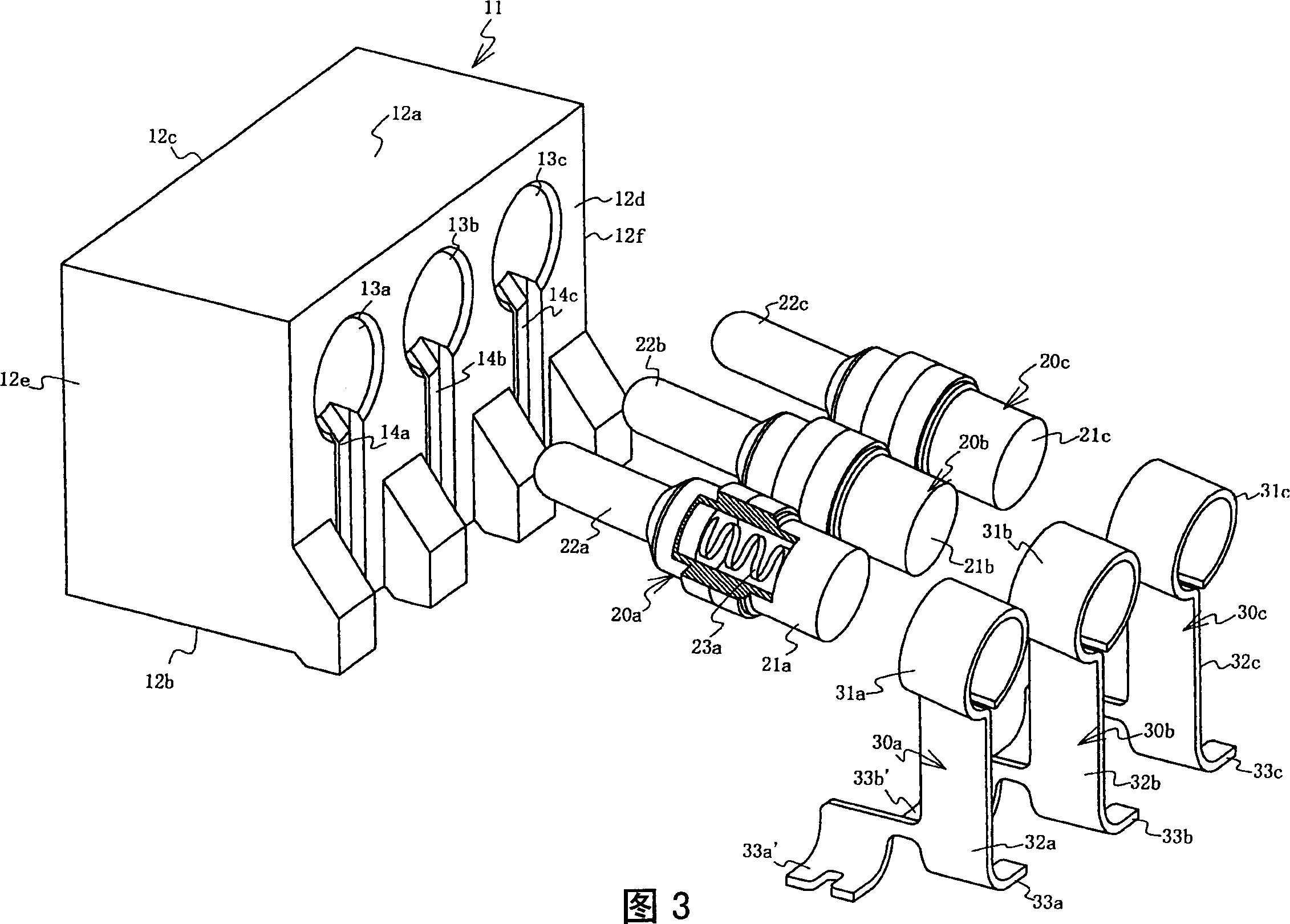

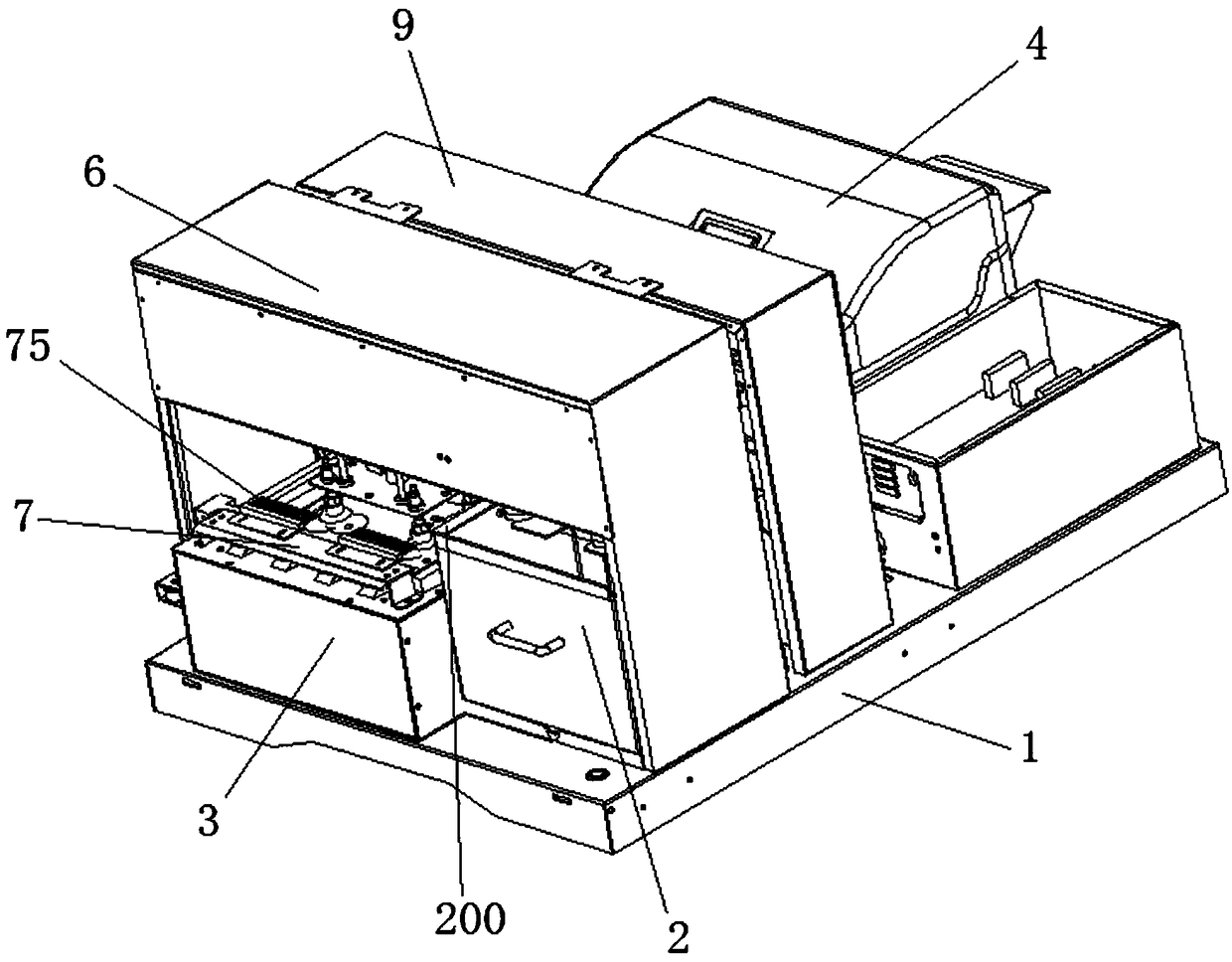

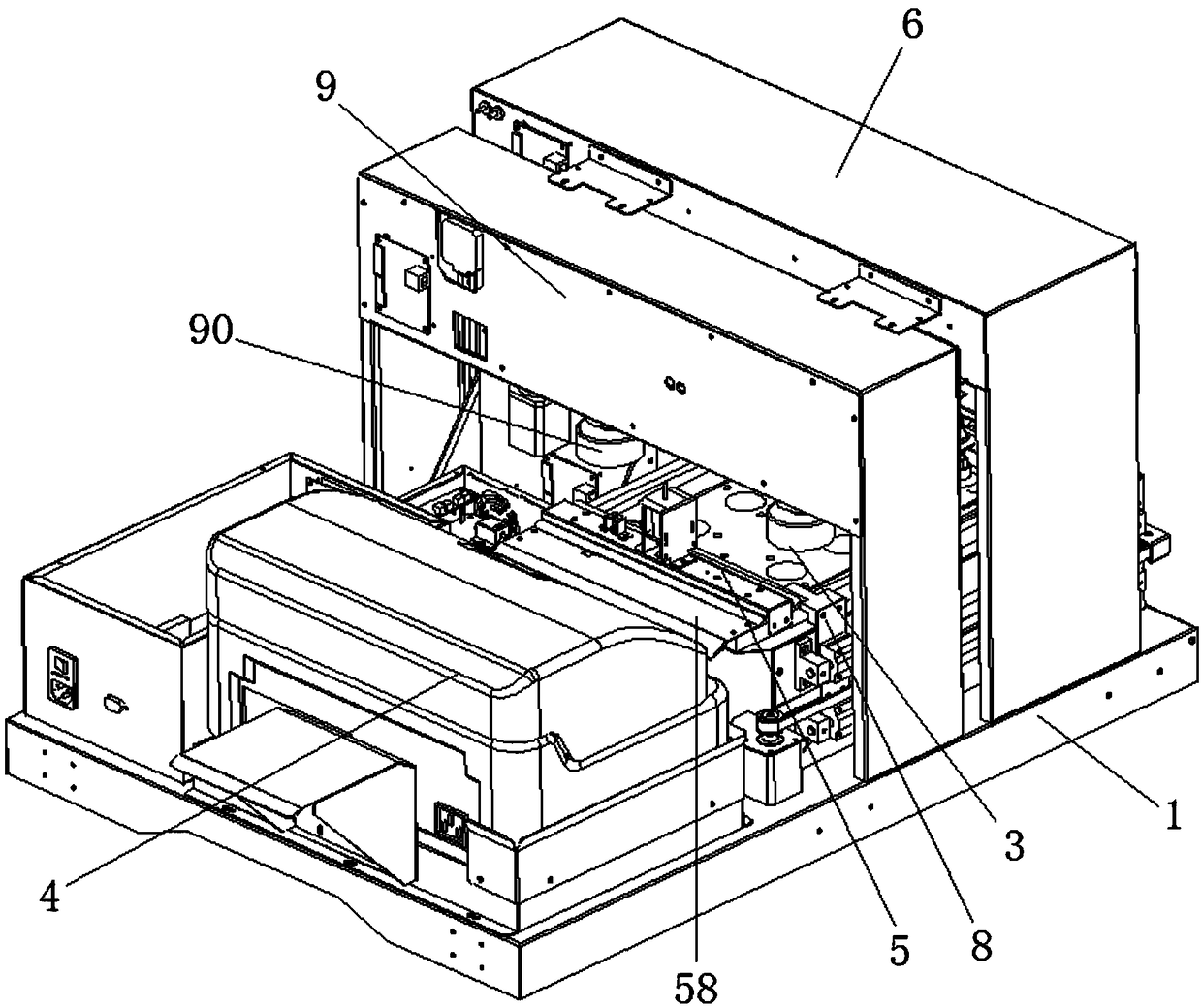

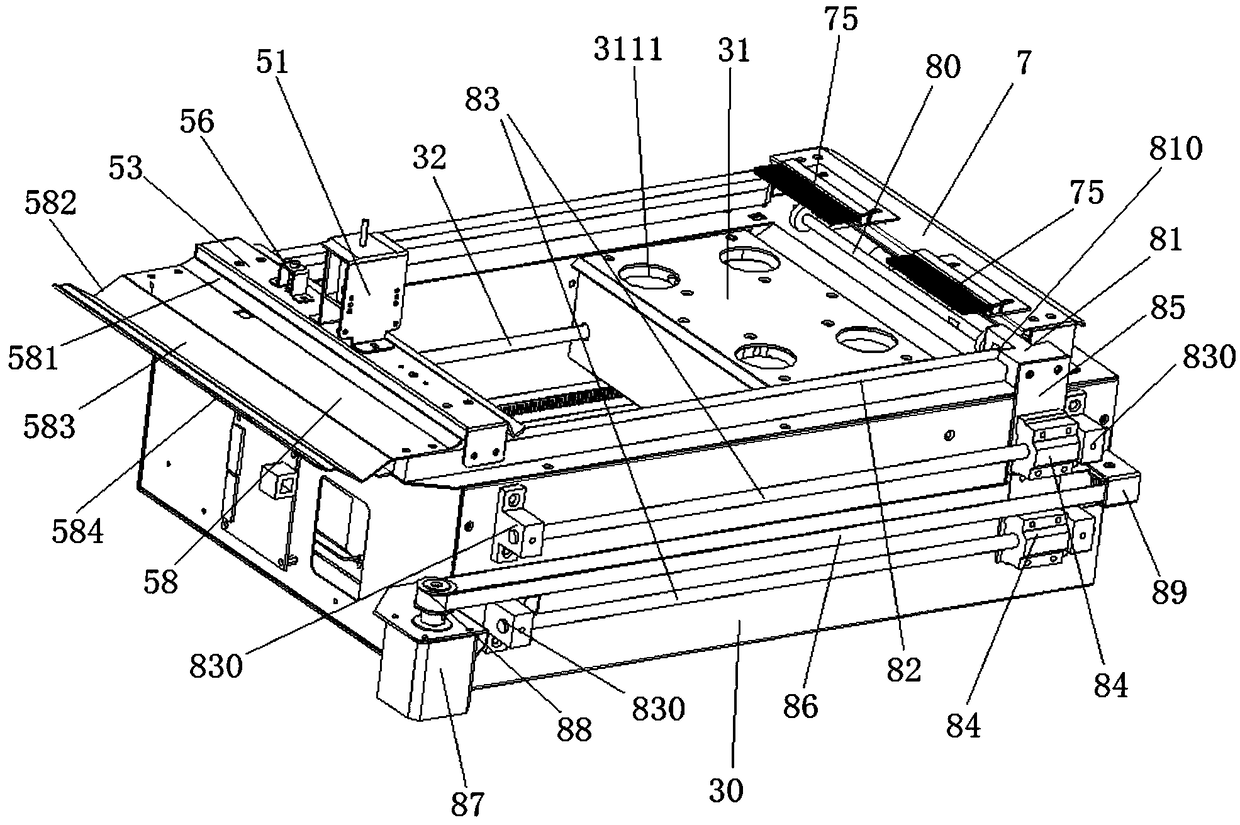

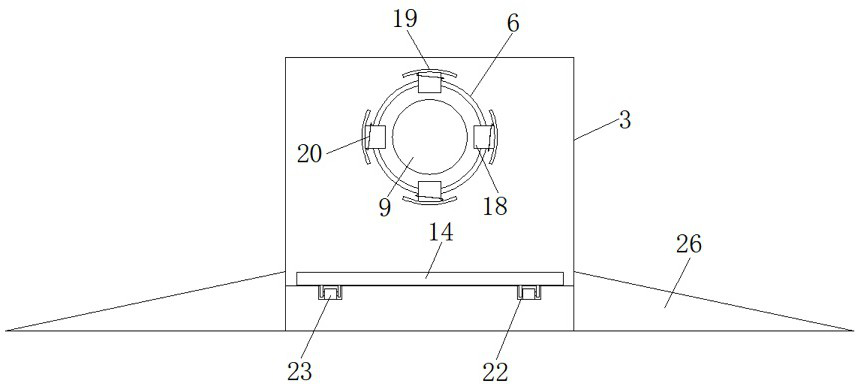

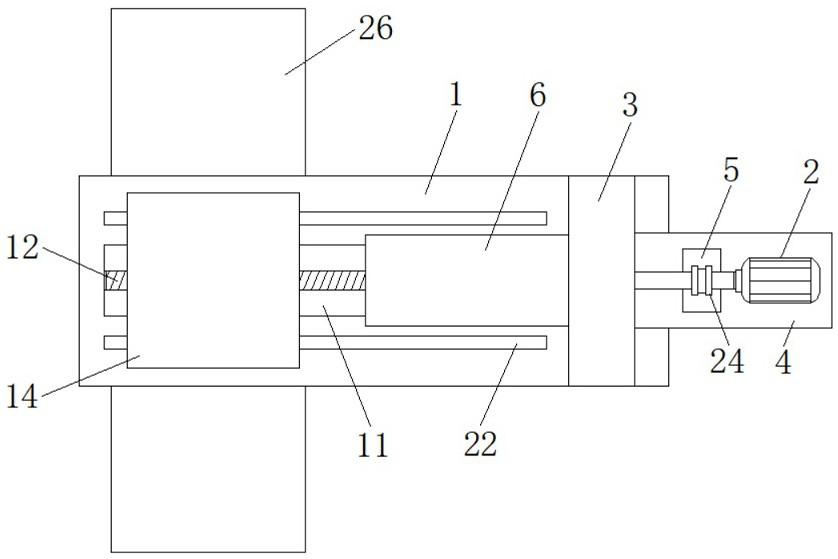

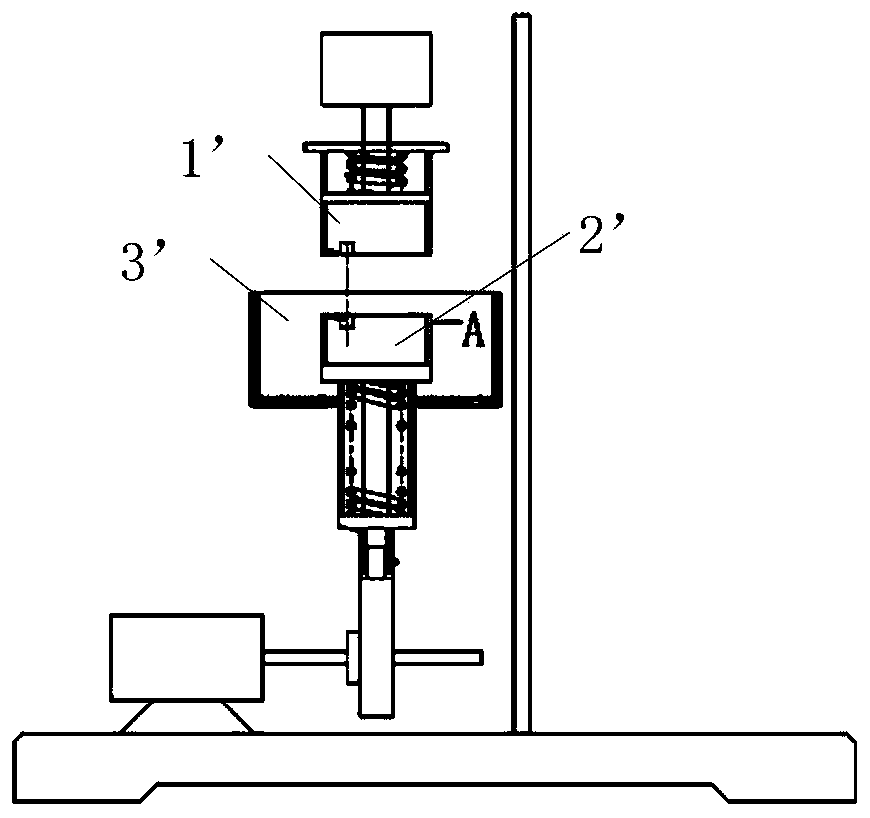

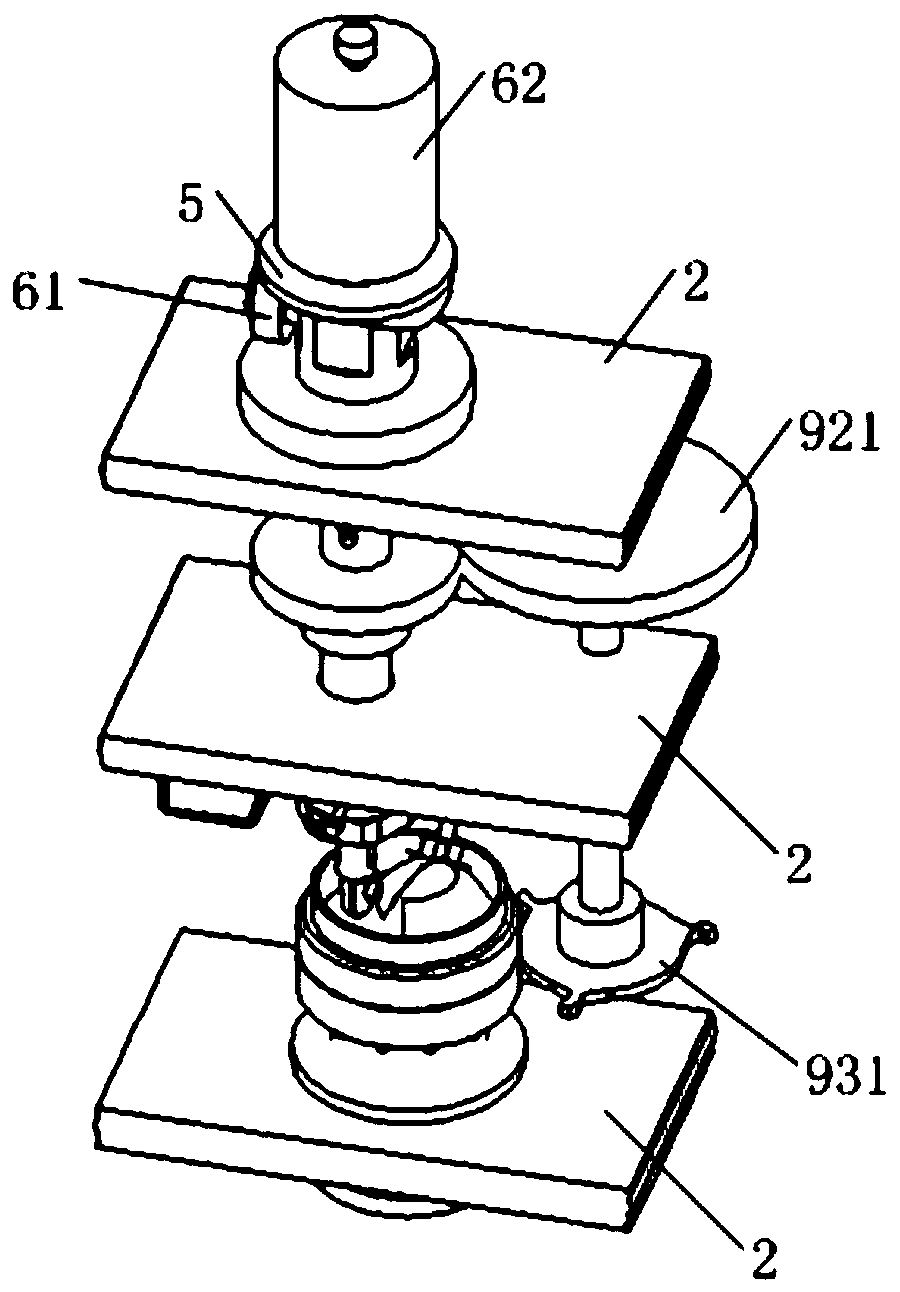

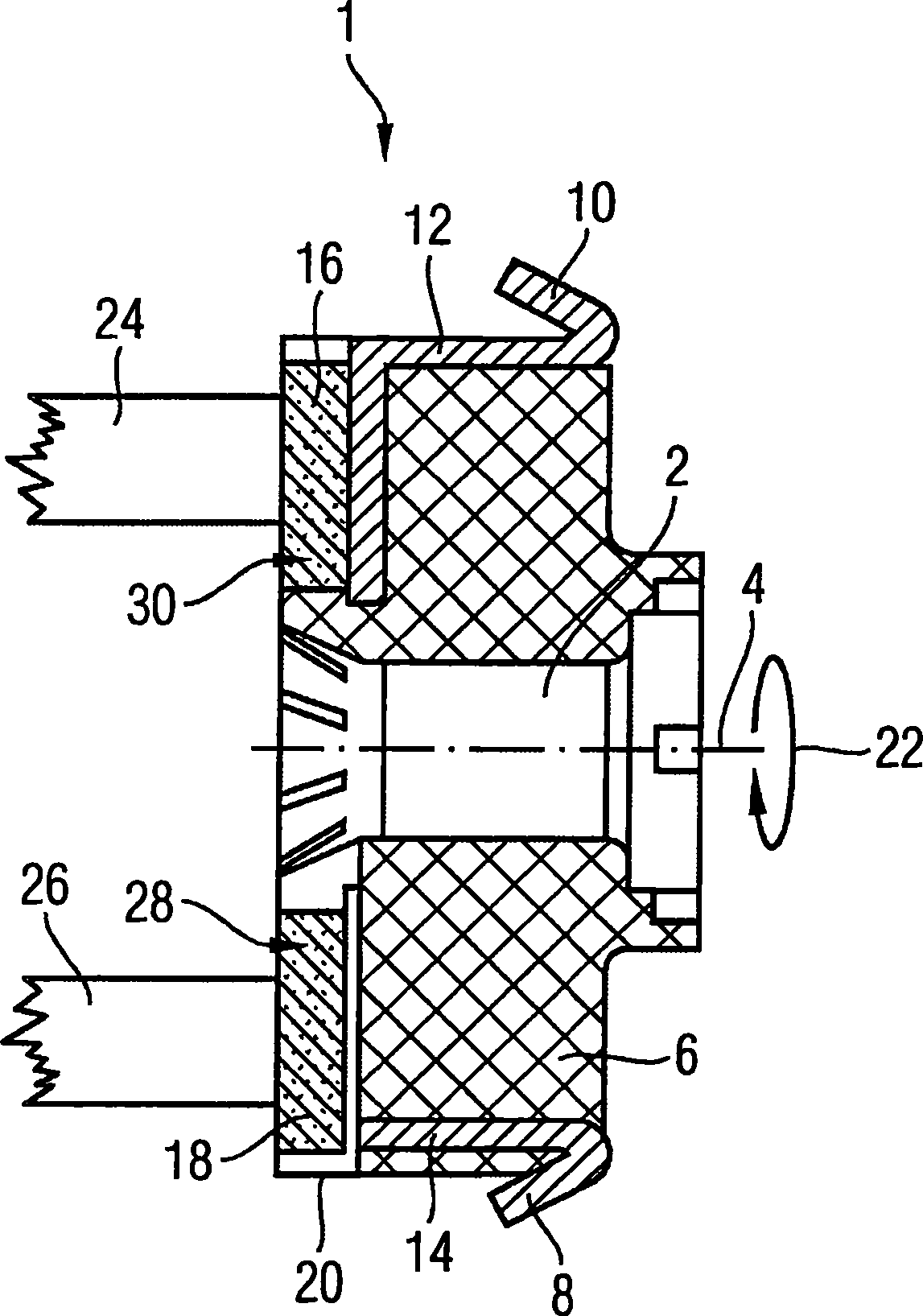

Impact friction fatigue testing machine

InactiveCN103900918ASimple structureSports reliableMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceMetallic materialsEngineering

The invention discloses an impact friction fatigue testing machine which comprises a reciprocating impact loading system, a rotary friction system, a drive system, a guide block and a rack, wherein the rack is of a vertical box frame structure, an upper box plate and a lower box plate are arranged at the middle of the rack, through holes are formed in the centers of the upper box plate and the lower box plate, and the drive system is arranged on the lower bottom surface of the lower box plate; the rotary friction system is located just above the drive system, and is placed in the through holes of the upper box body and the lower box body to be installed on the rack, and the reciprocating impact loading system is arranged on the rack through the guide block and located above the rotary friction system. According to the impact friction fatigue testing machine, through changing different test parameters, different impact loads and friction loads are adjusted, and two dynamic loads of an impact force and a friction force simultaneously act on a metal material to perform a fatigue test, thus the fatigue failure performance of the metal material is tested and evaluated.

Owner:YANSHAN UNIV

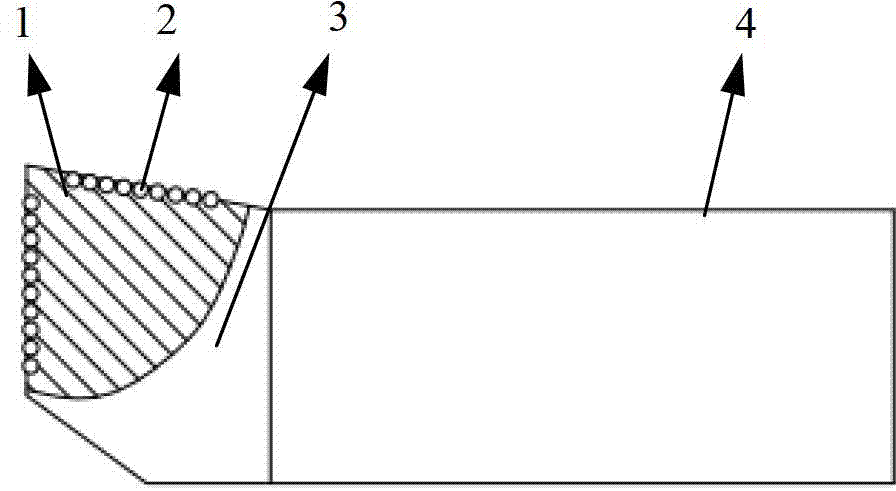

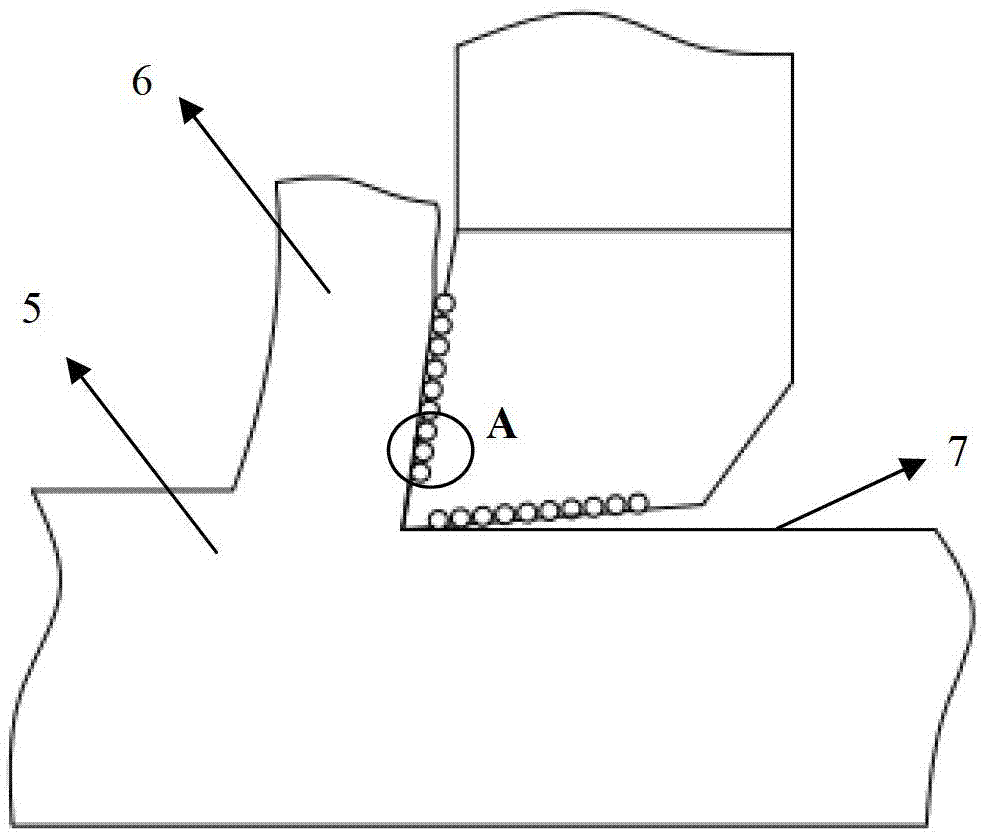

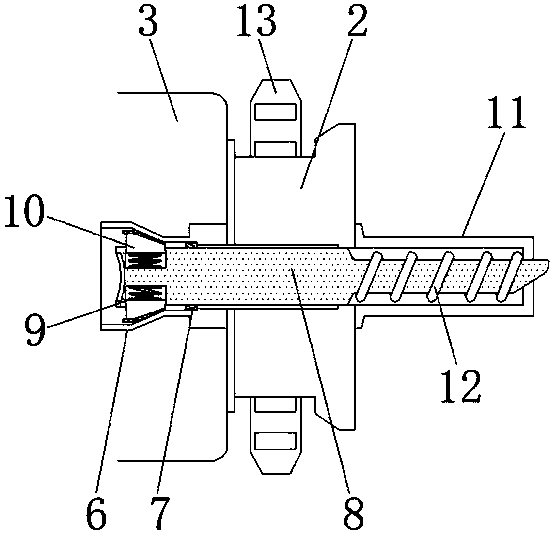

Cutting tool structure based on rolling anti-attrition principle

InactiveCN103084594AImprove integrityReduce surface roughnessTurning toolsEngineeringStructure based

The invention relates to a cutting tool structure based on a rolling anti-attrition principle. The cutting tool structure comprises a cutting body (4) and a cutting head (3) which are arranged integrally. Microgrooves (1) are arranged in the front cutting face and the rear cutting face of the cutting head, and balls (2) are arranged inside the microgrooves in an embedding mode. Compared with the prior art, the cutting tool structure based on the rolling anti-attrition principle can improve the precision of a finished surface, reduce frictional work generated by sliding friction in traditional, so that cutting heat is reduced, and the physical performance of the surfaces of machining workpieces is improved. Cutting tools of the cutting toll structure are strong in generality, good in cutting performance, long in service life, and high in quality of the finished surface.

Owner:SHANGHAI JIAO TONG UNIV

Shock-proof high-voltage power distribution cabinet

InactiveCN107946947ASolve the problem of not having anti-shock functionAvoid interruptionSubstation/switching arrangement casingsAnti-seismic devicesElectricityShock mount

The invention discloses a shock-proof high-voltage power distribution cabinet. The shock-proof high-voltage power distribution cabinet comprises a shock-proof shell, wherein the bottom part of the inner wall of the shock-proof shell is fixedly connected with a shock-proof support; the top part of the shock-proof support is fixedly connected with a high-voltage power distribution cabinet body; thetop parts of two sides of the high-voltage power distribution cabinet body are fixedly connected with fixed blocks; a sliding groove is formed in one side, which is far away from the high-voltage power distribution cabinet body, of each fixed block. According to the shock-proof high-voltage power distribution cabinet disclosed by the invention, by arranging the sliding blocks, supporting springs,connecting rods, pressing plates, telescopic rods, square plates, spring placement grooves, clamping springs and clamping grooves, the problem that a common high-voltage power distribution cabinet hasno a shock-proof function is solved, the situation that an internal circuit in the high-voltage power distribution cabinet body is broken off or damaged as the high-voltage power distribution cabinetbody is in resonance with the ground during strong shaking of the ground can be prevented, the situation that electricity cannot be supplied to users anymore can be prevented from happening, the riskis small, a professional is not required for emergency maintenance anymore, and great convenience is brought for electricity workers, residents or enterprises and the like.

Owner:伍文谦

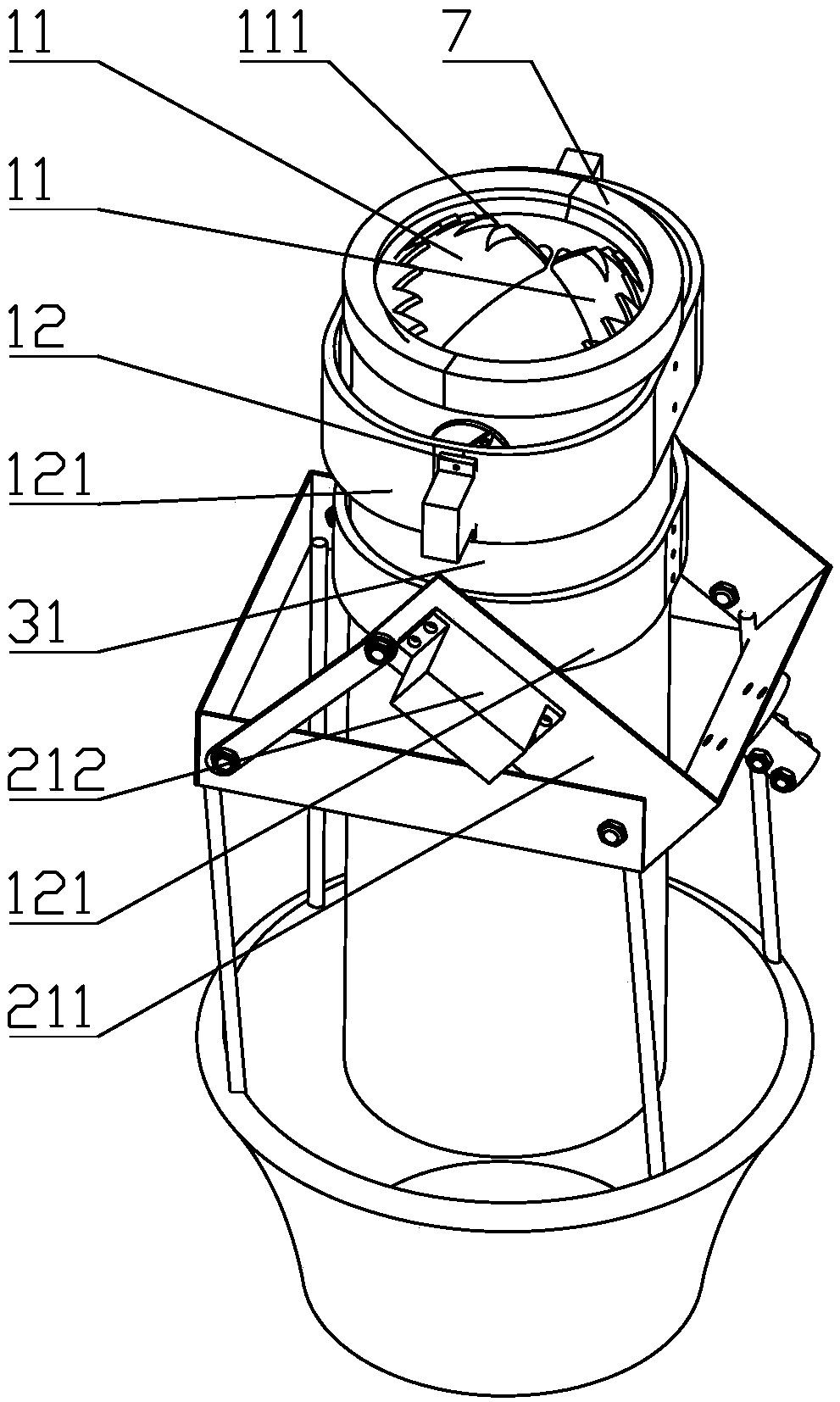

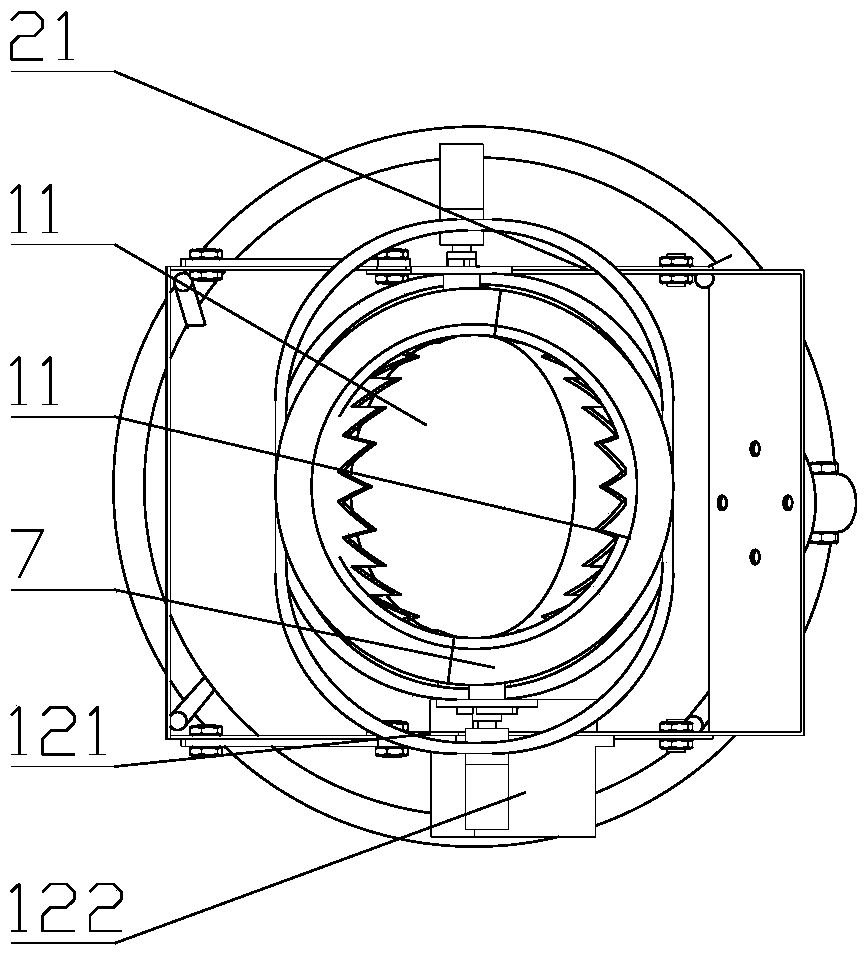

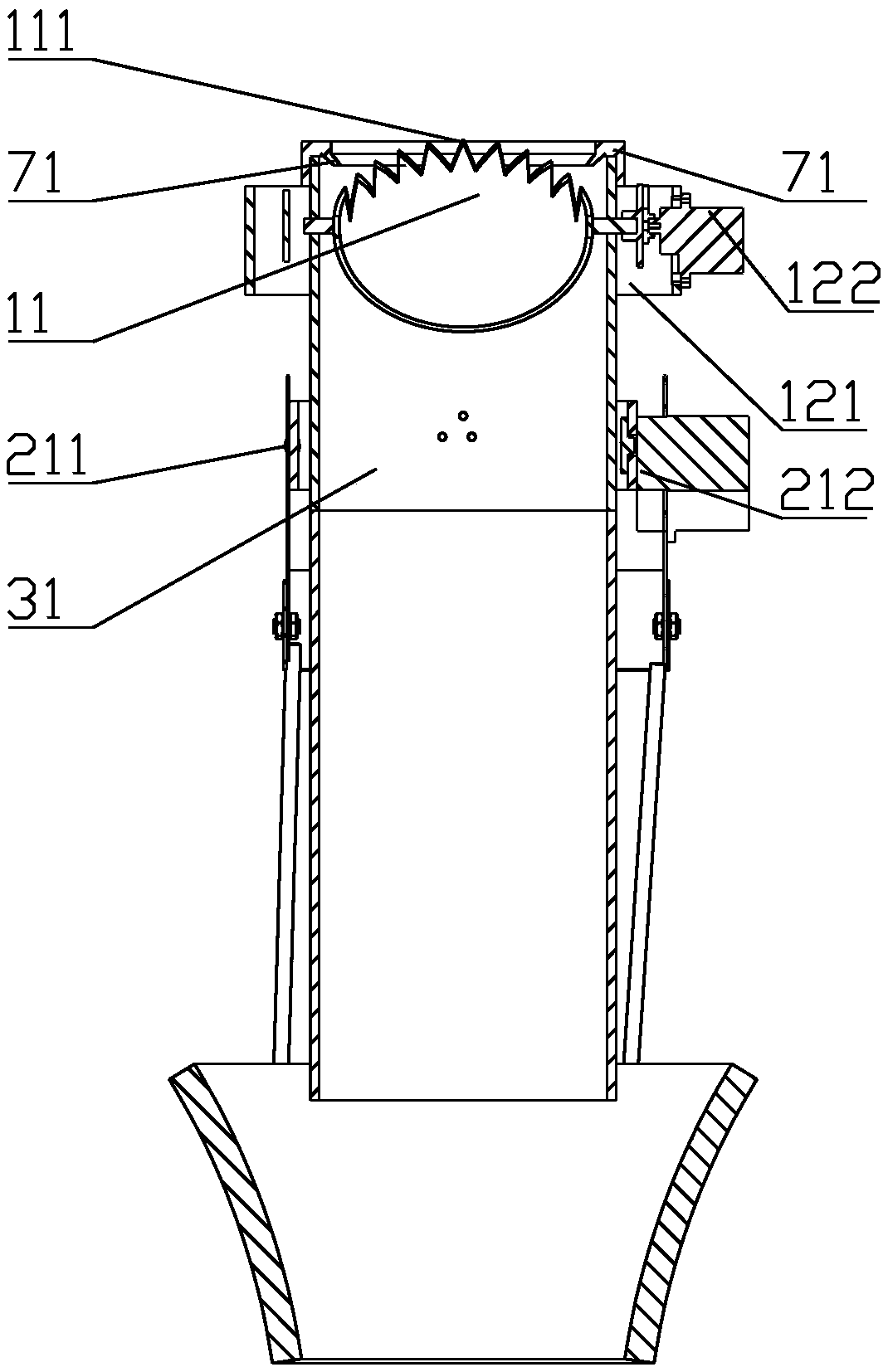

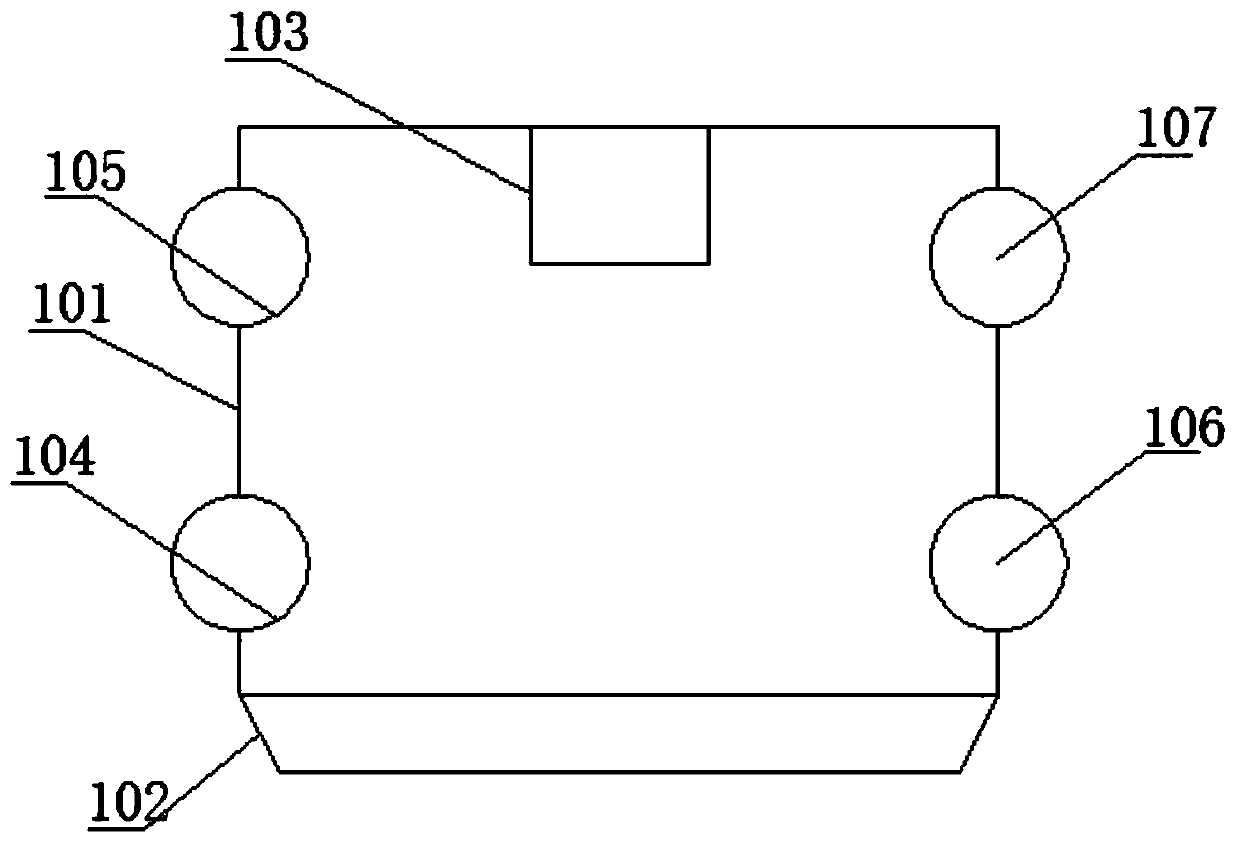

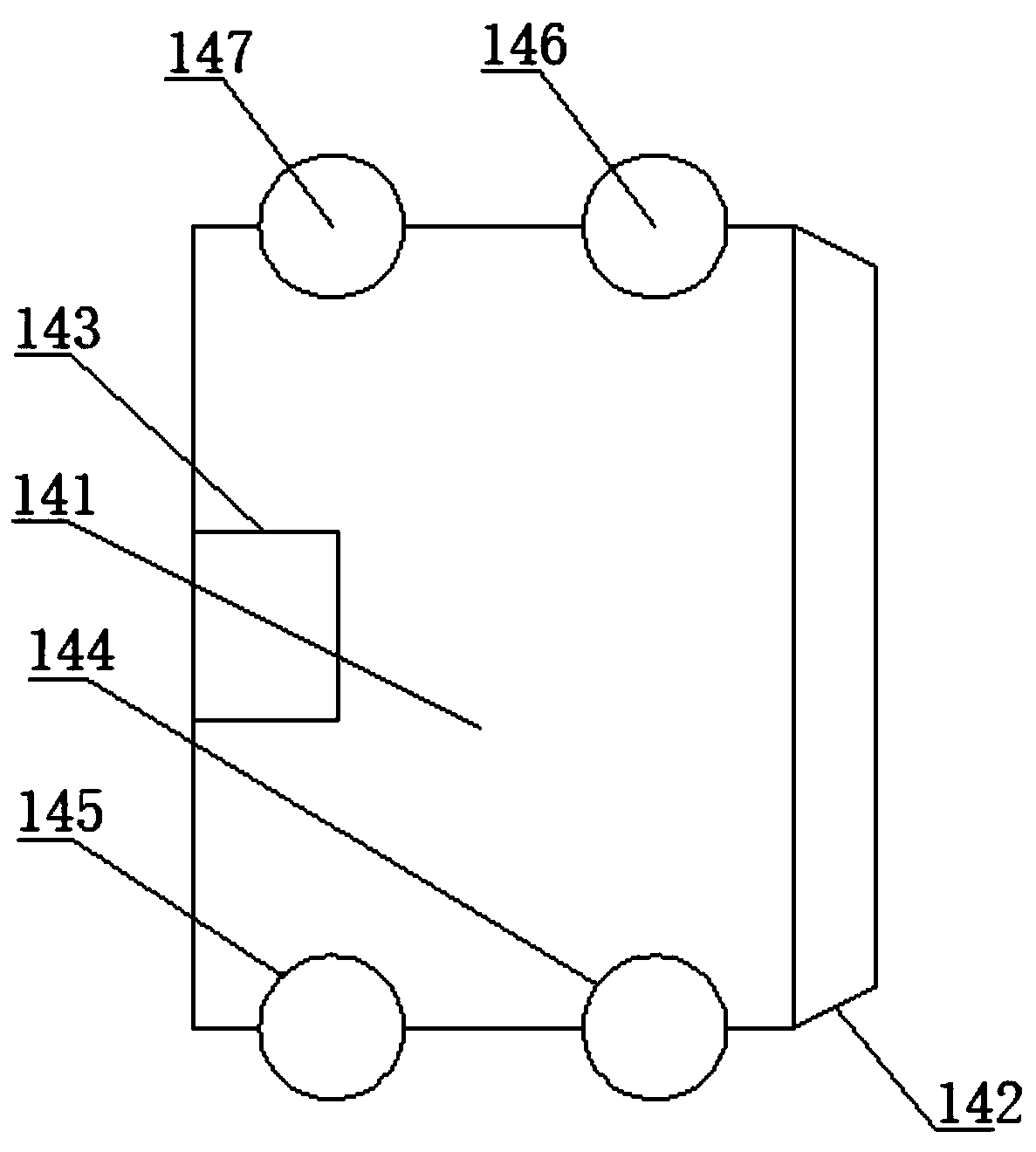

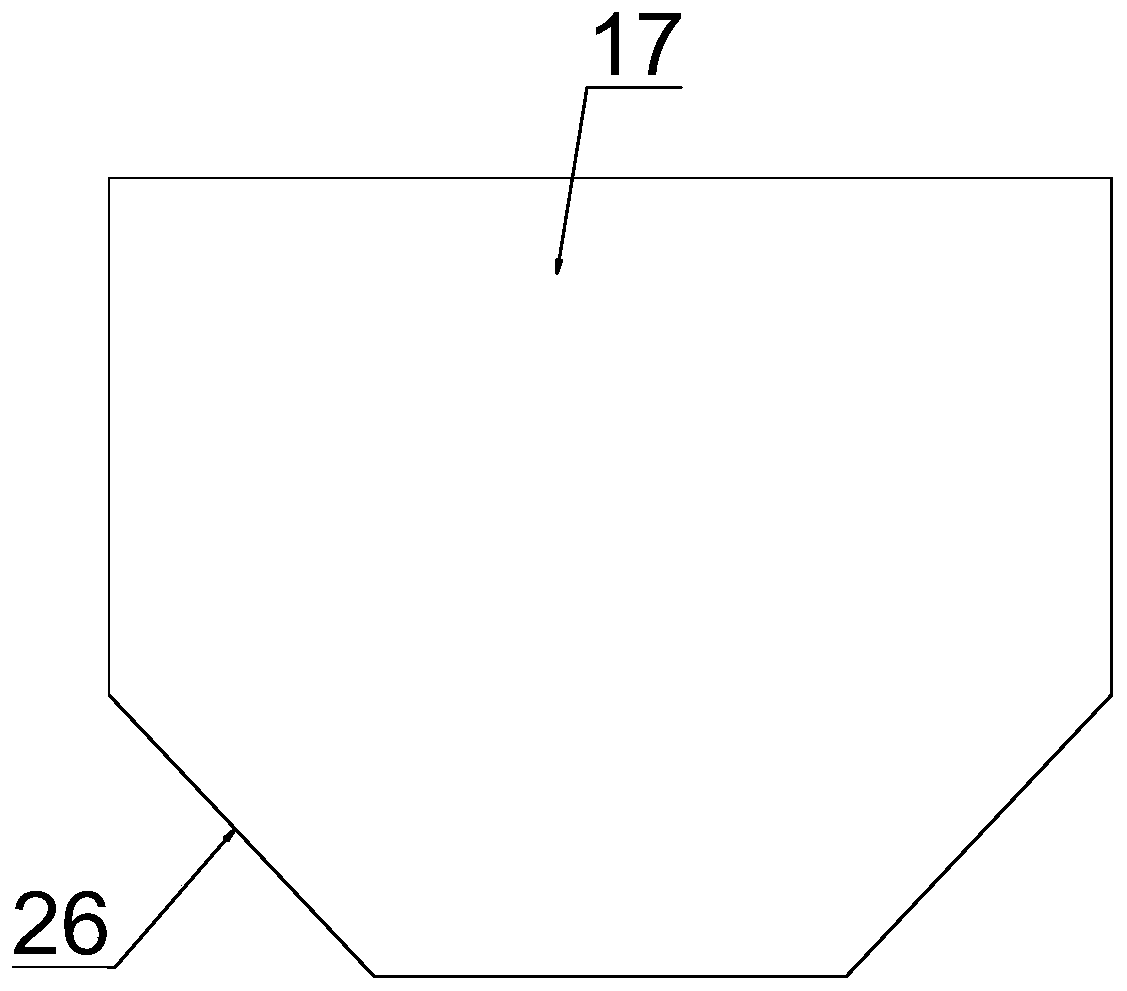

Walking-type automatic fruit picking and collecting robot

The invention provides a walking-type automatic fruit picking and collecting robot. The walking-type automatic fruit picking and collecting robot includes a picking head, a positioning mechanism, a collection mechanism and a movement mechanism; the picking head adopts an arc part to coat and fix a fruit before a fruit stem is cut off, so that the fruit stem is accurately cut off; by adopting a sawtooth-shaped blade design, gradual cutting can be achieved, and phenomena are greatly reduced that a flat blade is likely to working failure and getting clamped when the fruit stem is cut off; after being separated from a branch, the fruit finally enters a collection basket along a flexible fruit guide box in dependence on the gravity of the fruit, and then picking is completed. The walking-type automatic fruit picking and collecting robot is simple in structure, and separation and collection are integrally designed; by adopting the walking-type automatic fruit picking and collecting robot, at-height positioning and automatic picking can be achieved, the picking efficiency is high, it is ensured that the fruit is not damaged, fruits are easy and convenient to collect, automation movement and transportation can be achieved, and time and labor are saved; the walking-type automatic fruit picking and collecting robot is suitable for picking multiple kinds of fruits and has excellent marketprospects.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Self-cleaning flue gas treatment pipeline with dynamic gas filter plate

InactiveCN111550640AImprove filtration efficiencyNot easy to damageDispersed particle filtrationTransportation and packagingFlue gasMechanical engineering

The invention discloses a self-cleaning flue gas treatment pipeline with a dynamic gas filter plate, and belongs to the field of flue gas treatment. The self-cleaning flue gas treatment pipeline withthe dynamic gas filter plate can generate a certain damping and force unloading effect on flue gas impact force through the arrangement of an inner variable layer, so that the dynamic gas filter plateis effectively protected from being damaged; meanwhile, a bidirectional movable through rod is arranged in the dynamic gas filter plate, and the repulsive force effect generated by a reverse thrust net on the bidirectional movable through rod is matched, so that when the flue gas inlet speed is continuously changed, the bidirectional movable through rod can continuously move left and right, and therefore the friction effect on the inner walls of the pores of the dynamic gas filter plate is achieved, the pores are continuously blocked while the flue gas is filtered, the blocking can be achieved without stopping the filtering process of the flue gas, and then the filtering efficiency of the flue gas is remarkably improved; and under the action of a fluctuation blocking layer, the blocking effect of the bidirectional movable through rod on the dynamic gas filter plate is more obvious.

Owner:顾晓杰

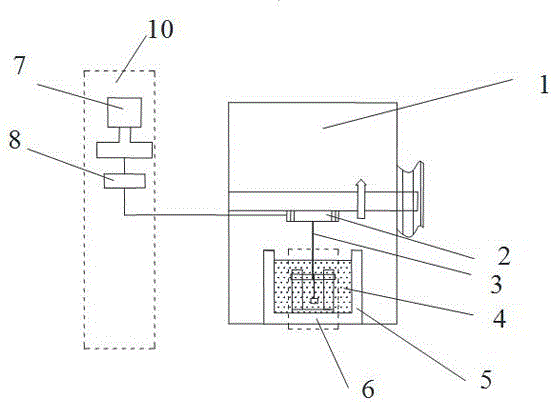

Testing system and testing method for fibrous material friction characteristics in normal and low temperature environment

PendingCN106769842AImplement testAchieve frictionUsing mechanical meansMaterial analysisTesting tubesTest fixture

The invention discloses a testing system for fibrous material friction characteristics in a normal or low temperature environment. The system comprises a tensile testing machine, a strain acquisition device, a testing device and a monitoring and control system, the testing device comprises a testing tube, clump weights and a testing support, the testing tube is horizontally placed on the testing support, after cellosilk is wound around the testing tube a round, a clump weight is hung on the lower end of the cellosilk, and the upper end is connected with the strain acquisition device; the testing system further comprises a U-shaped Dewar type container, the testing device is located in the U-shaped Dewar type container, the Dewar type container contains liquid nitrogen, and the whole testing device is immersed in the liquid nitrogen; the invention provides a testing method for the fibrous material friction characteristics in the normal or low temperature environment at the same time. A traditional force sensor is replaced by the strain acquisition device to capture micro-deformation in the friction process of the cellosilk, the test temperature of a low temperature is provided by the Dewar type container, and therefore the tests of the friction property of the cellosilk in the normal environment and in the low temperature environment are achieved.

Owner:LANZHOU UNIVERSITY

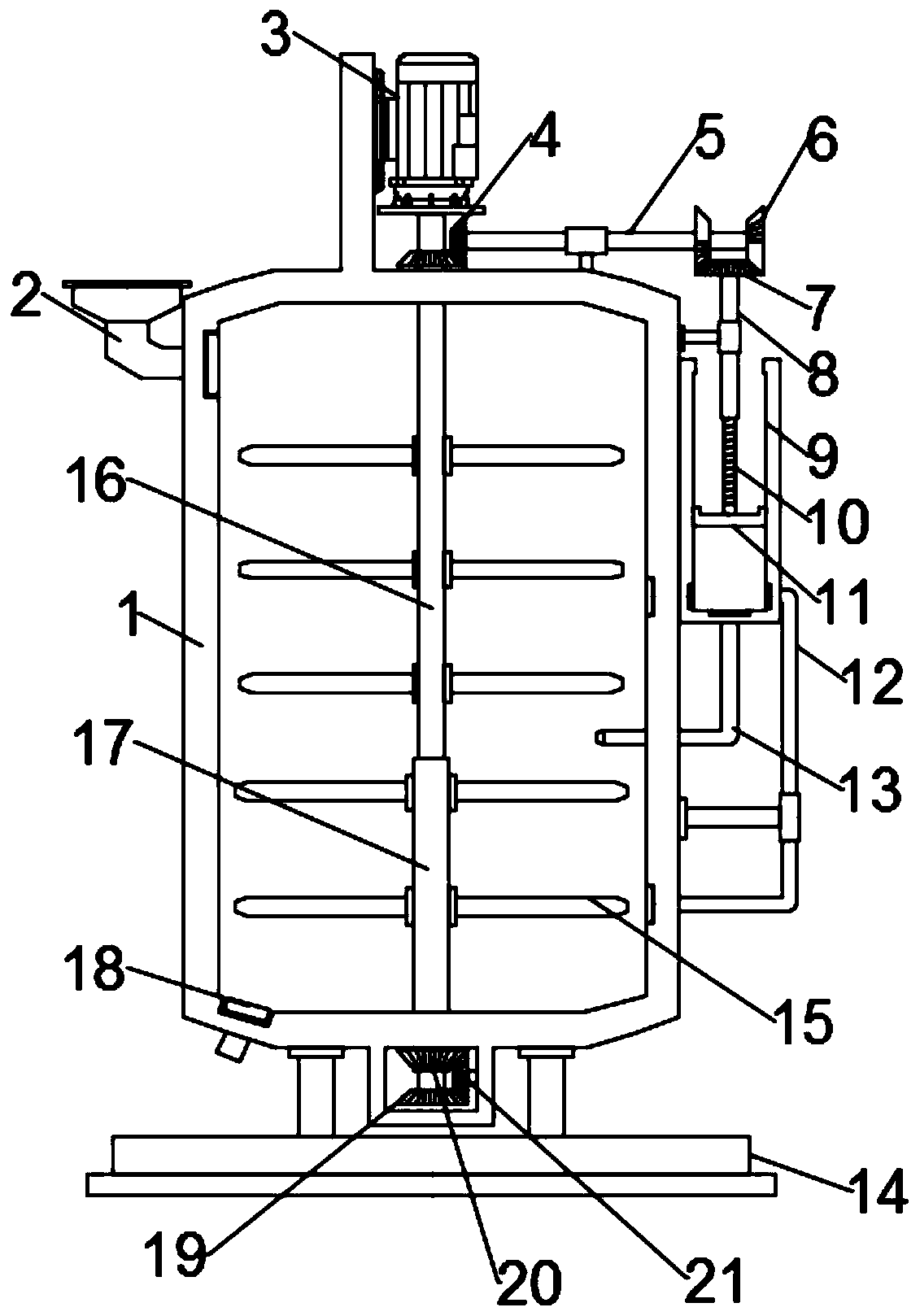

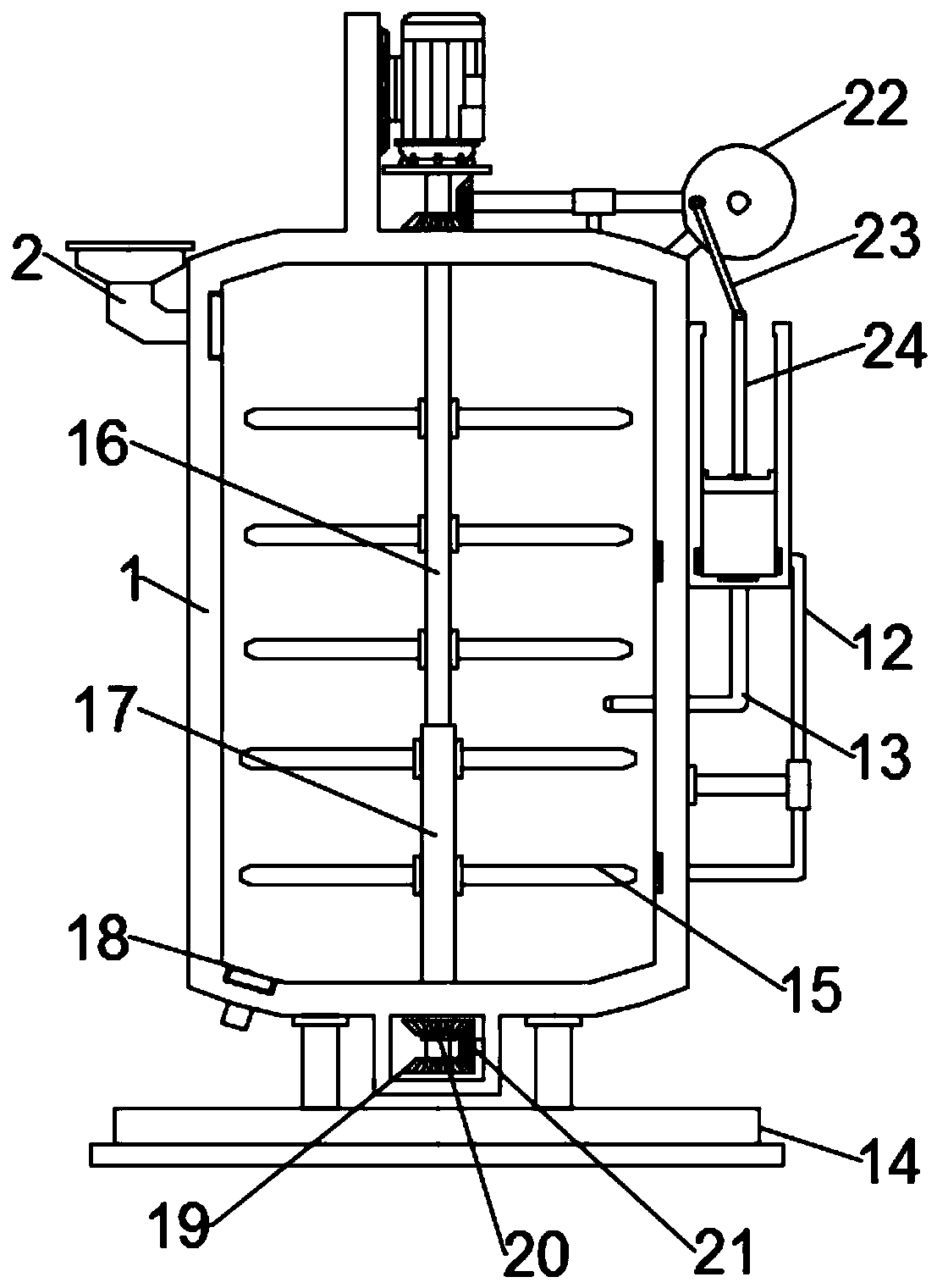

Stirring device for biological pharmacy

PendingCN110302689AGood dispersionAchieve frictionFlow mixersTransportation and packagingPharmacyPulp and paper industry

The invention relates to the technical field of pharmaceutical related devices, in particular to a stirring device for biological pharmacy. The stirring device for biological pharmacy comprises a stirring barrel; a bottom plate is fixed to the lower end of the stirring barrel through a support, the bottom plate plays an effective stabilizing role, a stirring assembly driven by a motor arranged atthe upper end of the stirring barrel is arranged on the inner side of the stirring barrel, wherein the stirring assembly comprises a stirring shaft, a sleeve andstirring rods, the lower end of the stirring shaft penetrates through the bottom of the stirring barrel and is rotatably connected with the sleeve sleeving the stirring shaft and penetrating through the stirring barrel, the rotating direction of the stirring shaft is opposite to the rotating direction of the sleeve, and at least one group of stirring rods are correspondingly arranged on the stirring shaft and the sleeve which are located on the inner side of the stirring barrel. According to the stirring device for biological pharmacy, design is novel, when the arranged motor works, the stirring shaft and the sleeve rotate oppositely, thus the stirring shaft and the adjacent stirring rods on the sleeve rotate, drug liquid is stirred, the friction between liquid can be achieved, and thus the stirring effect is improved.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Electric connector

InactiveCN1581592AAchieve frictionReliable electrical connectionIncorrect coupling preventionCoupling contact membersProbe typeContact failure

An electric connector using a probe-type contact(s) is provided to prevent it from having contact failure and is characterized in that it comprises a housing having at least one through hole, a probe-type contact(s) inserted into the through hole(s), and a terminal portion(s) connected to the probe-type contact(s). In the probe-type contact, a pin-shaped contact(s) is housed in a conductive tubular body in such manner that the contact is energized to move freely by a spring. The tip of the pin-shaped contact is tilted upward at a predetermined angle in a horizontal direction, and is installed into the through hole so as to protrude from the front wall surface of the housing.

Owner:JST MFG CO LTD

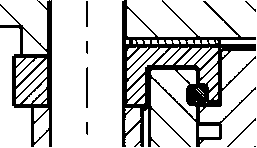

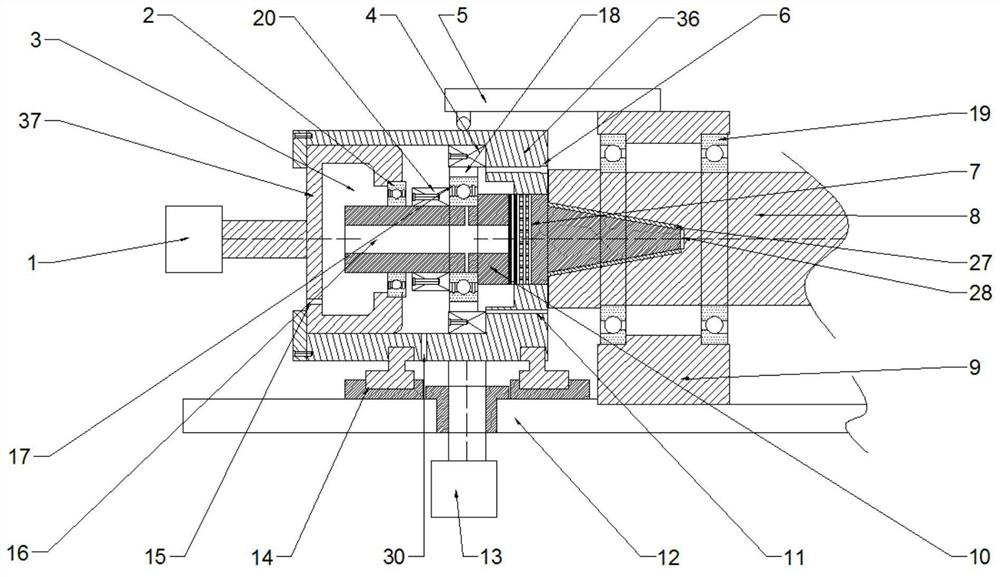

Ultralow-temperature vacuum sealing structure and full-ceramic rolling bearing performance testing device

ActiveCN111896258AImplement Motion LoadingMeasure and control ambient temperatureMachine part testingRolling-element bearingElectric machinery

The invention discloses an ultralow-temperature vacuum sealing structure and a full-ceramic rolling bearing performance testing device, and belongs to the technical field of bearing testing devices. The ultralow-temperature vacuum sealing structure comprises a fixed support, a main shaft mechanism, an ultralow-temperature vacuum sealing chamber and a stress application assembly. The main shaft mechanism comprises a sample main shaft and a driving main shaft; the ultralow-temperature vacuum sealing chamber comprises a vacuum sealing cavity and an axial loading plug, and the sample main shaft isarranged in the vacuum sealing cavity; and the full-ceramic rolling bearing performance testing device comprises an ultralow-temperature vacuum sealing structure, a two-stage vacuum system, a self-pressurization liquid nitrogen tank, a signal acquisition system, a heating pipe, a motor, a controller and an upper computer. The ultralow-temperature vacuum sealing structure and the all-ceramic rolling bearing performance testing device can realize dynamic testing of the friction performance and the vibration performance of the all-ceramic rolling bearing in an ultralow-temperature vacuum environment and under the conditions of different temperatures, vacuum degrees, loads and rotating speeds, and are convenient to operate and high in accuracy.

Owner:SHENYANG JIANZHU UNIVERSITY

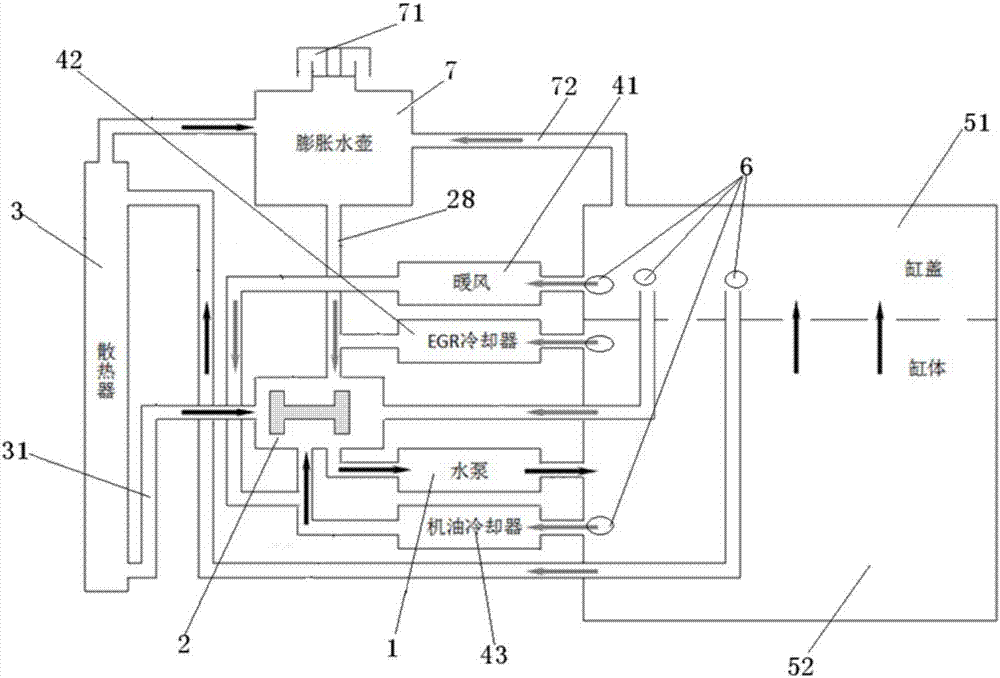

Vehicle cooling system

ActiveCN107165715AImprove boot performanceHigh trafficCoolant flow controlMachines/enginesWater flowEngineering

The invention discloses a vehicle cooling system which comprises a radiator, a cylinder body, a cylinder cover, a flow control structure, a heater water return pipeline, an oil cooler water return pipeline, a cooler water return pipeline and a water pump. The flow control structure comprises a water temperature sensor, a control structure body and a main valve structure. According to the vehicle cooling system, the water temperature sensor sends water temperature signals of the heater water return pipeline, the oil cooler water return pipeline, the cooler water return pipeline and a water inlet pipeline of the radiator to the control structure body in time, and according to the water temperature signals, the control structure body flexibly controls the main valve structure to open or close all the pipelines, so that the situation that water flow branch flows in all the pipelines are flexibly controlled is realized, overall on-demand deployment is realized, and unnecessary energy consumption losses are avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Abrasion resistance testing equipment for textile material

PendingCN112213218AComprehensive test rangeCompact structureInvestigating abrasion/wear resistanceElectric machineryTesting equipment

Abrasion resistance testing equipment for textile materials comprises a first motor, a rotating plate, a friction mechanism, a second motor, a driving gear, a mounting frame, a mounting cover, a supporting frame, a control panel, a supporting table and a rack. The first motor and the second motor are both arranged on the mounting frame, the first motor is in driving connection with the rotating plate, and the second motor is in driving connection with the driving gear; the multiple friction mechanisms are evenly arranged around the rotating center shaft of the rotating plate, each friction mechanism comprises a driven gear, a rotating shaft, a friction table and an installing mechanism used for installing the friction table, the surfaces of the multiple friction tables in the multiple friction mechanisms are different in granularity, the installing mechanisms are connected with the rotating shaft, and the driven gears are arranged on the rotating shafts. The rotating shaft is rotationally arranged on the rotating plate, and the driven gear in the friction mechanism located at the lowest position is in engaged connection with the driving gear; and the mounting frame is arranged on the mounting cover. Friction tables with different friction granularities can be switched, and therefore friction of different degrees can be conducted on textile materials.

Owner:SUZHOU BABEL TEXTILE TECH CO LTD

Automated certificate making device

PendingCN109493538AAvoid stickingAchieve frictionCoin-freed apparatus detailsApparatus for meter-controlled dispensingElectromagnetic lockComputer science

The invention discloses an automated certificate making device. The automated certificate making device comprises a certificate box, a printer, a certificate drawing mechanism and a certificate feeding mechanism, wherein the certificate feeding mechanism is arranged at the certificate feeding end of the printer and comprises a certificate feeding wheel module for driving certificates in and out ofthe printer, the certificate feeding wheel module comprises a paper pickup wheel and a certificate feeding pressure wheel opposite to the paper pickup wheel, and the certificate feeding mechanism also comprises an electromagnetic lock for controlling the certificate feeding pressure wheel to move up and down. According to the automated certificate making device, the certificate feeding mechanismcan adjust the height of certificate feeding pressure wheel through the electromagnetic lock to control the friction between the certificate feeding pressure wheel and the surface of the certificatesaccording to the adjusted height of the certificate feeding pressure wheel, thereby being applicable to the certificates of different thicknesses; a first vacuum sucker module moves blank certificatesout of a certificate outlet at the top of the certificate box to avoid drawing out neighboring certificates along; when the first vacuum sucker module sucks paper up, a page turning rod moves horizontally to achieve certificate page turning, and a hairbrush brushes over pages to avoid page adhesion during page turning.

Owner:深圳市赛义德信息技术有限公司

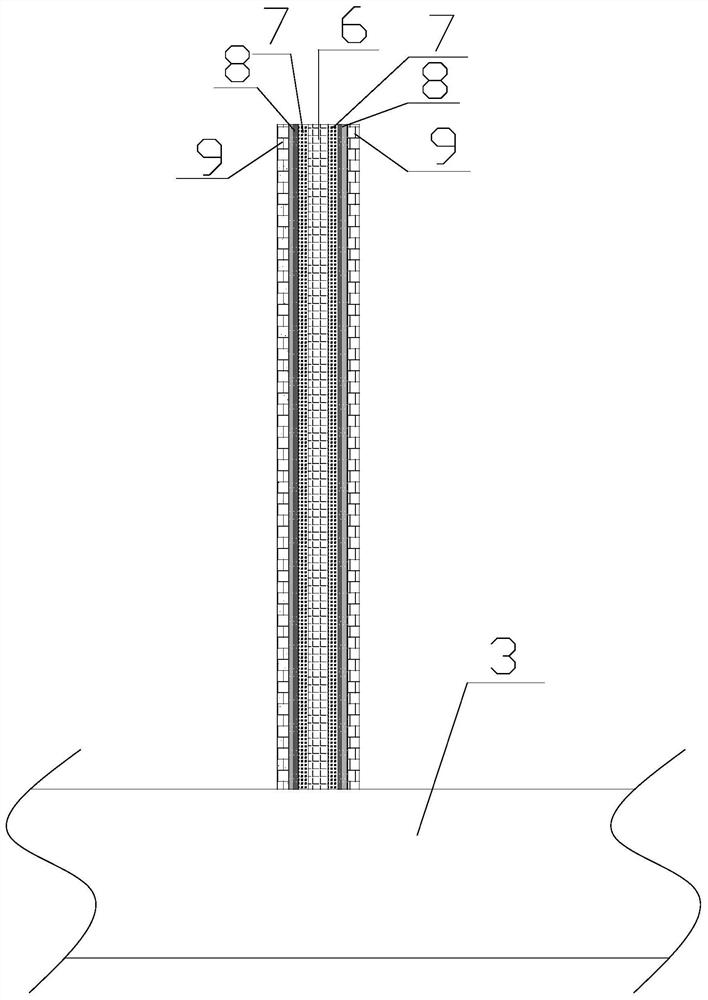

A power cable laying device

ActiveCN112928698BRealize the purpose of erectionSave human effortFilament handlingApparatus for laying cablesPower cableElectric machine

The invention discloses a power cable laying device, comprising a base and a driving motor. A first support plate is fixedly installed on the top of the base, and a mounting plate is fixedly installed on one side wall of the first support plate. The motor is fixedly mounted on the mounting plate, and the mounting plate is provided with a through opening. The present invention uses the base, the drive motor, the first support plate, the installation plate, the through hole, the rotating shaft, the notch, the first threaded rod, the push block, the sliding groove, the second threaded rod, the sliding block and the supporting mechanism. , the cable take-up wheel is moved to the rotating shaft by pushing the cable take-up wheel to the bearing plate, and then the first threaded rod and the second threaded rod are driven to rotate by the driving motor, and the multiple support blocks are pushed through the push block at the same time. The block movement can realize the purpose of supporting the cable take-up wheel through the plurality of second support plates, so that the erection purpose of the cable take-up wheel can be realized, and a lot of manpower can be saved.

Owner:广东欧姆龙电力工程有限公司 +1

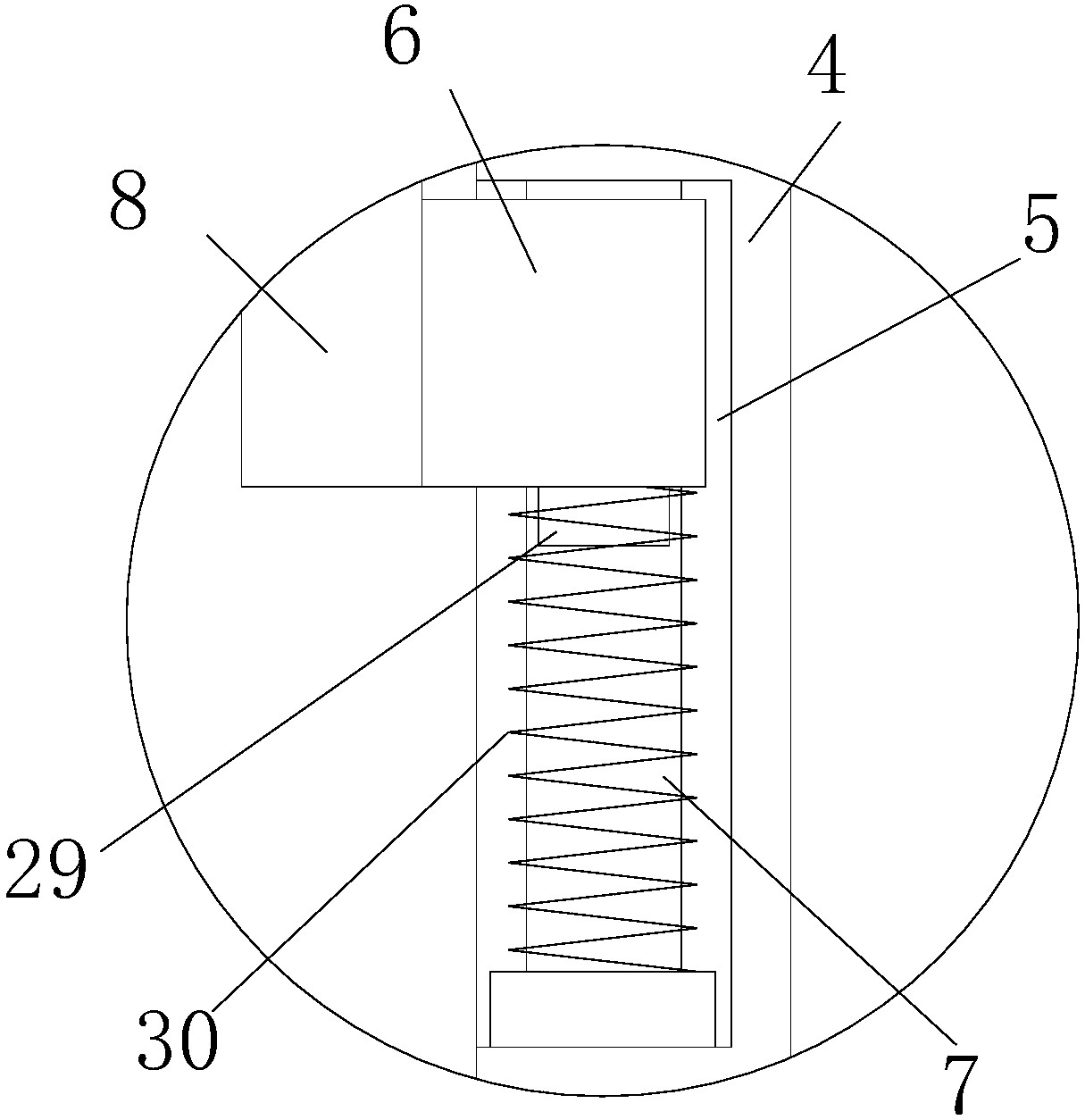

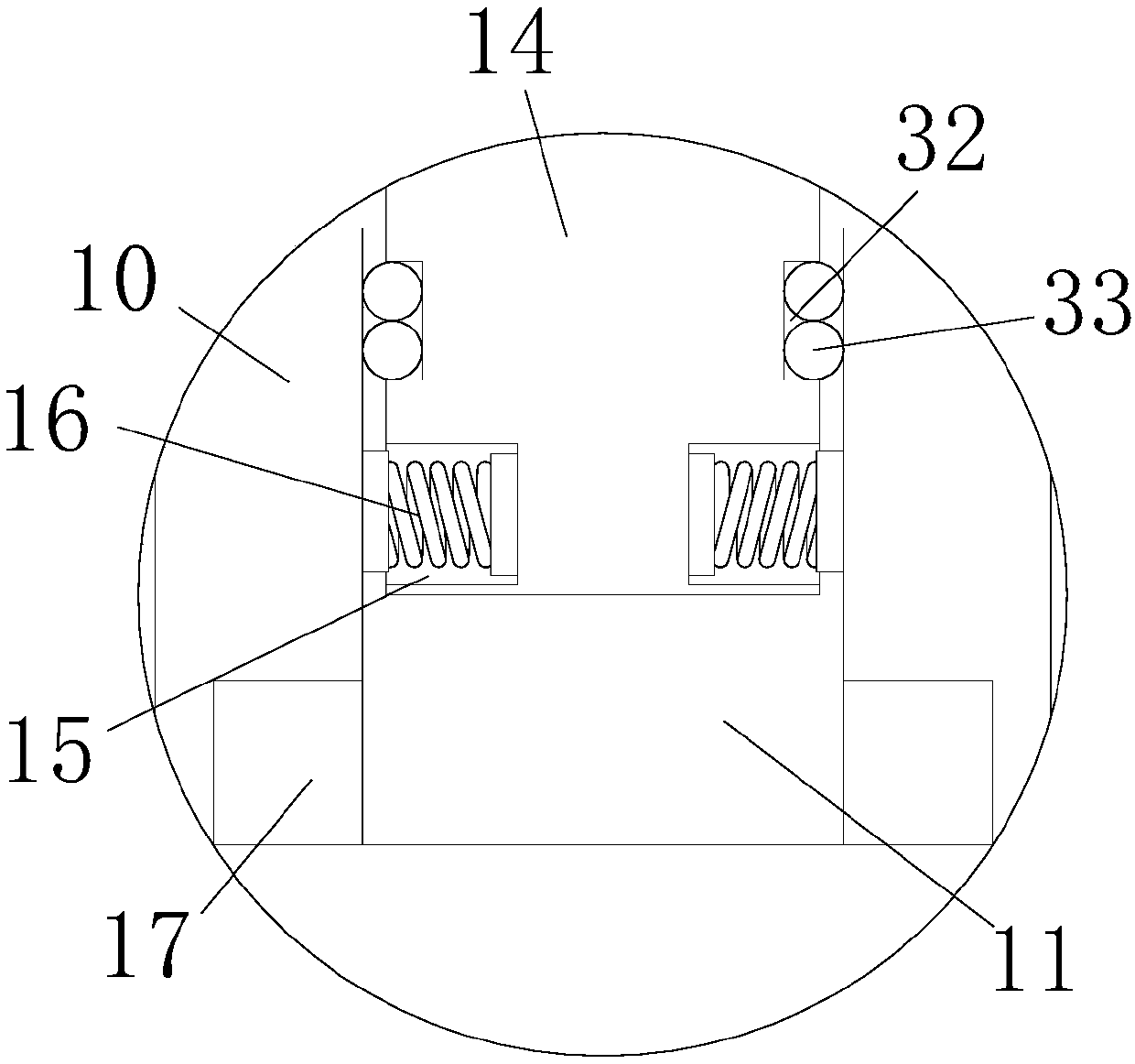

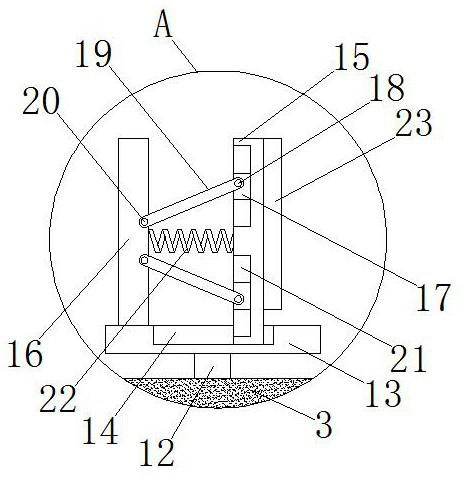

Energy conversion type buffer bracket

ActiveCN110159700AAchieve frictionImprove protectionSpringsShock absorbersFriction effectCoil spring

The invention discloses an energy conversion type buffer bracket comprising a main bottom support baseplate. According to the energy conversion type buffer bracket, a spiral spring used for buffer support, and the movement effect caused by vibration can be converted into friction between components; thus, elasticity and rebounding are reduced by using the friction force, namely that the buffer support is implemented in an energy conversion mode, and the buffer effect of the bracket is better; the protection and working stability of component equipment is higher; the bracket is provided with apiston plate type longitudinal pressure liquid drive mechanism, and internal hydraulic oil can be enabled to flow under the effect of top pressure directionally, so that the driving effect is achieved; the bracket is provided with a piston plate type horizontal liquid pressure driven mechanism, and the longitudinal pressure is converted into a bidirectional horizontal pressure under the effect ofliquid, so that a fictional component is driven; the bracket is provided with a bolt mounting gantry type top pressure mechanism, and necessary pressure can be provided by using the elasticity of thespiral spring; and the friction effect between the components is achieved.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Screening device for plastic masterbatch

The invention discloses a screening device for plastic masterbatch. The screening device comprises a box body, a connecting box is arranged on the upper side of the box body, a moving plate is arranged on the outer wall of the connecting box in an inserting mode, a connecting plate is fixedly connected with the end, located in the connecting box, of the moving plate, a plurality of brush heads arefixed on the lower side wall of the connecting plate, a limited plate is fixed on the outer wall of the end, located in the connecting box, of the moving plate, two expansion springs are fixed between the side, away from the connecting plate, of the limited plate and the inner wall of the connecting box, a fixing plate is fixed on the outer wall of the connecting box, a first motor is fixed at the end portion of the fixing plate, and an incomplete gear is fixed at the driving end of the first motor. According to the screening device for the plastic masterbatch, by scraping a resin raw material and guiding the resin raw material to a screen, rolling of a vertical raw material is achieved through up and down swing of the screen, impurities in the resin raw material are removed, cleaning ofthe resin raw material is achieved, and the quality and properties of plastic masterbatch produced subsequently are ensured.

Owner:格来纳亚洲塑料技术(上海)有限公司

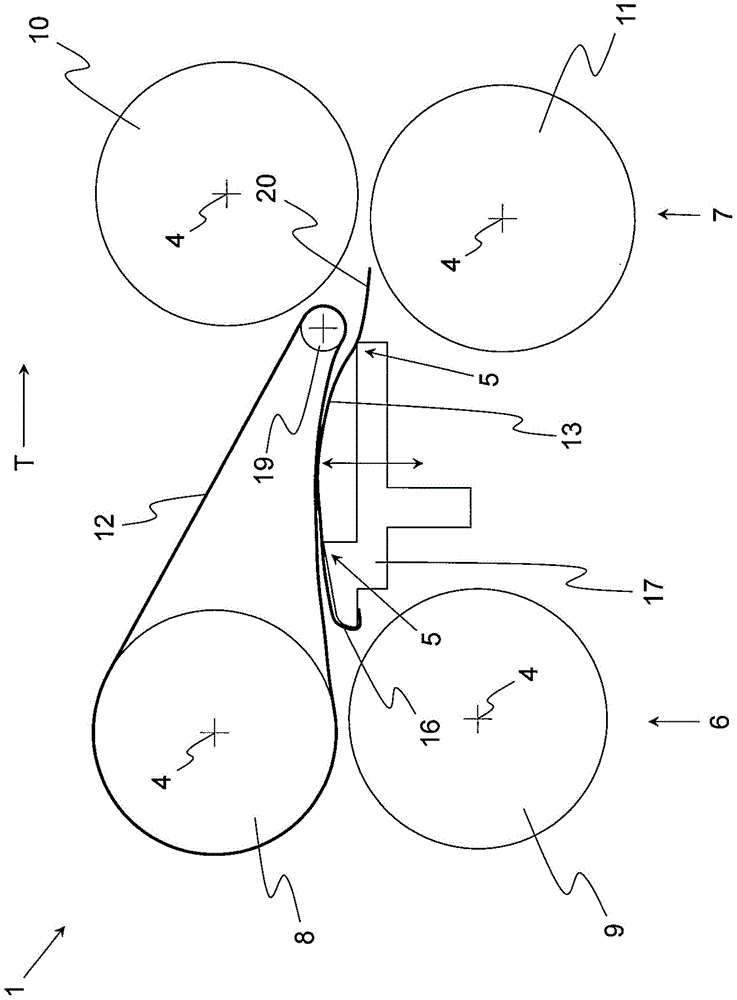

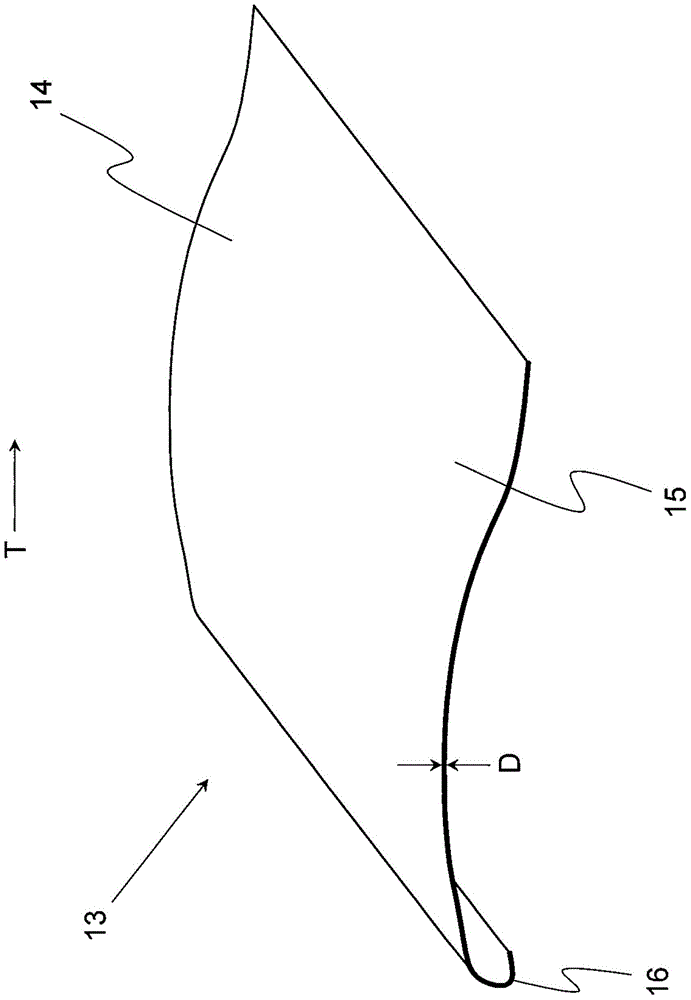

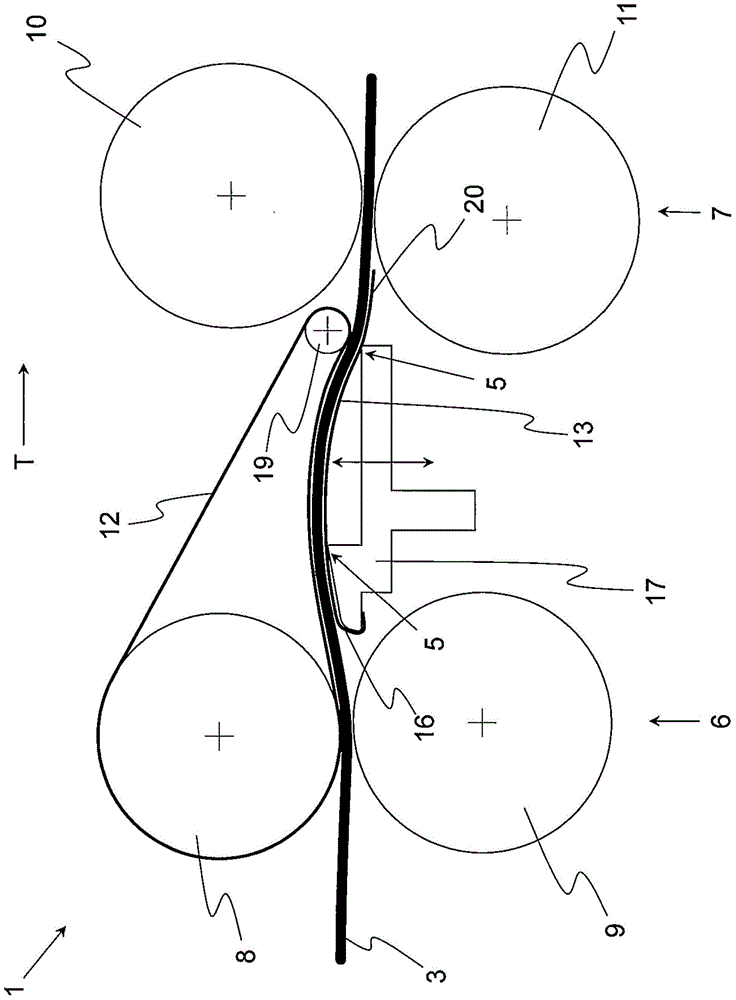

Roller stretching assembly of a workstation of a textile machine that processes staple fibers and textile machine

The invention relates to a roller stretching assembly of a workstation of a textile machine that processes staple fibers. The roller stretching assembly is used for stretching at least one cluster-type staple fiber strand that enters the assembly in a conveying direction. The roller stretching assembly has at least one stretching region, which is defined by a roller assembly at an entrance and a roller assembly at an exit, wherein the roller assembly at the entrance includes a feeding roller and feeding cooperation roller that work together, and the roller assembly at the exit includes a delivering roller and a delivering cooperation roller that work together. The roller stretching assembly includes an annular belt which is wound around the feeding roller and a belt guide member spaced from the feeding roller in the conveying direction so as to be guided. The annular belt is provided with at least one fastened fiber guide element that has at least part of elastic sections and that is fixed in position. During running of the roller stretching assembly, the fiber guide element presses the staple fiber strand facing the section that extending between the feeding roller and the belt guide member, and matches the contour of the annular belt on the at least part of the sections.

Owner:DITF DEUT INST FUR TEXTIL UND FASERFORSCHUNG DENKENDORF

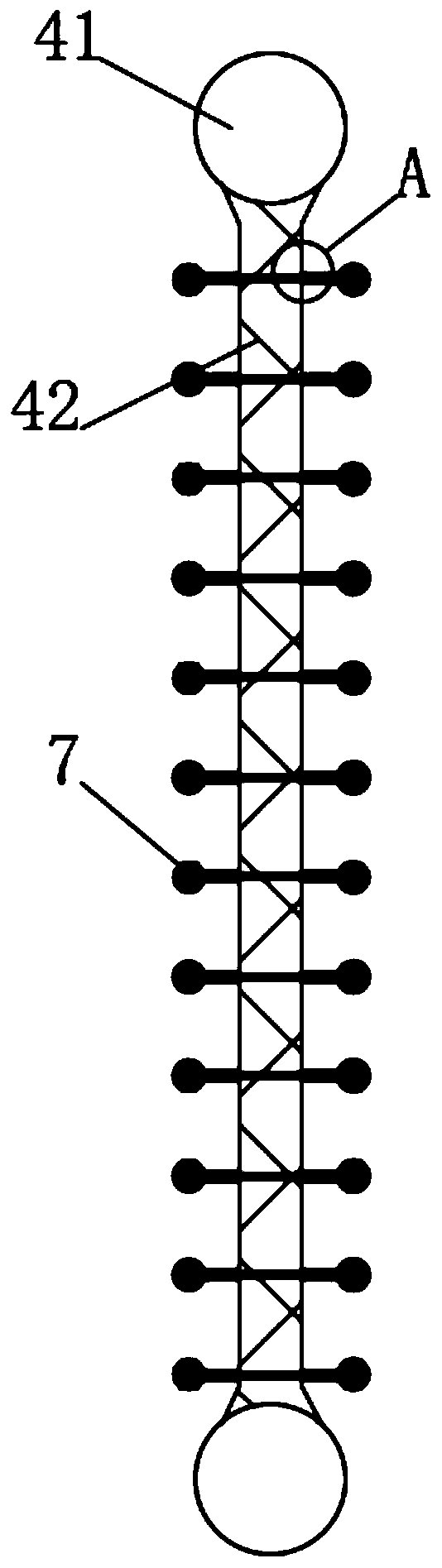

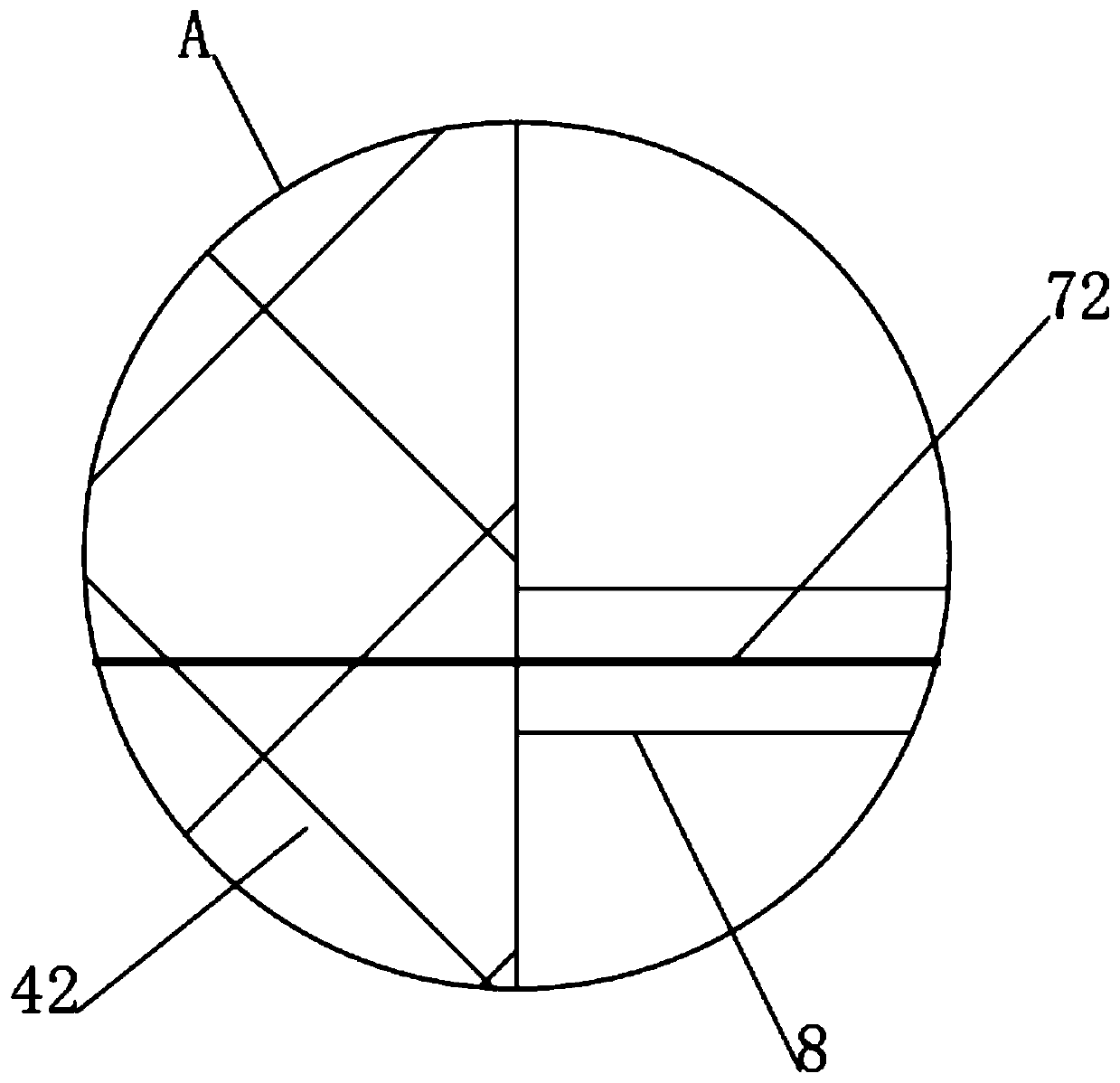

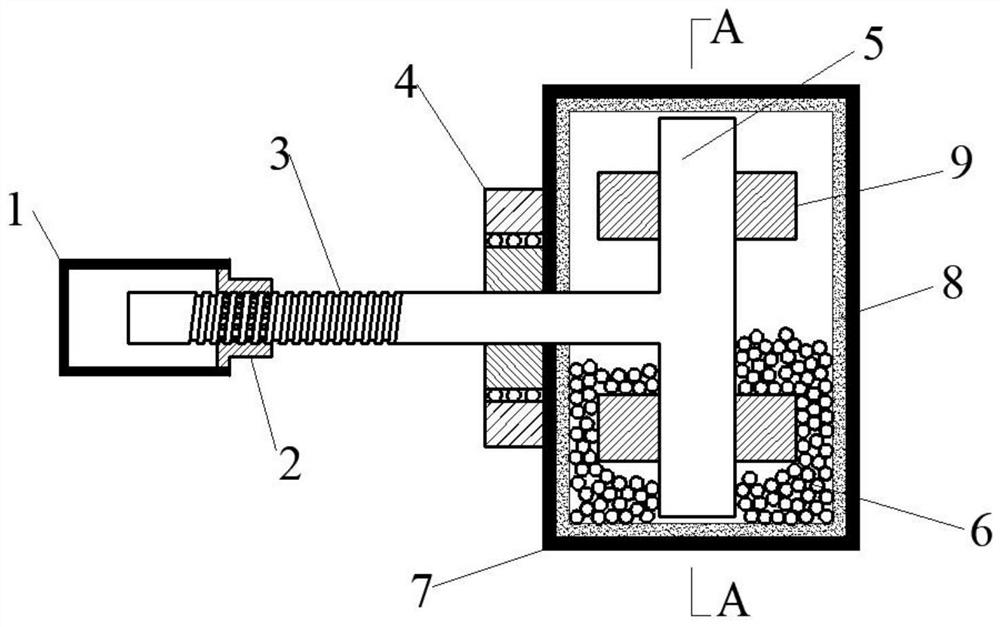

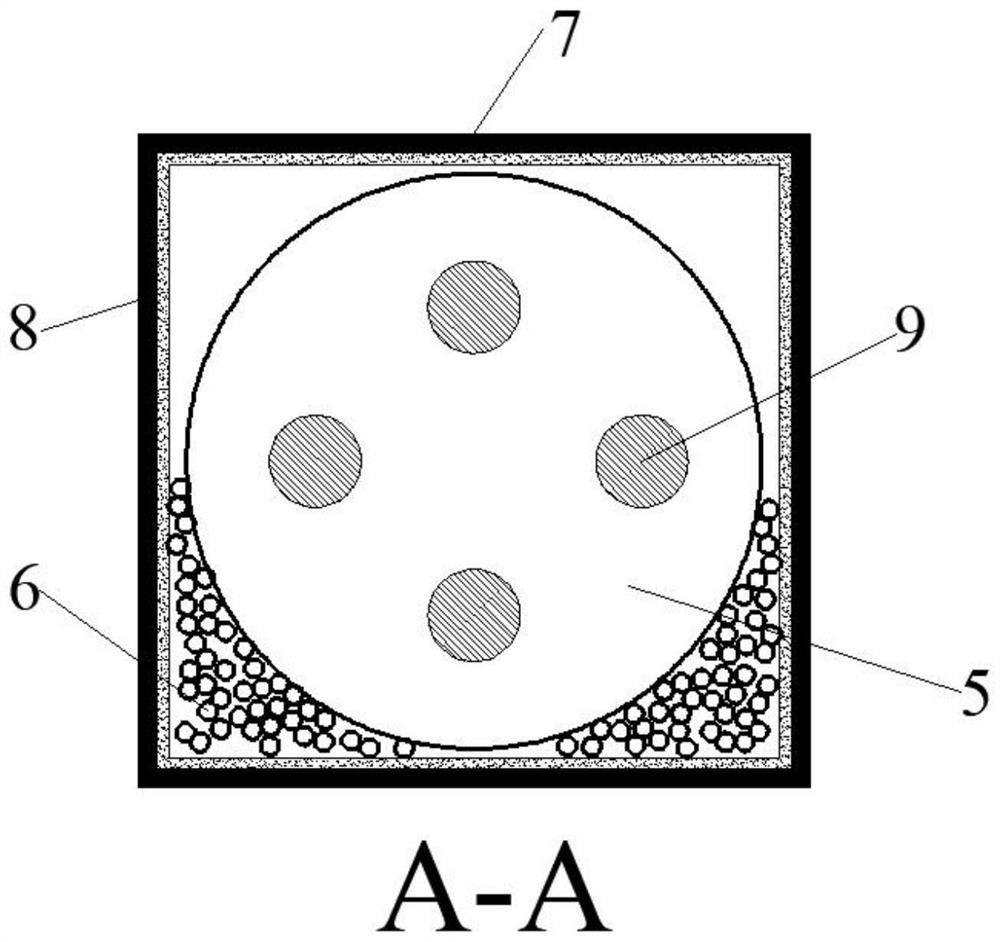

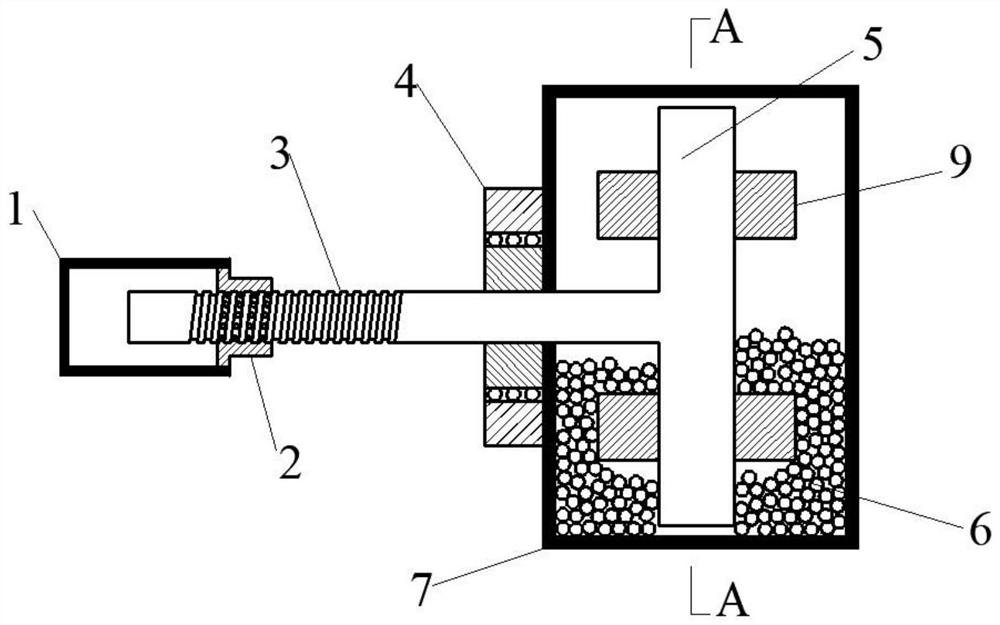

Particle damper

ActiveCN112681856AReduced dynamic responseAchieve frictionProtective buildings/sheltersShock proofingFriction effectEnergy absorption

The invention discloses a particle damper. The particle damper comprises an inerter energy absorption mechanism and a friction energy dissipation mechanism, wherein the inerter energy absorption mechanism is installed on a controlled component and configured to rotate and generate inertia force when the controlled component vibrates, and then vibration energy of the controlled component is absorbed; and the friction energy dissipation mechanism is connected with the action end of the inerter energy absorption mechanism and configured to rotate along with the inerter energy absorption mechanism and generate a collision and / or friction effect when the inerter energy absorption mechanism rotates, so that the energy of the particle damper is consumed. The particle damper has the advantages of simple structure, low price, rich raw materials, convenient and fast installation and the like, has the dual functions of inerter energy absorption and damping particle energy dissipation, and can achieve the function of effectively absorbing and dissipating the energy of a controlled structure when the structure shakes (vibrates) slightly.

Owner:BEIJING UNIV OF TECH +1

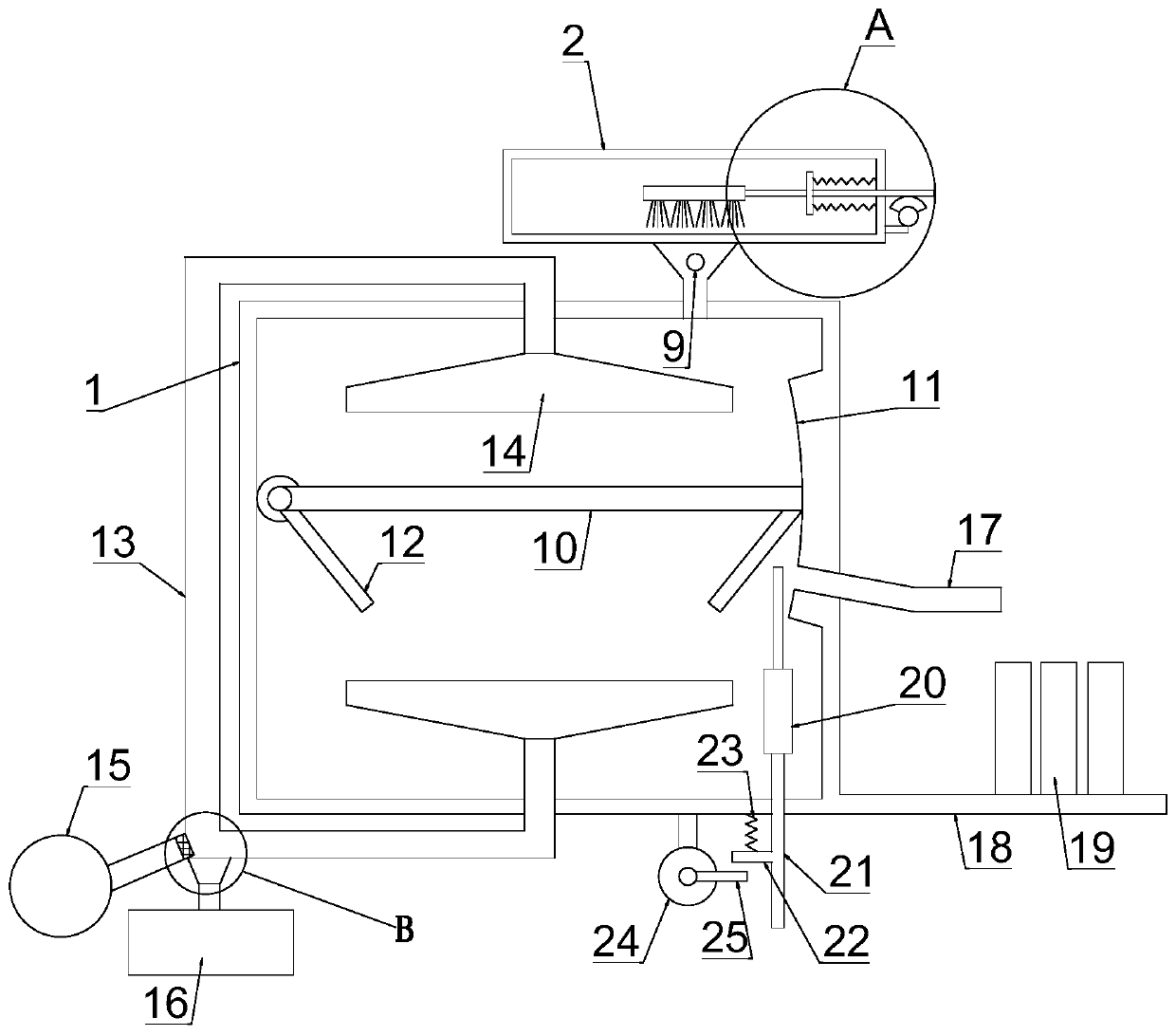

Simulated chewing composite resin material abrasion tester

PendingCN110186801AAchieve biteAchieve frictionInvestigating abrasion/wear resistanceEngineeringHardness

The invention relates to a dental material abrasion tester, in particular to a simulated chewing composite resin material abrasion tester. The simulated chewing composite resin material abrasion tester consists of a moving device, a pair grinding coupling and a frame, wherein the moving device and the pair grinding coupling are connected to the frame; the moving device is connected with a specimenclamp for fixing a specimen; the specimen clamp can be lifted and rotated repeatedly relative to the frame, and can move close to or far from the pair grinding coupling; the pair grinding coupling can rotate relative to the frame; and one side of the pair grinding coupling close to the specimen clamp is provided with an abrasive for simulating food. The simulated chewing composite resin materialabrasion tester provided by the invention has the characteristics that the occlusion contact and friction process between the specimen and the pair grinding coupling are carried out intermittently respectively, and meanwhile a low-hardness soft abrasive and the elastic pair grinding coupling are adopted, so that the technical problems of uneven wear of the specimen and inconsistence between the surface abrasion pattern and the actual clinical situation are solved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

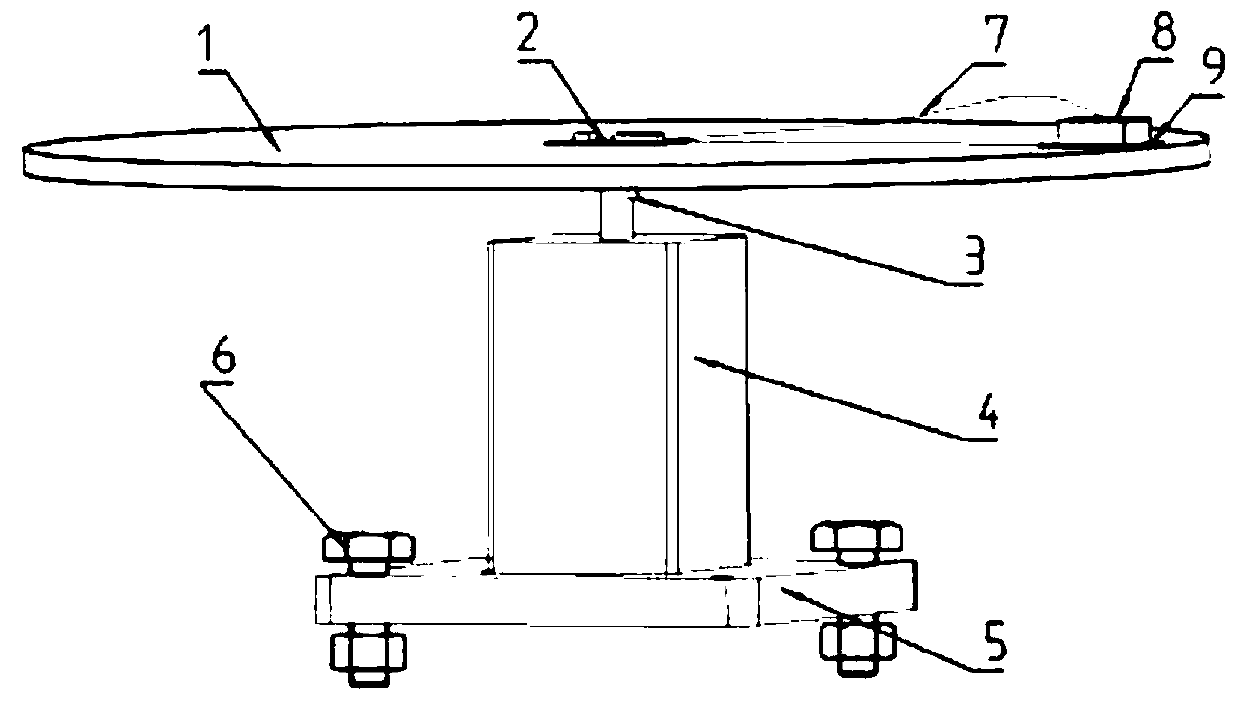

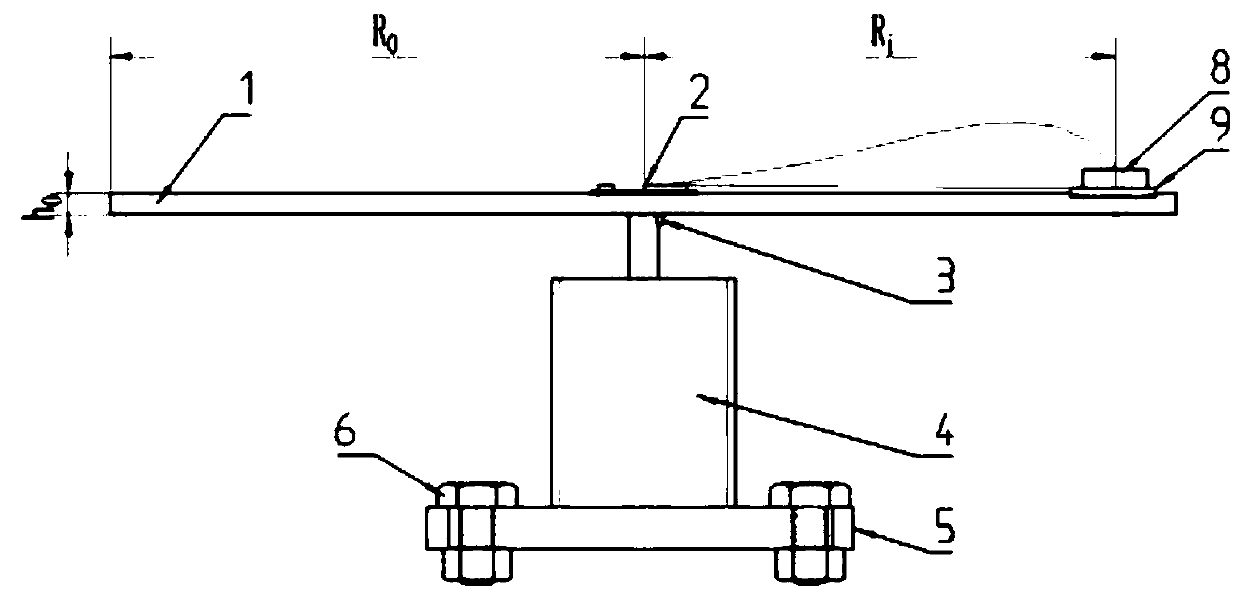

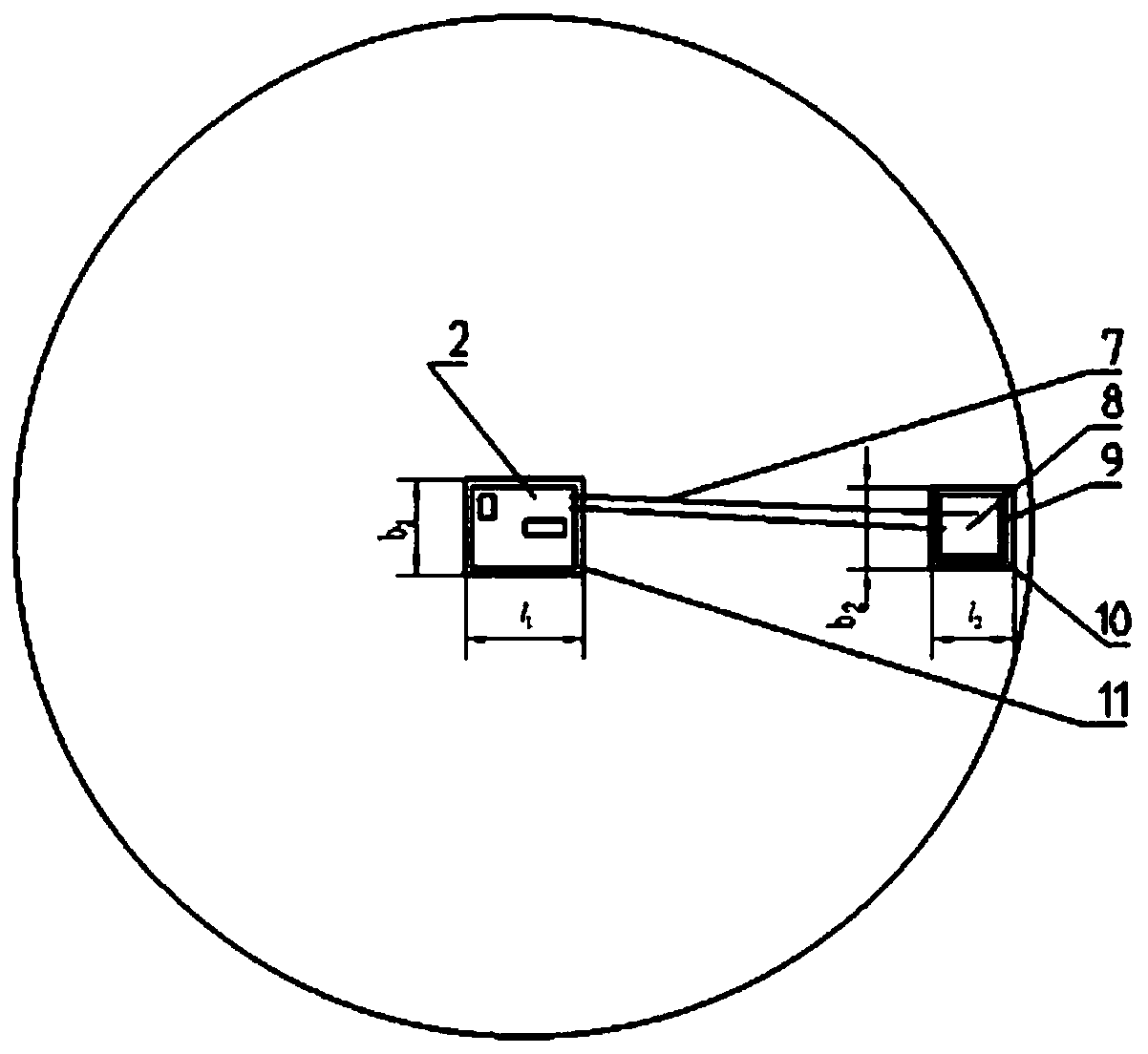

Centrifugal soil tangential adhesion friction test device and its test calculation method

ActiveCN106996844BAchieve frictionRealize quantitative analysisApparatus for force/torque/work measurementCircular discSoil science

The invention discloses a centrifugal soil tangential adhesion friction test device and a test and calculation method thereof. The device is composed of a homogeneous rotating disc, a minimum single-chip microcomputer system, a connecting key, a speed regulating motor, a motor fixing frame and a fixing bolt. The minimum single-chip microcomputer system is fixedly arranged on the homogeneous rotating disc. The homogeneous rotating disc is fixedly arranged on the upper end of the speed regulating motor through the connecting key. The speed regulating motor is fixedly arranged on the motor fixing frame. The fixing frame is fixed on a work surface. The method of recording the state that soil is separated from a soil touch test piece along the tangential direction of circular movement on the soil touch test piece can be realized. Current between the upper and lower ends of wet clay is measured by using the single-chip microcomputer, and the tangential adhesion friction between the tested soil and the soil touch test piece can be calculated by recording the rotating speed of the motor when the soil is separated from the soil touch piece according to a tangential adhesion friction calculation formula. Testing of the tangential adhesion friction between the soil of different properties and parameters and different soil touch materials can be realized.

Owner:JILIN UNIV

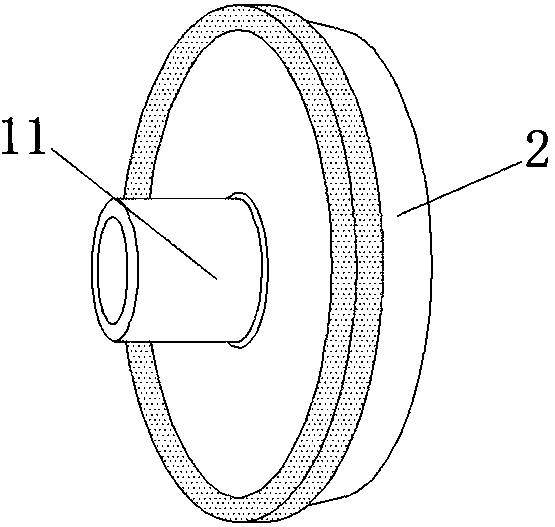

Fuel pomp

InactiveCN1886588AAchieve frictionIncreased abrasive wearRotary current collectorMachines/enginesGraphiteHardness

The invention relates to a fuel pump comprising an electromotive drive that has a commutator (20) and carbon brushes (24, 26) that brush alternately against commutator segments (16, 18) when said commutator (20) is rotated. The aim of the invention is to improve the corrosion resistance and to clean the carbon brushes (24, 26). To achieve this, the commutator segments (16, 18) contain graphite and at least one commutator segment (16, 18) contains graphite and an admixture of a material (30) that has a greater hardness than graphite.

Owner:SIEMENS AG

Water circulation type cooling equipment for three-roller mill

ActiveCN109876889AAvoid wasteful situationsImprove heat dissipation and cooling efficiencyGrain treatmentsArchitectural engineeringElectric machinery

The invention discloses water circulation type cooling equipment for a three-roller mill. The cooling equipment comprises a base, a fixing loop bar and a servo motor; the inside surface of the base isprovided with a connecting shaft of which the outer side is fixedly connected with a first transmission roller, and the outside surface of the first transmission roller is fixedly connected with a convex block; the inside surface of the first transmission roller is provided with heat emission holes, and the first transmission roller is internally provided with a cooling pipe; the inside surface of the right side of the first transmission roller is fixedly connected with a fixing block, and the inside surface of the fixing block is provided with a sealing ring; and the fixing block is internally provided with movable rods. According to the water circulation type cooling equipment for the three-roller mill, the effect of circulating flow of cooling liquid in the cooling pipe is achieved asthe three movable rods are squeezed through second connecting rods in sequence continuously, so that the water circulation type cooling work is performed for the transmission roller in cooperation with the heat emission holes; and the waste of the cooling liquid is avoided while the heat-sink cooling efficiency of the overall device is improved.

Owner:浙江羲和新材料科技有限公司

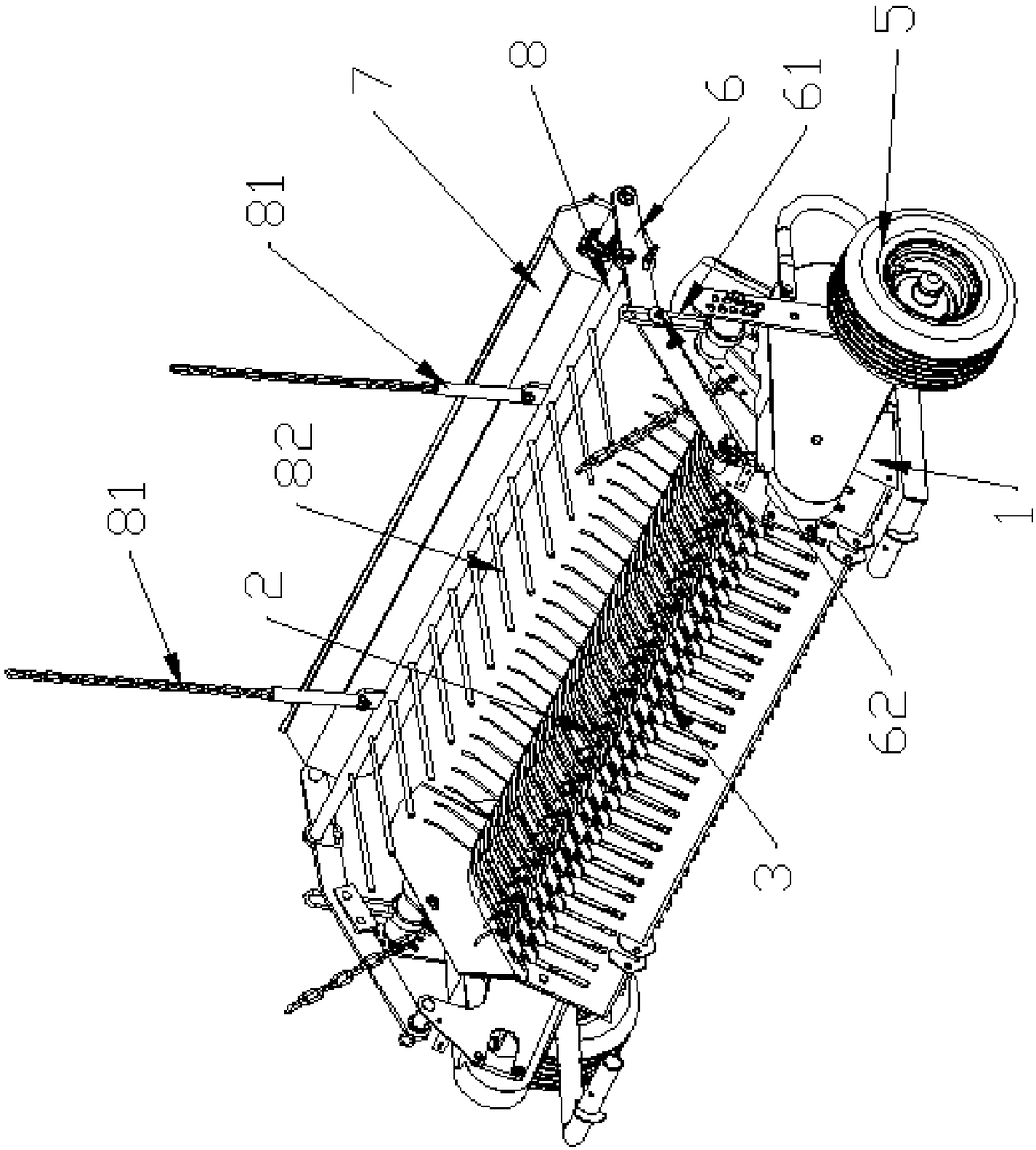

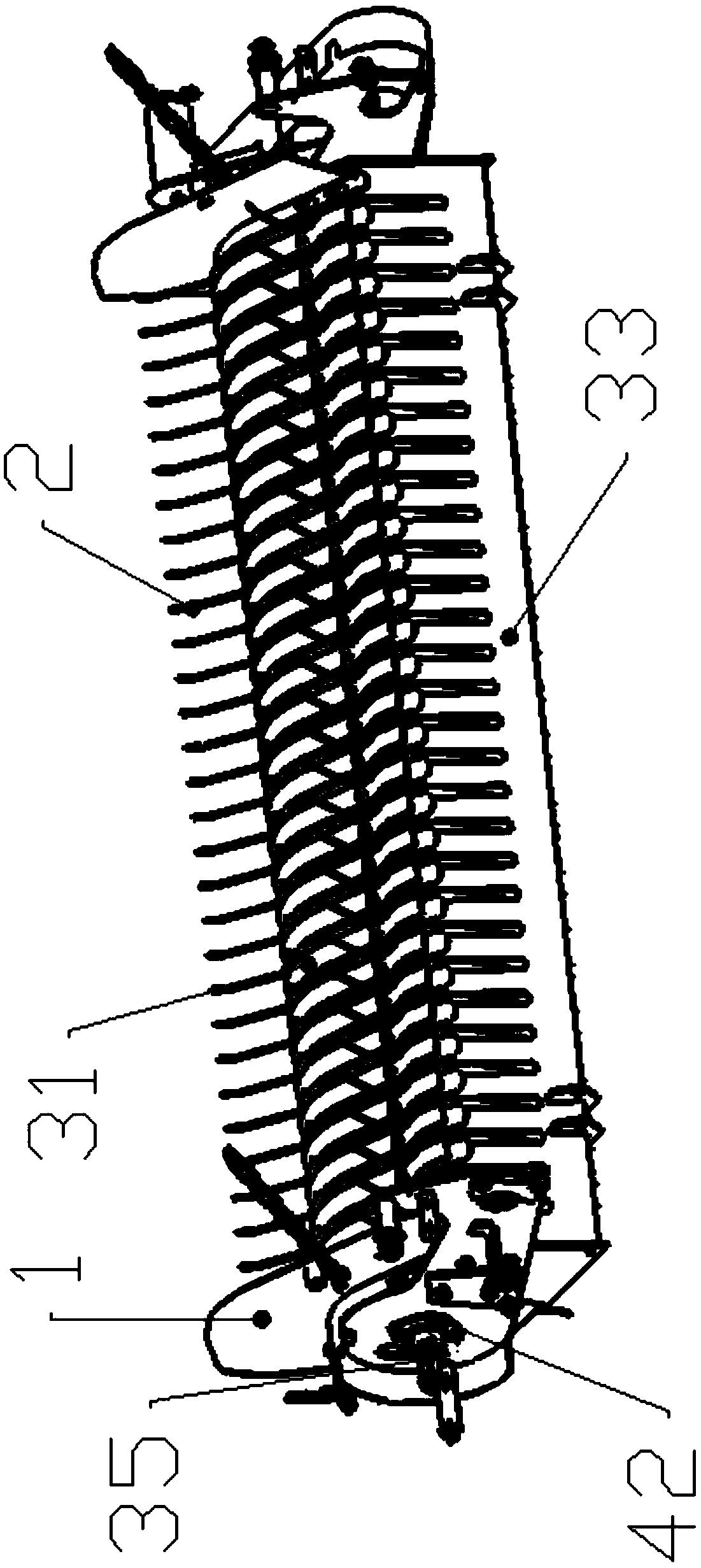

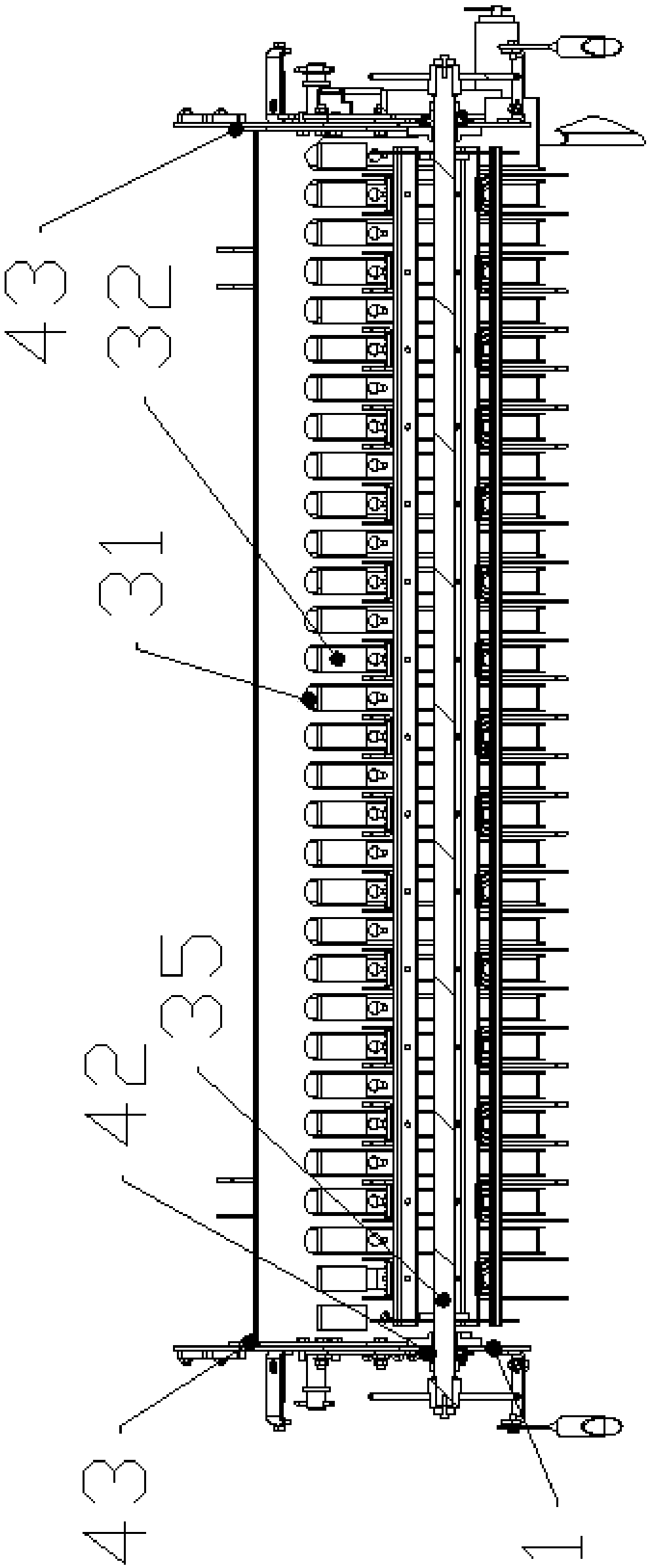

Pickup device for straw baler

PendingCN109328660APrevent upward scatterImprove work efficiencyLoadersEngineeringMechanical engineering

The invention provides a pickup device for a straw baler, and belongs to the field of agricultural baler devices. The pickup device comprises a machine frame, a rotating assembly, retainer assembliesand elastic claw assemblies. The rotating assembly is erected on the machine frame and rotationally connected with the machine frame. The elastic claw assemblies are fixedly arranged on the rotating assembly. The retainer assemblies are arranged on the outer ring of the rotating assembly. The retainer assemblies are arranged between every two adjacent elastic claw assemblies. A follower wheel assembly is arranged at the lower end of the machine frame. Supporting force arms are symmetrically arranged at the upper end of the machine frame. One end of each supporting force arm is hinged to the machine frame. The other end of each supporting force arm is provided with a floating wheel. A floating roller is erected on the symmetrical supporting force arms and rotationally connected with the supporting force arms. A positioning rod is arranged on each supporting force arm and provided with a plurality of comb teeth. The upper end of each positioning rod is provided with a limiting chain connected with a fixing piece. The pickup device is simple in structure, low in cost, high in carding efficiency, not prone to getting stuck, low in failure rate and stable in performance.

Owner:天津威猛机械制造有限公司

Perforating machine fixing device for communication device manufacturing

InactiveCN111660368AImprove buffering effectImprove protectionMetal working apparatusEngineeringMachine

The invention discloses a perforating machine fixing device for communication device manufacturing. The perforating machine fixing device for communication device manufacturing comprises a supportingarm; the bottom of the supporting arm is fixedly connected with an operating table; a perforating device is arranged above the operating table; one side surface, close to the supporting arm, of the perforating device is fixedly connected to the outer surface of the supporting arm; a groove is formed in the upper surface of the operating table; a cavity is formed in the operating table; a fixed block is arranged in the cavity; a first bearing is fixedly embedded into the fixed block; the inner ring of the first bearing is fixedly connected with a positive-negative threaded rod; a second bearingis fixedly embedded into the left inside wall of the cavity; a third bearing is fixedly embedded into the right inside wall of the cavity; one end, close to one end of the second bearing, of the positive-negative threaded rod is fixedly connected to the inner ring of the second bearing; and one end, close to the third bearing, of the positive-negative threaded rod penetrates through the third bearing and extends to the outside of the cavity. The perforating machine fixing device for communication device manufacturing improves the protection on parts, and achieves a fixing effect on the parts.

Owner:陈金杰

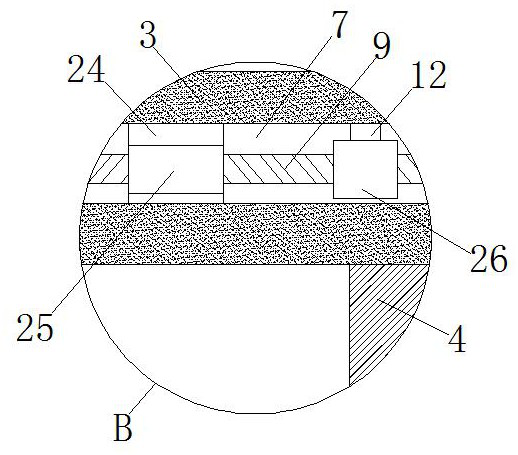

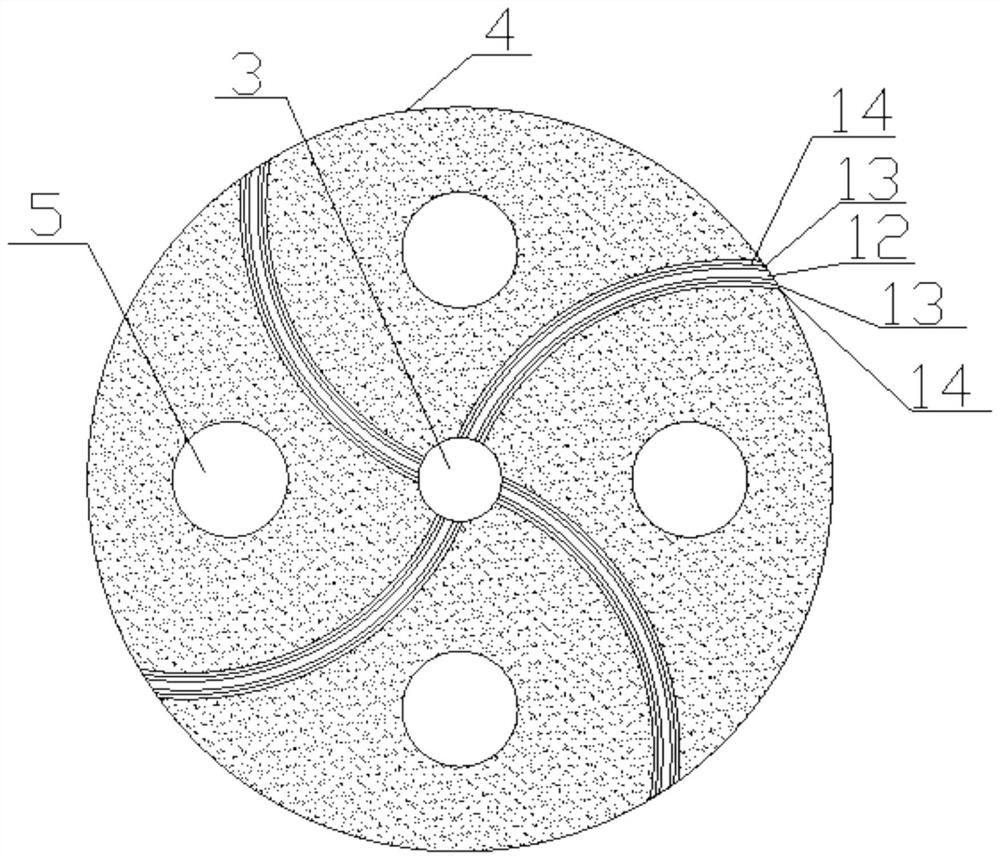

Grinding disc and horizontal grinding machine

PendingCN111940068AExtend your lifeAchieve frictionGrain treatmentsRubber layered productsEngineeringMaterials science

The invention provides a grinding disc used in a horizontal grinding machine. The grinding disc is of a three-layer sandwich structure, a sandwich layer is a first manganese steel layer, two sides ofthe sandwich layer are provided with first composite layers, the side, close to the sandwich layer, of each first composite layer is provided with a first permanent magnet layer, the side, away from the sandwich layer, of each first composite layer is provided with a first rubber layer, and the surface field intensity of each first rubber layer is 10-30 mT. Two sides of the grinding disc are eachprovided with four arc-shaped stirring blades. Each stirring blade is of a three-layer sandwich structure, wherein a sandwich layer of the stirring blade is a second manganese steel layer, two sides of the second manganese steel layer are provided with second composite layers, the side, close to the second manganese steel layer, of each second composite layer is provided with a second permanent magnet layer, the side, away from the second manganese steel layer, of each second composite layer is provided with a second rubber layer, and the surface field intensity of each second rubber layer is10-30 mT. Magnetite layers can be formed through the low field intensity, so that the grinding disc and the stirring blades are protected, and the service life of the horizontal grinding machine is prolonged.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com