Electric connector

A technology of electrical connectors and contactors, applied in the direction of connection, fixed connection, circuit, etc., can solve the problems of inability to realize electrical connection, poor contact, etc., and achieve the effects of preventing peeling, good friction, and realizing design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

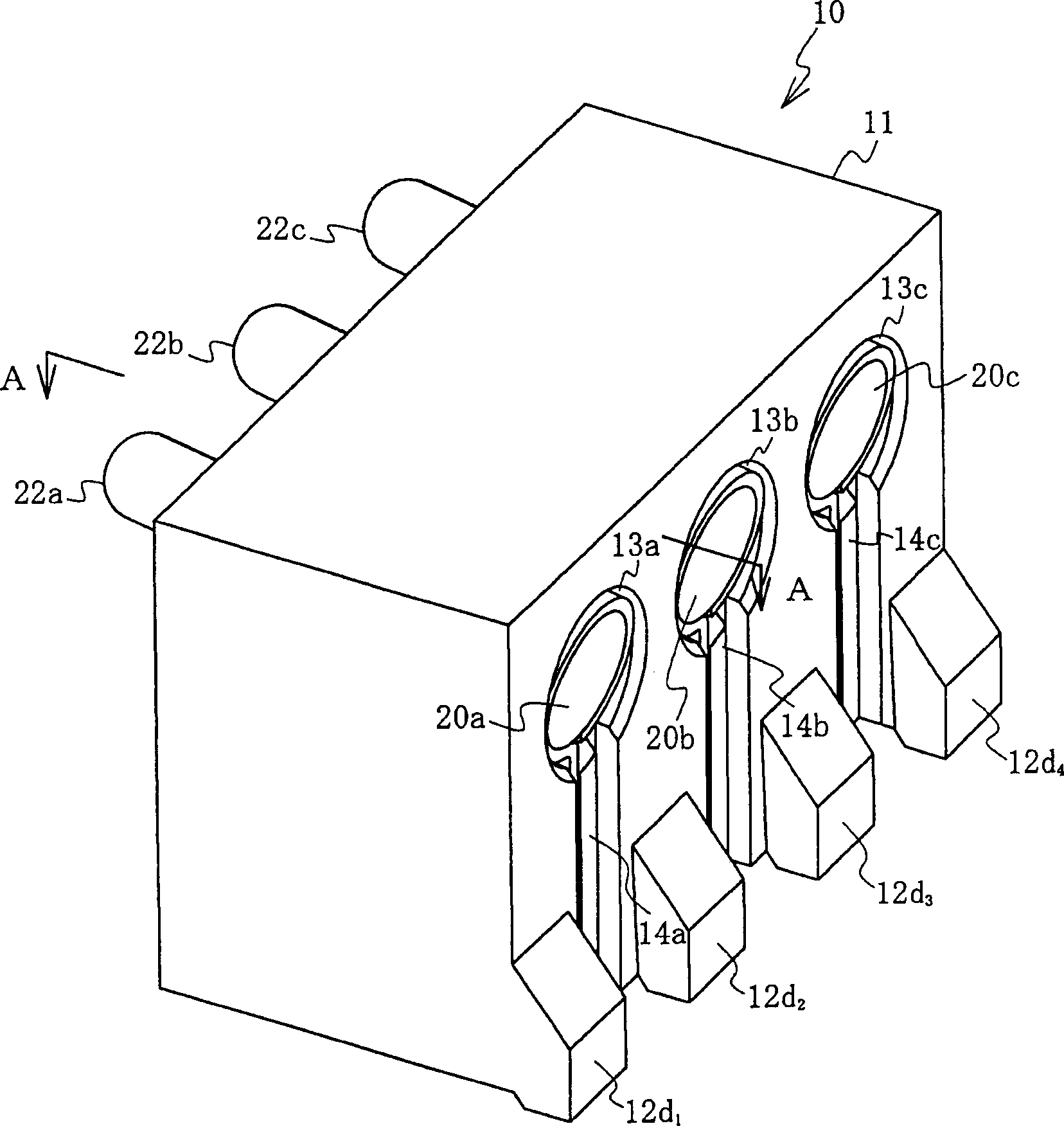

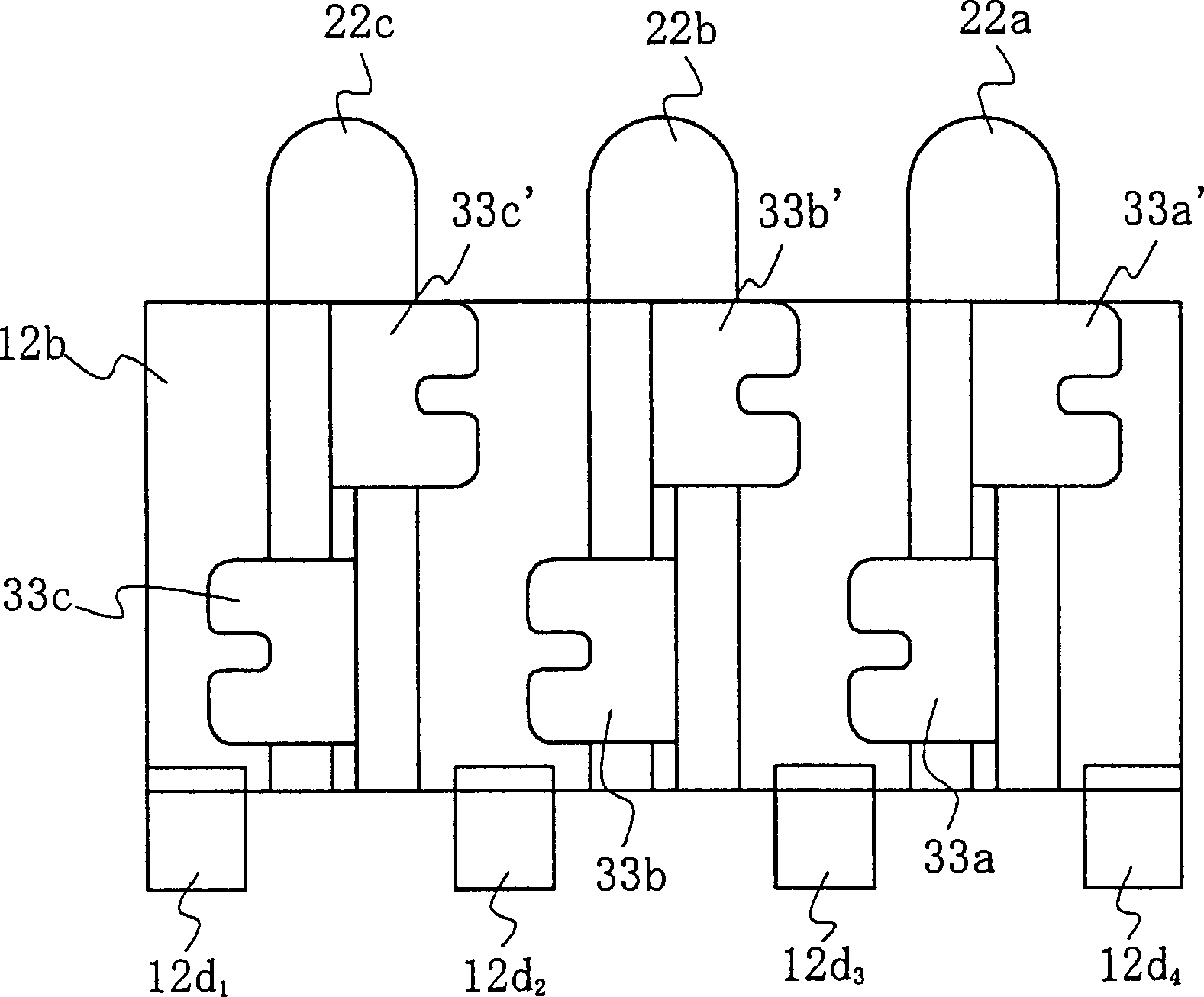

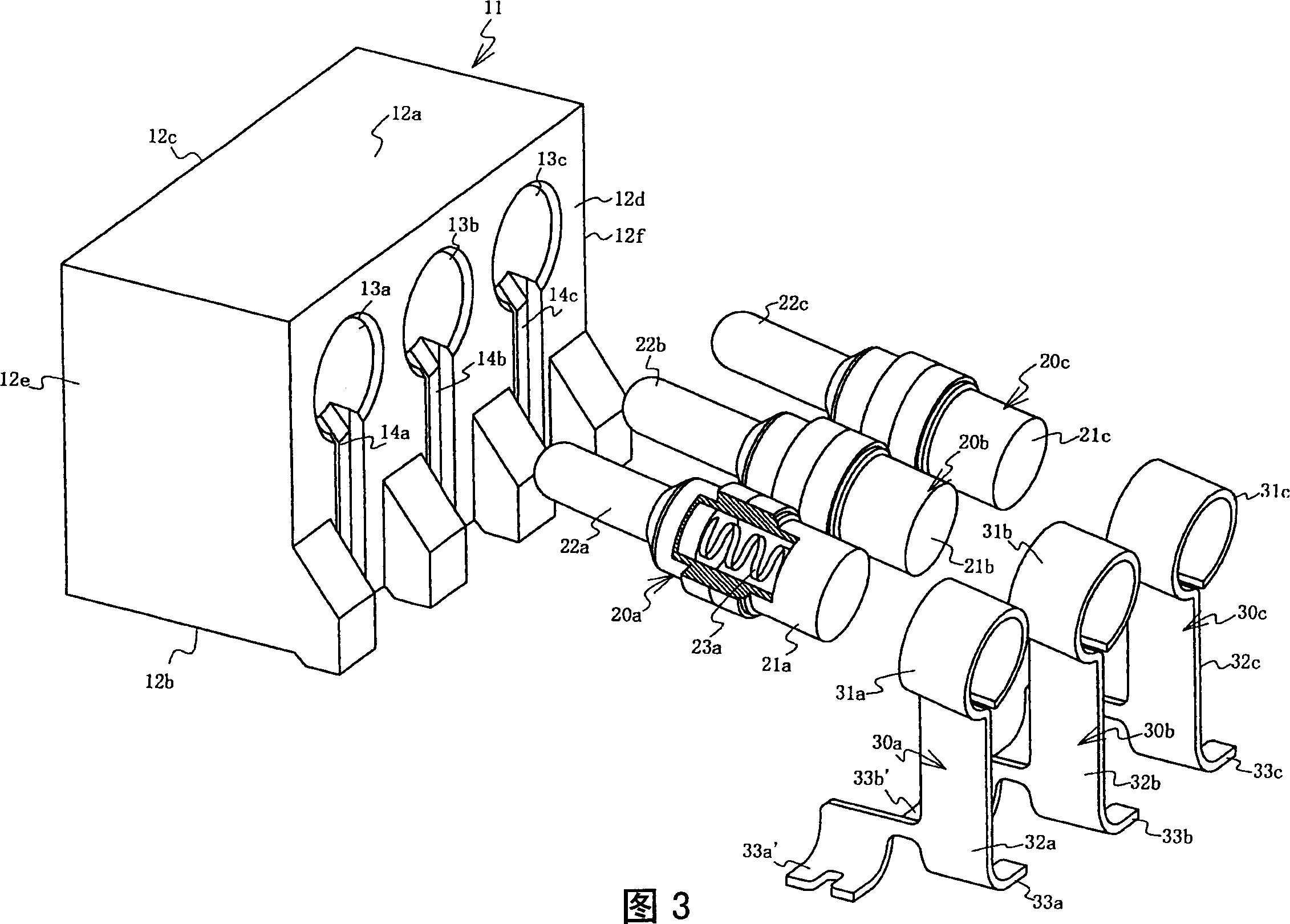

[0034] figure 1 It is a perspective view showing the appearance of the electrical connector of the present invention, figure 2 is the bottom view of the electrical connector, Figure 3 is the figure 1 The exploded perspective view of the electrical connector exploded, Figure 4 along figure 1 The cross-sectional view of the A-A line in Fig. 5 shows the terminal part of Fig. 3, Fig. 5(a) is a left side view, Fig. 5(b) is a front view, Fig. 5(c) is a bottom view, Figure 6 To show the side view of the probe type contactor, Figure 7 It is a side view showing the connection state between the electrical connector and the equipment.

[0035] The electrical connector 10 like figure 1 , shown in FIG. 3 , including a housing 11, the housing 11 has, for example, three through holes 13a-13c; probe-type contactors 20a-20c inserted into each through-hole; terminal parts 30a-20c connected to each probe-type contactor 30c, each of the above-mentioned probe type contacts 20a-20c is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com