Fuel pomp

A technology of fuel pump and commutator plate, applied in the field of fuel pump, can solve problems such as deposition, and achieve the effects of low production, good cleaning and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

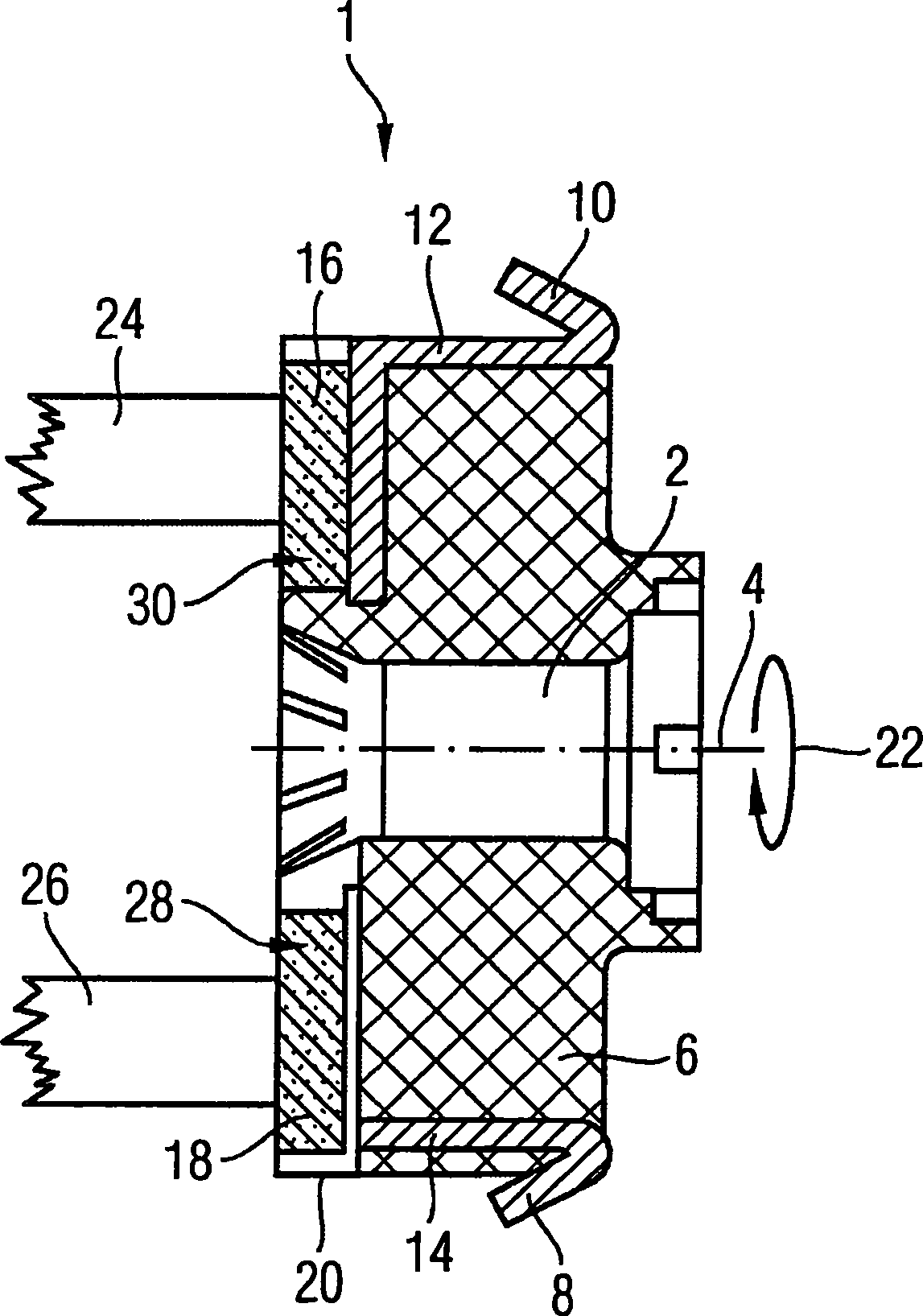

[0016] The figure shows a rotor 1 of a commutator motor (not further shown) of a fuel pump. During fuel pump operation, a rotor 1 with a rotor shaft 2 rotates about a rotor axis 4 and is provided with rotor coils 6 . The ends of the rotor coil 6 are electrically conductively connected to the connection terminals 8 , 10 of the contact pieces 12 , 14 .

[0017] Furthermore, the commutator segments 16 , 18 of a graphite, preferably composed of graphite, coaxially arranged on the rotor shaft 2 are connected to the commutator segments 16 , 18 with the contact segments 12 , 14 . The segments 16 , 18 are thus electrically connected to the rotor coil 6 . The segments 16 , 18 of the commutator 20 are oriented radially away from the commutator axis with respect to the commutator axis which coincides with the rotor axis 4 . When the rotor 1 rotates (marked with arrow 22) and thus the commutator 20 rotates, the carbon brushes 24, 26 preloaded by means of spring means (not shown) slide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com