Floating cylinder liner mechanism for friction test of cylinder liner and piston in ignition state

A cylinder liner and friction technology, applied in the field of diesel engine testing, can solve problems such as the inability to reflect the influence of load friction work, achieve safe and reliable friction and friction power consumption testing, low transformation and processing costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

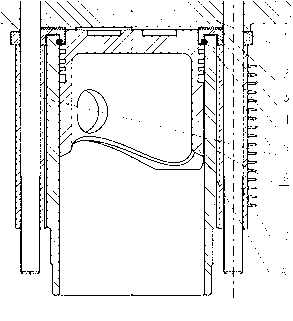

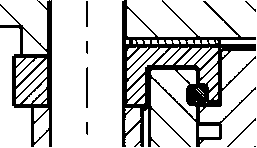

[0017] Such as figure 1 As shown, a floating cylinder liner mechanism for testing the friction between the cylinder liner and the piston in the ignition state, which includes a nested cylinder head 1, a sealing copper pad 2, a nested intermediate body 3, a sealing ring 4, a support guide cylinder 5, a cylinder Sleeve 6, cylinder head bolt 7, piston 8, upper embedded seam 9, stepped inner groove 10, characterized in that the lower end of the nested cylinder head 1 is connected to the upper end of the nested intermediate body 3 through the upper embedded seam 9, and the copper is sealed The pad 2 is connected between the nested cylinder head 1 and the nested intermediate body 3, and the nested intermediate body 3 is provided with an upper embedding spigot 9 and a stepped inner groove 10, and the stepped inner groove of the nested intermediate body 3 10 is connected with the cylinder liner 6; the cylinder head bolt 7 is sequentially connected with the nested cylinder head 1, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com