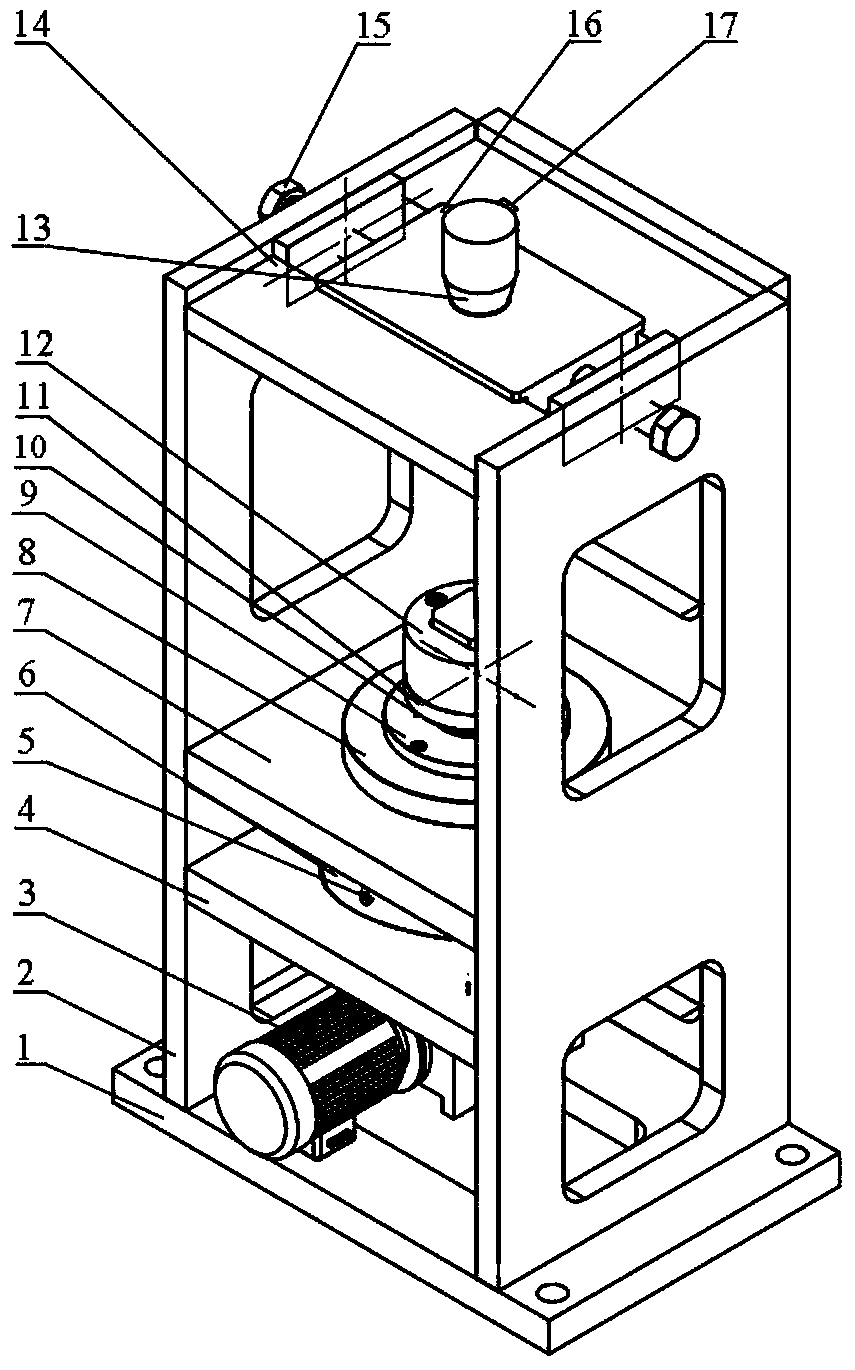

Impact friction fatigue testing machine

A fatigue testing machine, impact friction technology, applied in the direction of testing wear resistance, using repetitive force/pulse force to test the strength of materials, etc., can solve the problems of single cyclic load, can not realize loading under complex force conditions, and achieve reliable movement. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Utilize the present invention to carry out the impact friction fatigue test to the high manganese steel used for the frog, and the technological parameter is:

[0034] Rotary friction system speed: 28rpm;

[0035] Shock Loading System Shock Force: 10 4 N;

[0036] Impact frequency: 29HZ;

[0037] Test temperature: 25°C;

[0038] Test time: 6h;

[0039] The structure of high manganese steel for frogs is a single-phase austenite structure obtained by water quenching, with an average grain size of 100 μm. The surface of the sample is polished.

[0040] After treatment, a small amount of impact friction fatigue cracks and spalling occurred on the surface of the sample, such as Figure 7 shown.

Embodiment 2

[0042] Utilize the present invention to carry out the impact friction fatigue test to the high manganese steel used for the frog, and the technological parameter is:

[0043] Rotary friction system speed: 28rpm;

[0044] Shock Loading System Shock Force: 10 4 N;

[0045] Impact frequency: 29HZ;

[0046] Test temperature: 25°C;

[0047] Test time: 10h;

[0048] The structure of high manganese steel for frogs is a single-phase austenite structure obtained by water quenching, with an average grain size of 100 μm. The surface of the sample is polished.

[0049] After treatment, a large number of impact friction fatigue cracks and peeling occurred on the surface of the sample, such as Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com