Simulated chewing composite resin material abrasion tester

A composite resin and wear test technology, which is applied in the field of medical devices, can solve the problems of inconsistent wear methods and results of test pieces, uneven wear of test pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

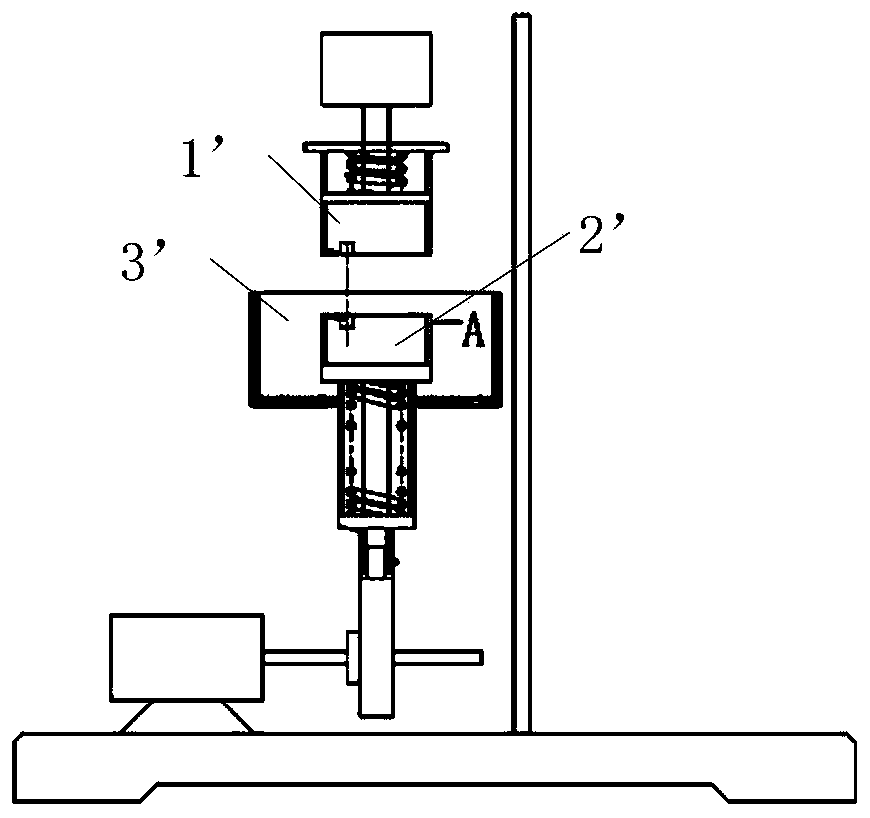

[0066] In the prior art, the upper and lower groups of test pieces are worn along the fixed axis, so that the wear amount of the test piece close to the axis of the maxillary simulation mechanism is small, and the wear amount of the part far away from the axis is large, so that the wear of the test piece There are unidirectional wear marks on the worn surface, and the wear damage pattern is directional, resulting in uneven wear on the surface of the specimen, which is not conducive to the measurement of the wear test results.

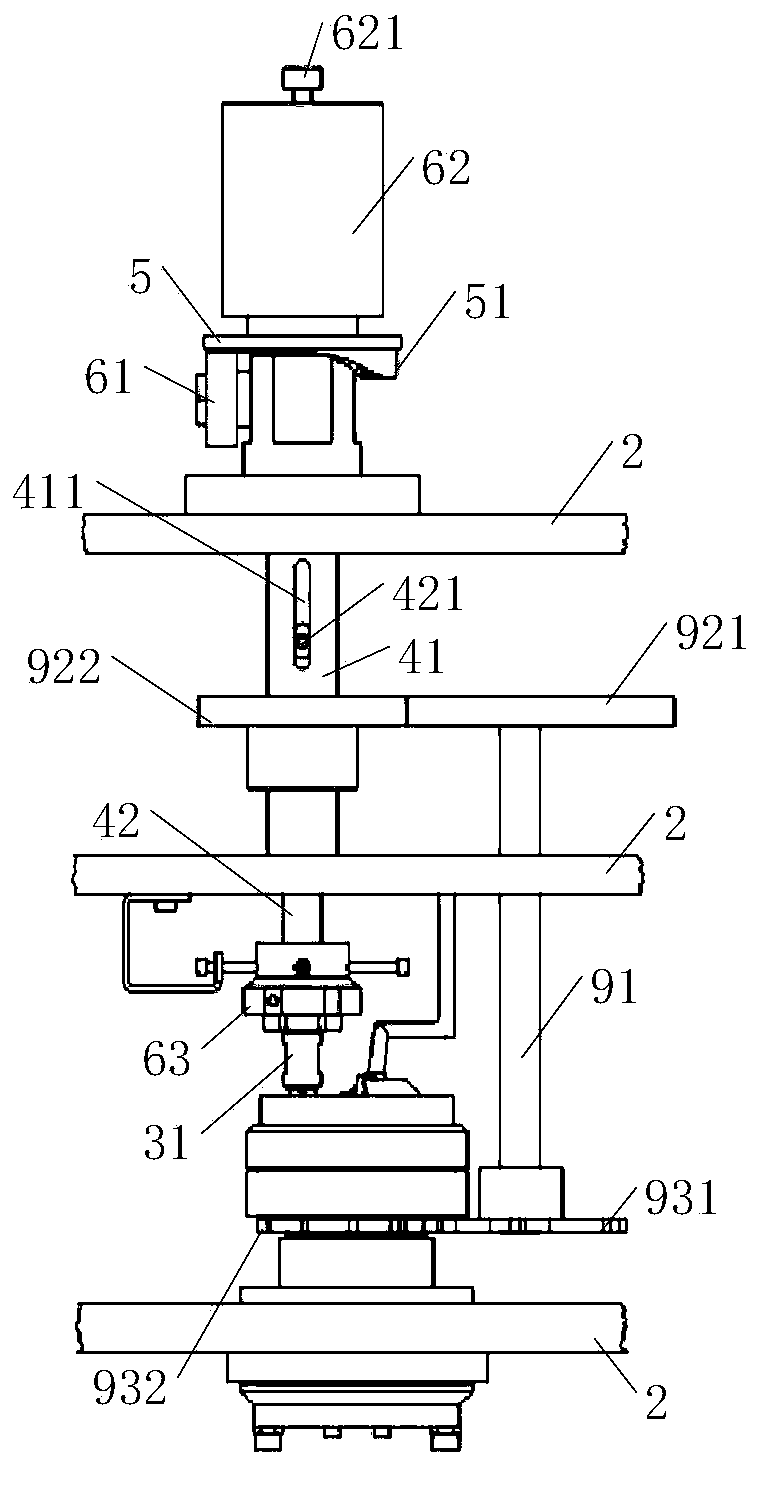

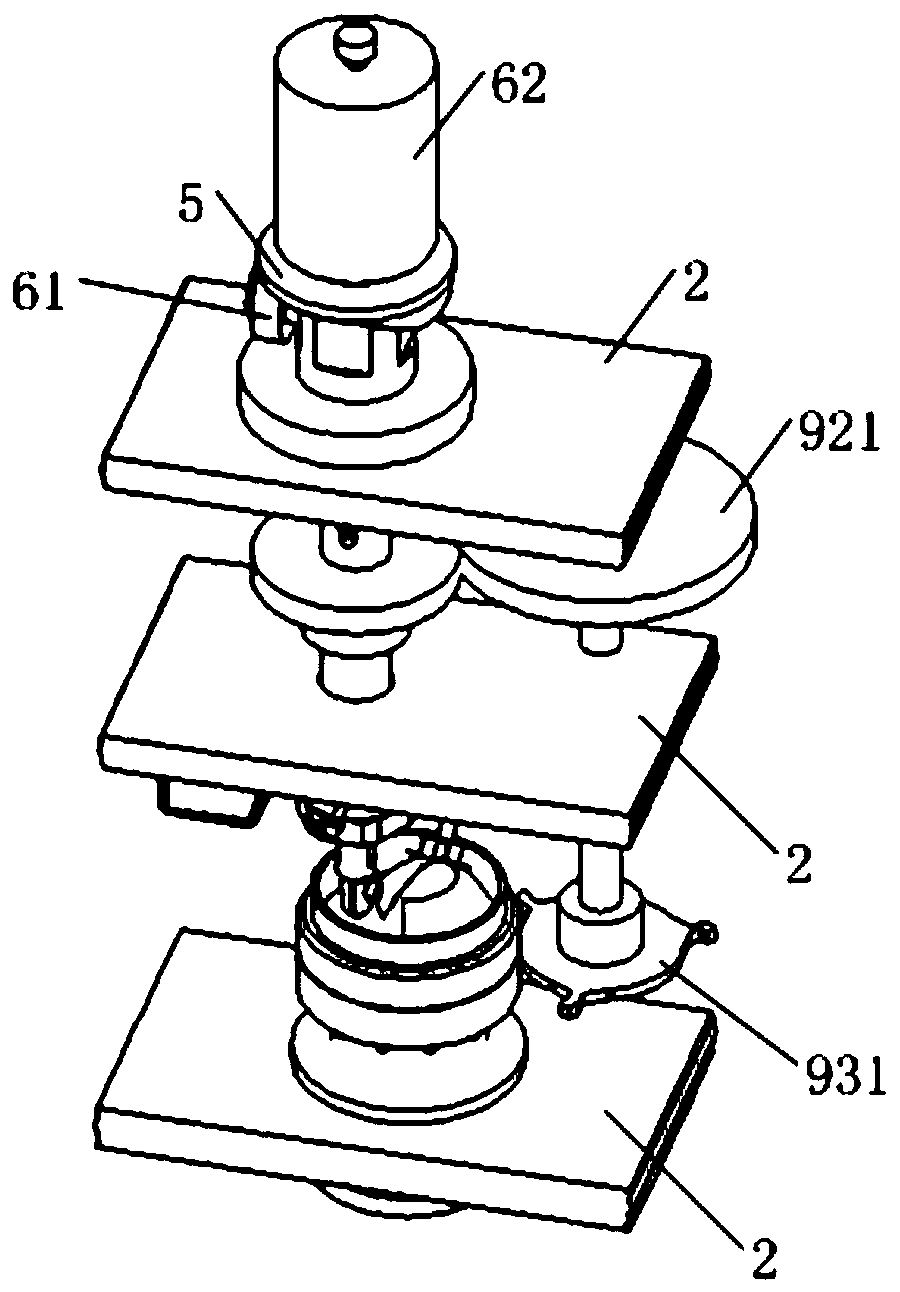

[0067] For the above problems, see Figure 2-Figure 10 As shown, the present embodiment provides a simulated chewing type composite resin material abrasion tester, the simulated chewing type composite resin material wear tester includes a movement device, a pair of grinding couples 1 and a frame 2, and the movement device and the pair of grinding pairs The pieces 1 are all connected to the frame 2; the moving device is connected with a test piece clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com