Rolling shaft type tongs

A technology of pliers and rollers, applied in the field of pliers, which can solve the problems of excessive bite of the pliers mouth, damage to objects, and the inability of users to cut objects easily, so as to achieve the effect of convenient use and prevention of damage to objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

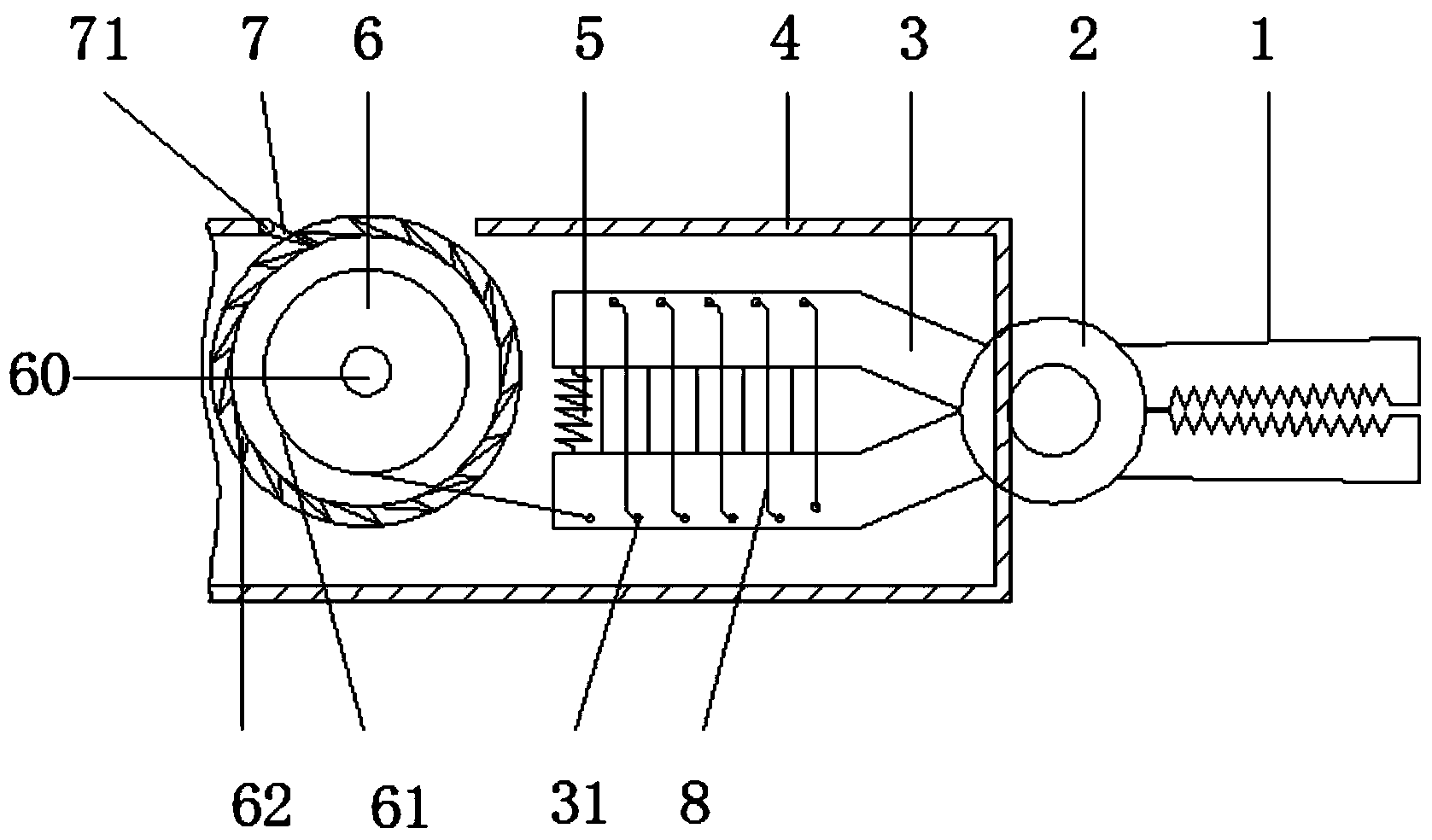

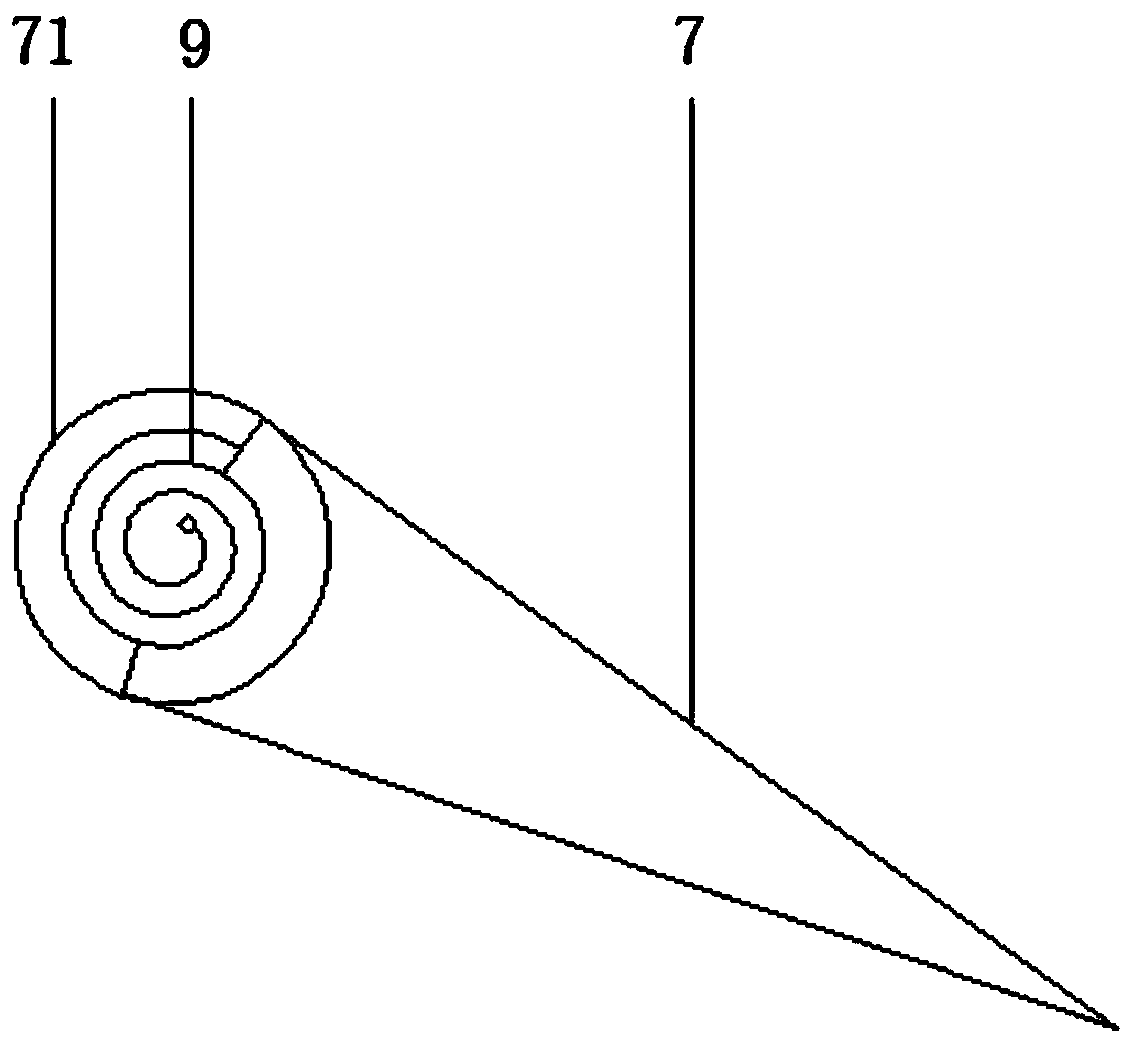

[0013] exist figure 1 , figure 2 In the embodiment shown, the roller type pliers include a pliers mouth 1, a pliers cheek 2, a handle 3, and a casing 4 surrounding the handle; the ends of the two arms of the handle 3 are connected to a compression spring 5; The two ends are respectively connected to the two arms of the handle 3; the two arms of the handle 3 each have a row of through holes 31 evenly arranged in the axial direction, and there is a metal wire 8 between the two arms of the handle 3, and the metal The wire 8 forms a spiral shape and passes through each of the through holes 31 in turn. The edge of the through hole 31 is rounded, and the metal coil is wound on the handle 3 for 5 times. The rounded shape can effectively reduce the metal The frictional force of the wire 8 sliding at the through hole 31; one end of the metal wire 8 is fixed on the handle 3, and the other end is connected to a wire winding reel 6 with a wire winding slot 61; the wire reel 6 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com