Eccentric bearing eccentric distance image alignment and press fitting system

An eccentric bearing and eccentric distance technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult press-fitting accuracy, and achieve the effect of accurate alignment angle, simple structure and excellent speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

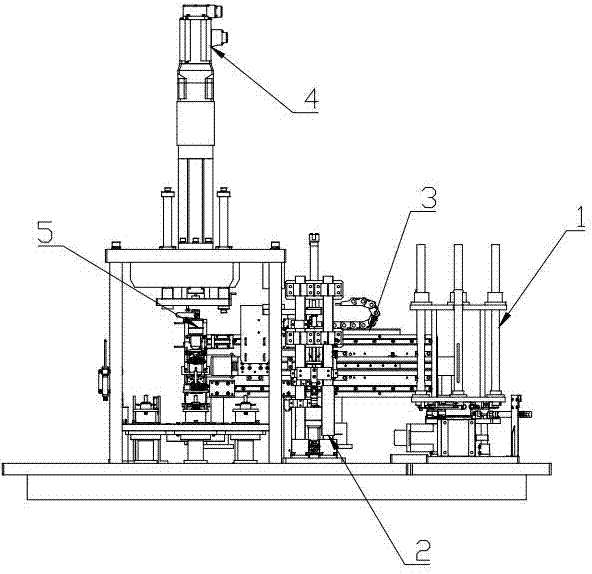

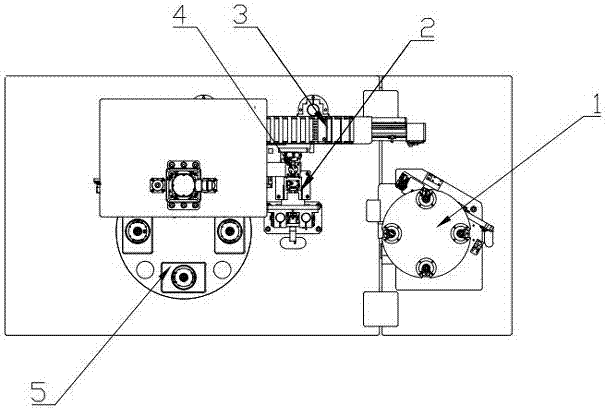

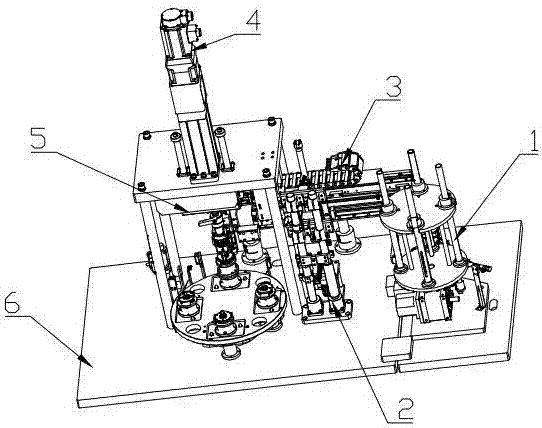

[0039] According to attached Figure 1~3 , the eccentric bearing eccentric distance image alignment and press-fitting system in this embodiment specifically includes a support platform 6 on which the eccentric bearing feeding mechanism 1, alignment mechanism 2, transfer mechanism 3 and press-fitting mechanism are sequentially arranged. Mechanism 5 realizes the continuous operation of the four processes of continuous feeding of eccentric bearings, image alignment, station transfer, and press-fit assembly, and completes the automatic assembly system for eccentric bearings.

[0040] Among them, the feeding mechanism 1 takes out the eccentric bearings one by one and continuously feeds them to the transfer mechanism 3; When the eccentric bearing is sent to the alignment mechanism 2, the bearing of the alignment mechanism 2 is also sent to the press-fit mechanism 5; the alignment mechanism 2 scans the outer elliptical contour of the bearing based on the center of the inner circle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com