An anti-loosening tail cap mechanism and its lighting device

A technology of anti-loosening and tail cover, which is applied in the direction of lighting devices, lighting auxiliary devices, electric lighting devices with built-in batteries, etc., can solve the problems of poor contact and easy loosening of the tail cover mechanism, and achieve good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

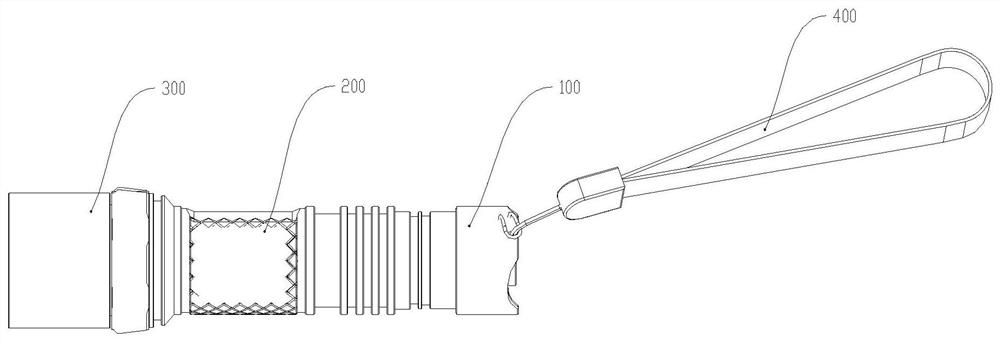

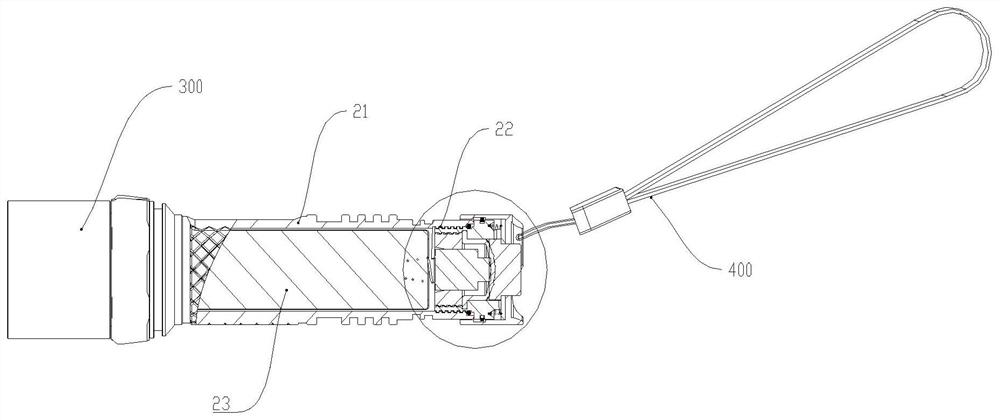

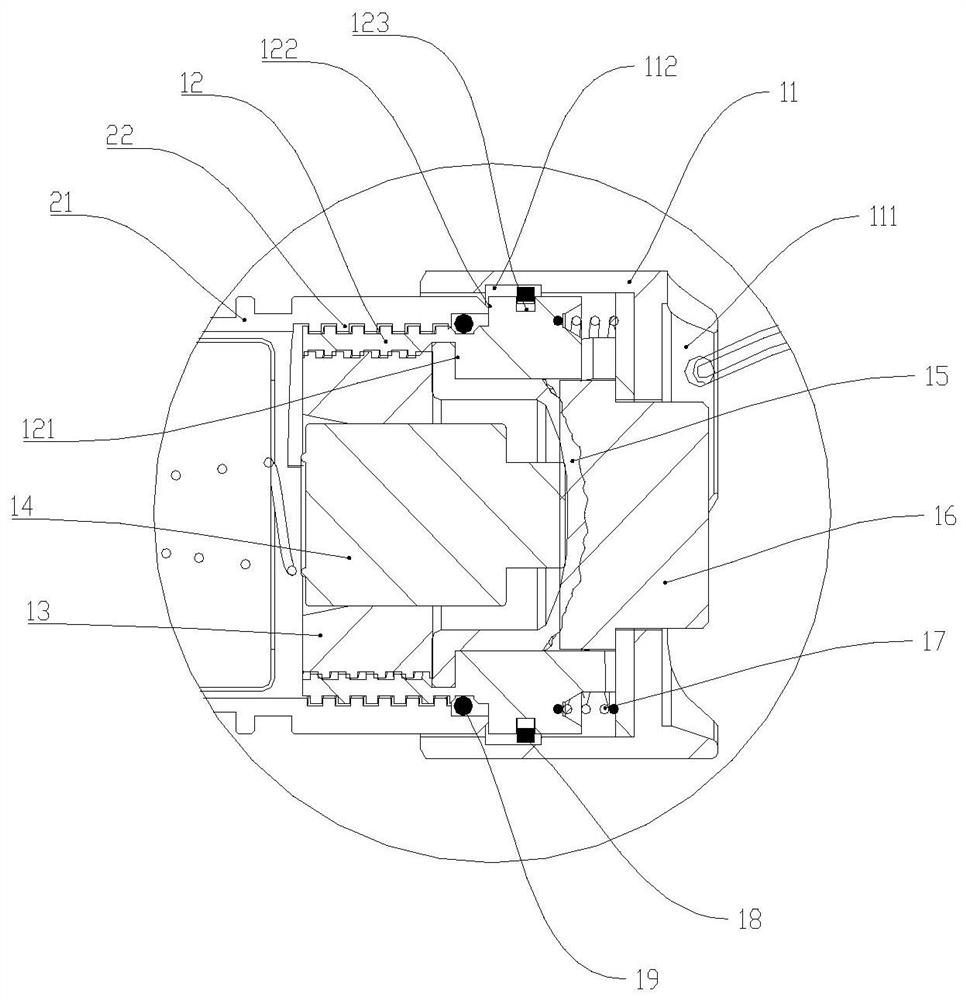

[0021] The present invention will be further elaborated below with reference to the accompanying drawings.

[0022] Please refer to the attached figure 1 To attach Figure 5 , in this embodiment, the anti-loosening tail cap mechanism includes: a tail cap 11, the tail cap 11 includes a cylindrical cover, the bottom of the cover is provided with a cover bottom, and the bottom of the cover is provided with a tail button for piercing 16 through holes. The outer cover conductive connection ring 12 located in the tail cover 11, a snap ring 18 is also provided between the inner wall of the tail cover 11 and the inner wall of the outer cover conductive connection ring 12, through the snap ring 18, so that the tail cap 11 is clamped on the outer cover conductive connecting ring 12 to limit the tail cover 11 to rotate arbitrarily around the axial direction without moving back and forth. Specifically, the snap ring 18 is a C-shaped snap ring, and the conductive connection ring 12 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com