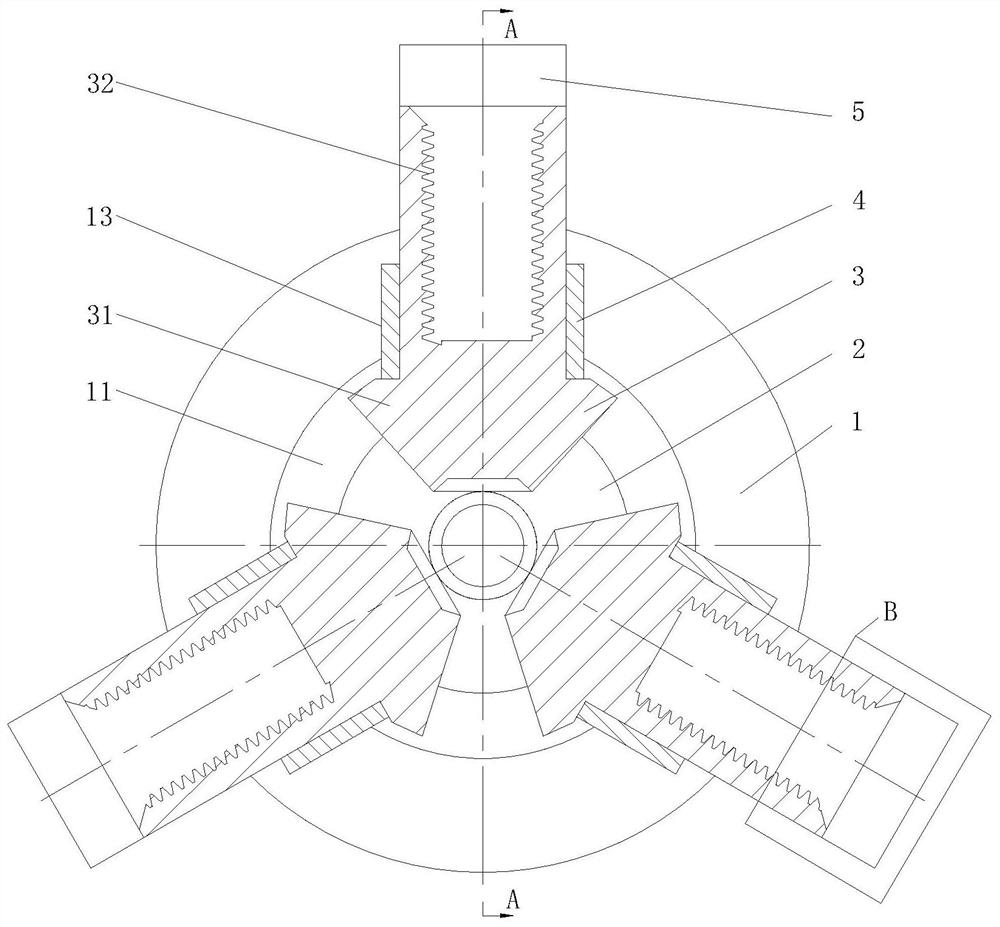

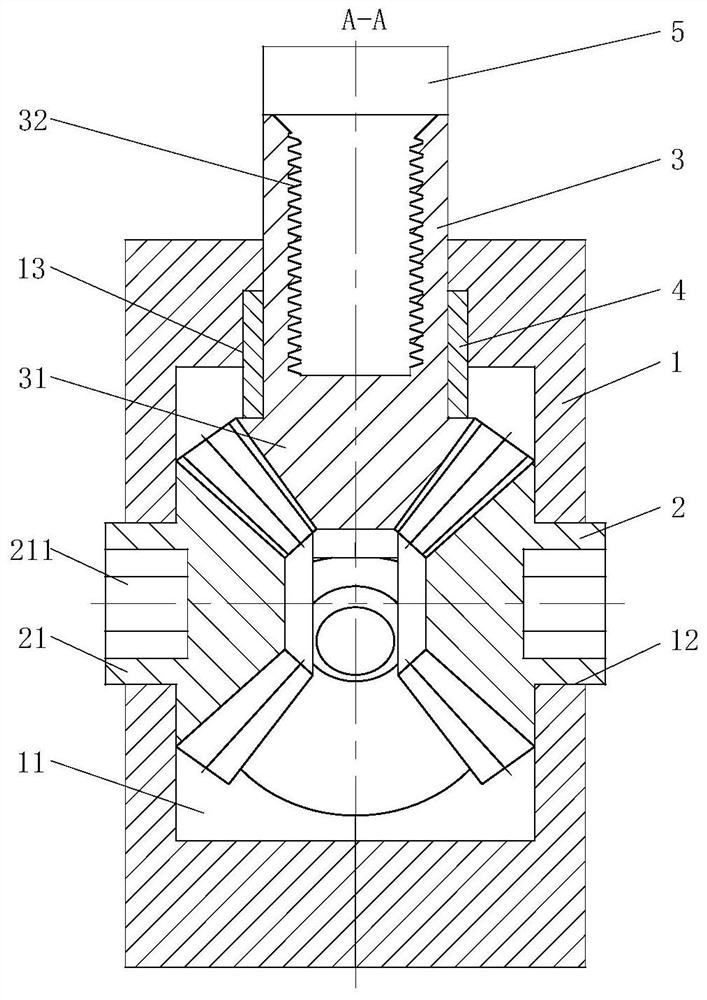

A herringbone steel bar quick connection sleeve

A quick connection and herringbone technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of cumbersome operation, complex structure, and affecting the connection efficiency of steel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

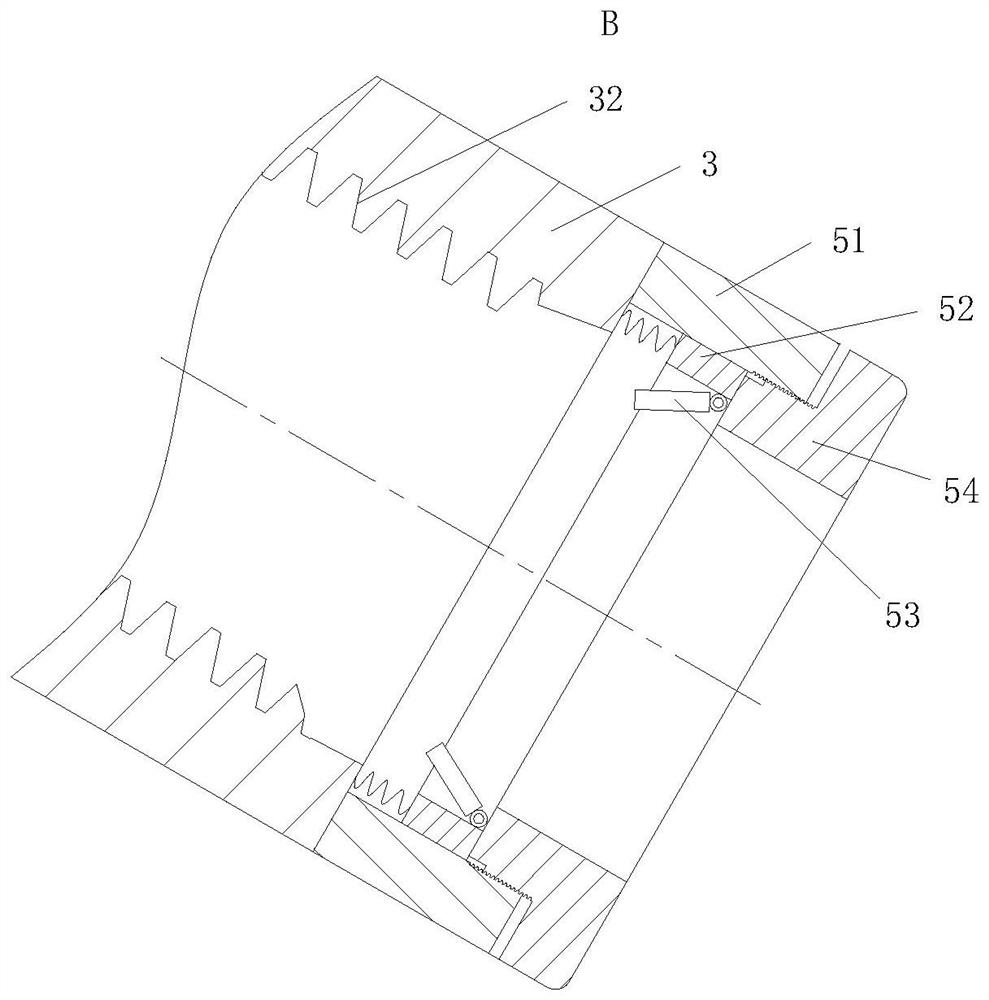

[0028] When working, insert the steel bar into the transitional helical module 5, and the transitional helical module 5 realizes the clamping of the steel bar, and then inserts the inner hexagonal wrench into the inner hexagonal concave hole 211 at the end of the short shaft 21 of the driving bevel gear 2 to drive the driving bevel gear 2 Rotate, drive bevel gear 2 to drive threaded pipe 3 to rotate through gear meshing, threaded pipe 3 drives transitional helical module 5 to rotate, transitional helical module 5 transmits the steel bar to the threaded blind hole 32 of threaded pipe 3, and then realizes the connection between the steel bar skeleton Herringbone connection, at the same time, the three steel bars can be directly inserted into the sleeve without external force clamping, and synchronous locking can be realized; the first implementation of the transitional helical module 5: after the steel bar is inserted into the transitional helical module 5, the other end of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com