High-precision and low-energy-consumption high-speed air floating type electric spindle

A low-energy, high-precision technology, used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems that the air-floating spindle cannot meet the needs of the market and the air consumption of the spindle is large, and achieve high machining accuracy and The effect of processing efficiency, uniform annular gas film and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

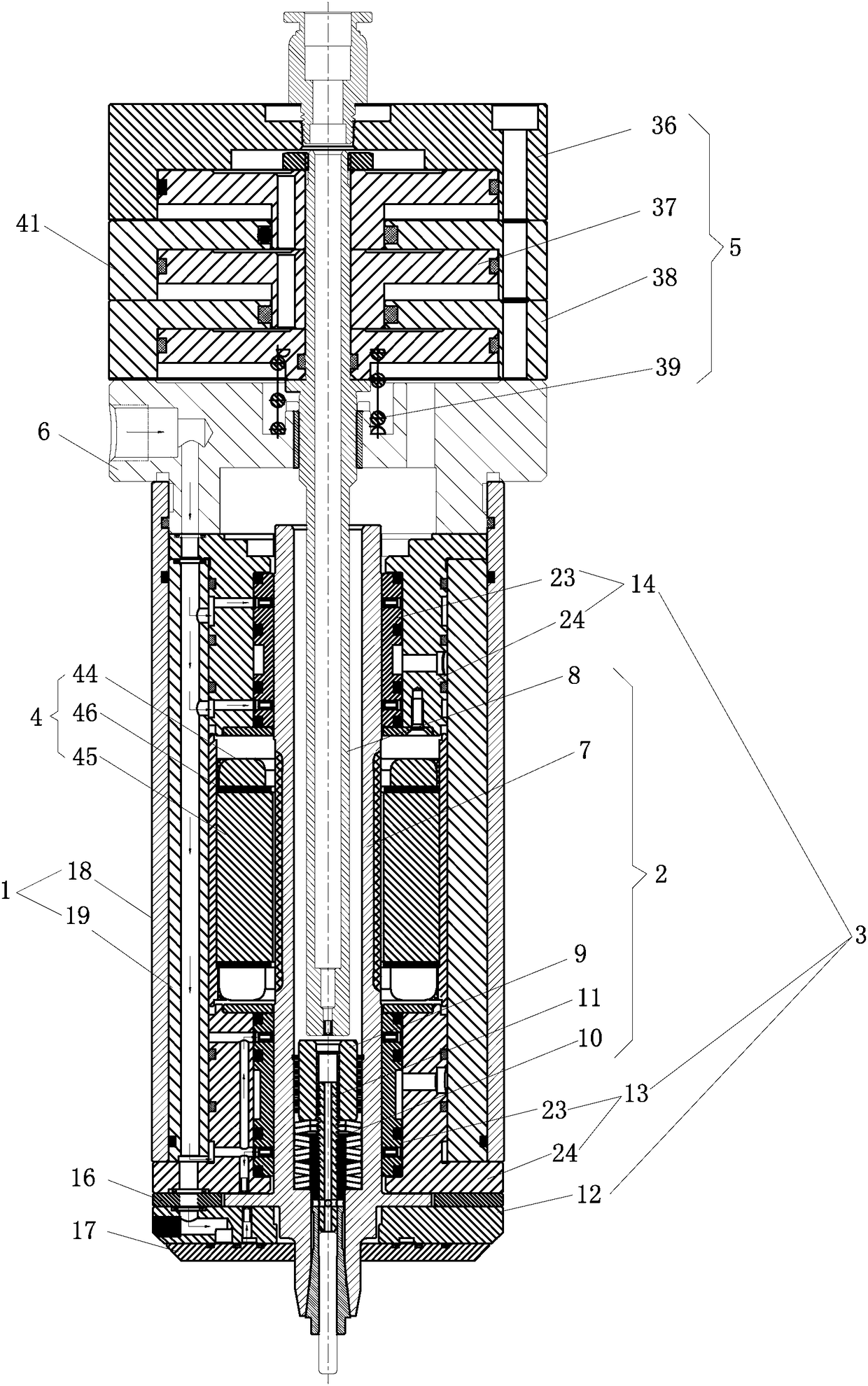

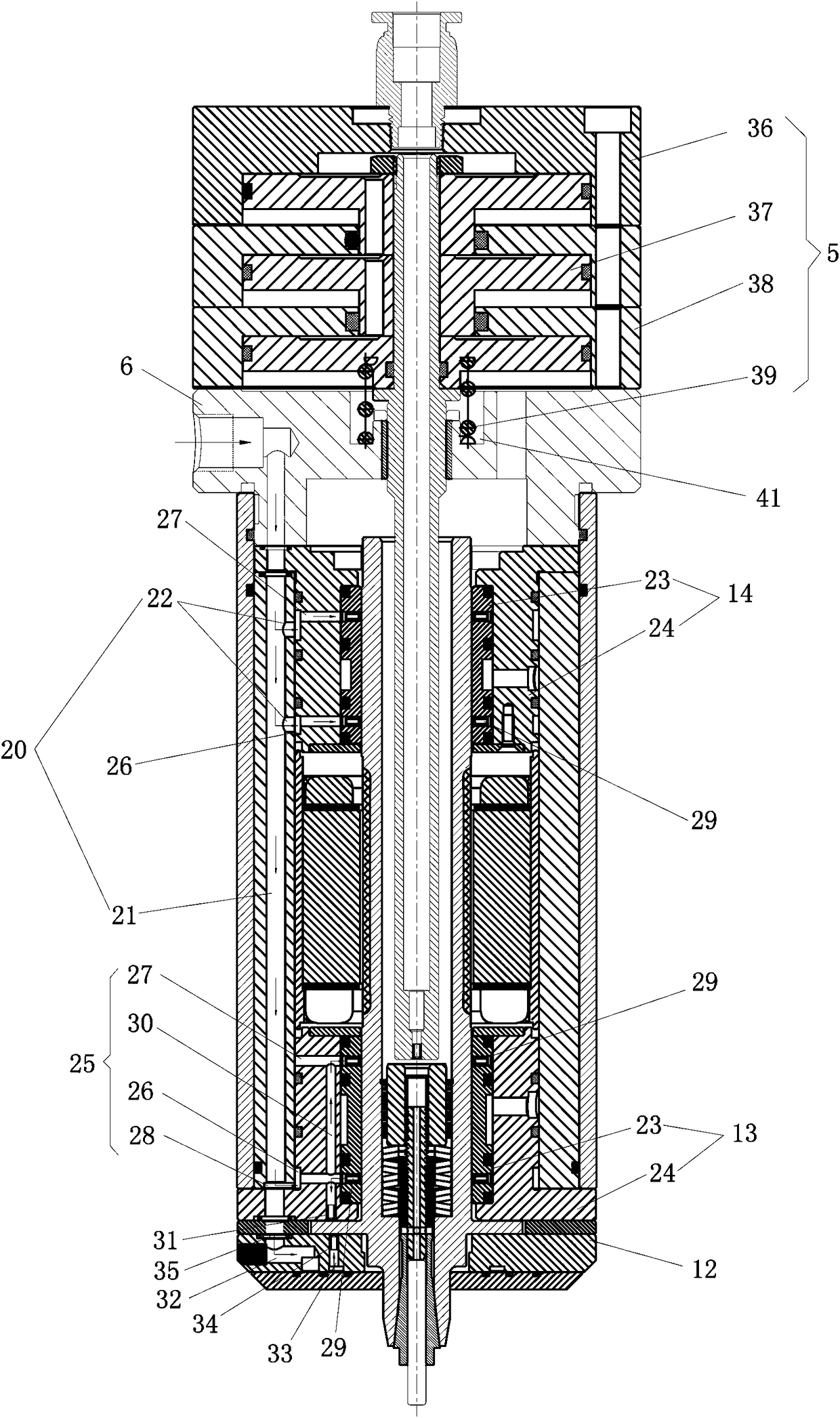

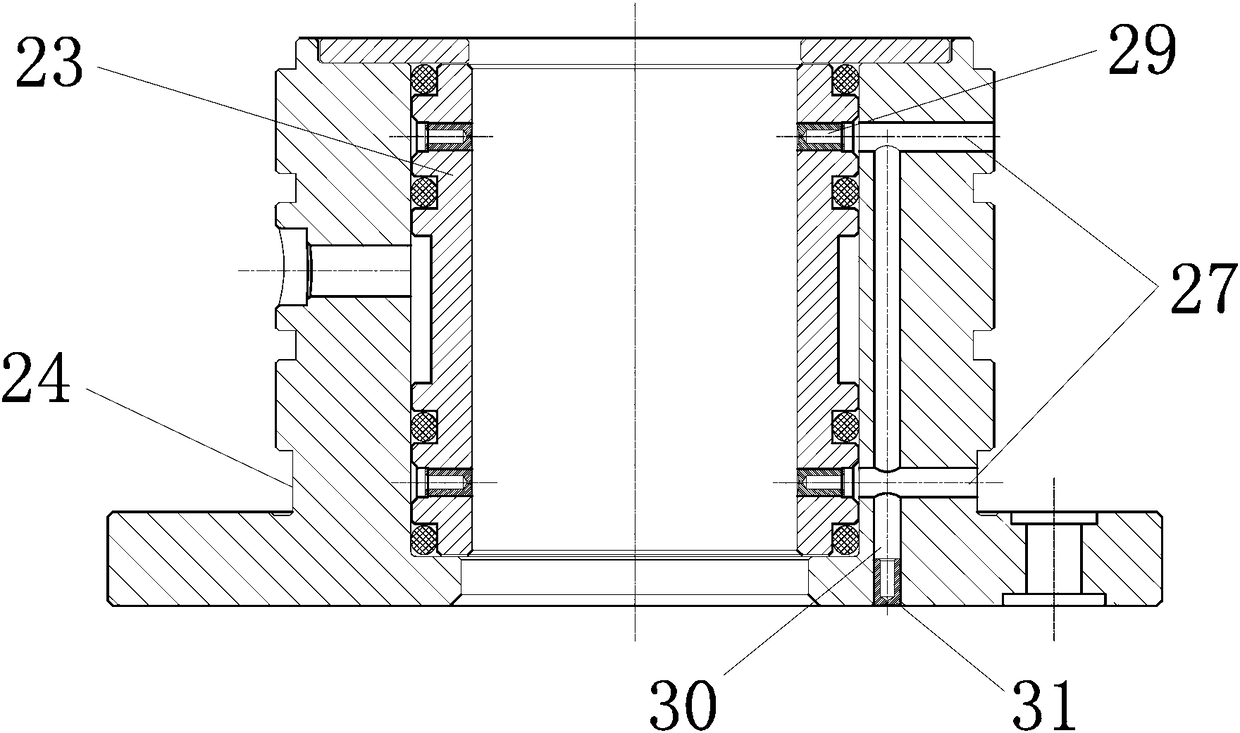

[0022] Such as Figure 1-5 As shown, a high-speed air-floating electric spindle with high precision and low energy consumption includes a main body mechanism 1, a rotor mechanism 2, a bearing mechanism 3, a stator mechanism 4, a cylinder mechanism 5 and a rear seat mechanism 6. The rotor mechanism 2, bearing The mechanism 3 and the stator mechanism 4 are respectively installed in the inner cavity of the main body mechanism 1, the rear seat mechanism 6 is arranged between the cylinder mechanism 5 and the main body mechanism 1, and the rotor mechanism 2 includes The ejector rod 8, the pull rod 9, the elastic assembly 10 and the chuck assembly 11 arranged in the shaft core 7, one end of the ejector rod 8 is connected to the cylinder mechanism 5 in a transmission manner, and the other end is connected to the pull rod 9 in a transmission manner. The elastic assembly 10 is composed of several disk springs sleeved on the chuck assembly 11. The chuck assembly 11 is connected to the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com