Walking-type automatic fruit picking and collecting robot

An automatic picking and walking technology, used in picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high staff requirements, high labor intensity, fruit damage, etc., to avoid inaccurate and unreliable positions, reduce The effect of bumping and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

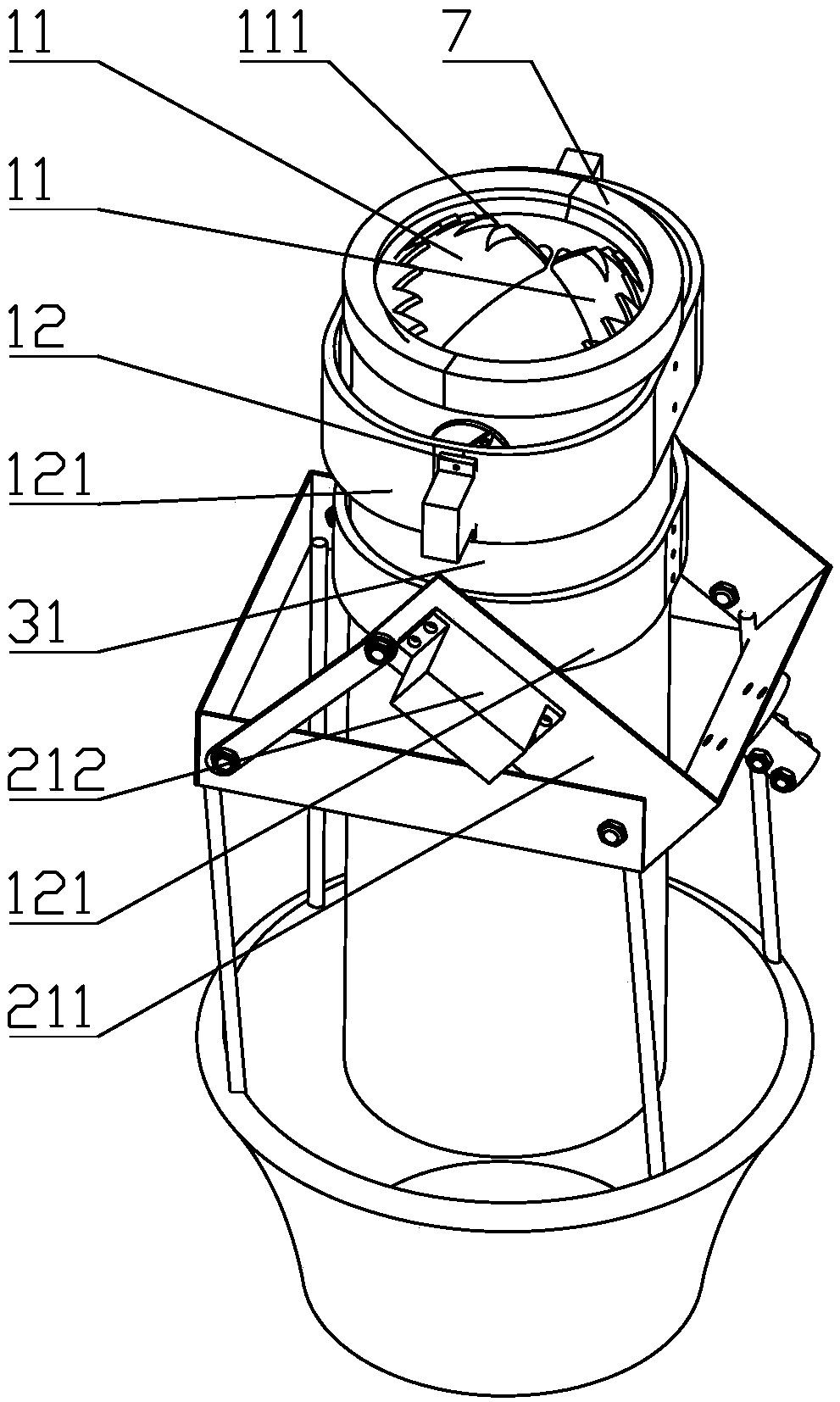

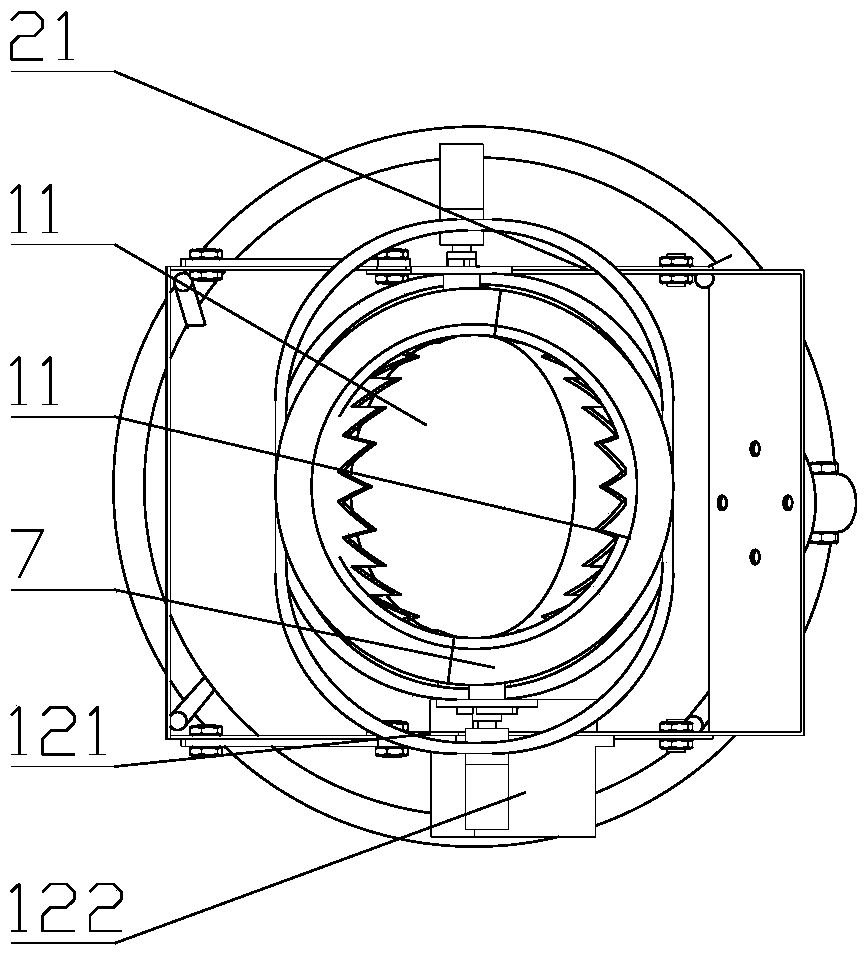

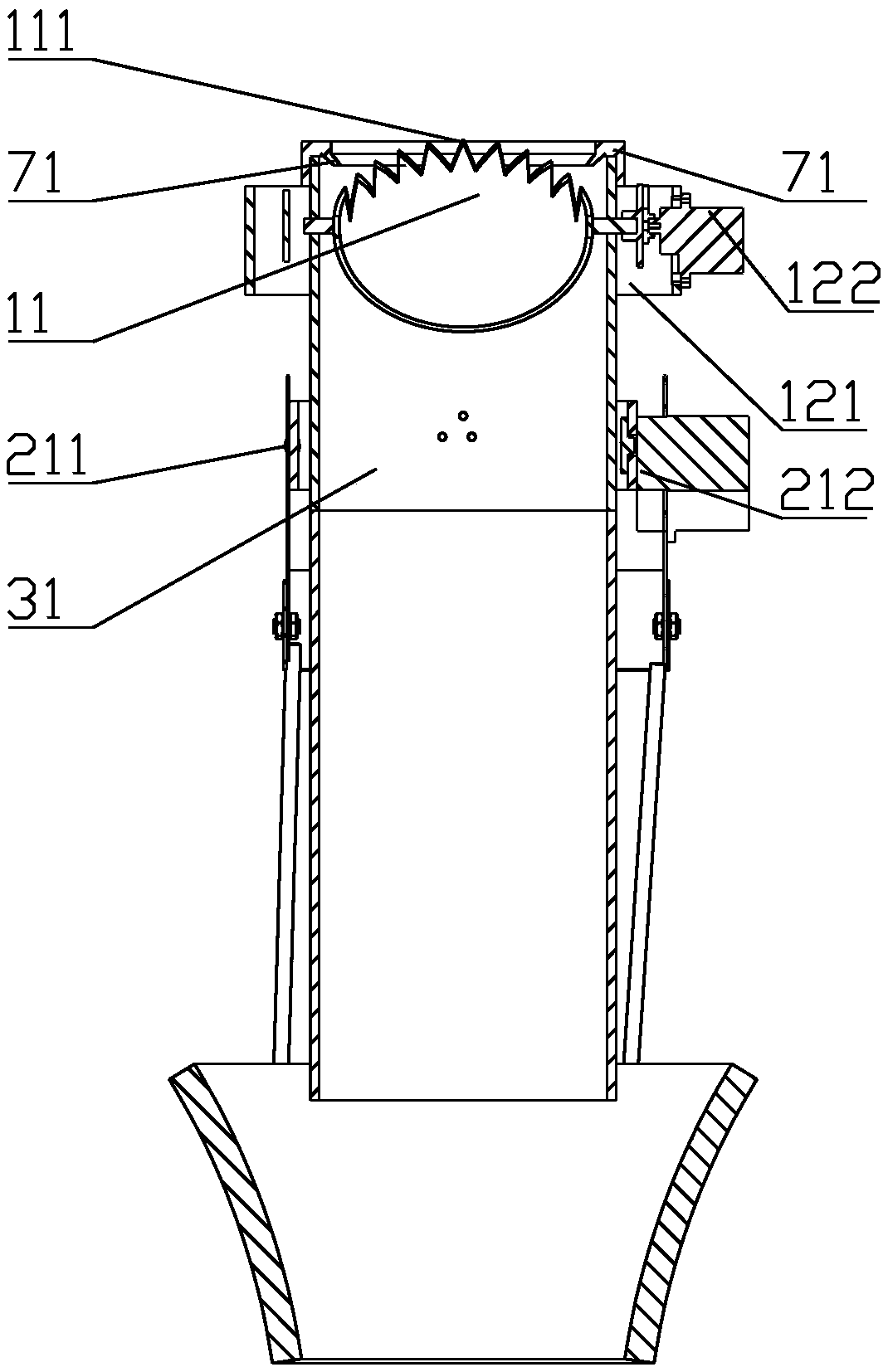

[0044] Embodiment one: combined with attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , electric fruit picking head, including picking head 1; said picking head 1 includes arc-shaped cutter 11 and driving mechanism 12; The outer end of the structure is connected with the output rotating shaft of the drive mechanism 12, so that the cutter 11 is driven by the drive mechanism 12 to realize the rotation around the axis; the tail ends of the two cutters 11 are relatively rotated and Combine to form a receiving tray structure to realize the lifting of the fruit; and then realize the cutting of the fruit stem through the relative rotational movement of the cutter heads 111 of the two cutters 11. In this solution, by using the arc-shaped cutter 11, the fruit can be covered and fixed before cutting the fruit stem, that is, the fruit can be positioned, and the fruit stem can be cut accurately, and the two relative knife heads ...

Embodiment 2

[0059] Embodiment two: combined with attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 9 , Figure 10 with Figure 11 , walking type fruit automatic picking collection robot, comprises picking head 1, positioning mechanism 2, collecting mechanism 3, moving mechanism 4; Said picking head 1 comprises arc cutter 11 and drive mechanism 12; The head of two said cutters 11 The end arc-shaped cutter heads 111 are arranged oppositely; the outer end of the arc-shaped structure of the cutter 11 is connected to the output rotating shaft of the drive mechanism 12, so that the cutter 11 is driven by the drive mechanism 12 to realize rotation around the axis; The tail ends of the two cutting knives 11 are relatively rotated and combined to form a receiving tray structure to realize the lifting of the fruit; and then through the relative rotational movement of the cutter heads 111 of the two cutting knives 11, the fruit is achieved. The shearing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com