Air-flow vortex balling machine for producing spherical graphite

A technology of spherical graphite and airflow, which is applied in the direction of grain processing, etc., can solve the problems of unreasonable design of crushing chamber or spheroidization chamber, uneven product particle size distribution, unreasonable design of grinding disc and cutter, etc., and achieve good airtight performance and low noise. Small, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

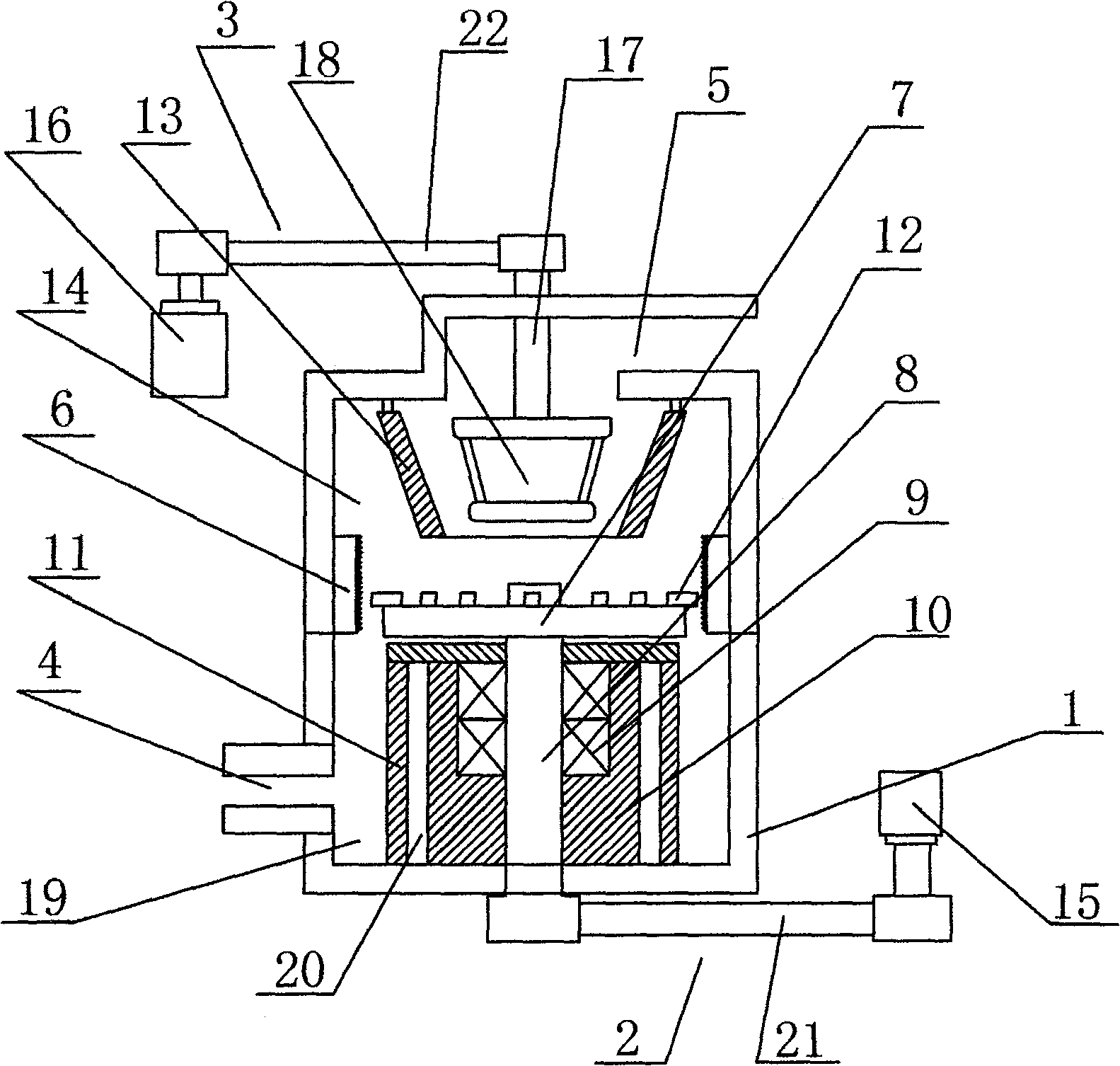

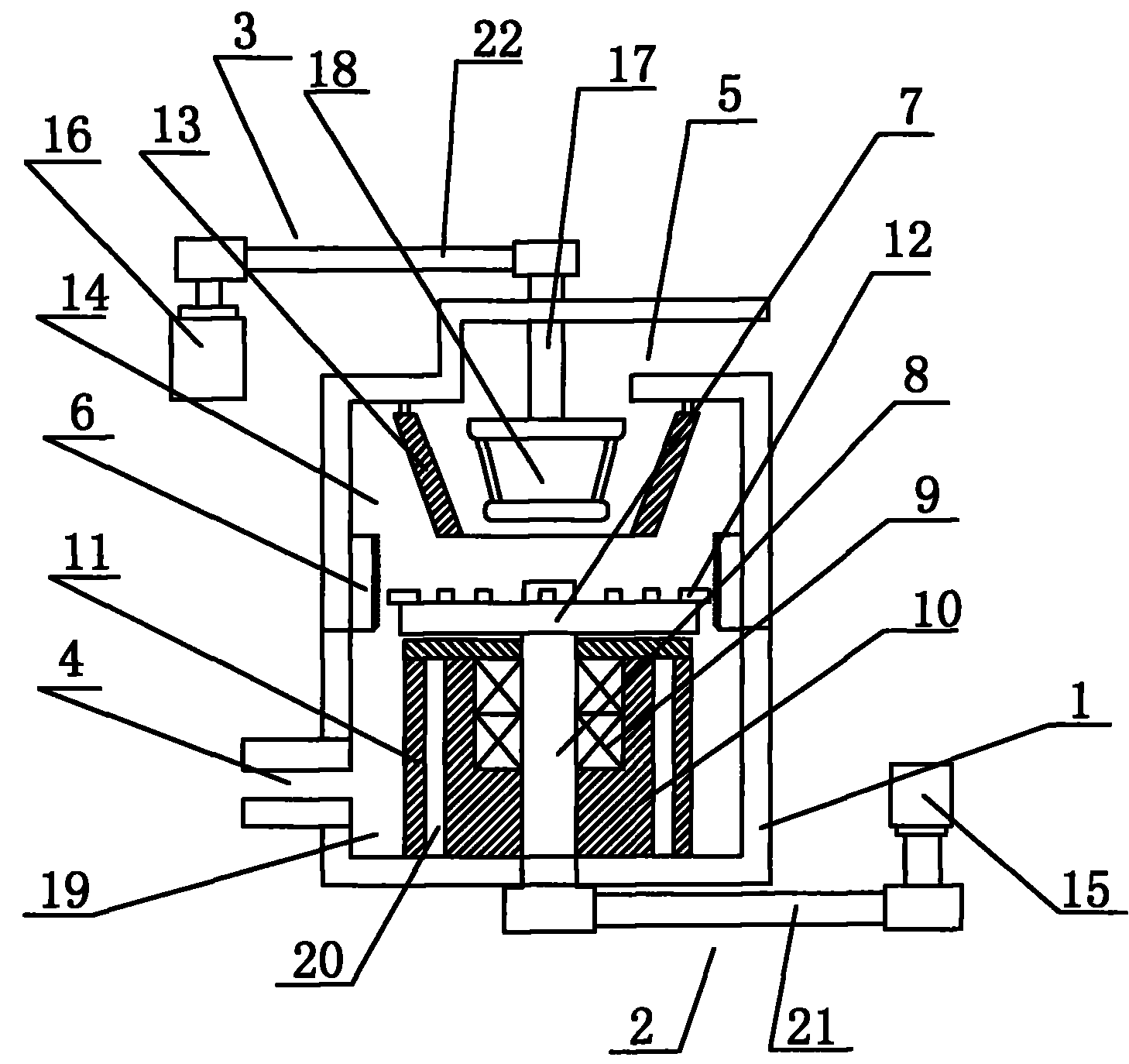

[0020] As shown in the figure, the airflow vortex spheroidizer used to produce spherical graphite is composed of a body 1, a spheroidization transmission device 2 and an internal classifier transmission device 3. 1 is provided with a discharge port 5 at the top, and a ring gear 6 is provided in the middle of the inner wall of the body 1. Between the lower end surface of the ring gear 6 and the bottom surface of the body 1 is a material flow chamber 19, and the lower end surface of the ring gear 6 and the top surface of the body 1 There is a spheroidizing chamber 14 in between; a sealing body 11 is provided in the material flow chamber 19, and a powder spheroidizing turntable 7 is arranged on the upper end of the sealing body 11, and the circumferential end surface of the powder spheroidizing turntable 7 and the ring gear 6 Relatively, on the circumference of the powder spheroidizing turntable 7, powder knives 12 are equidistantly arranged on a plane. The turntable 7; the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com