Cutting tool structure based on rolling anti-attrition principle

A cutting tool, rolling and anti-friction technology, applied in the direction of tools for lathes, turning equipment, manufacturing tools, etc., to achieve the effect of improving quality, reducing cutting temperature, and improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

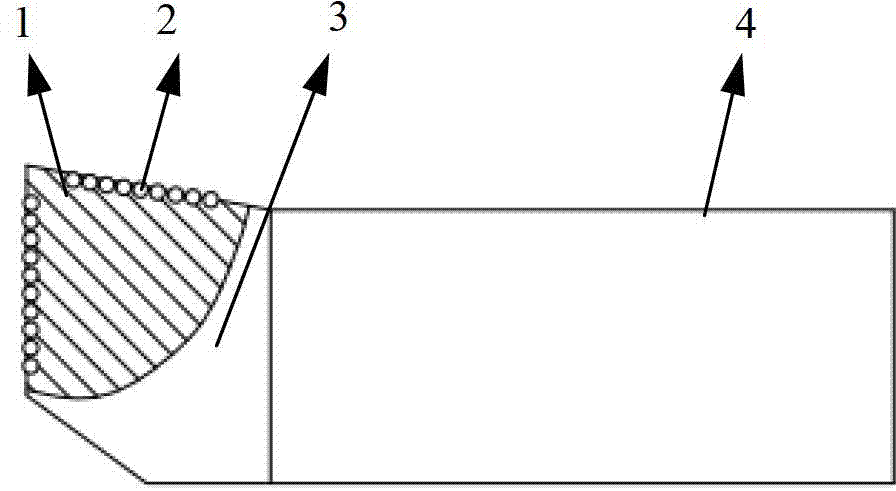

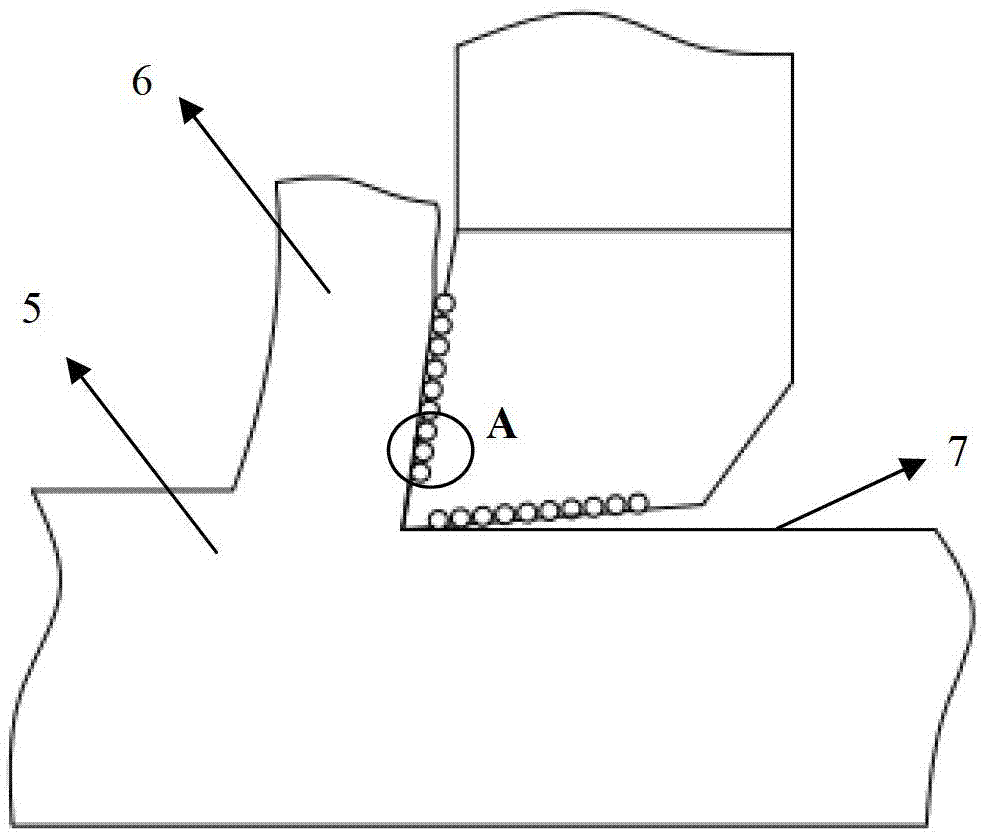

[0019] Such as Figure 1~4 As shown, a cutting tool structure based on the principle of rolling wear reduction includes an integrated cutter body 4 and a cutter head 3, the rake face and flank face of the cutter head are provided with microgrooves 1, microgrooves 1 The depth gradually decreases along the direction away from the tool tip. The microgroove 1 is formed by arranging a plurality of microholes, each microhole is embedded with a ball 2, the diameter of the ball 2 is slightly smaller than the diameter of the microhole, and can roll freely in the microhole.

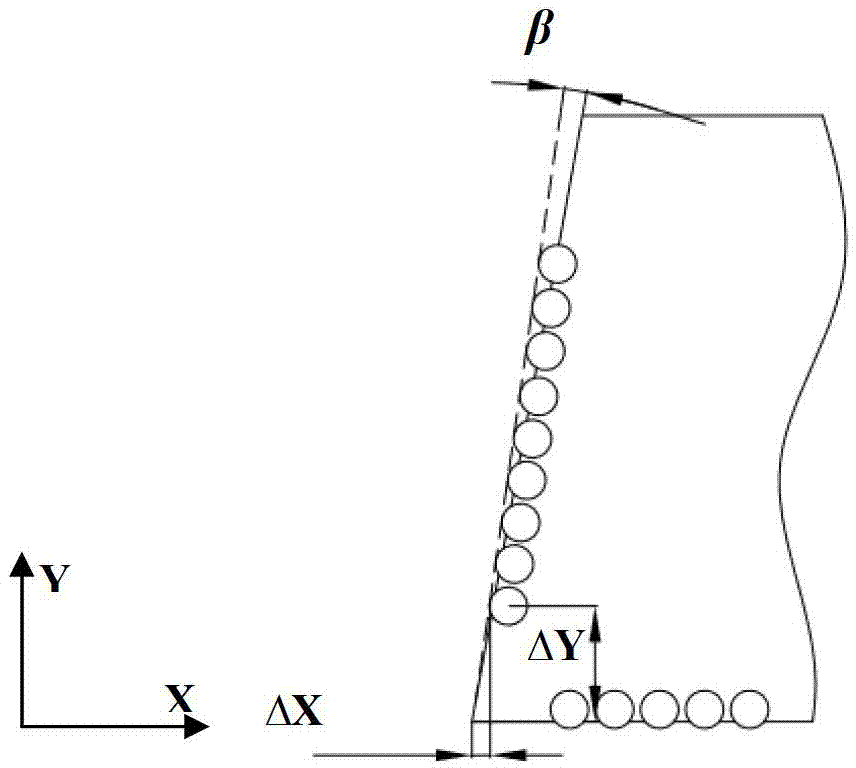

[0020] Such as figure 2 As shown, the distances of the ball closest to the tool tip in the X and Y directions are ΔX and ΔY, respectively, ΔX=0.5-5mm and ΔY=0.5-2mm. On the one hand, it is to ensure that the tool tip contacts the workpiece first during cutting, and on the other hand, to prevent the tool tip from breaking, it is necessary to keep a certain distance between the first ball and the tool tip. The de...

Embodiment 2

[0023] The micro-groove is groove-shaped, and the distances from the end of the micro-groove to the tip of the knife in the X and Y directions are ΔX and ΔY respectively, ΔX=0.5mm and ΔY=2mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com