Patents

Literature

49results about How to "Good preload effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

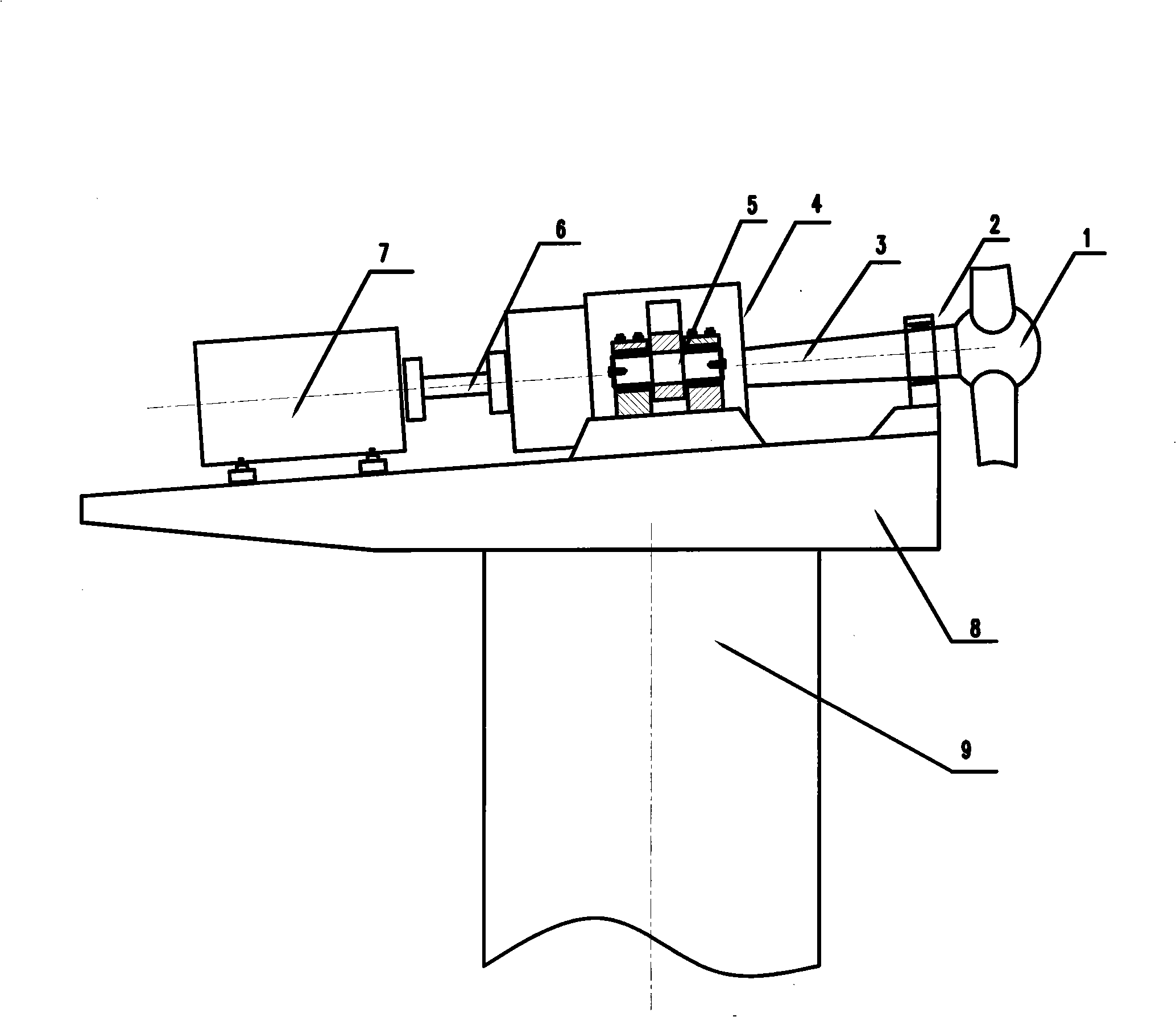

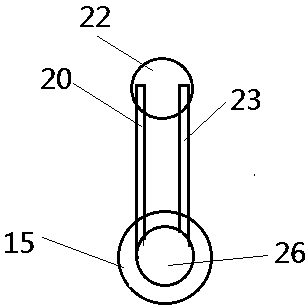

Elastic support installation method for wind power plant and its elastic element

InactiveCN101333998ASo as not to damageEasy to installWind motor assemblyMachines/enginesPeaking power plantWind driven

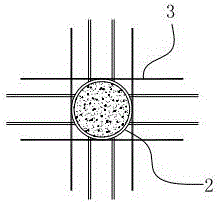

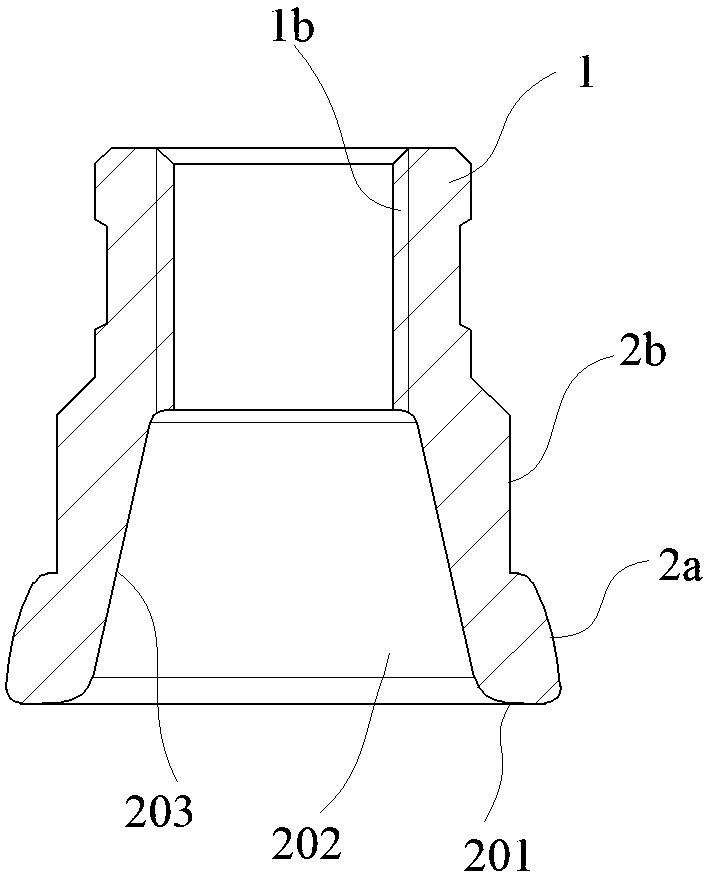

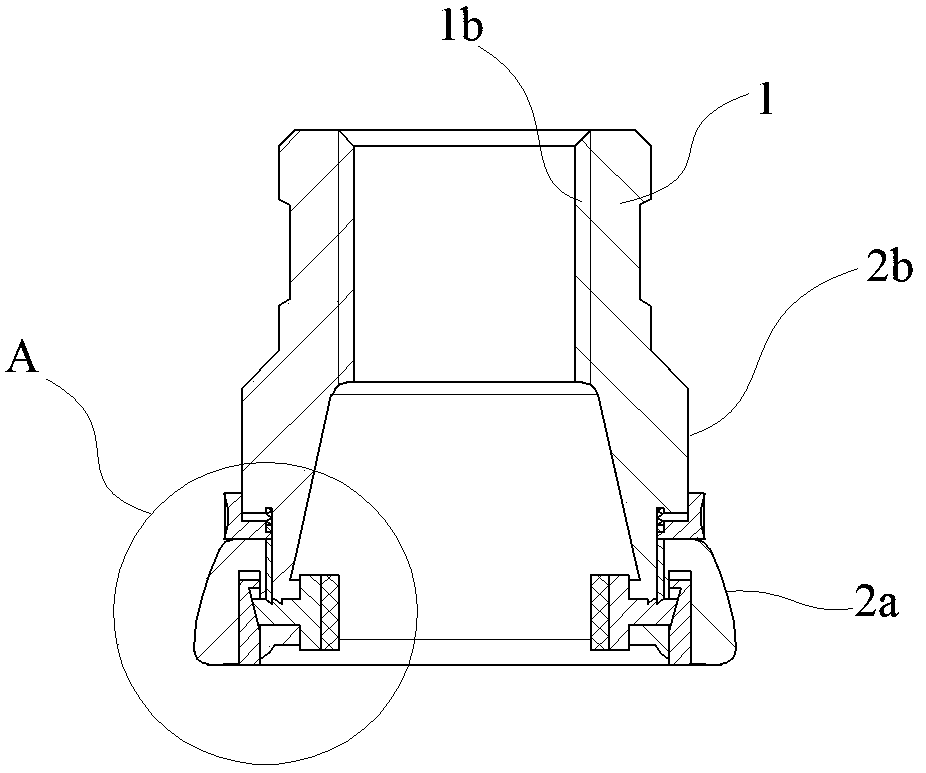

The invention relates to an elastic support installation method and an elastic element thereof used for a wind power generation equipment. Elastic supports are installed at both sides of a gearbox and installed in a supporting seat by adopting a radial pretension compression method to form the elastic support for the gearbox of a wind driven generating unit. The elastic support installation method adopts the radial pretension compression method that the elastic supports are arranged in the supporting seat after being radially compressed through a special compression tool or directly utilizing the supporting seat in order to tightly embrace a core axle and to generate a certain pre-compression force. The gearbox elastic support of the wind driven generating unit comprises an elastic body, an outer tile and an inner tile, wherein, the outer tile adopts a multiple-flap arc structure of more than two flaps, the elastic body adopts at least more than one layer, the elastic support adopts an integral structure or a split type combined structure, each outer tile adopts a concentric circular arc with respect to the inner tile under the initial state, and variable radius structures with unequal radiuses are adopted among the outer tile, the inner tile, the core axle and the supporting seat.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

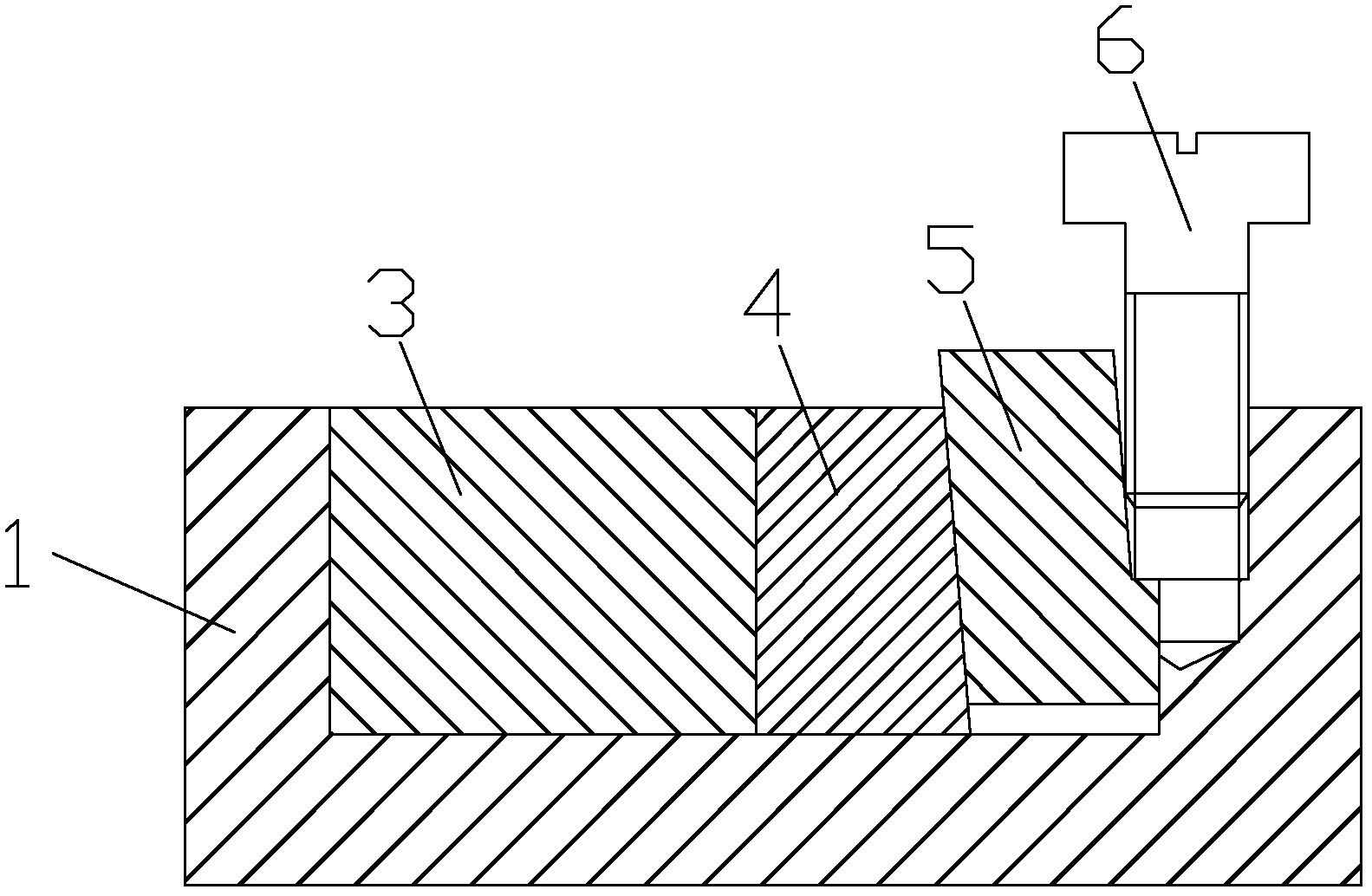

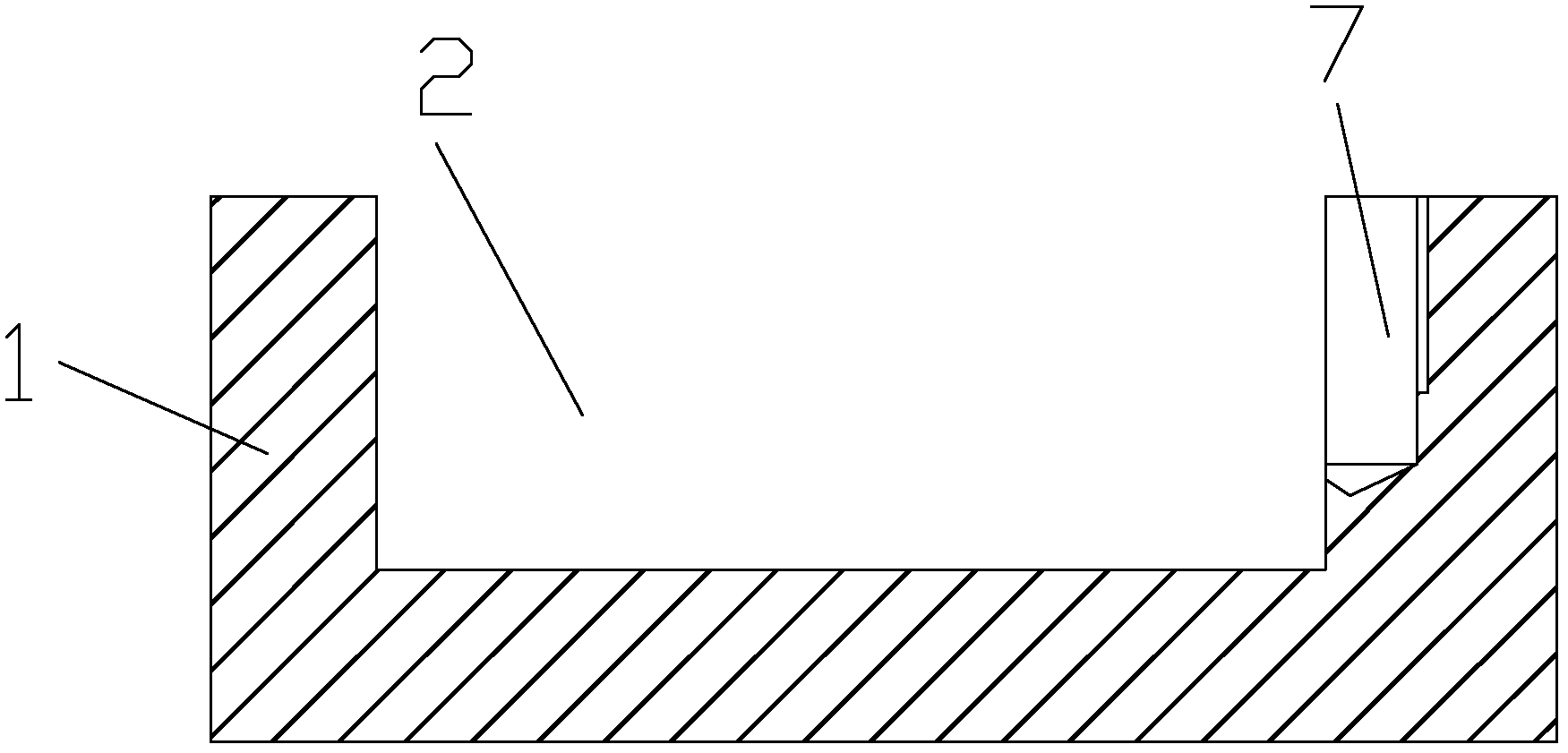

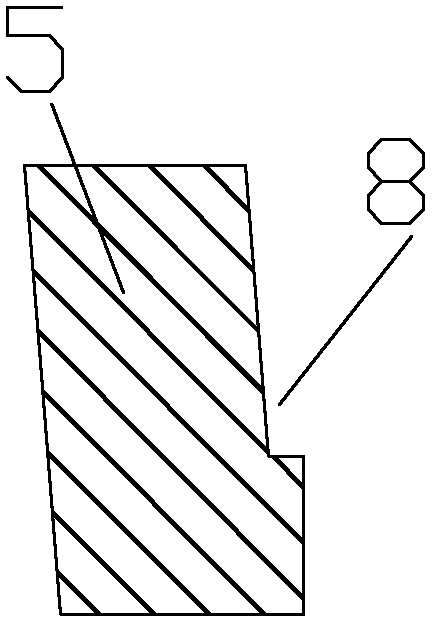

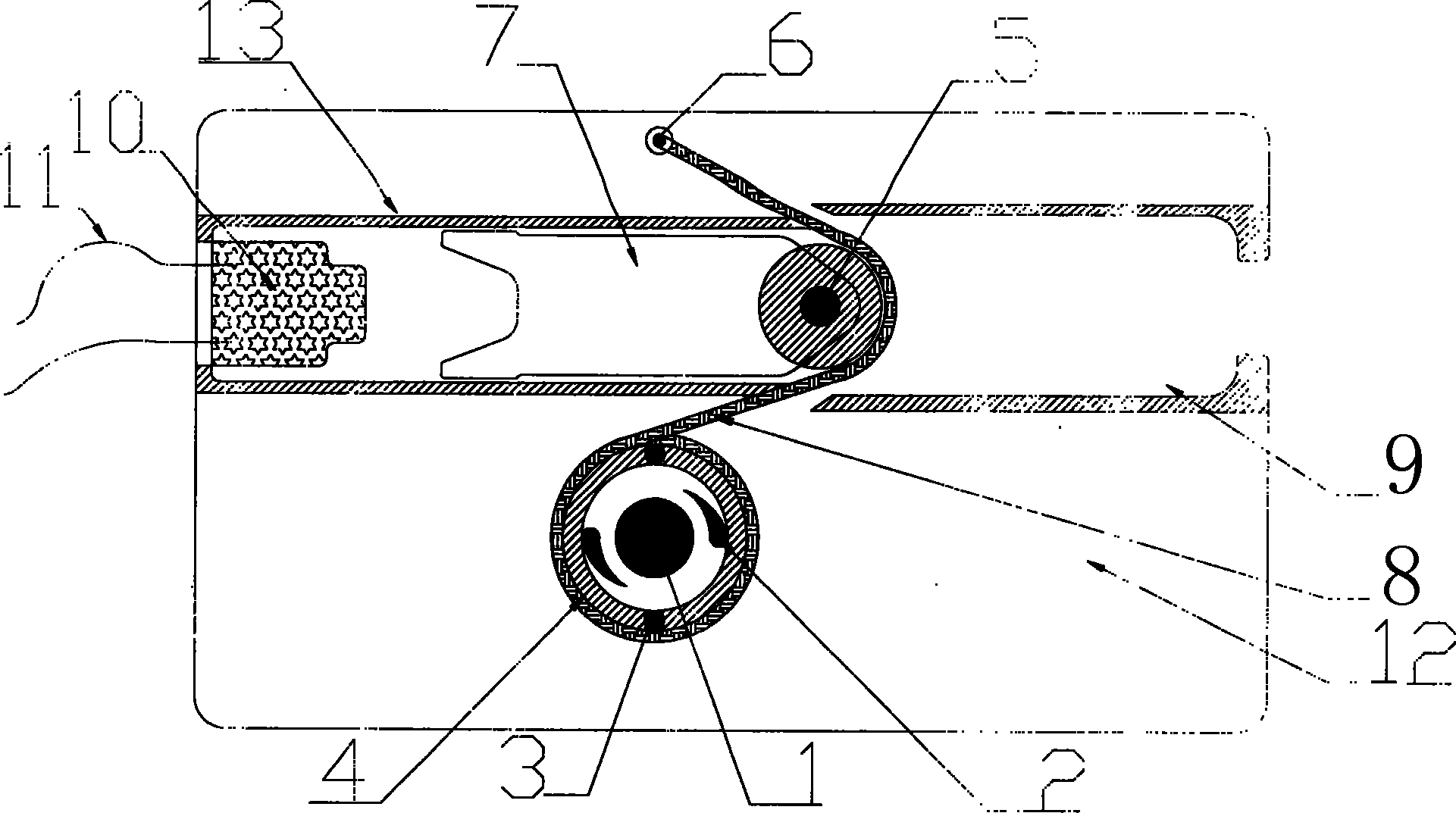

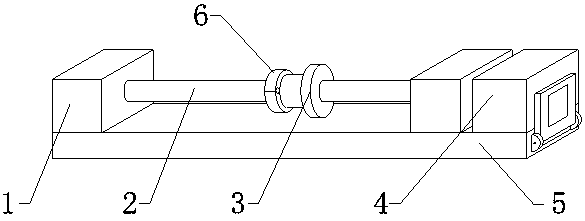

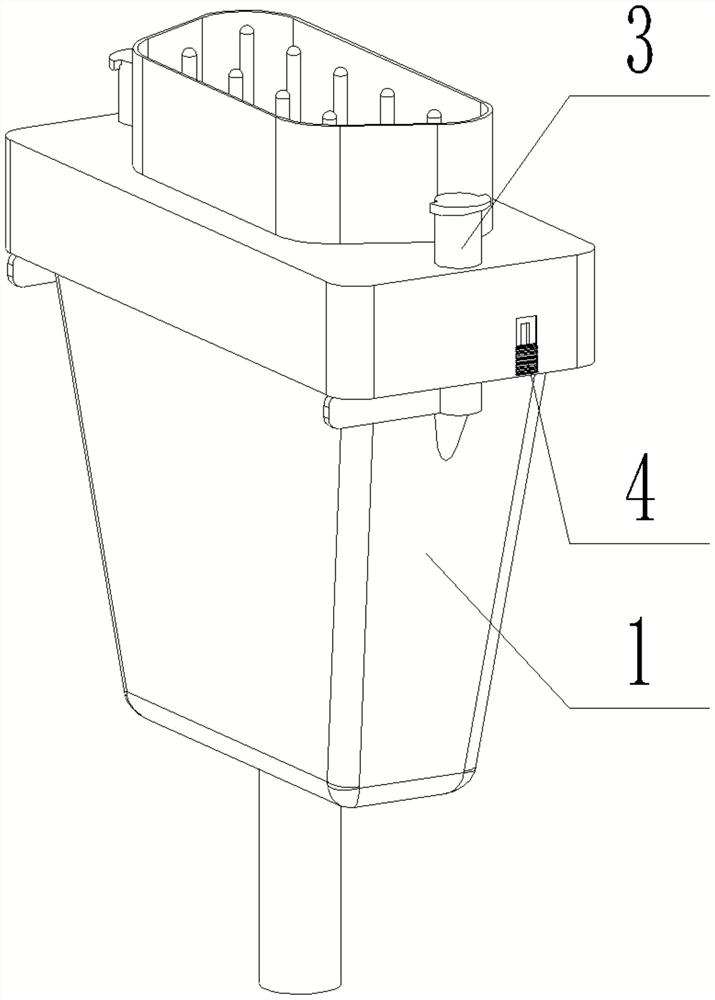

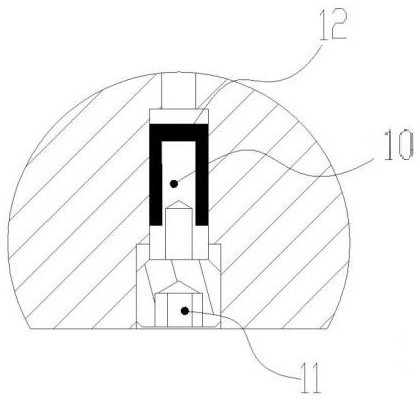

Pre-tightening device

InactiveCN102619821ASimple structureGood preload effectFriction grip releasable fasteningsMountingsEngineeringScrew press

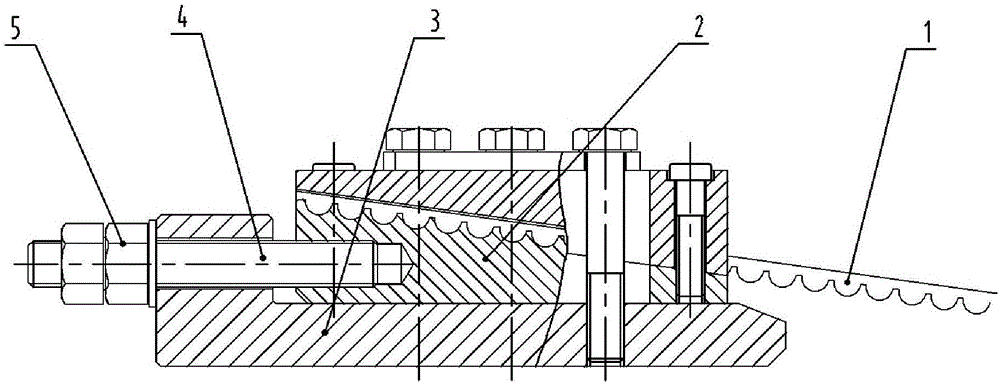

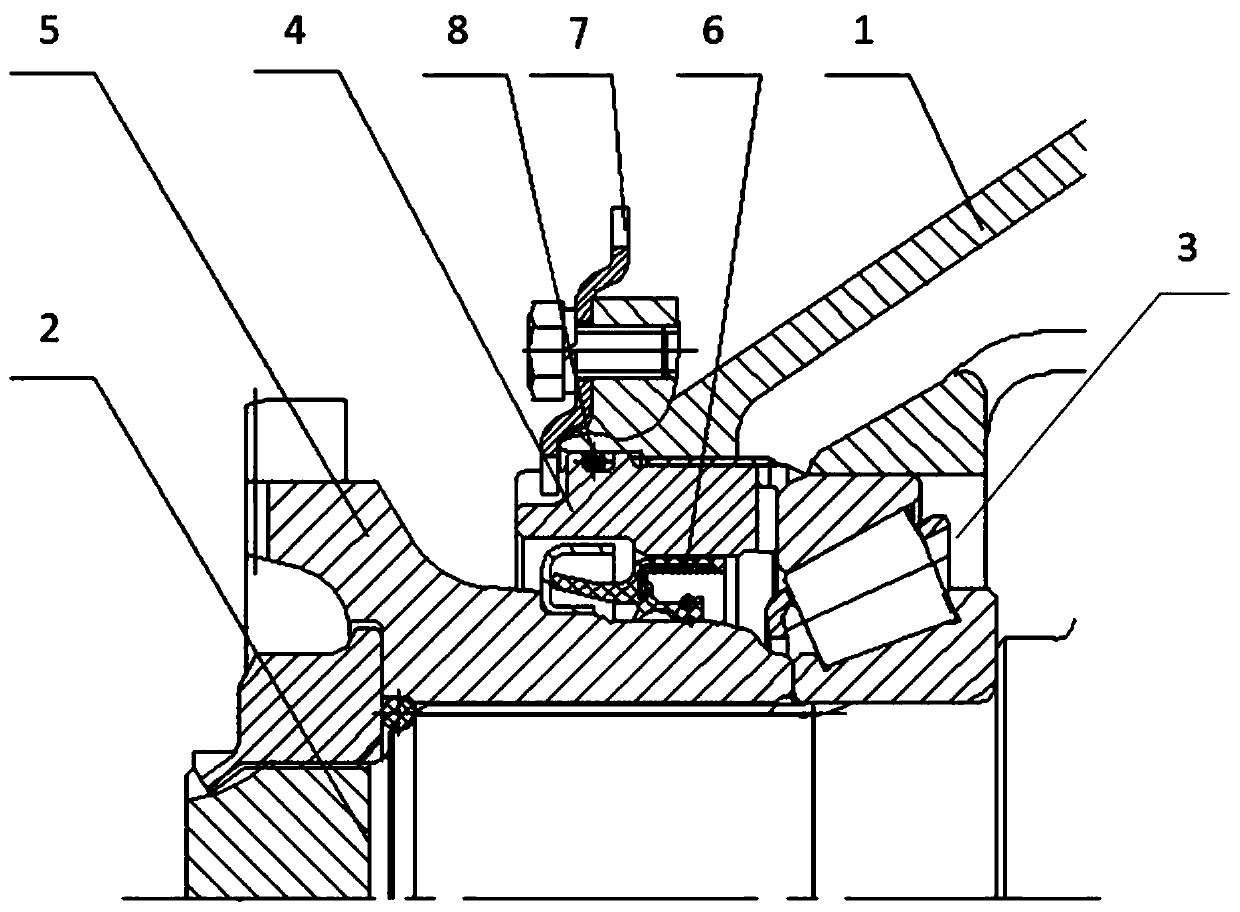

The invention discloses a pre-tightening device, which comprises a machine body, piezoelectric ceramics, a fixed wedge, a moving wedge, a screw, a screw hole and a conical hole. A groove is arranged on the machine body. The piezoelectric ceramics is arranged on one side of the groove. One side of the piezoelectric ceramics is adjacent to a side of the groove, and the other side of the piezoelectric ceramics is adjacent to a vertical face of the fixed wedge. The other end portion of the groove is provided with the screw hole. The moving wedge is inserted into a space between the fixed wedge and the other end of the groove. An inclined face of the moving wedge is adjacent to an inclined face of the fixed wedge. The conical hole is arranged at the end portion of the vertical face of the moving wedge. The screw is screwed into the screw hole, and one part of the screw is inserted into the conical hole too. When the screw is screwed downwards, the screw presses the moving wedge downwards to pre-tighten the piezoelectric ceramics. In the technical scheme, the screw is screwed into the screw hole, and one part of the screw is inserted into the conical hole too; and when the screw is screwed downwards, the screw presses the moving wedge downwards to pre-tighten the piezoelectric ceramics. The pre-tightening device is simple in structure and good in pre-tightening effect.

Owner:SUZHOU TANGFENG ELECTRICAL APPLIANCE

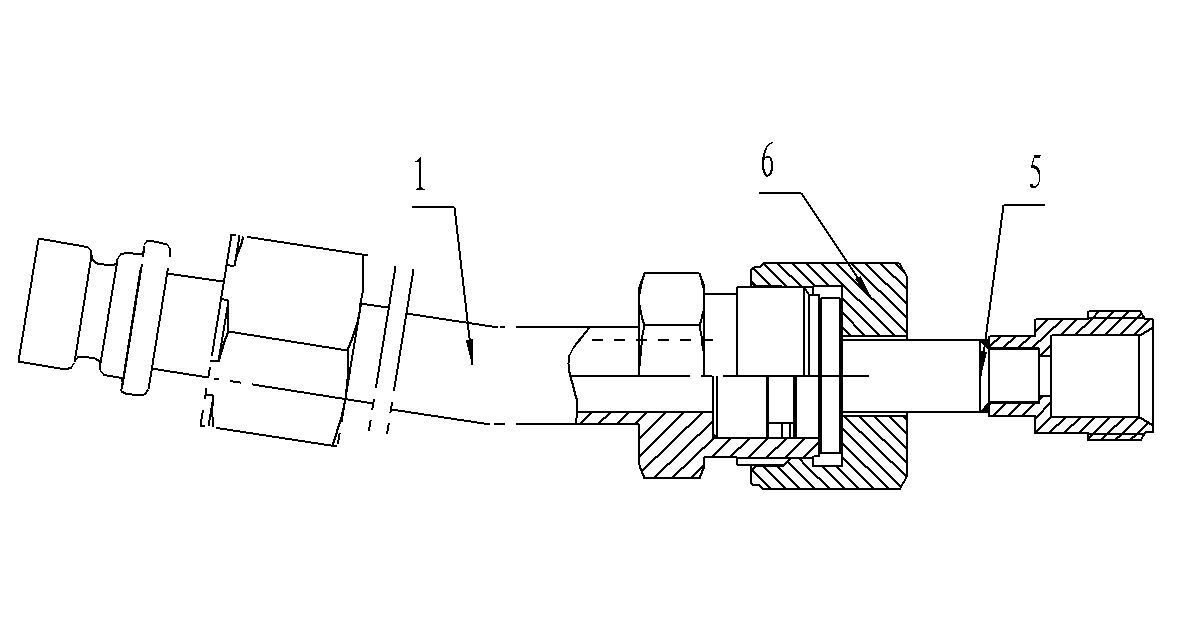

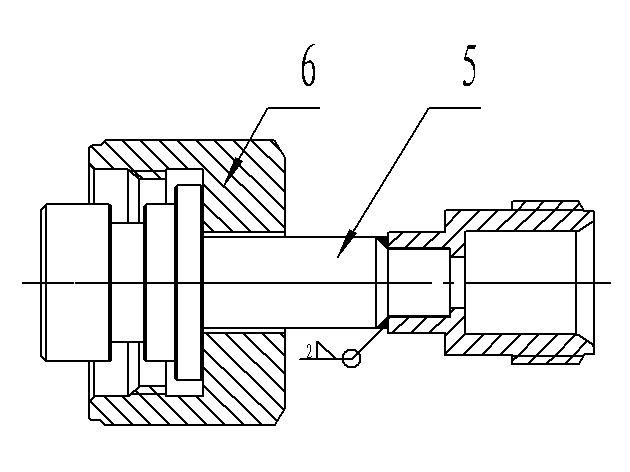

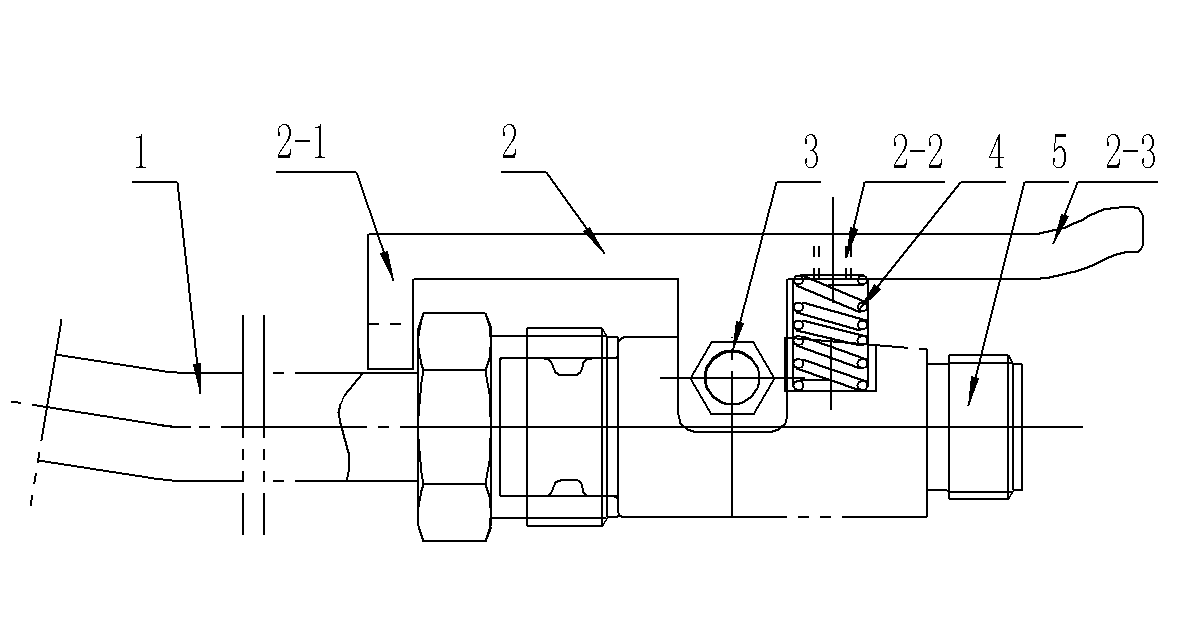

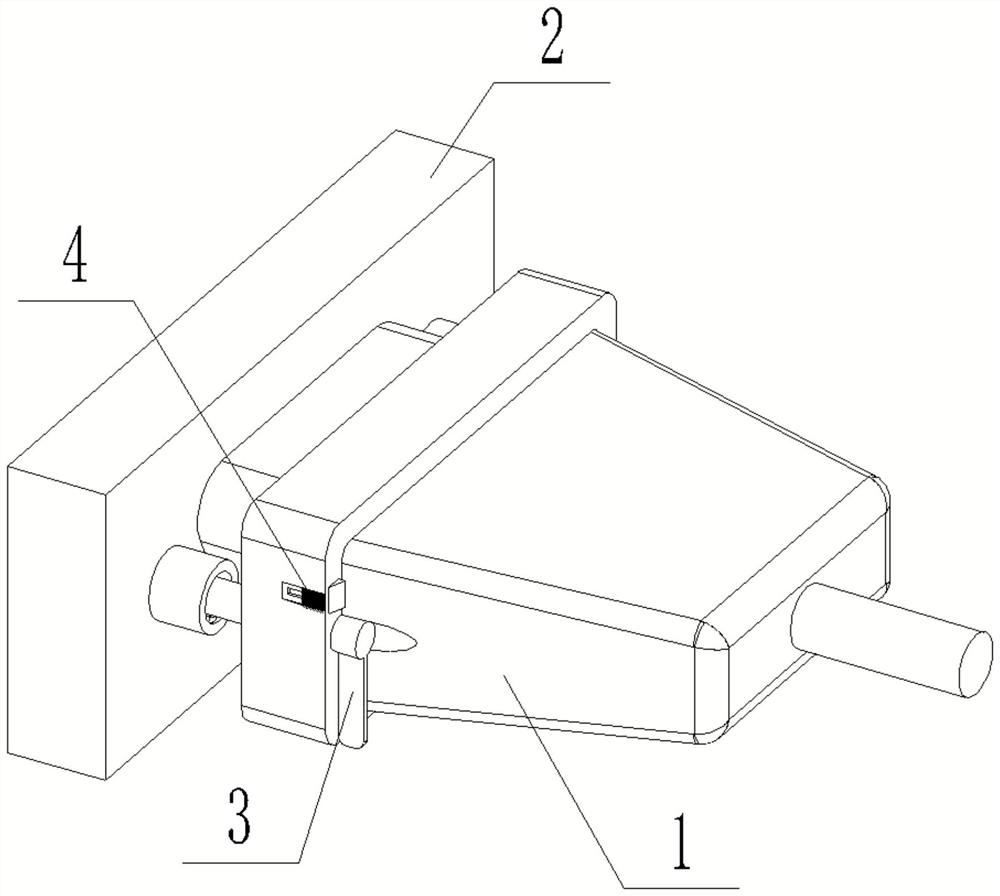

Air tightness detection clamp

InactiveCN103216696AClosely connectedGuaranteed preloadCouplingsEngineeringUltimate tensile strength

The invention discloses an air tightness detection clamp, which relates to the machining field of the mechanical tool. The air tightness detection clamp comprises an air inlet pipe connector (5), wherein the air inlet pipe connector (5) is hinged with a clamping part (2); the clamping part (2) is provided with a protruded claw part (2-1) at the front part of a hinged position, and is provided with a handle part (2-2) at the rear part of the hinged position; and a shaft pin (2-3) is arranged between the hinged position and the handle part (2-2), the shaft pin (2-3) is movably plugged into a groove arranged on the air inlet pipe connector (5), and a spring (4) is arranged between the shaft pin (2-3) and the groove. Compared with the prior art, the problems of the existing air tightness detection tool that the efficiency is low and the labor intensity is large can be solved.

Owner:柳州力通汽车科技有限公司

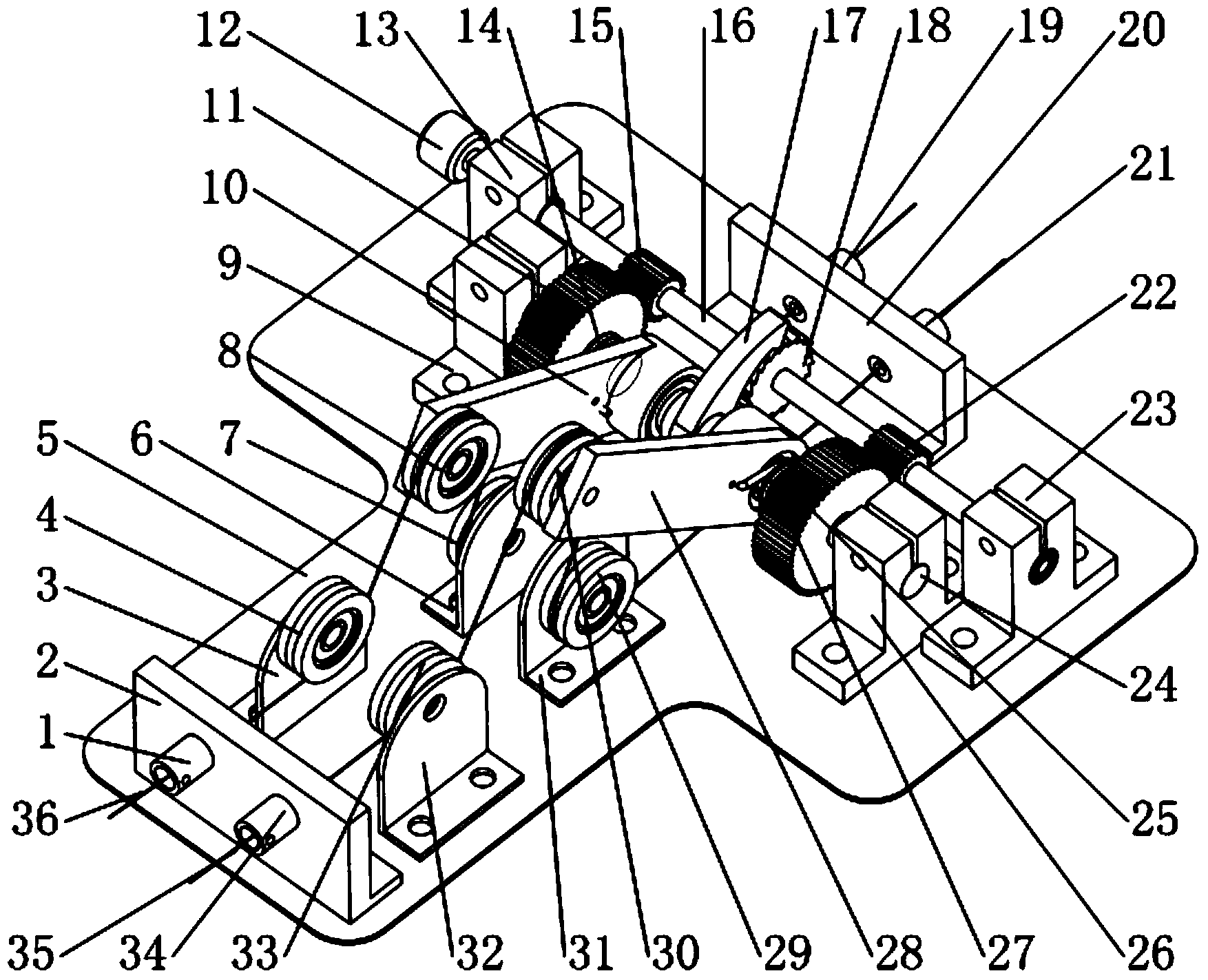

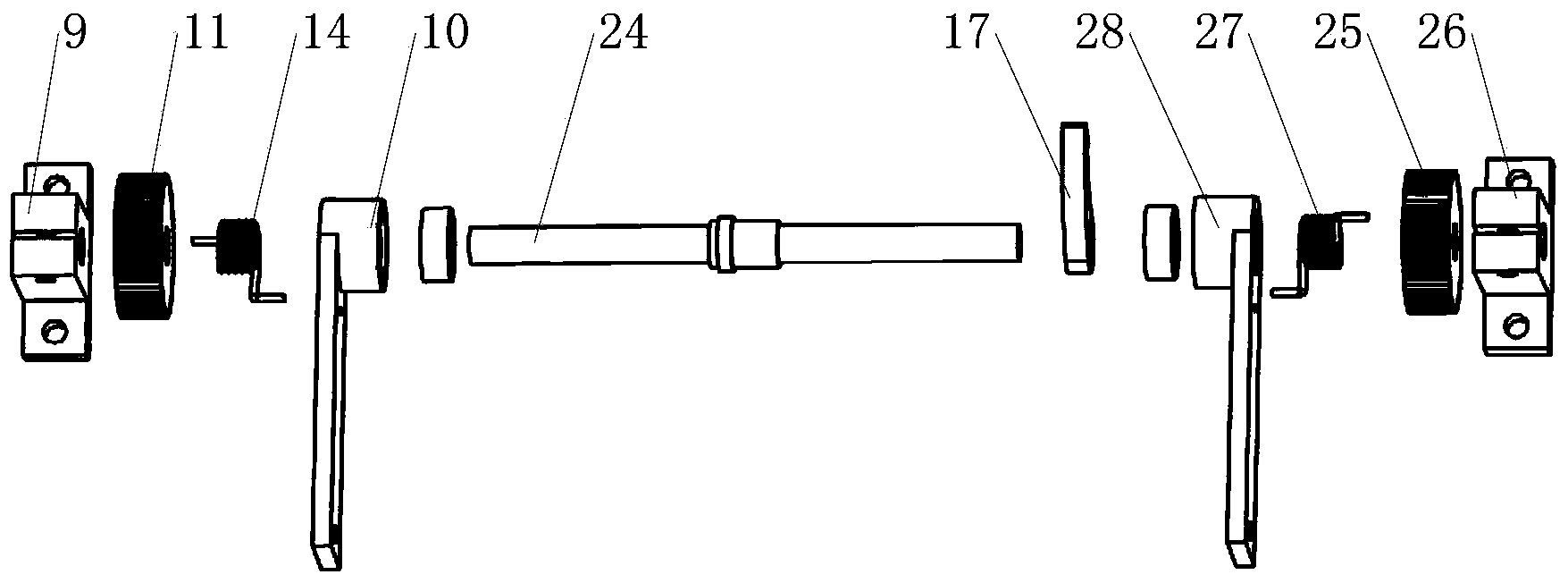

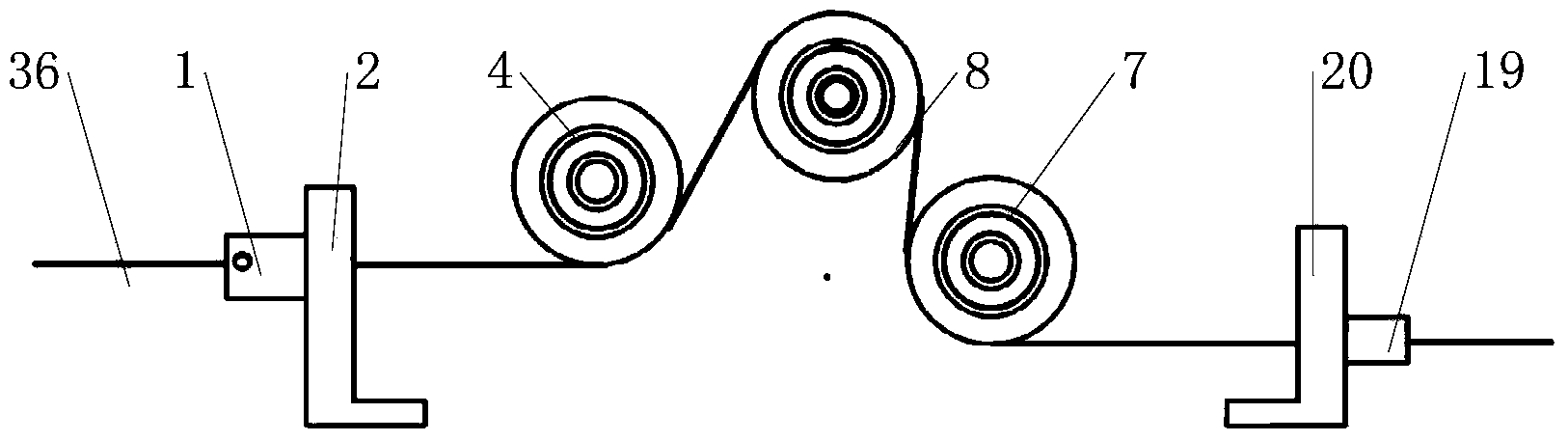

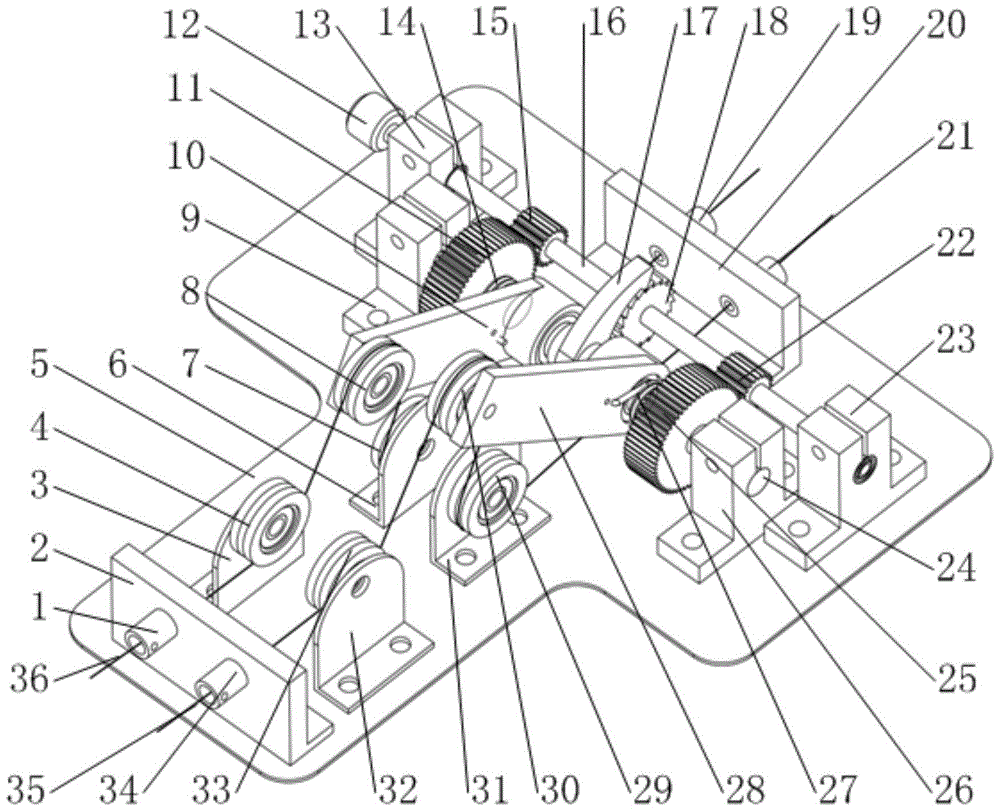

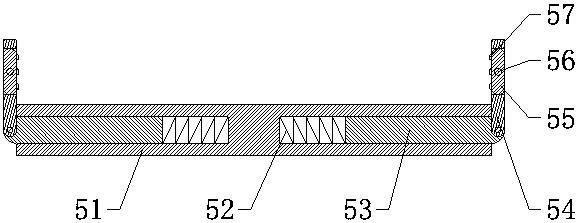

Automatic adjustment type steel wire rope tensioning device

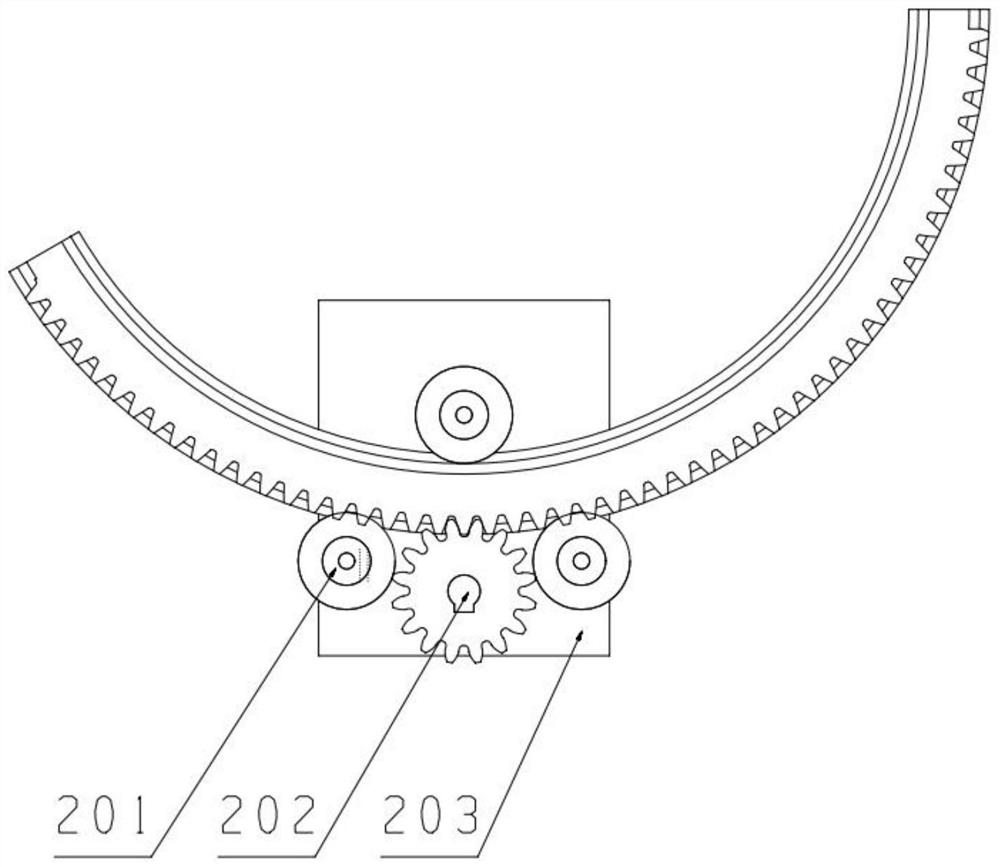

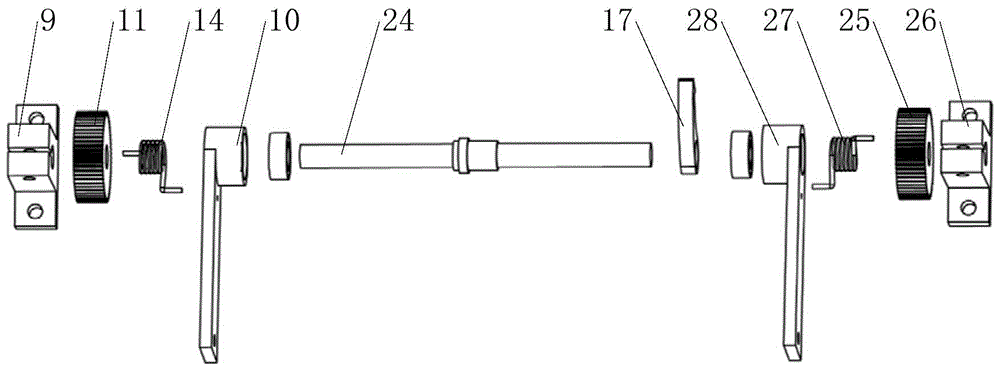

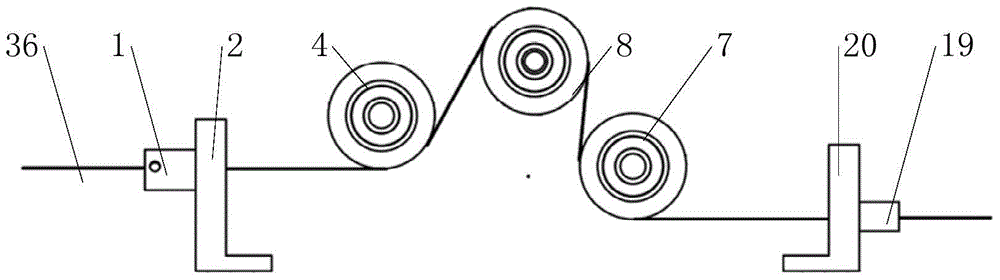

The invention discloses an automatic adjustment type steel wire rope tensioning device. The automatic adjustment type steel wire rope tensioning device comprises a base, guide wheels, tensioning wheels, a rotating shaft, a fixed shaft, a swing arm, a fixing piece and torsional springs, wherein the guide wheels are fixed on the base; the tensioning wheels are matched with the guide wheels; the rotating shaft is connected onto the base in a rotating mode, and driving gears are fixed on the rotating shaft; the fixed shaft is fixed on the base, and driven gears engaged with the driving gears are connected onto the fixed shaft in a rotating mode; the swing arm is connected onto the fixed shaft in a rotating mode, one end of the swing arm is coupled with the tensioning wheel; the fixing piece is used for realizing relative fixation of the rotating shaft and the base; the torsional springs are also arranged on the fixed shaft in a sleeving mode, one end of each of the torsional spring is fixed with the swing arm, and the other ends of the torsional springs are fixed with the driven gears. The automatic adjustment type steel wire rope tensioning device is compact in structure, high in pretensioning efficiency, adjustable in pretensioning force, good in pretensioning effect and low in manufacturing cost, meanwhile can realize automatic pretensioning, and can be applied to small and light instruments.

Owner:ZHEJIANG UNIV

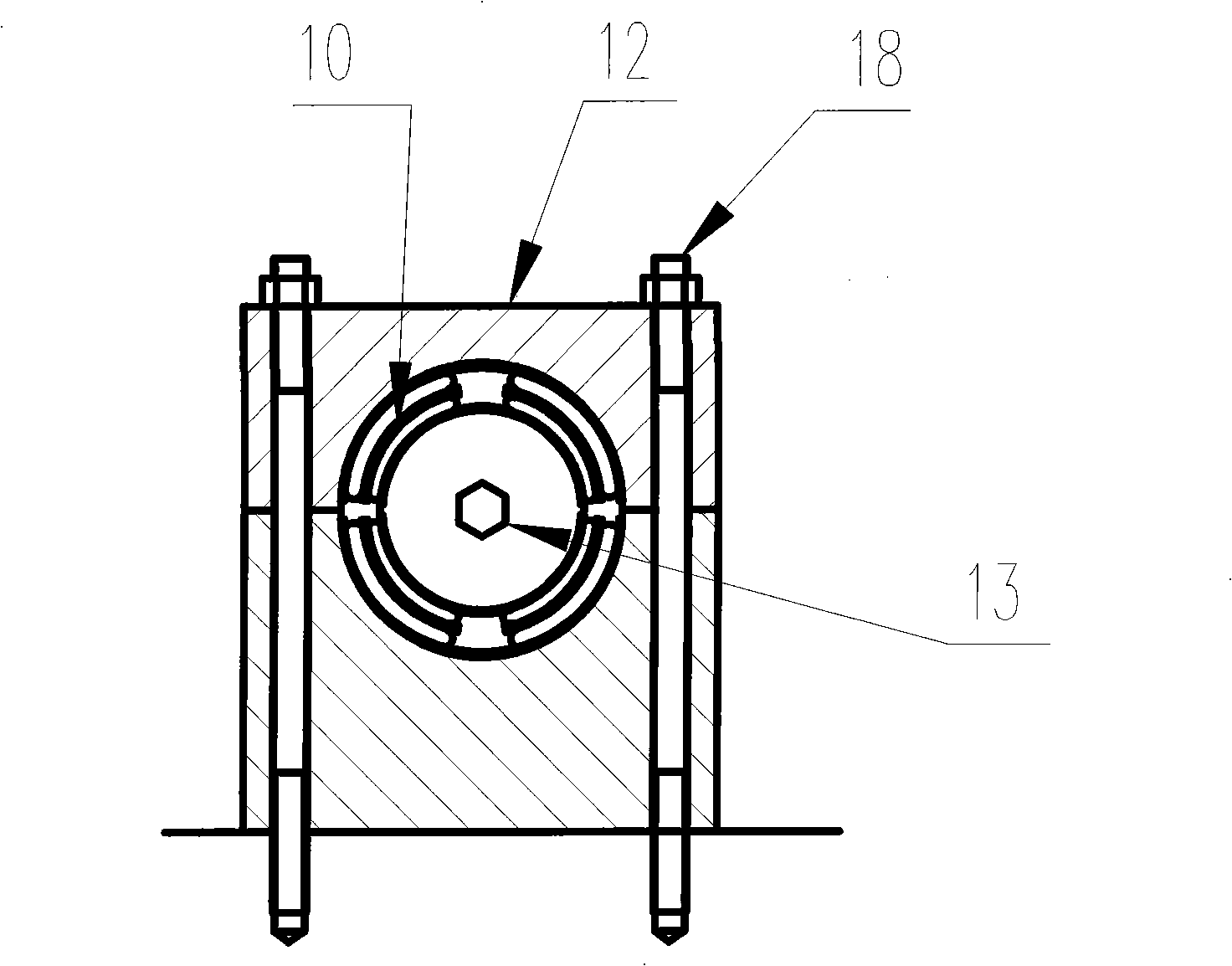

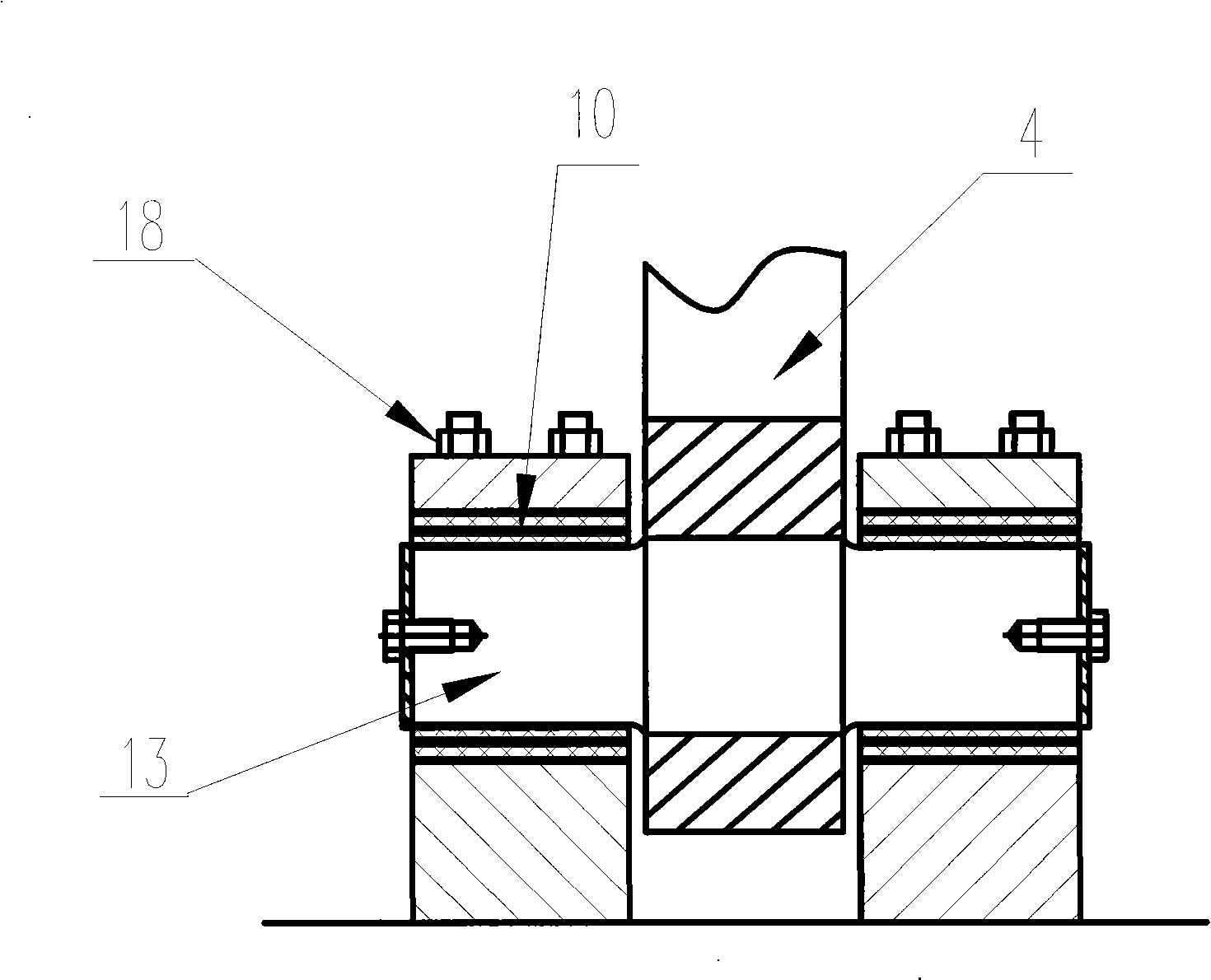

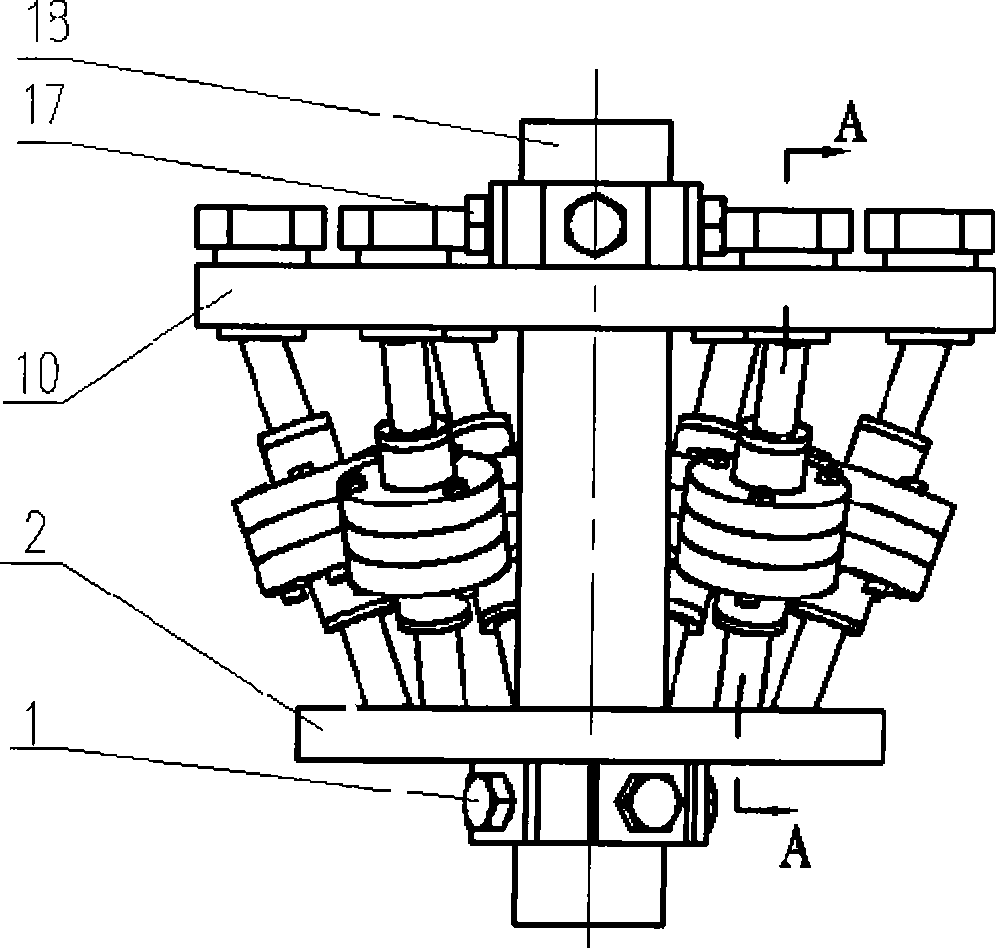

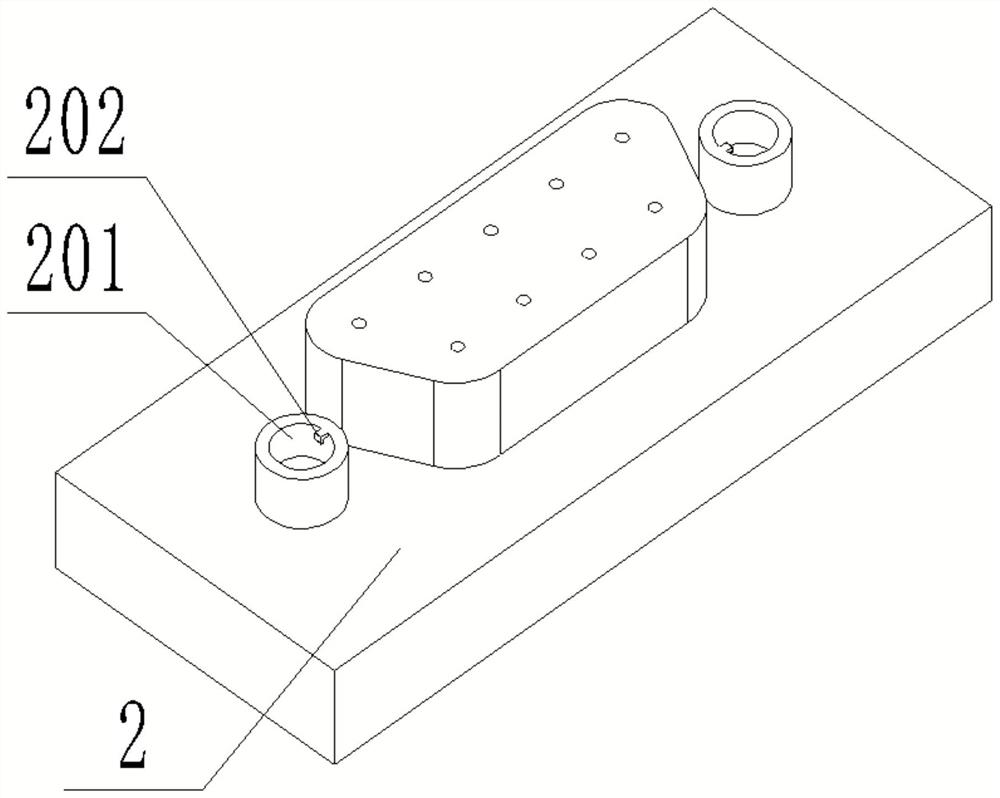

Multi-point partial pre-fastening method with adjustable load sharing mechanism

InactiveCN101419101AAdjustable structural parametersSimple structureForce measurement using piezo-electric devicesPiezoelectric quartzEngineering

The invention relates to a multipoint local pretightening method for adjustable load sharing mechanisms, which belongs to the field of a sensing test method and a sensing test device. The method realizes multipoint local pretightening by adjustment of a pretightening screw to drive a pretightening slider, and realizes adjustment of structural parameters through a mounting length adjustable measuring rod. The multipoint local pretightening method adjusts the length of the measuring rod according to the actual demand of measurement and assembly, performs multipoint local pretightening force adjustment, and makes the measuring rod exerted by the pretightening force. The device adopted comprises six groups of adjustable load sharing mechanisms with the same structures, wherein each group of adjustable load sharing mechanisms consist of an upper platform, a lower platform, the pretightening screw, the pretightening slider, an upper connecting rod, a lower connecting rod, an upper round nut, a lower round nut, an upper connecting flange, a lower connecting flange, a group of piezoelectric quartz sensors and a positioning ring. The multipoint local pretightening method realizes multipoint local pretightening and adjustment of the structural parameters, and has the characteristics of good pretightening effect, strong large-load sharing capacity, convenient assembling operation, high precision, good stability and simple structure.

Owner:DALIAN UNIV OF TECH

Highly effective pre-tighter for pre-tightened safety belt

The invention discloses a high-efficiency preloading device for preloading safety belt with simple structure, small cubage, low cost and high power transferring benefit. The invention comprise piston bar, guide head of piston bar, cylinder, gas generator, signal wire of gas generator, connecting rope, core shaft of scrolling device, power wheel, stopping claw, base and sliding way of piston bar. When vehicle impact happens sensor transfers contact signal to gas generator so as to generate blasting. Generated high-pressure gas pushes the piston bar in cylinder and the guide head of piston bar move and the connecting rope is pushed to move. The connecting rope draws the power wheel rotate. When the power wheel rotates the stopping claw is driven to move together and extrudes towards to inside. Extruded stopping claw makes the power wheel and the end of core shaft of scrolling device lock together so that the core shaft of scrolling device rotate in phase as the power wheel rotate and safety belt on it returns so as to draw crewman back and eliminate crewman gap. The preloading purpose is achieved and protecting effect of safety belt is improved.

Owner:上海冠驰汽车安全技术有限公司

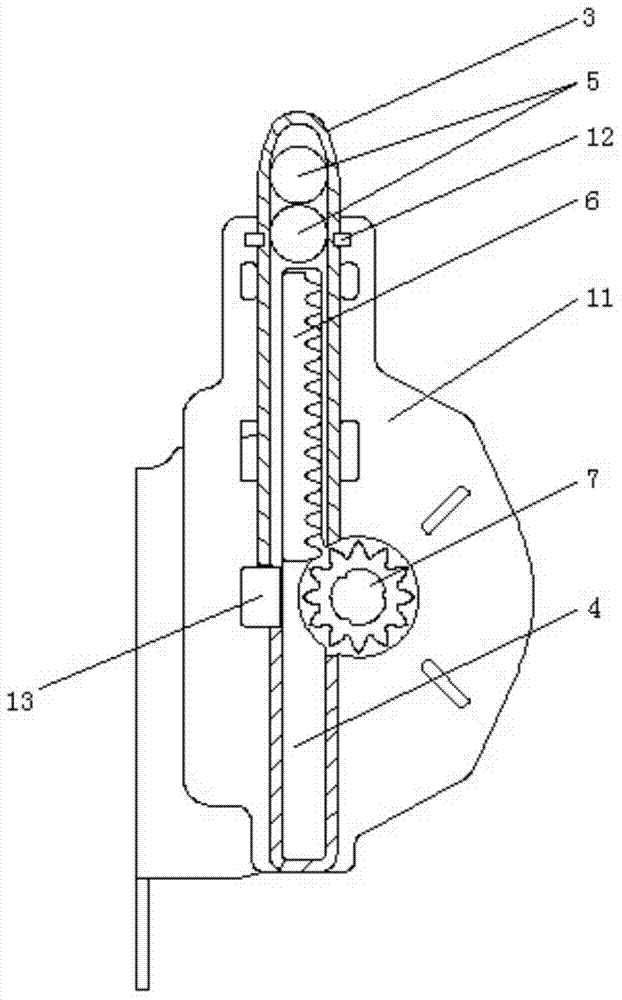

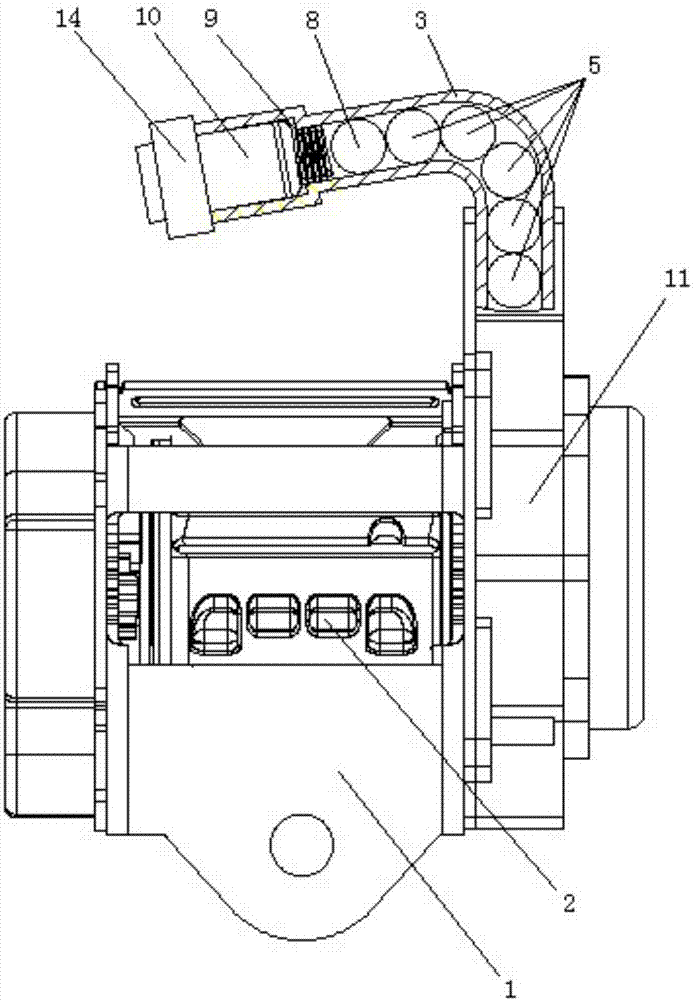

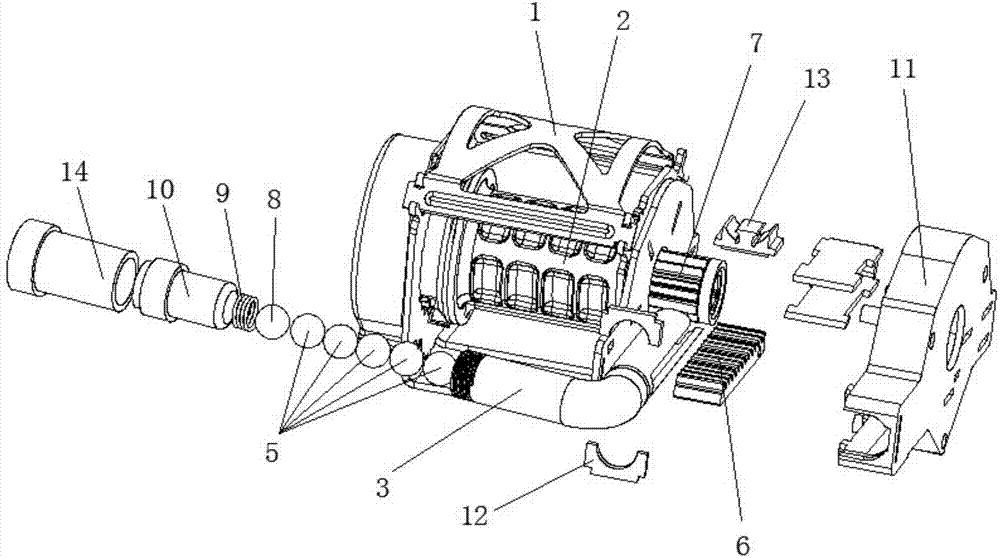

Safety belt retractor with pre-tightening device

InactiveCN104742857AIncrease the rewind strokeIncrease binding forceBelt retractorsEngineeringEnergy efficient transmission

The invention relates to a safety belt retractor with a pre-tightening device. The safety belt retractor comprises a frame, winding shafts and the pre-tightening device. The pre-tightening device comprises a round pipe, a U-shaped plate, a force transmission ball set, a rack, a gear, a sealing ball, a spring, a gas generator and a housing. The round pipe is linked with the U-shaped plate and then is fixedly arranged in the housing; the linkage portion of the round pipe and the U-shaped plate is a linear segment portion, and one end, not linked with the U-shaped plate, of the round pipe is provided with the gas generator; the spring is arranged at one end, stretching into the round pipe, of the gear generator; and a long groove is formed in the linear segment portion of the round pipe, and the rack is fixedly arranged in the long groove. The sealing ball and the force transmission ball set are arranged in the round pipe and located between the spring and the rack; the gear and the winding shafts are coaxially and fixedly connected; and when the rack is fixed through a shearing pin, the rack and he gear are in the non-meshing state, and when the rack descends, the rack can be meshed with the gear. A plurality of force transmission components are utilized for carrying out energy efficient transmission, the retracting stroke of a safety belt is increased, and the retractor is simple in structure and low in manufacturing cost.

Owner:常州博万达汽车安全设备有限公司

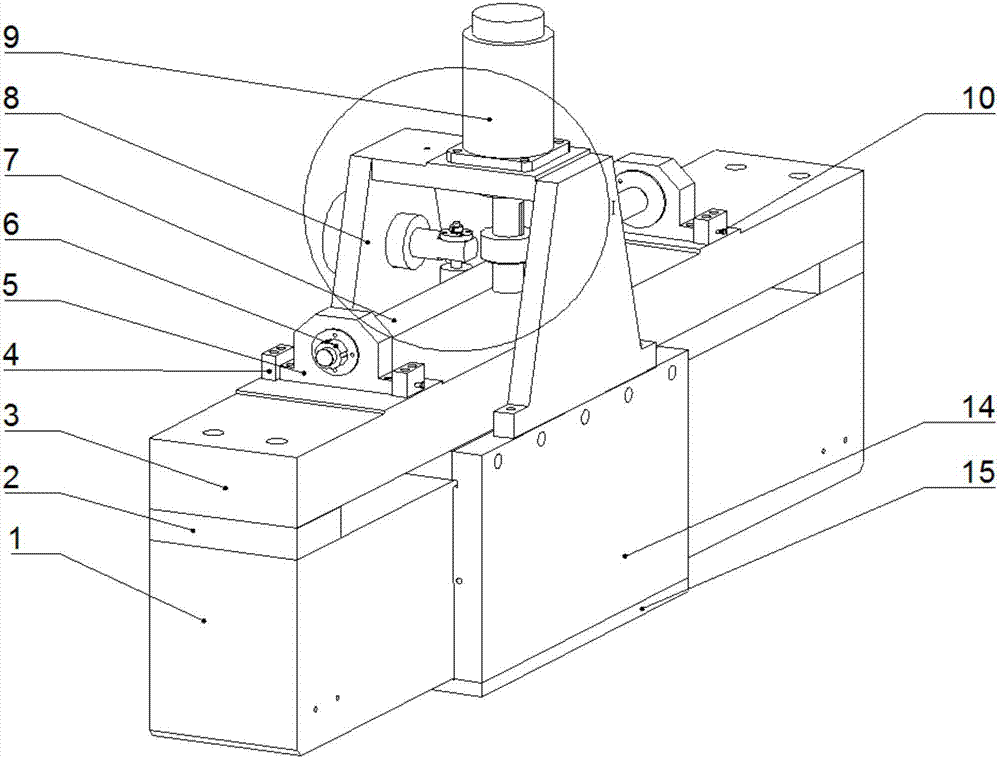

Friction lever driving air static pressure guide rail

InactiveCN107042445AIncrease stiffnessLoad largeGrinding carriagesOptical surface grinding machinesBall screwEngineering

The invention relates to a friction lever driving air static pressure guide rail, belongs to the technical field of machine tool equipment units and components, and has the benefits as follows: 1, an upper cross beam and a lower cross beam are adopted for forming a double-cross beam structure, so that the rectangular air static pressure guide rail is high in motion accuracy, frictionless, free from pollution; a back pressure structural design is adopted, an aerostatic guide rail mover is utilized to be arranged on the lower cross beam in a sleeving manner, so that an aerostatic back pressure area is formed between the upper surface of the aerostatic guide rail mover and the upper cross beam, and the load-bearing rigidity of the aerostatic guide rail is improved; besides, with the adoption of the friction lever driving structure, the advantages of high precision, micro-feeding and no transmission clearance are achieved, and the friction lever driving air static pressure guide rail is more economic and practical compared with the driving method adopting a linear motor or ball screw; 2, the aerostatic guide rail mover of the air static pressure guide rail adopts a porous restriction material, thereby being high in rigidity, high in the load-bearing capacity and high in precision, and capable of ensuring a good sliding effect while meeting the back pressure requirements; 3, by adopting a pre-tightening mechanism comprising a puller bolt and a preloaded spring for pre-tightening a pre-tightening friction wheel, the operation is convenient, the pre-tightening effect is good, and the stepless regulation on the pre-tightening force can be realized.

Owner:XI AN JIAOTONG UNIV

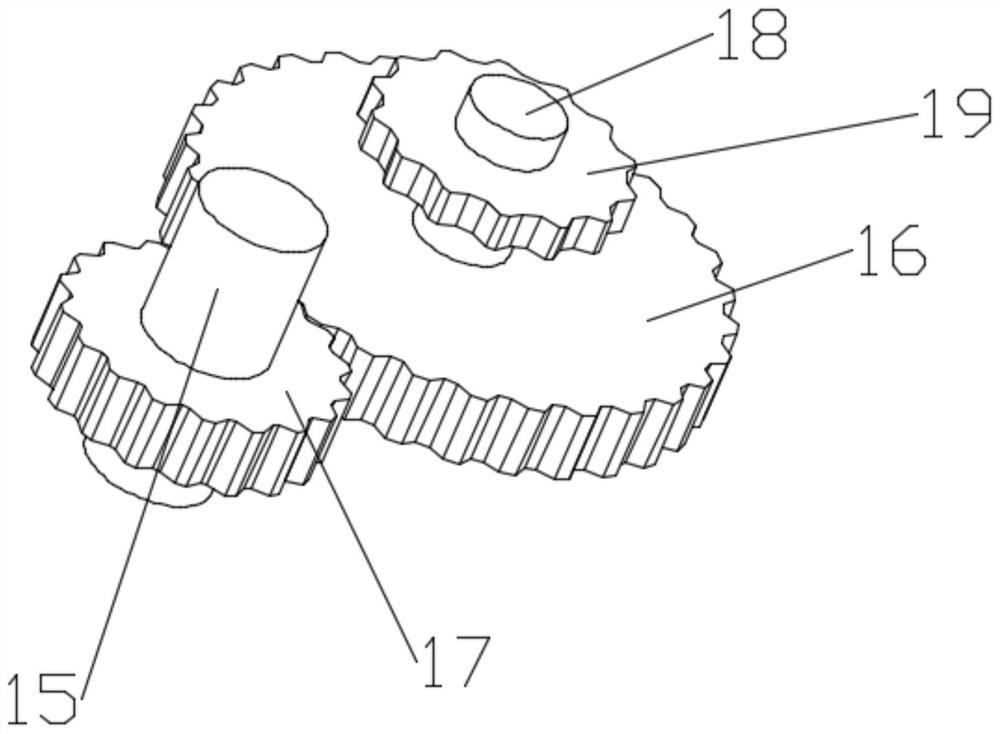

Open-close type chain cutter sisal hemp harvesting device

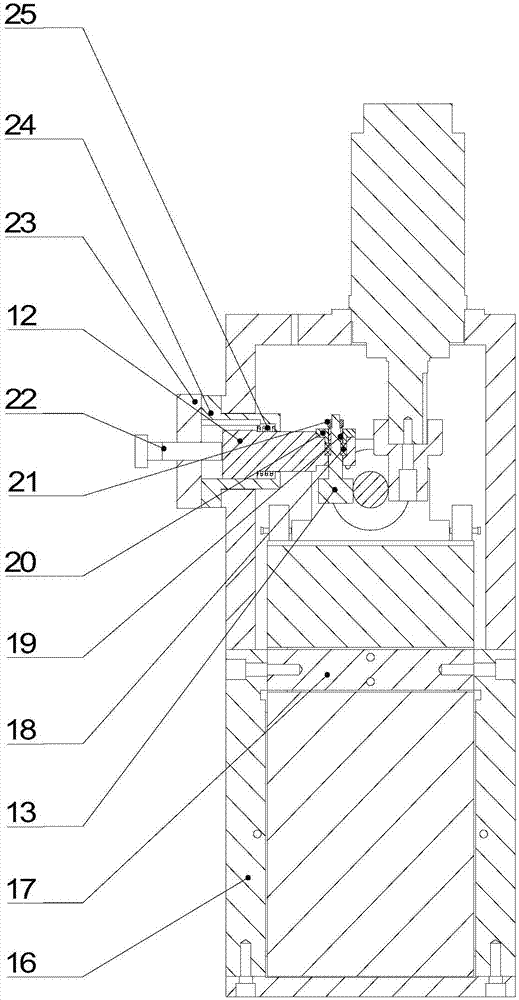

ActiveCN112913469ARealize no dead angle cuttingSolve the problem of mechanized harvestingHarvestersAgricultural undercarriagesElectric machineryEngineering

The invention relates to an open-close type chain cutter sisal hemp harvesting device. The open-close type chain cutter sisal hemp harvesting device comprises an open-close type chain cutter cutterhead mechanism for clamping and cutting sisal hemp, a circumference feeding mechanism for driving the open-close type chain cutter cutterhead mechanism to rotate around a circle center on a horizontal plane, a circle center feeding mechanism for driving the open-close type chain cutter cutterhead mechanism to leave far away and approach to the circle center on the horizontal plane, and a Z-direction feeding mechanism for driving the open-close type chain cutter cutterhead mechanism to vertically move. The open-close type chain cutter cutterhead mechanism comprises an open-close cutterhead mechanism and a chain cutter mechanism; the open-close cutterhead mechanism comprises a fourth motor, a worm and gear mechanism and two circular arc-shaped cutterheads; the chain cutter mechanism comprises a fifth motor, a chain, a driving chain wheel, a driven chain wheel, a tensioning wheel, a tensioning mechanism, a crescent cutter blade and a cover plate; and the crescent blade is arranged at the outer side of the chain and forms a chain cutter structure with the chain. The open-close type chain cutter sisal hemp harvesting device provided by the invention solves the mechanical harvesting problem of sisal hemp leaves, ensures the harvesting efficiency and the harvesting quality, and belongs to the field of sisal hemp harvesting equipment.

Owner:SOUTH CHINA AGRI UNIV

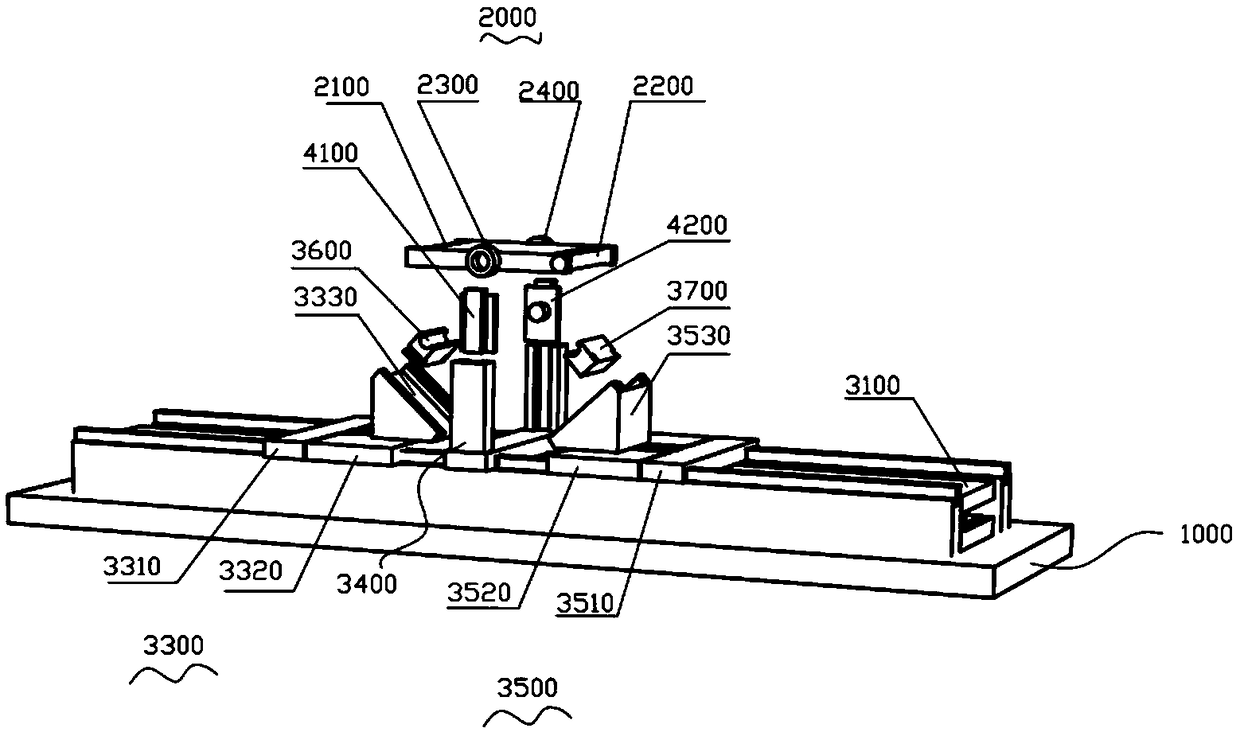

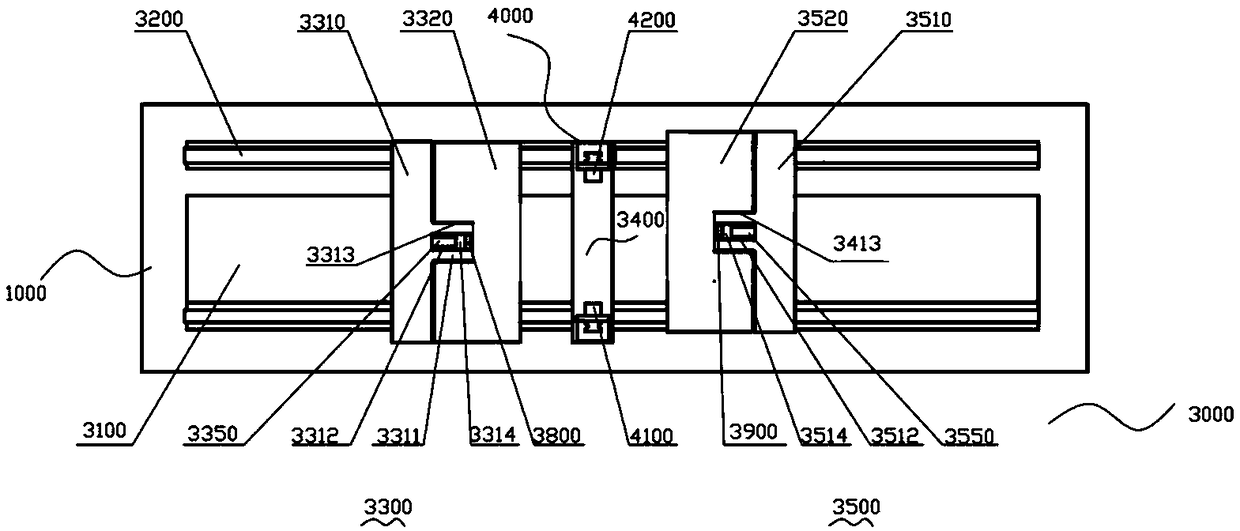

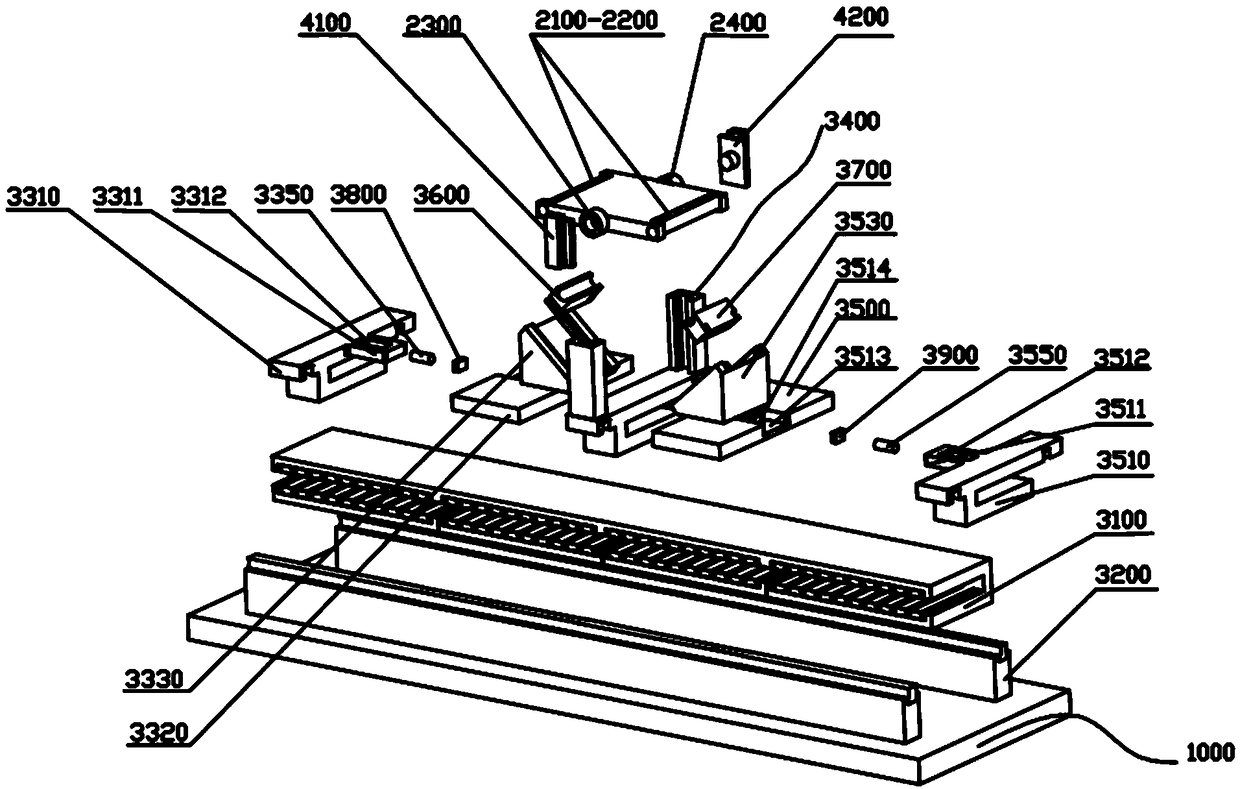

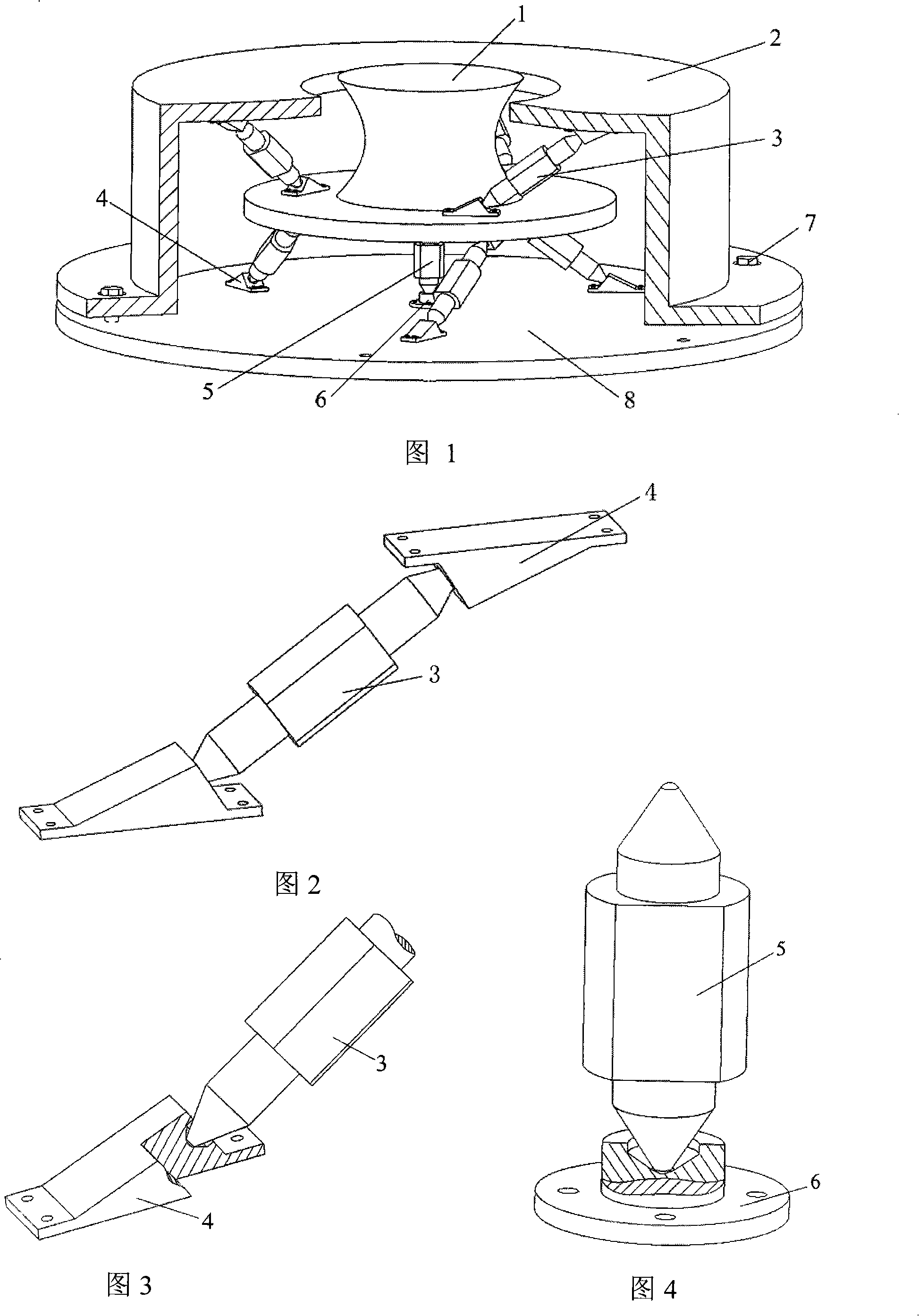

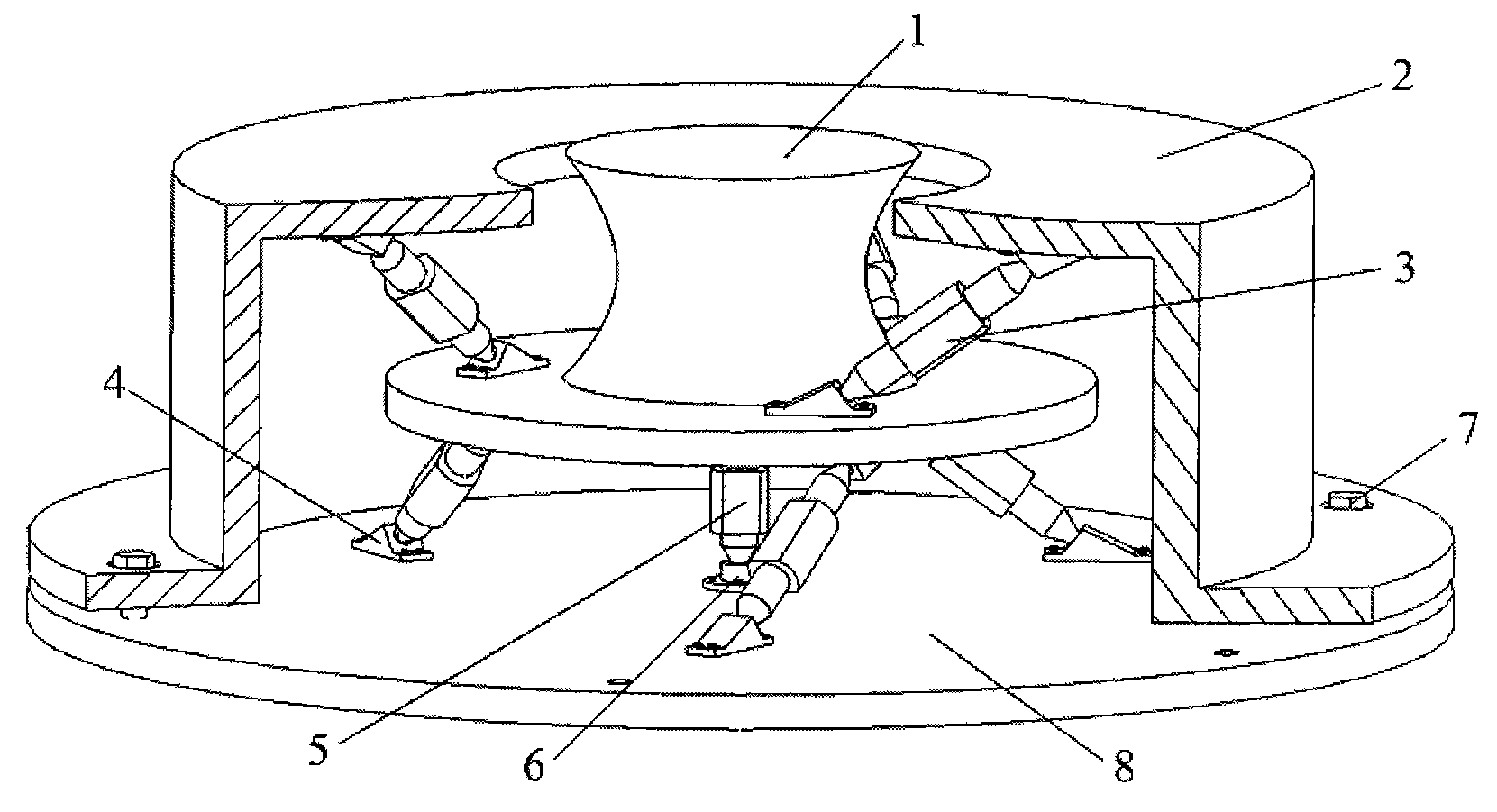

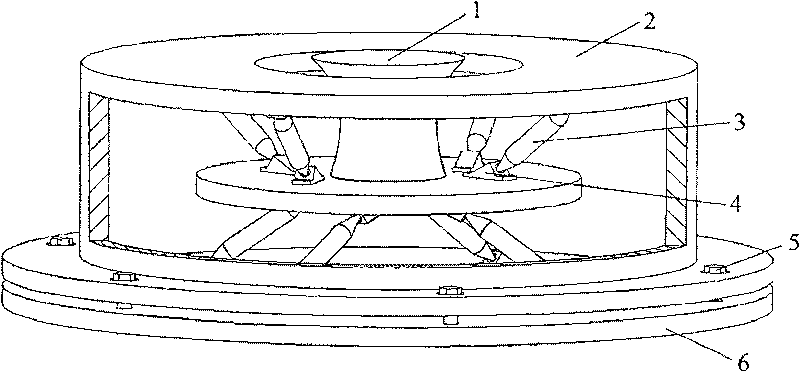

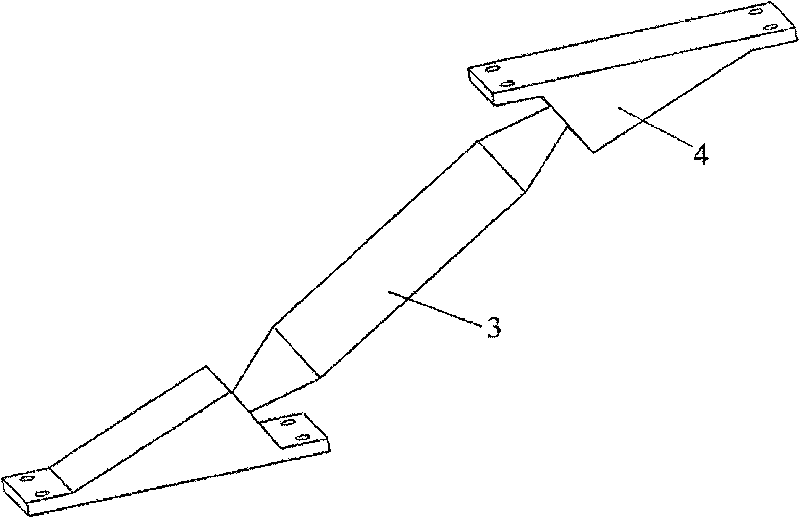

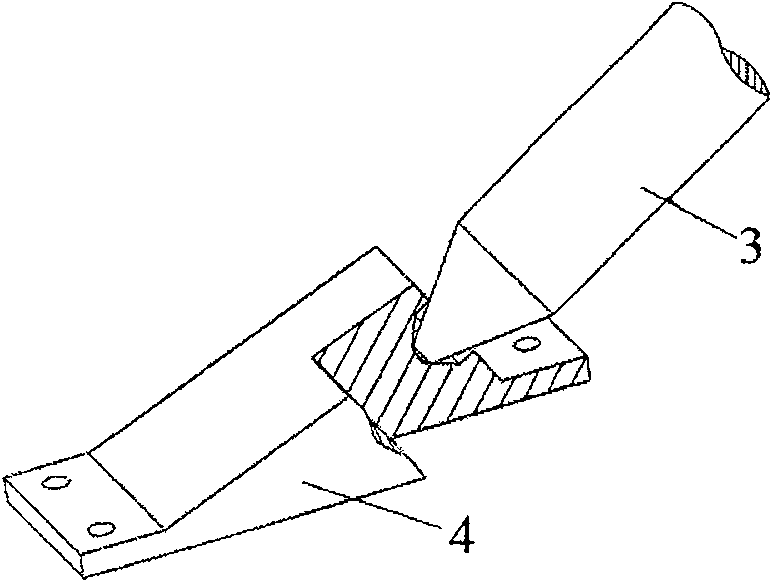

Common-stator large-stroke cross-scale three-degree-of-freedom parallel motion platform

PendingCN108747426AHigh accelerationGood preload effectPiezoelectric/electrostriction/magnetostriction machinesFeeding apparatusStatorMicro motion

The invention provides a common-stator large-stroke cross-scale three-degree-of-freedom parallel motion platform. The motion platform comprises a base, a working platform, a Y-axis motion system and aZ-axis motion suspension beam assembly; the working platform is arranged on the Z-axis motion suspension beam assembly; and the Z-axis motion suspension beam assembly is arranged on a middle macro-moving component. According to the motion platform, the whole macro-micro motion only needs one motor stator, three electric motors, driving sources of two piezoelectric ceramics to move coordinately, so that any combination of and macro-micro switching of the three-degree-of-freedom can be achieved; and each motion component adopts a macro micro common rail mode, a left macro-moving component, themiddle macro-moving component and a right macro-moving component move upwards, a driving structure on the single side is a design structure of a single motor and a common stator, the large-stroke motion can be realized, meanwhile, the high-speed and high-acceleration speed are achieved, and the motion platform realizes horizontal pitching motion.

Owner:GUANGDONG UNIV OF TECH

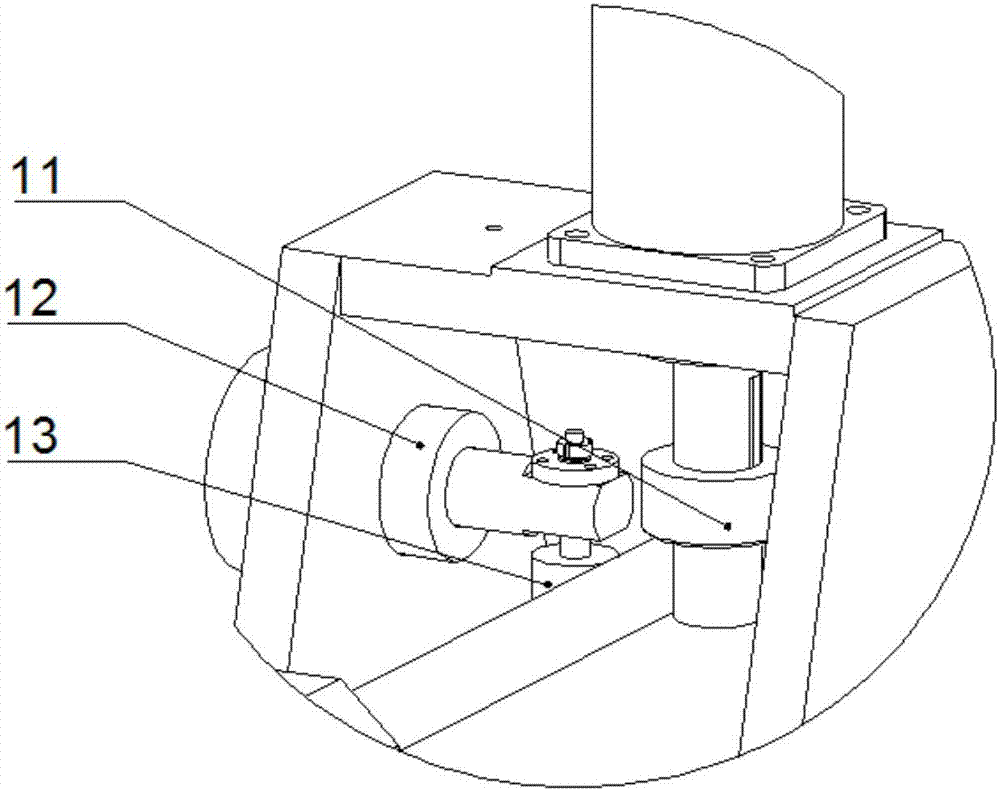

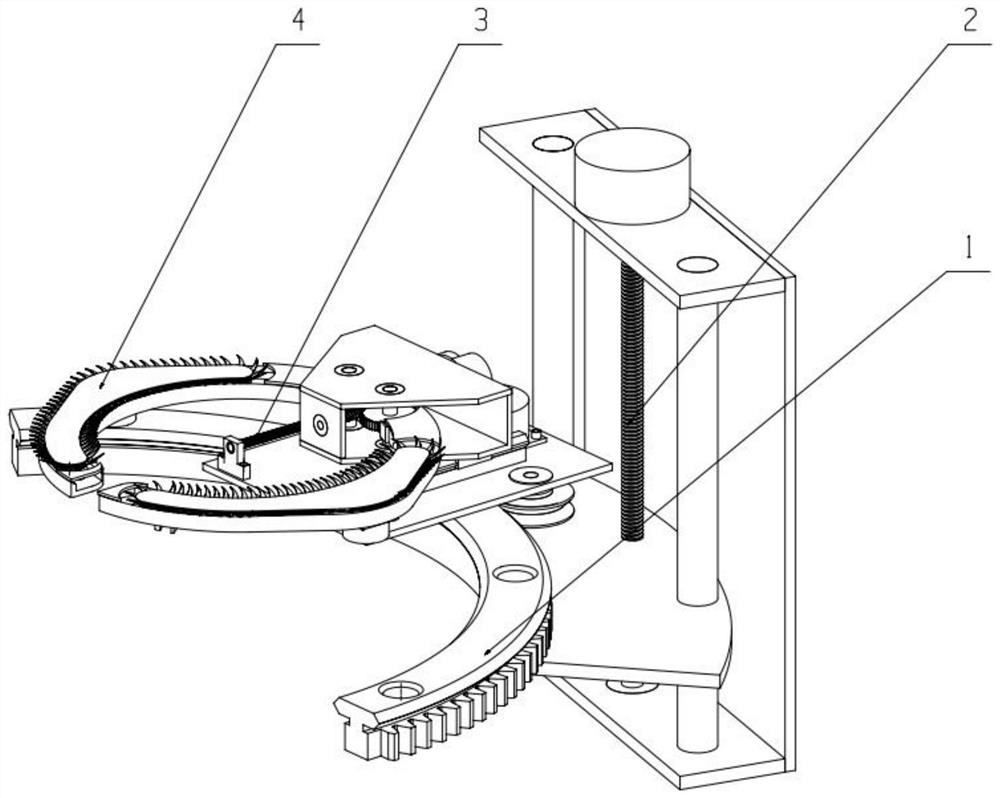

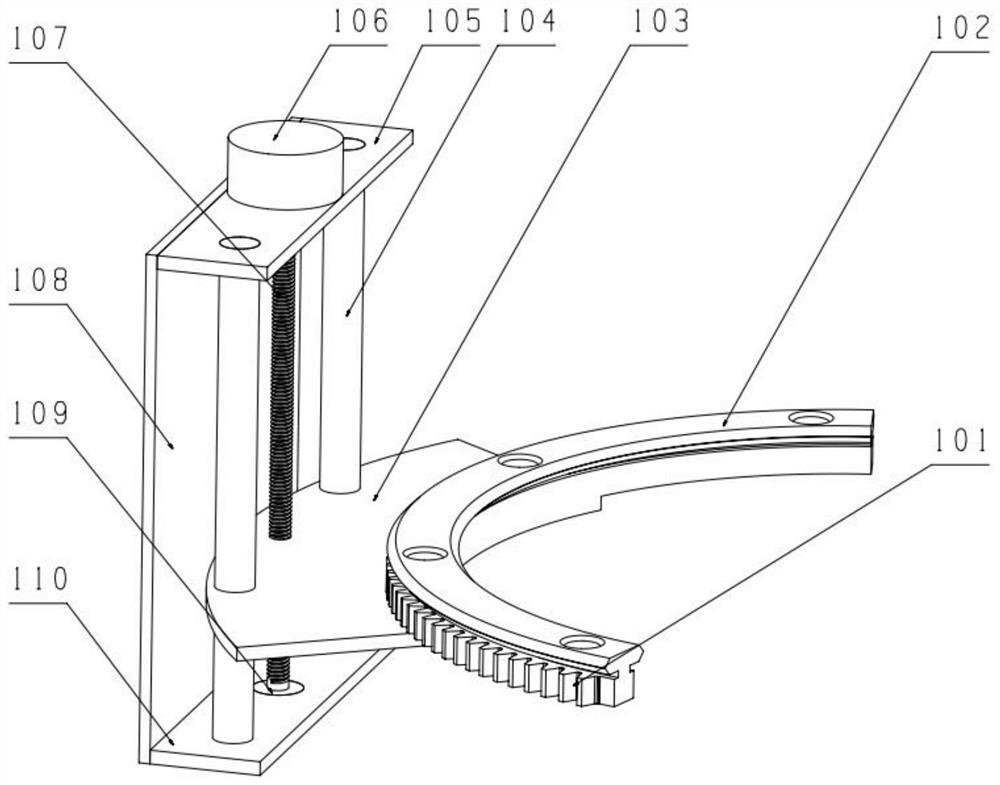

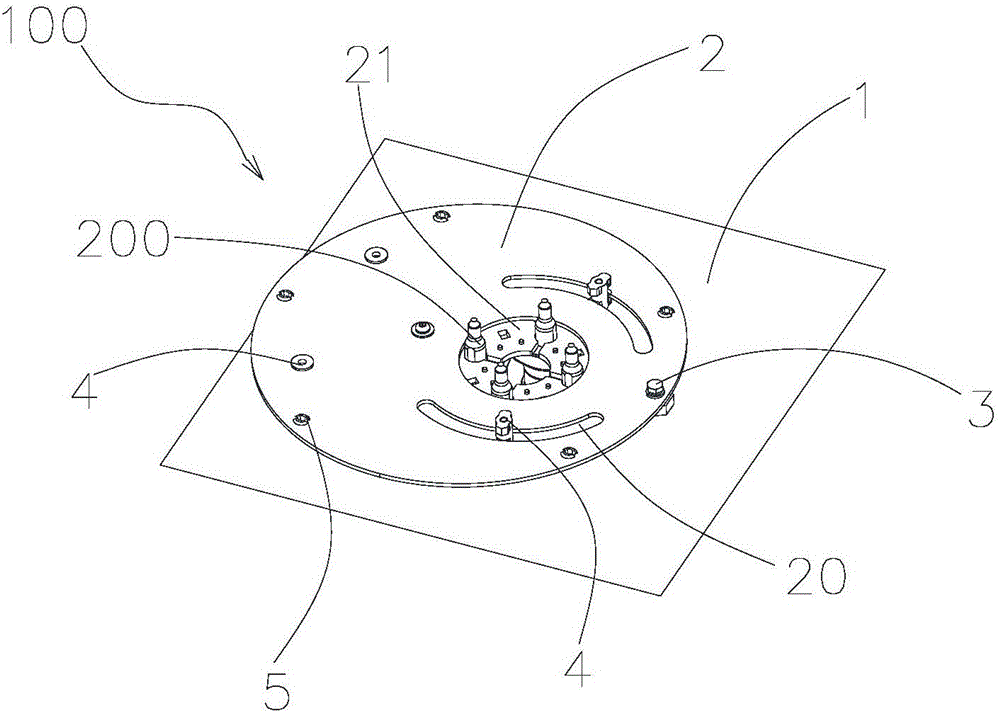

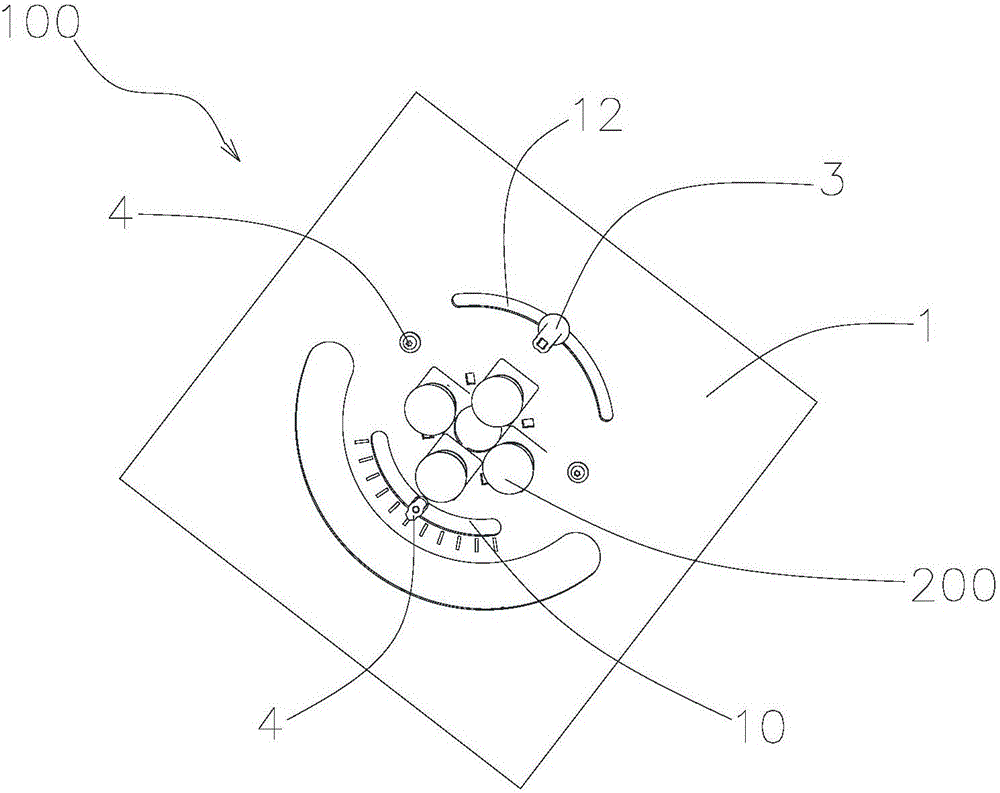

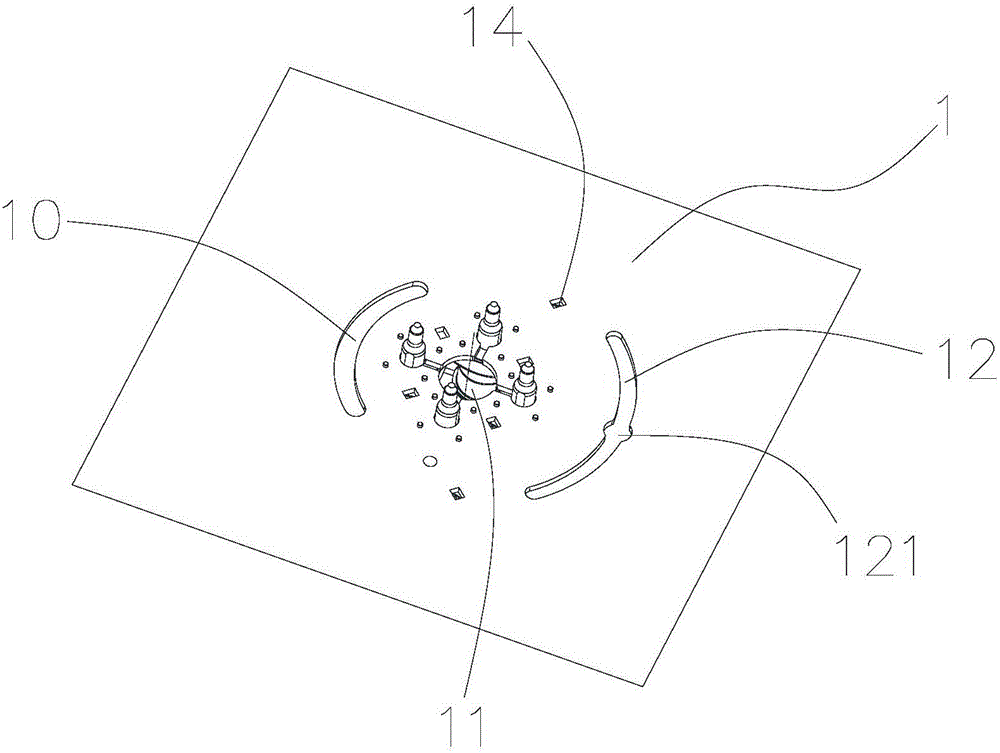

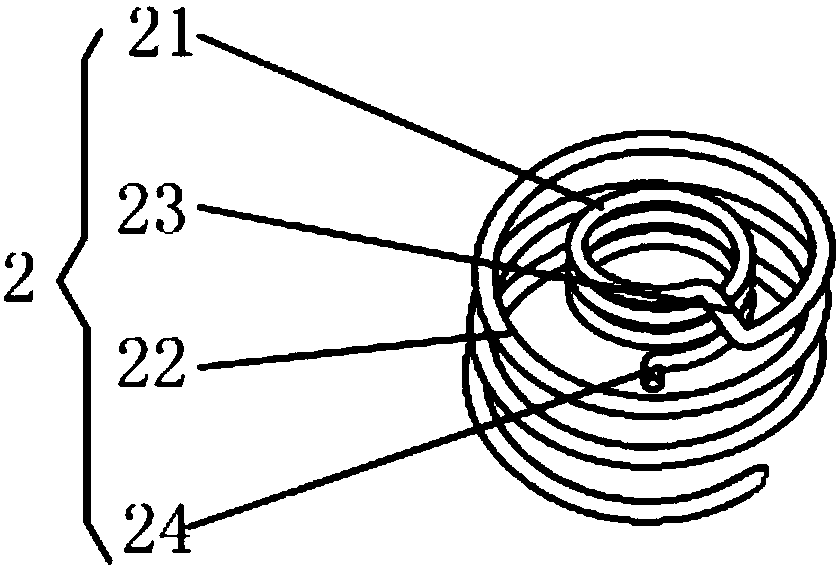

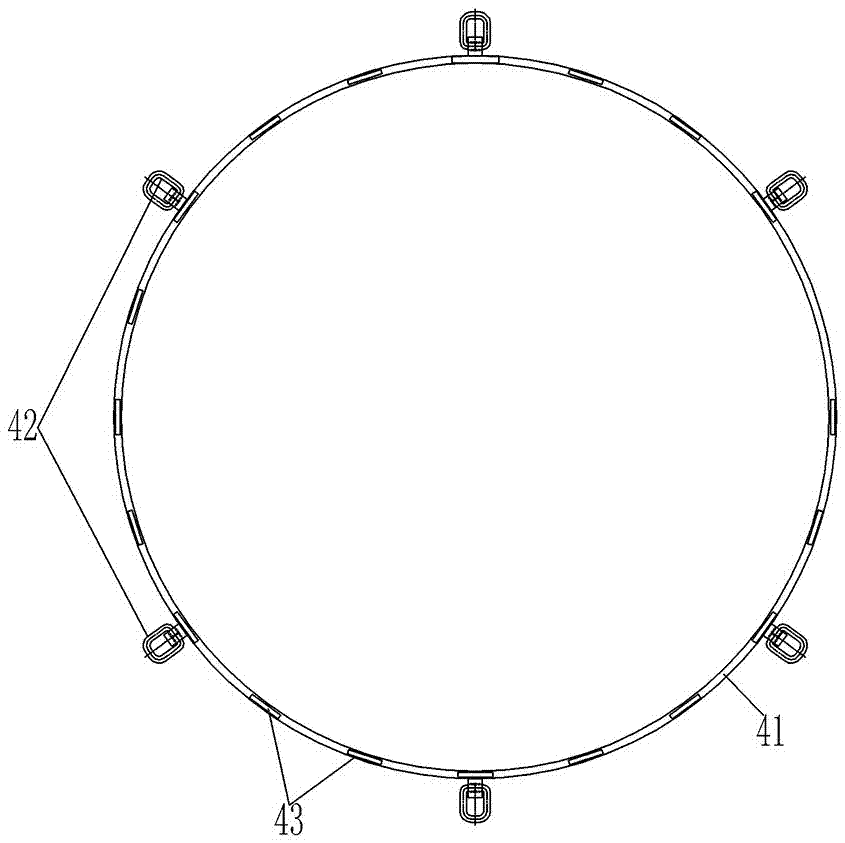

Antenna rotation mechanism and antenna

ActiveCN105914467AAvoid overturningVarious sizesAntennasRotating discElectrical and Electronics engineering

The invention provides an antenna rotation mechanism. The mechanism comprises a substrate and a rotating disc which is used for fixing an antenna main body and can be rotatably arranged on the substrate. The substrate and / or the rotating disc is provided with at least one arc limiting groove. Projections of centers of circles of the plurality of arc limiting grooves on the substrate are mutually superposed. A limiting assembly which is connected to the substrate and the rotating disc is arranged in each arc limiting groove. Through the plurality of concentric arc limiting grooves and the limiting assembly, a rotation angle of the rotating disc is limited and a virtual rotating shaft is constructed. An entity rotating shaft does not need to be installed so that occupation of the rotating shaft to a substrate installation space is avoided. In addition, the invention also relates to an antenna adopting the antenna rotation mechanism. The antenna possesses characteristics that the size is small; the structure is firm and reliable; and cross modulation is stable.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

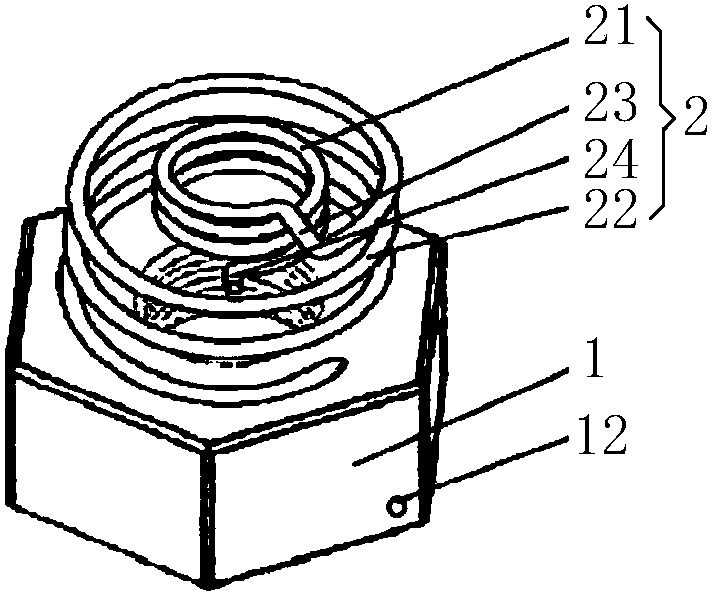

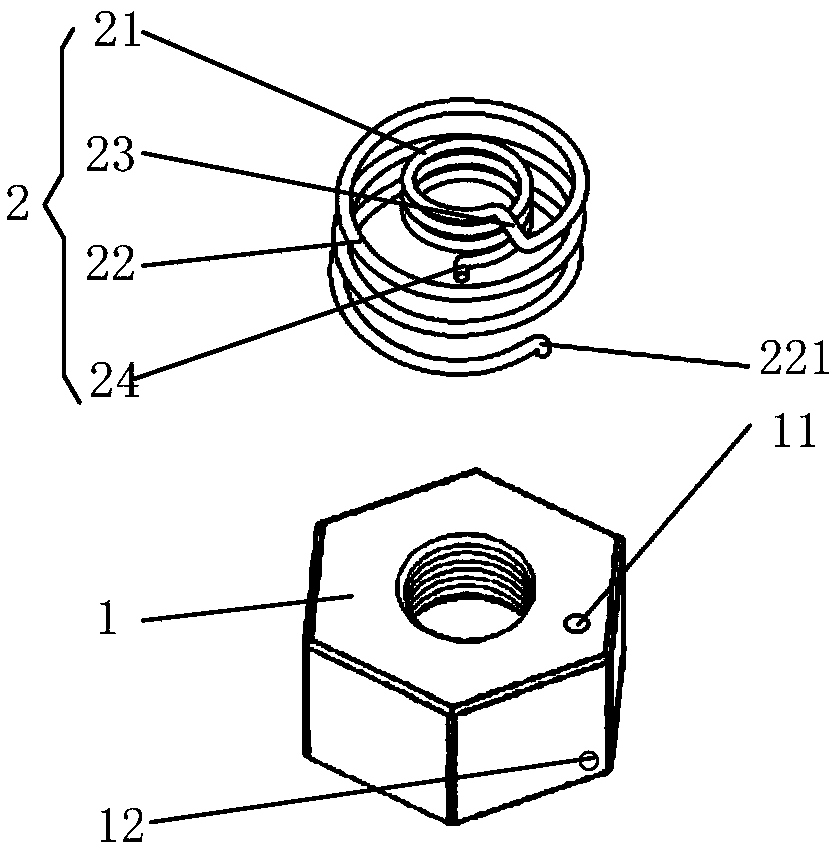

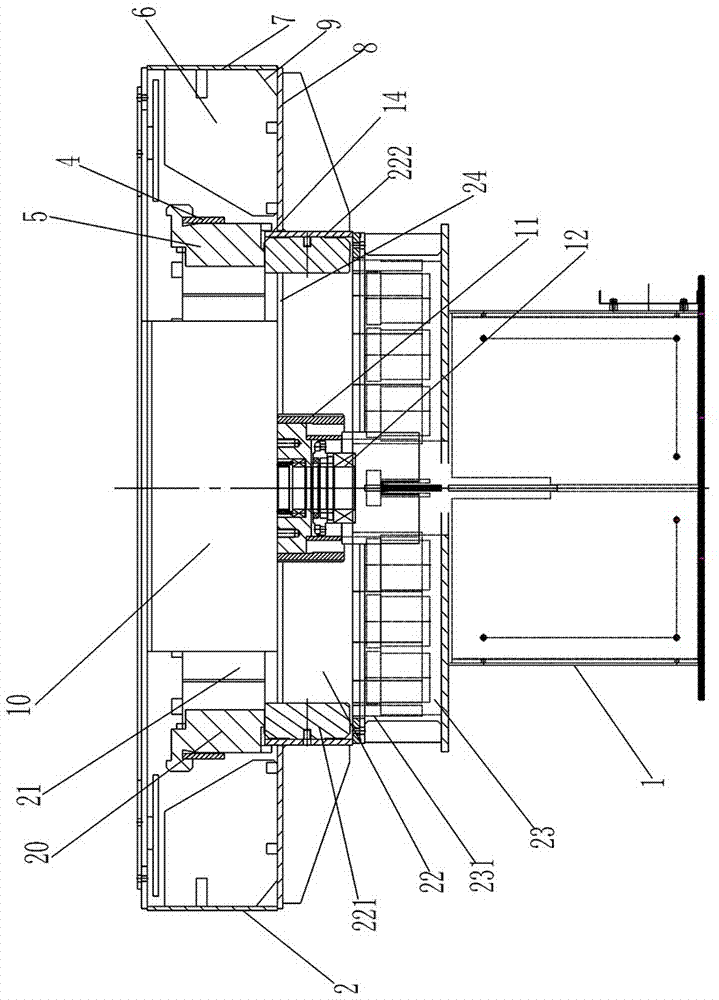

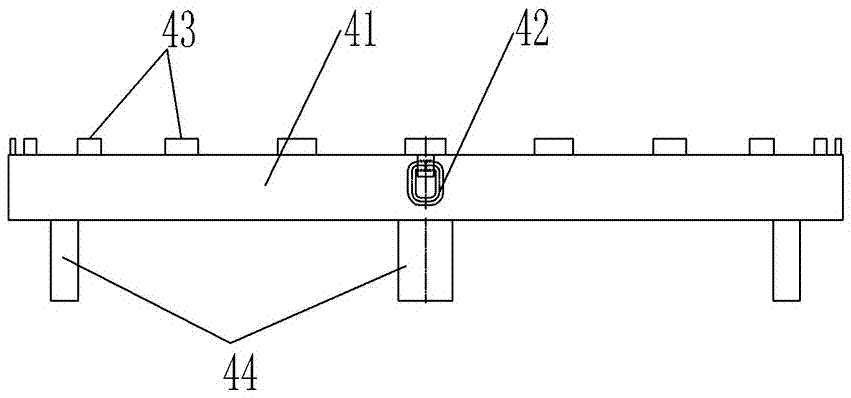

Elastic locking component, anti-loosening nut and anti-loosening bolt nut fastener

PendingCN108223547AConducive to opposite rotationSmooth movementNutsBoltsUltimate tensile strengthFastener

The invention relates to an elastic locking component, an anti-loosening nut and an anti-loosening bolt nut fastener. The elastic locking component comprises an inner spring and an outer spring arranged on the outer portion of the inner spring in a sleeving manner. One end of the outer spring is connected with the same end of the inner spring through an inner and outer spring connecting portion. The turning direction of the outer spring is opposite to that of the inner spring. The anti-loosening nut is used for being assembled with a bolt and is provided with a nut body and the elastic lockingcomponent. The other end of the outer spring is connected with the nut body, and the inner spring can be pressed on and wound around a thread of the bolt. The anti-loosening bolt nut fastener is provided with a pre-tightening sleeve and the above anti-loosening nut. The structure is simple, and the locking performance is good; only the nut body is modified, and the bolt or a fastening workpiece does not need to be modified; and it can be guaranteed that the fastener has good work intensity, and engineering safety can be guaranteed.

Owner:盐城市盐都区欧力达贸易有限公司

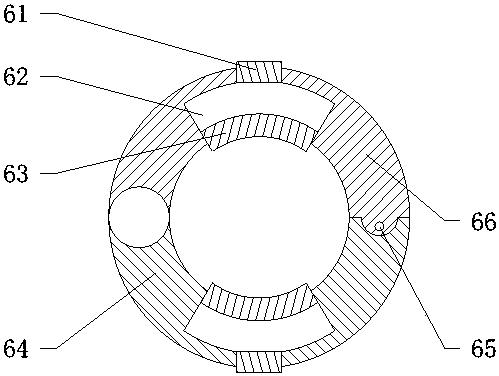

Centrifugal sand making machine

ActiveCN105435931AAchieve shapingReduce manufacturing costGrain treatmentsEngineeringMechanical engineering

The invention relates to a centrifugal sand making machine which comprises a housing provided with a crushing cavity, wherein the crushing cavity is internally provided with a rotor of which the rotation center axis extends along the vertical direction; a crushing lining plate assembly for carrying out crushing sand making on a material is arranged at the outer side of the rotor in the crushing cavity, and is detachably assembled in the crushing cavity; a support bottom plate which extends or is distributed along the circumferential direction of the rotor and is used for a material accumulation surface for accumulation and shaping of the formed material thrown out by the rotor is arranged at the circumferential outer side of the crushing lining plate assembly in the crushing cavity; a cylindrical outer material blocking surface extending along the vertical direction is arranged at the edge of the outer side of the support bottom plate; a material accumulation dent part is formed by the outer material blocking surface and the support bottom plate; and the inner side, facing towards the rotor, of the support bottom plate is a material falling side. The crushing sand making and shaping on the material are realized through putting or taking the crushing lining plate assembly into or out of the crushing cavity, no additional shaping machine is required to be equipped, the production cost can be lowered effectively, and an equipment utilization rate can be increased.

Owner:ZHENGZHOU ZHENGSHENG HEAVY IND TECH CO LTD

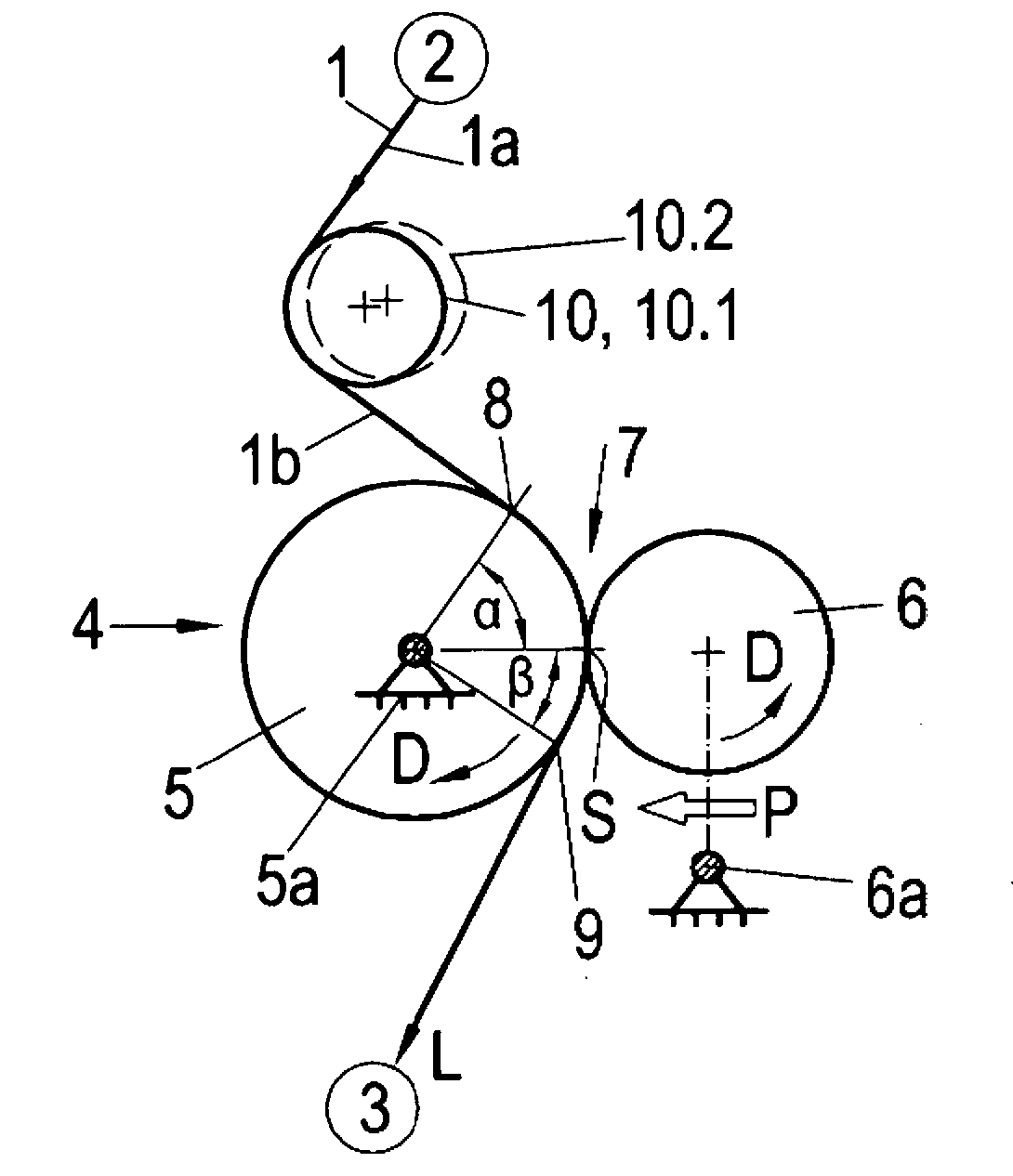

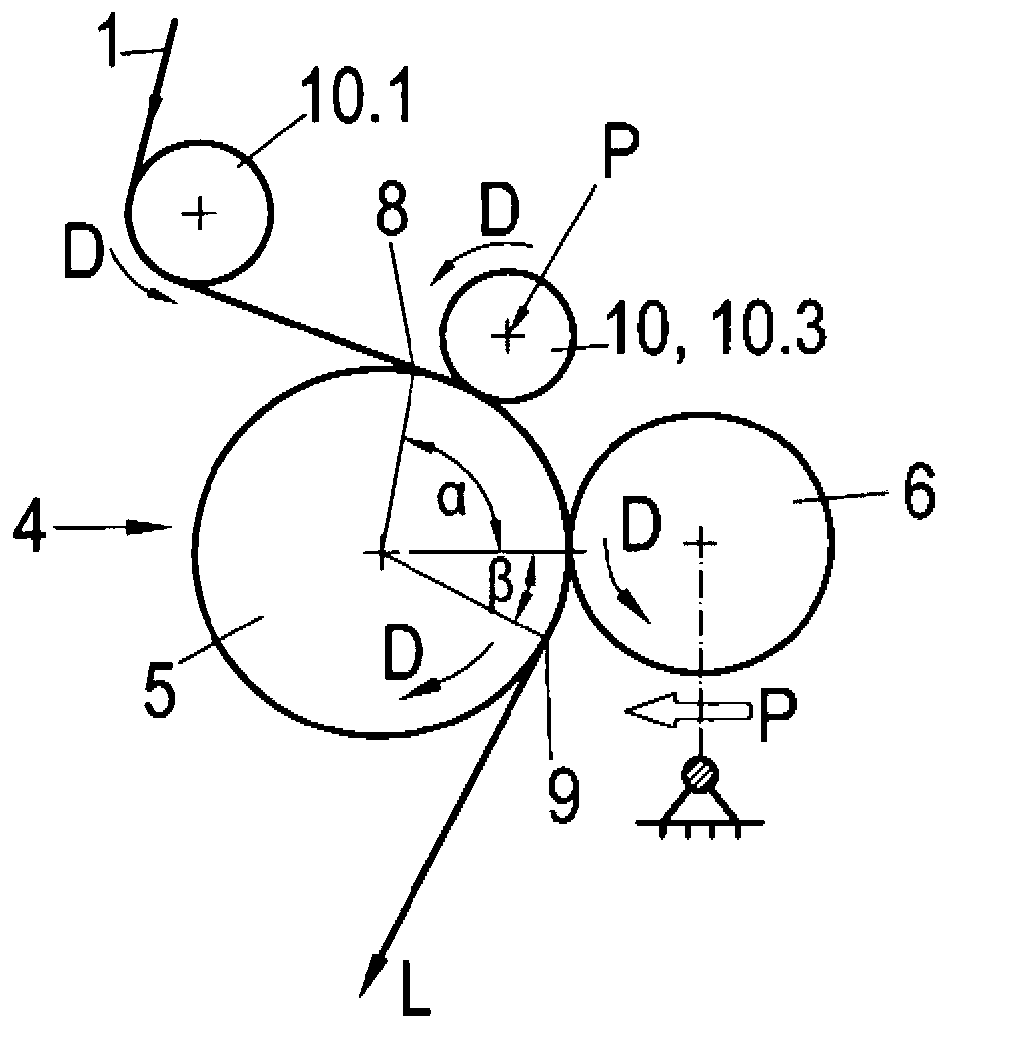

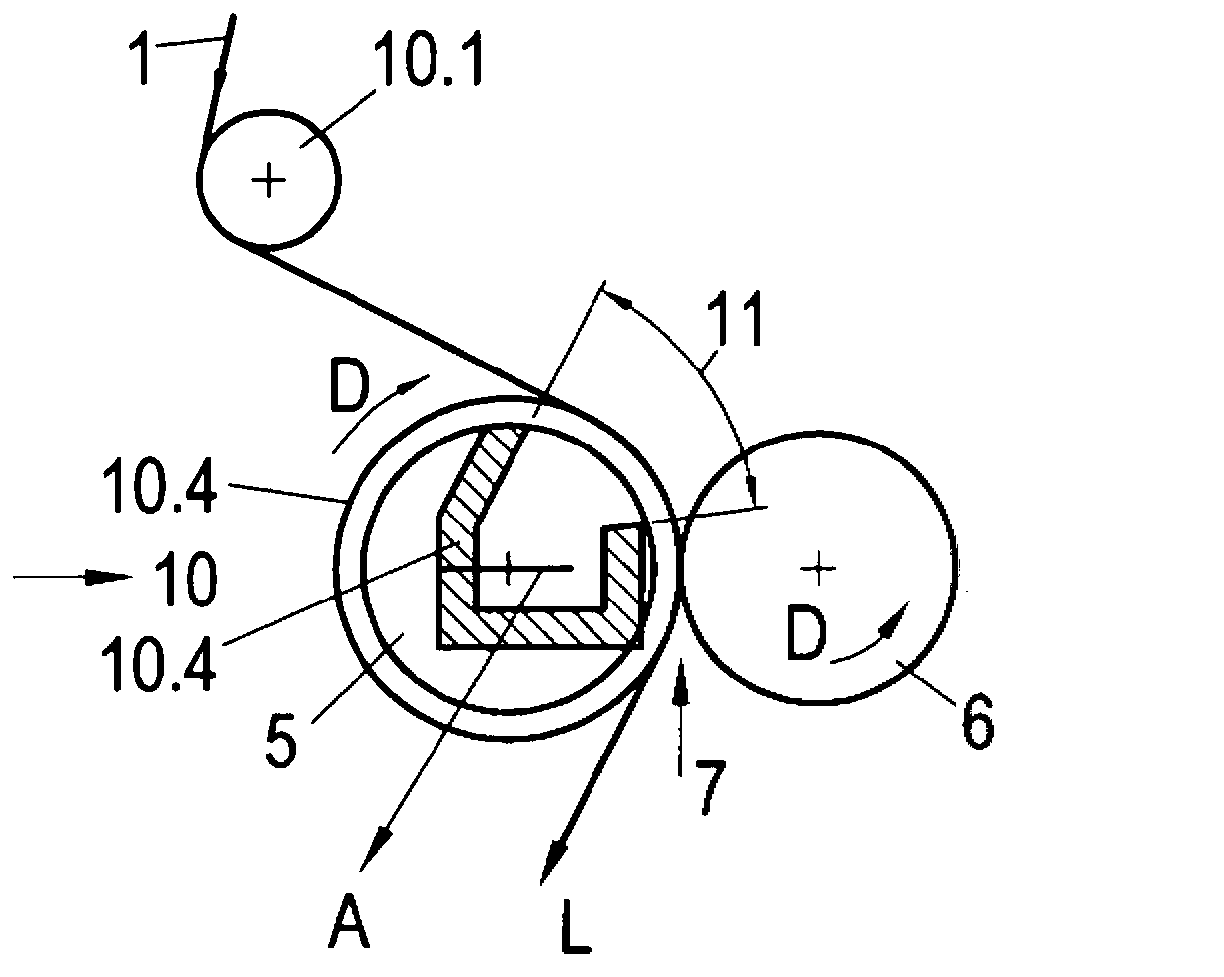

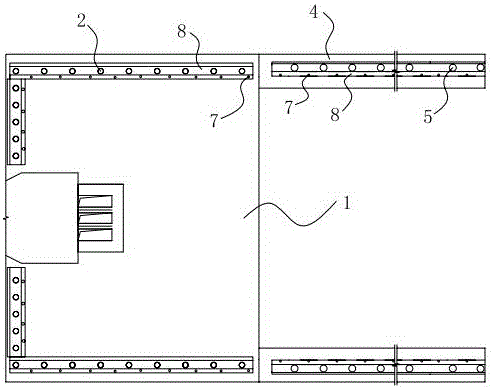

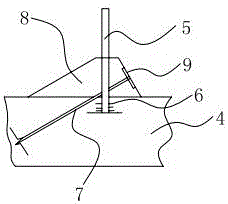

Device for treating a running paper, cardboard or other fiber material web

The invention relates to a device for treating a running paper, cardboard, or other fiber material web (1) during the production and / or refining process thereof, comprising at least one coating device (2) for applying a liquid or paste application medium, comprising at least one drying device (3) for drying the applied medium and comprising at least one draw press (4) for applying the required web tension after the individual treating devices, wherein the draw press (4) comprises a stationary, or non-pivotable roller (5) and a displaceable roller (6) that can be pressed against the stationary roller (5), together forming a press gap (7) through which the fiber material web (1) travels during the treatment thereof, wherein the fiber material web (1) partially enwraps the circumference of the stationary roller (5), that is, by a wrap angle on the inlet side and the outlet side of the press gap (7). According to the invention, a wrap angle (alpha) of greater than 5 DEG up to 180 DEG is provide for wrapping on the inlet side, while the wrap angle (beta) on the outlet side is negligible or insignificant, and that at least one auxiliary device (10) is provided for preventing air bubbles between the stationary roller (5) and the fiber material web (1) and for stabilizing the fiber material web (1) during the inlet side wrapping.

Owner:VOITH PATENT GMBH

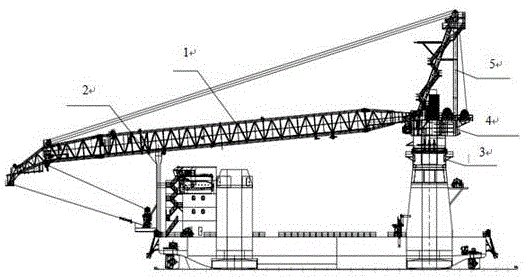

Hoisting process of full-circle slewing crane

InactiveCN105152041AReduced installation effortSpeed up the installation processCranesPropellerSlewing bearing

The invention relates to a hoisting process of a full-circle slewing crane. The hoisting process mainly comprises the following steps: component lifting: double hooks of a 1600T floating crane are utilized to hang a slewing chassis and a final-assembled lifting lug at the top of a propeller strut so as to hoist the slewing chassis and a propeller strut component; hoisting in place: the floating crane is utilized to shift the component to the position above a spud leg, and the component is adjusted in place; the component is slowly laid down onto a cylinder body, and all double-end studs can penetrate in place; after some of bolt pairs are pre-tightened, the floating crane can release the hooks, and all the bolt pairs are pre-tightened subsequently; mounting of remaining parts. The hoisting process has the advantages that a slewing bearing and all the slewing parts are mounted in place, integrally hoisted in place on site and connected with the cylinder body, so that the workload of site mounting is greatly reduced, and the mounting progress is accelerated.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

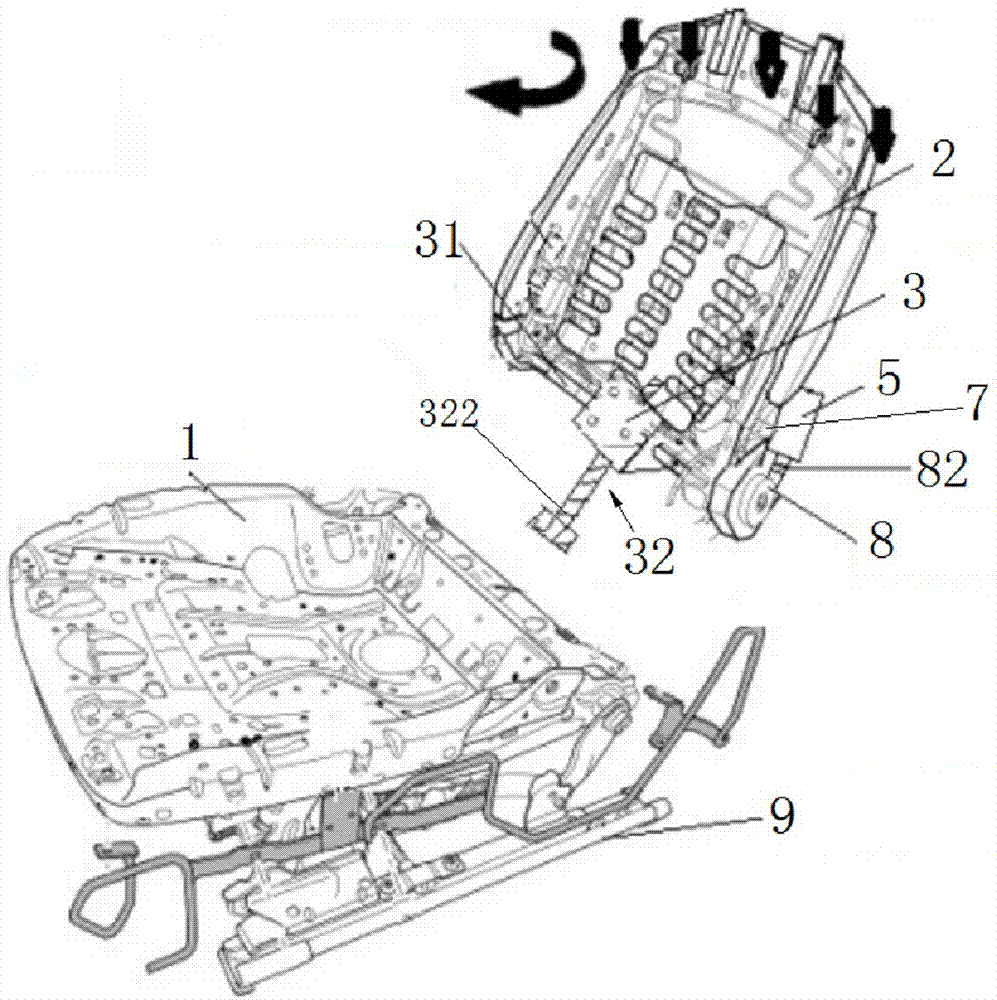

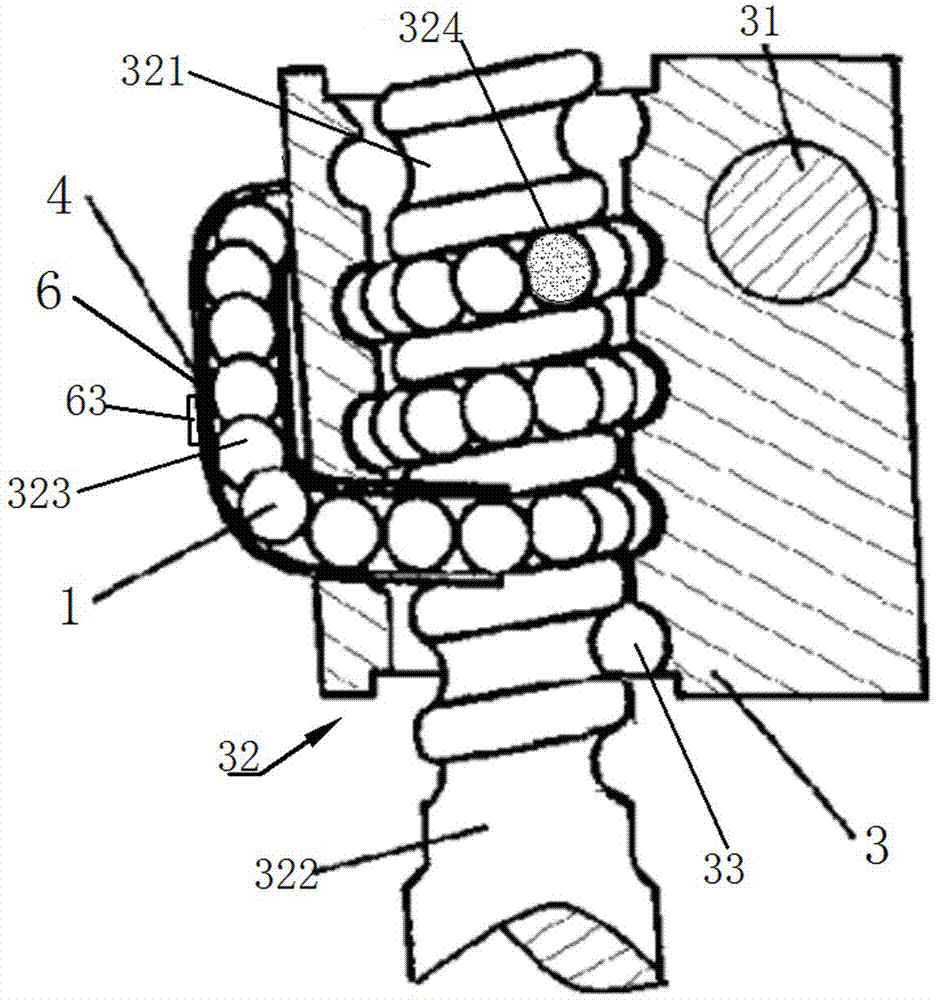

Vertical crash safety driving seat

The invention relates to a vertical crash safety driving seat which comprises a seat cushion framework, a backrest framework and a connecting assembly connected between the seat cushion framework and the backrest framework. A backrest inclination rotation shaft transversely penetrates through the connecting assembly. The backrest framework is in rotary connection with the connecting assembly through the backrest inclination rotation shaft and motor drive. An anti-crash supporting screw vertically penetrates through the lower portion of the connecting assembly and penetrates into the seat cushion framework. The seat cushion framework is connected with the connecting assembly through an anti-crash supporting rod screw. The anti-crash supporting rod screw comprises a screw portion located in the connecting assembly and a connecting port penetrating into the seat cushion framework. An inner thread cavity matched with a thread of the screw portion is formed in the connecting assembly. Balls are embedded between the screw portion and the thread matched with the inner thread cavity to form a ball screw structure. A ball guiding tube is further arranged outside the connecting assembly, and the ball guiding tube is provided with a crash normally-closed switch sensor.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

Automatically adjustable wire rope tensioner

The invention discloses an automatic adjustment type steel wire rope tensioning device. The automatic adjustment type steel wire rope tensioning device comprises a base, guide wheels, tensioning wheels, a rotating shaft, a fixed shaft, a swing arm, a fixing piece and torsional springs, wherein the guide wheels are fixed on the base; the tensioning wheels are matched with the guide wheels; the rotating shaft is connected onto the base in a rotating mode, and driving gears are fixed on the rotating shaft; the fixed shaft is fixed on the base, and driven gears engaged with the driving gears are connected onto the fixed shaft in a rotating mode; the swing arm is connected onto the fixed shaft in a rotating mode, one end of the swing arm is coupled with the tensioning wheel; the fixing piece is used for realizing relative fixation of the rotating shaft and the base; the torsional springs are also arranged on the fixed shaft in a sleeving mode, one end of each of the torsional spring is fixed with the swing arm, and the other ends of the torsional springs are fixed with the driven gears. The automatic adjustment type steel wire rope tensioning device is compact in structure, high in pretensioning efficiency, adjustable in pretensioning force, good in pretensioning effect and low in manufacturing cost, meanwhile can realize automatic pretensioning, and can be applied to small and light instruments.

Owner:ZHEJIANG UNIV

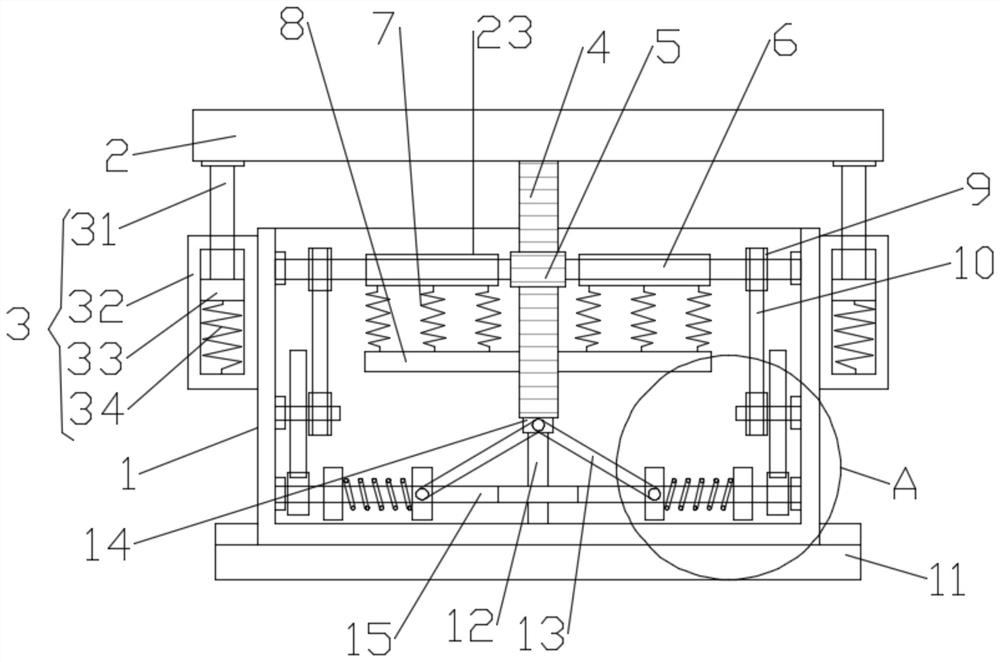

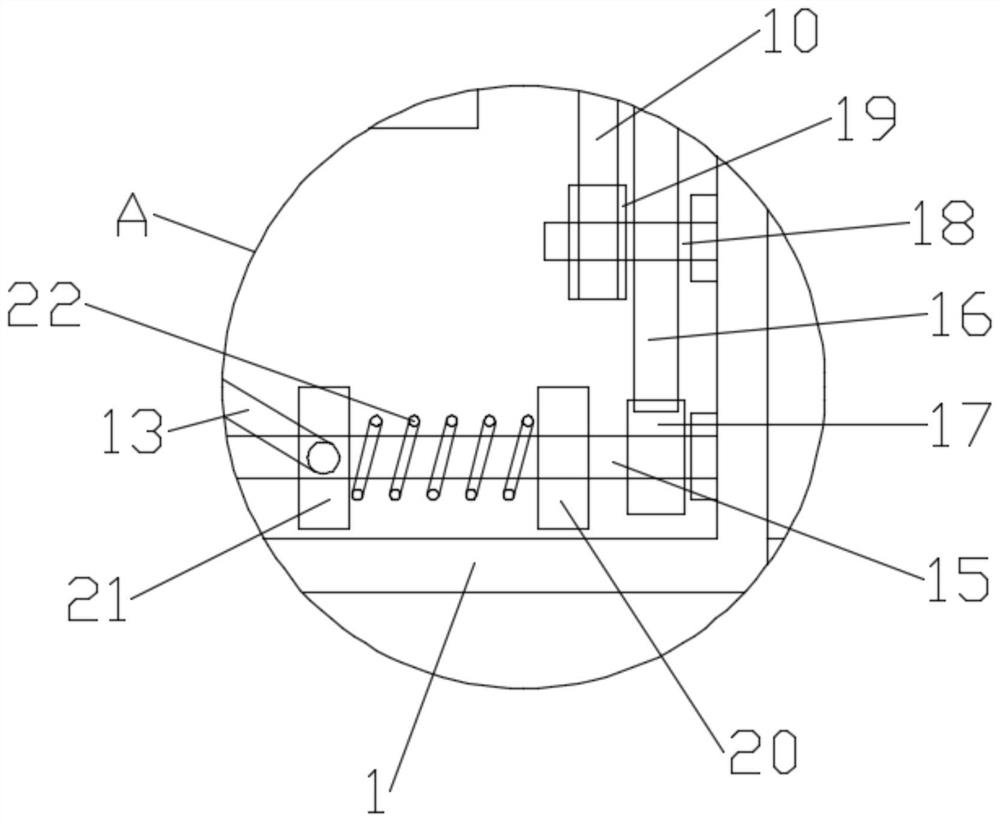

A shock-absorbing support device for electromechanical equipment

ActiveCN110778646BGood preload effectSmall buffer strokeNon-rotating vibration suppressionStands/trestlesGear driveGear wheel

The invention relates to the field of electromechanical equipment installation, in particular to an electromechanical equipment damping and supporting device. The device comprises a supporting tank and an equipment supporting platform, the supporting tank is fixedly installed on a supporting base, and the outer wall of the top of the supporting tank is fixedly provided with elastic supporting parts used for buffering and supporting the equipment supporting platform. A supporting toothed plate is fixedly installed on the bottom surface of the middle of the equipment supporting platform, a supporting rotating shaft is rotatably erected at an upper opening of the supporting tank, and an annular gear meshed with the supporting toothed plate is mounted in the middle of the supporting rotating shaft. A rotating screw rod linked with the supporting rotating shaft through a gear transmission assembly is rotationally arranged in a lower inner cavity of the supporting tank, external threads aremachined on the outer rings of the two sides of the rotating screw rod, and the outer rings of the two sides of the rotating screw rod are sleeved with supporting screw sleeves through threaded connection. The damping and supporting device can achieve effective buffering and supporting effects on shaking of the equipment supporting platform in the vertical direction.

Owner:SUZHOU LAIJIN ELECTROMECHANICAL AUTOMATION CO LTD

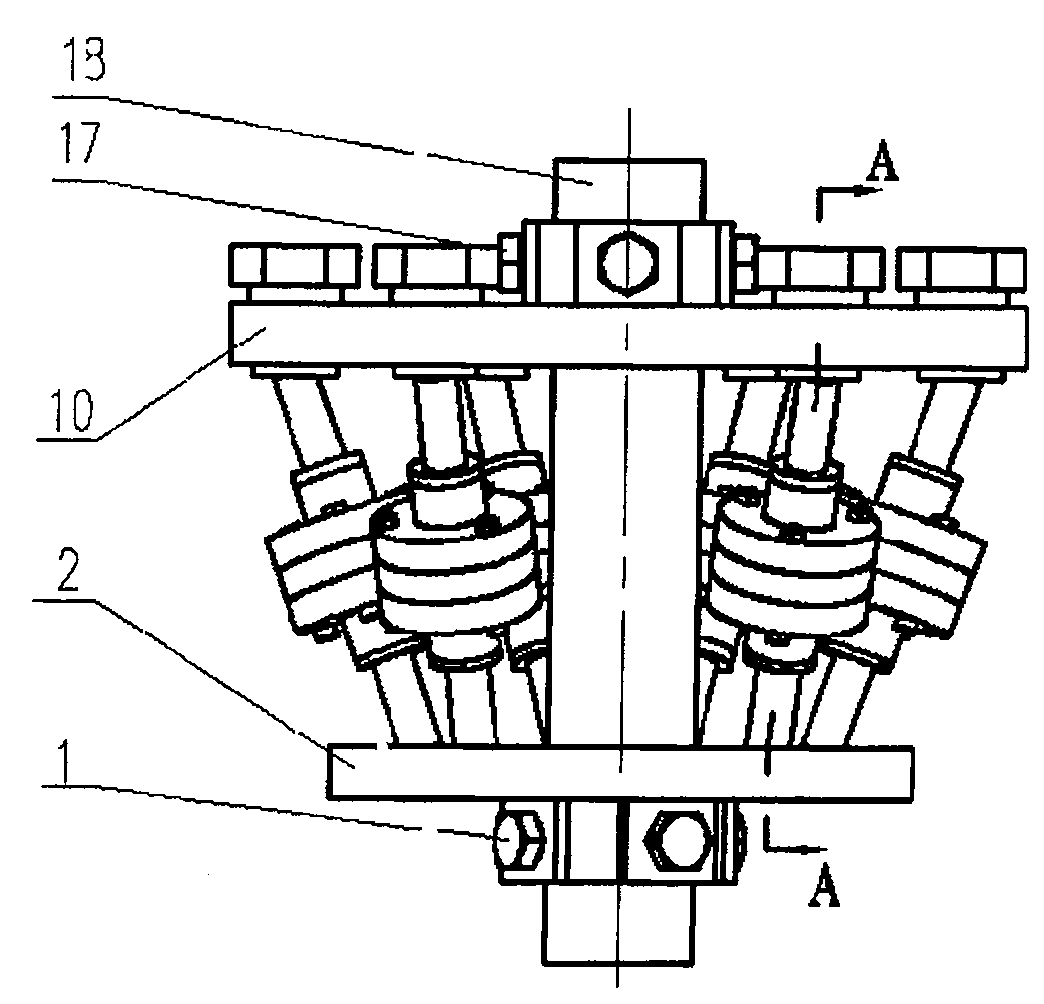

Multi-point partial pre-fastening method with adjustable load sharing mechanism

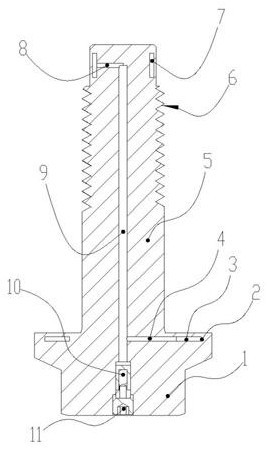

InactiveCN100587429CAdjustable structural parametersSimple structureForce measurement using piezo-electric devicesPiezoelectric quartzEngineering

The invention relates to a multipoint local pretightening method for adjustable load sharing mechanisms, which belongs to the field of a sensing test method and a sensing test device. The method realizes multipoint local pretightening by adjustment of a pretightening screw to drive a pretightening slider, and realizes adjustment of structural parameters through a mounting length adjustable measuring rod. The multipoint local pretightening method adjusts the length of the measuring rod according to the actual demand of measurement and assembly, performs multipoint local pretightening force adjustment, and makes the measuring rod exerted by the pretightening force. The device adopted comprises six groups of adjustable load sharing mechanisms with the same structures, wherein each group of adjustable load sharing mechanisms consist of an upper platform, a lower platform, the pretightening screw, the pretightening slider, an upper connecting rod, a lower connecting rod, an upper round nut,a lower round nut, an upper connecting flange, a lower connecting flange, a group of piezoelectric quartz sensors and a positioning ring. The multipoint local pretightening method realizes multipointlocal pretightening and adjustment of the structural parameters, and has the characteristics of good pretightening effect, strong large-load sharing capacity, convenient assembling operation, high precision, good stability and simple structure.

Owner:DALIAN UNIV OF TECH

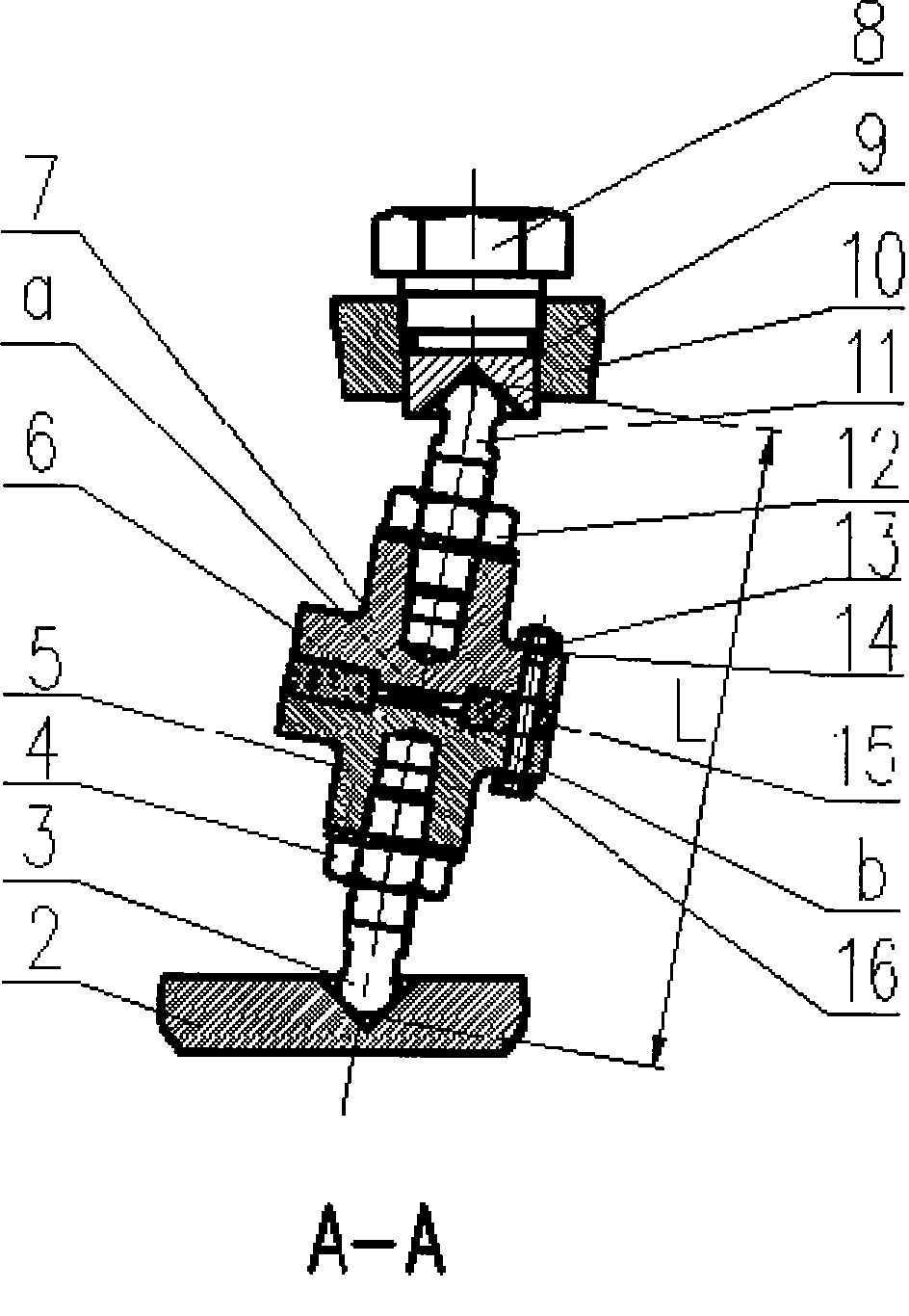

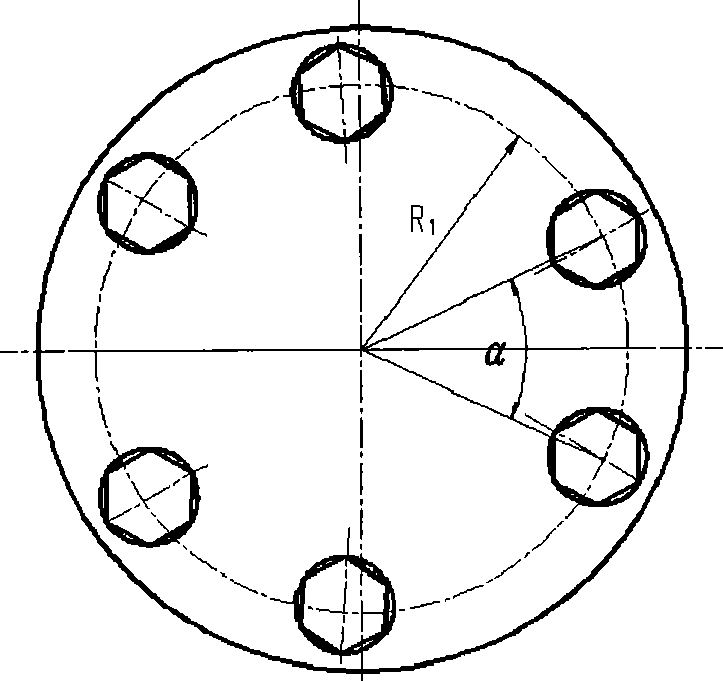

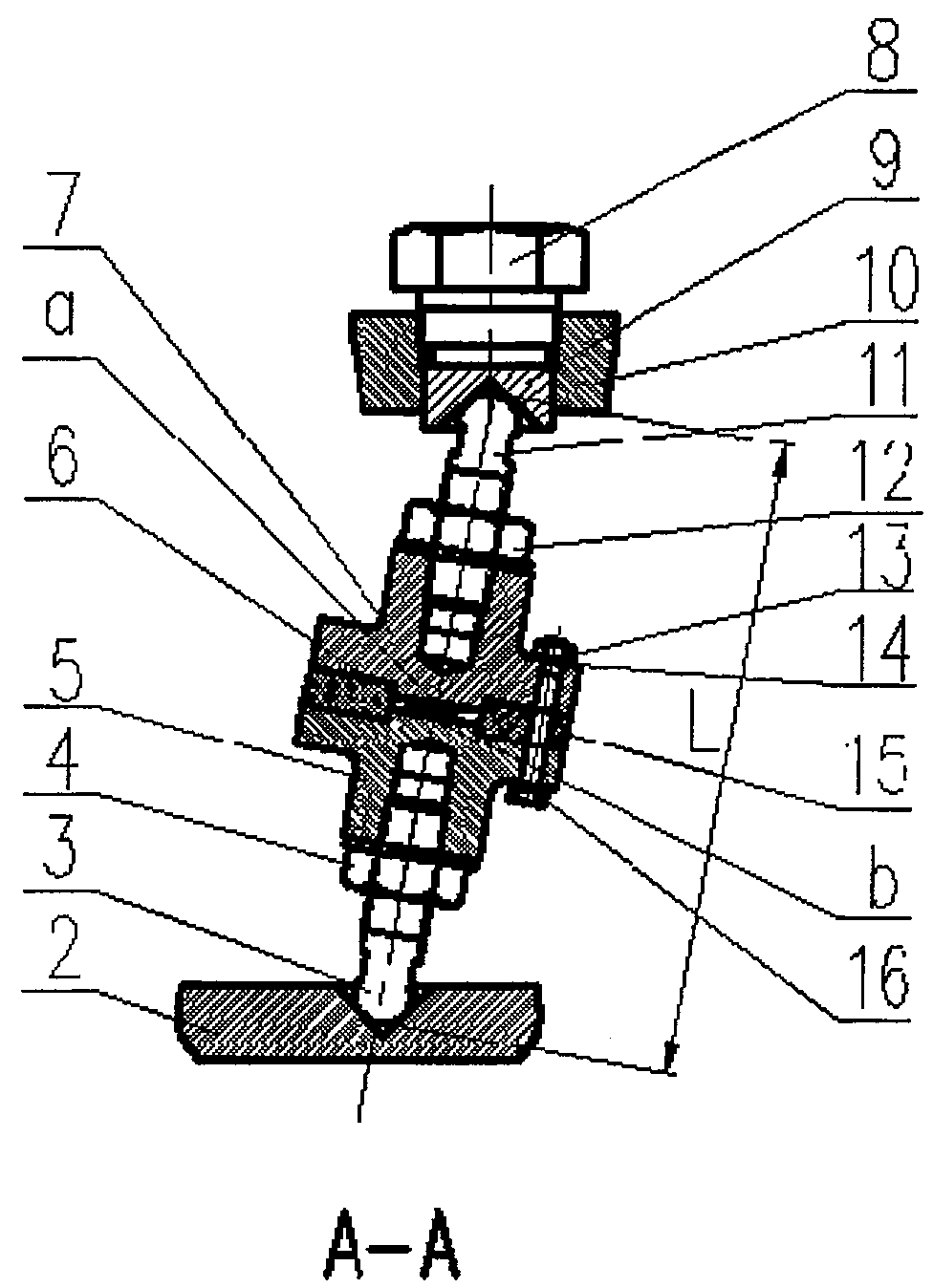

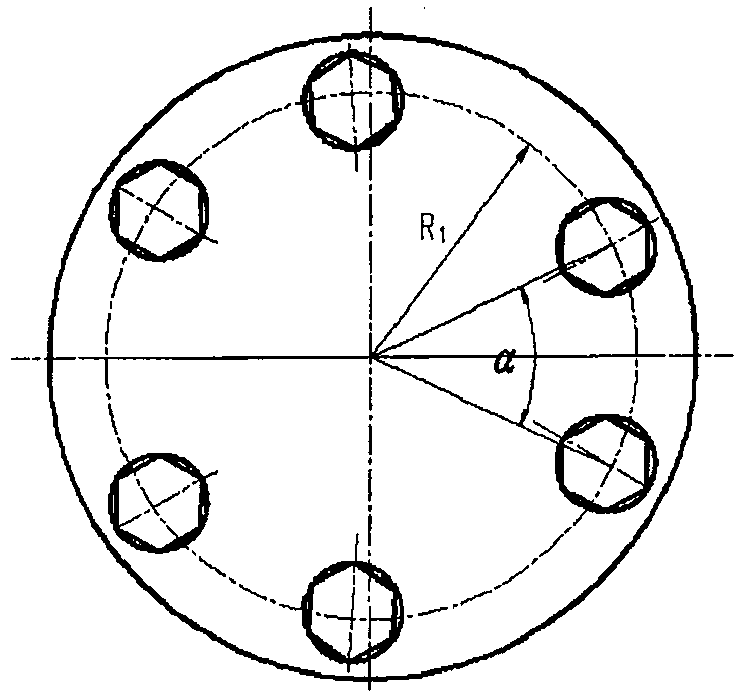

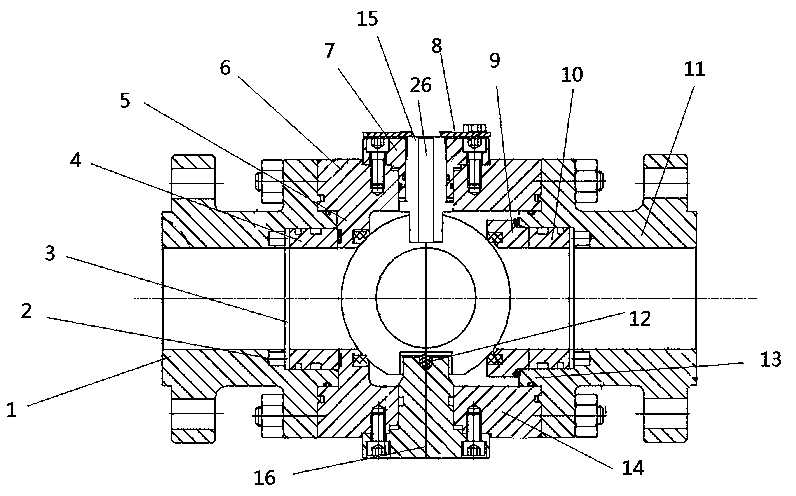

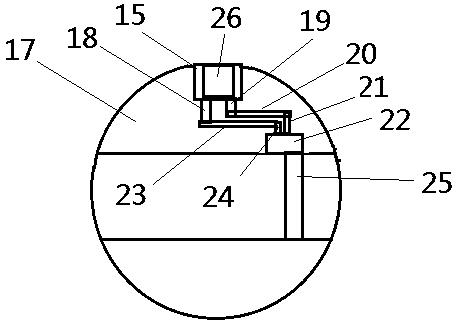

Six-dimensional force sensor of integral pre-tightening double-layer top and bottom asymmetry seven-rod parallel connection structure

InactiveCN101329207BSimple structureSimple measuring principleForce measurement using piezo-electric devicesCircular discForce sensor

The invention discloses a six-dimensional force sensor with the parallel-connected structure of seven rods that are integrally pre-tightened and asymmetrically arranged in an upper layer and a lower layer, which is characterized in that a force measuring platform (1) consists of a chassis and a supporting disk that are fixedly connected, three oblique ball socket holders (4) are evenly arranged on the upper surface and the lower surface of the chassis, and a round ball socket holder (6) is fixed at the center of the lower surface of the chassis; three oblique ball socket holders (4) are evenly arranged on the top inner loop surface of a pre-tightening platform (2); three oblique ball socket holders (4) are evenly arranged on the upper surface of a base (8), and a round ball socket holder (6) is fixed at the center of the upper surface of the base (8); a detecting component (3) and the oblique ball socket holders (4) as well as a middle detecting component (5) and the round ball socketholder (6) respectively form conehead-typed spherical pairs, and all the detecting components are connected with the pre-tightening platform (2), the force measuring platform (1) and the base (8) by bolts, pre-tightened and closed. The six-dimensional force sensor has simple structure, simple and convenient measuring principles, high measuring precision and larger loaded tilting moment, and can be applied to various situations that need six-dimensional force measurement in the fields of robots and aviation, etc.

Owner:YANSHAN UNIV

An operation and maintenance method for a double-shake, multi-gear, stably supported ball valve

ActiveCN108730556BGuaranteed connection formingStable structurePlug valvesOperating means/releasing devices for valvesEngineeringFlange

The invention provides an operation and maintenance method of a double-shake and multi-gear stable supporting ball valve. The operation and maintenance method comprises an operation method of the ballvalve, a multi-gear adjustment method and a mounting method of the ball valve. The ball valve comprises a left flange, a pre-tightening part, a spacer ring, a left pressing ring, a lower convex valveseat, an upper valve body, a shaft sleeve, a connecting plate, a right valve seat, a right pressing ring, a pressing plate flange, a lower spring, a left protruding part, a lower valve body, an outervalve rod, a lower valve shaft, a ball body, a first long rod, a first short rod, an upper connecting rod, a second long rod, a secondary shaft, a lower connecting rod, a second short rod, a secondary valve plate and an inner valve rod. The multi-gear adjustment method is as follows: a plurality of gears comprise a ball body full-open gear, a ball body full-closed gear, a temporary closing gear and a temporary adjustment gear; the temporary adjustment gear is driven by the inner valve rod and the inner valve rod is rotates to drive a corresponding transmission mechanism to fully close the secondary valve plate to form the temporary closing gear, so that the secondary valve plate is not completely closed to form the temporary adjustment gear.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ball screw pre-tightening device

The invention provides a ball screw pre-tightening device which comprises a supporting plate, a spring, a telescopic plate, a clamping plate, a rotating plate, a rotating shaft, a sucker, pre-tightening bolts, elastic air bags, arc clamping plates, a lower connecting ring and an upper connecting ring, wherein the inner wall of the supporting plate is connected with the spring; the telescopic plateis installed at the outer end of the spring; the outer end of the telescopic plate is connected with the clamping plate through a connecting rod; the rotating plate is arranged in the clamping plate;the clamping plate is connected with the rotating plate through the rotating shaft; and the sucker is pasted at the inner end of the rotating plate. The supporting effect is improved through the design, the pre-tightening bolts are installed at the upper end of the upper connecting ring and the lower end of the lower connecting ring, the elastic air bags are assembled at the inner ends of the pre-tightening bolts, the arc clamping plates are arranged at the inner ends of the elastic air bags, the dynamic pre-tightening function is realized through the design, and the device is convenient to use, convenient to operate and capable of improving the pre-tightening effect, and can be rapidly mounted and dismounted.

Owner:山东省汶上县丝杠有限责任公司

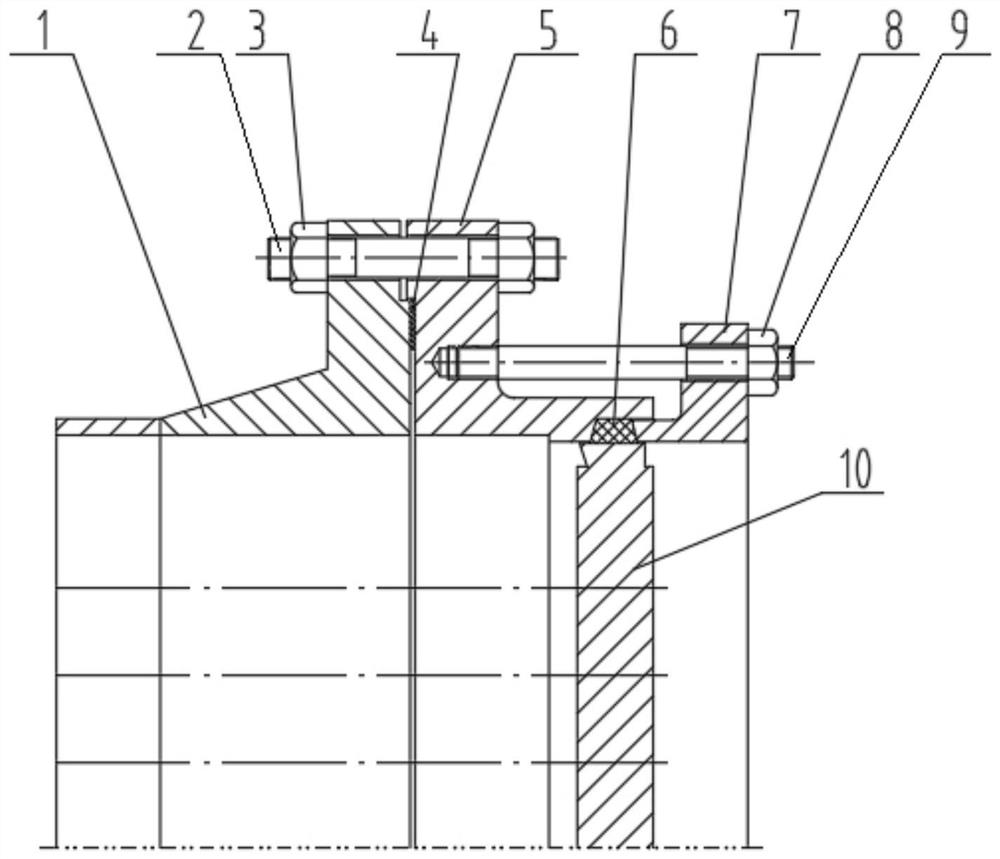

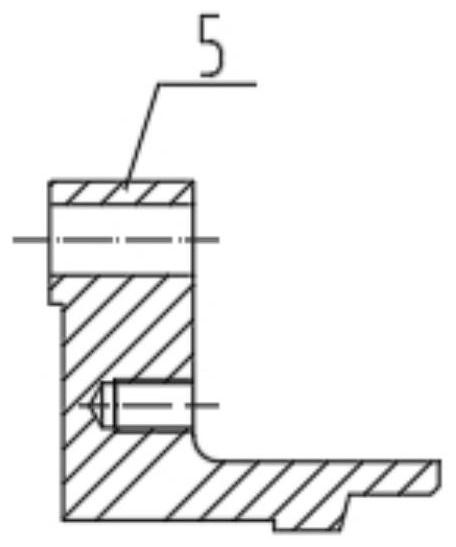

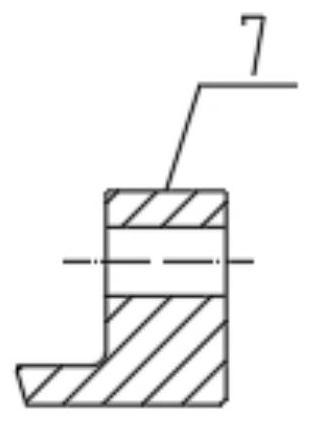

Pressure test tool for floating head heat exchanger

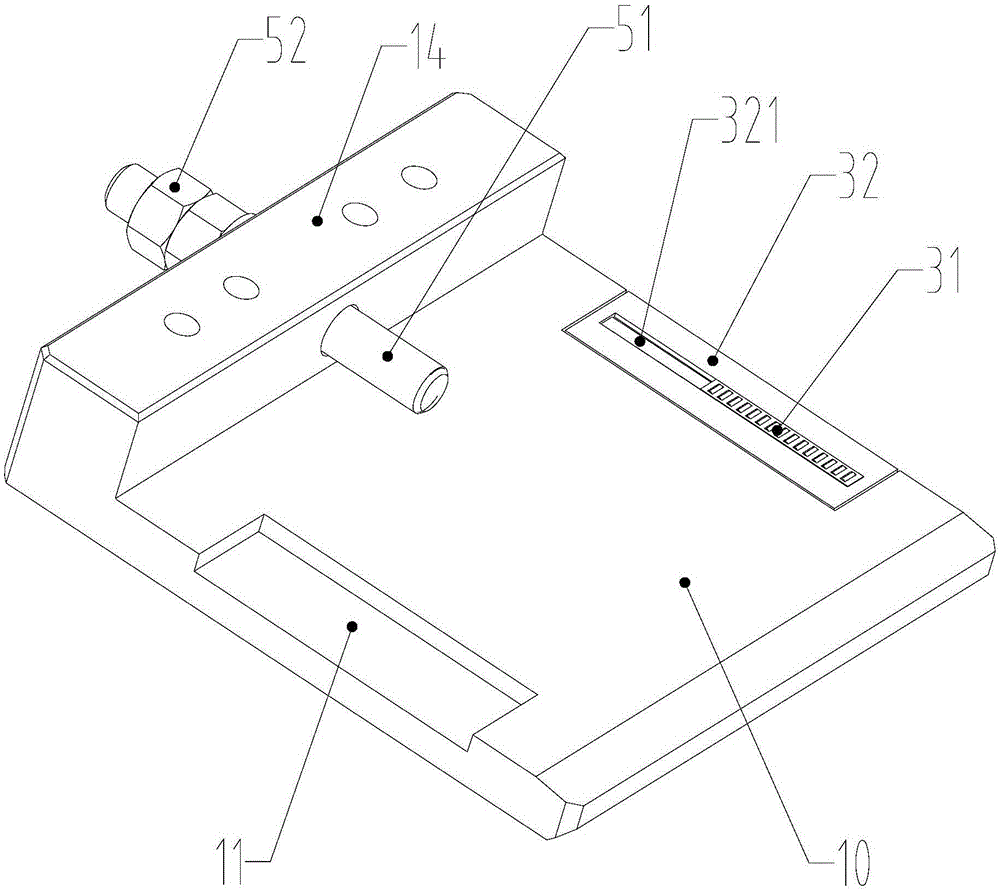

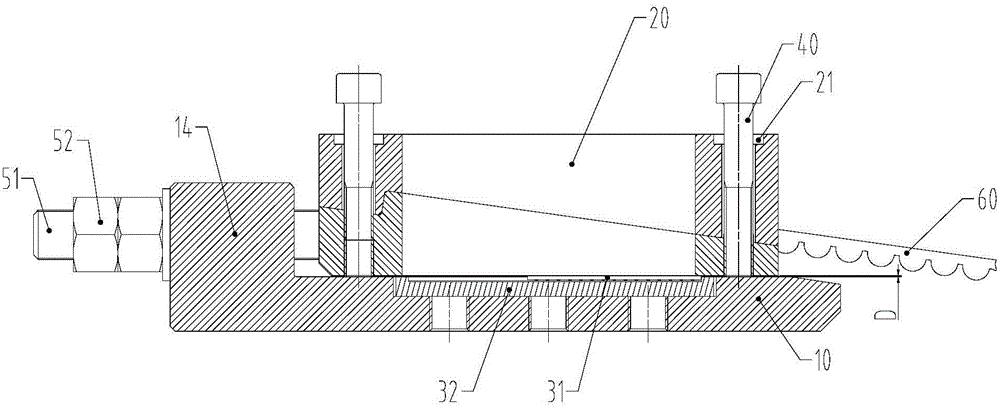

PendingCN112113753AEasy to installGood preload effectMachine part testingMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention provides a pressure test tool for a floating head heat exchanger. The pressure test tool comprises an equipment flange, an equipment stud, an equipment nut, a gasket, a tool flange, a filler, a gland, a pressure test nut, a pressure test bolt and a floating tube plate, wherein the equipment flange and the tool flange are connected through the equipment stud and the equipment nut; thetool flange and the gland are connected through the pressure test bolt and the pressure test nut; the equipment flange and the tool flange are sealed through the gasket; and the floating tube plate,the tool flange and the gland are sealed through the filler. The pressure test tool has the advantages of being convenient to install, good in pre-tightening effect, safe and reliable in performance and capable of being repeatedly used.

Owner:大连派思燃气设备有限公司

Locking plug-in structure for electronic plug-in installation

ActiveCN109638567BEasy to screw inPrevent looseningCoupling device detailsComputer hardwareLocking mechanism

Owner:临沂鹏泰新型建材合伙企业(有限合伙)

Protection pile construction process special for motor train unit train body impact test platform

ActiveCN106284394AImprove connection strengthAvoid mechanical damageBulkheads/pilesEngineeringUnit train

The invention discloses a protection pile construction process special for a motor train unit train body impact test platform. The protection pile construction process comprises the following steps that 1, a main protection pile sleeve is arranged; 2, an auxiliary protection pile sleeve is arranged; 3, a pre-stressed anchor cable is arranged; 4, an impact platform foundation and a protection file foundation are poured; 5, sleeve compacting reinforcement is carried out; 6, a connecting part is arranged; 7, pre-tightening anchoring is carried out. The process is easy to construct, safe, reliable, high in connecting strength and good in protection performance, a motor train can be effectively prevented from impacting a building in the testing process, personal safety is protected, and tail machine damage is reduced.

Owner:QINGDAO NO 1 CONSTR GRP

Toothed belt pre-tightening device and method

The invention provides a toothed belt pre-tightening device and method. The toothed belt pre-tightening device comprises a toothed plate base, a toothed plate, a friction reduction part and position adjusting pieces, wherein the toothed plate base is provided with at least one first installation groove, the toothed plate is arranged on the toothed plate base, the friction reduction part is arranged in the first installation groove and has a working position where the friction reduction part makes contact with the bottom face of the toothed plate, and the position adjusting pieces are arranged on the toothed plate or the toothed plate base and control the bottom face of the toothed plate to make contact with or be separated from the friction reduction part. The toothed belt pre-tightening device can adjust the friction force between the toothed plate and the toothed plate base according to requirements and is better in pre-tightening effect.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Six-dimensional force sensor of integral pre-tightening double-layer top and bottom asymmetry eight-rod parallel connection structure

InactiveCN101329208BSimple structureSimple measuring principleForce measurement using piezo-electric devicesCircular discAviation

Owner:YANSHAN UNIV

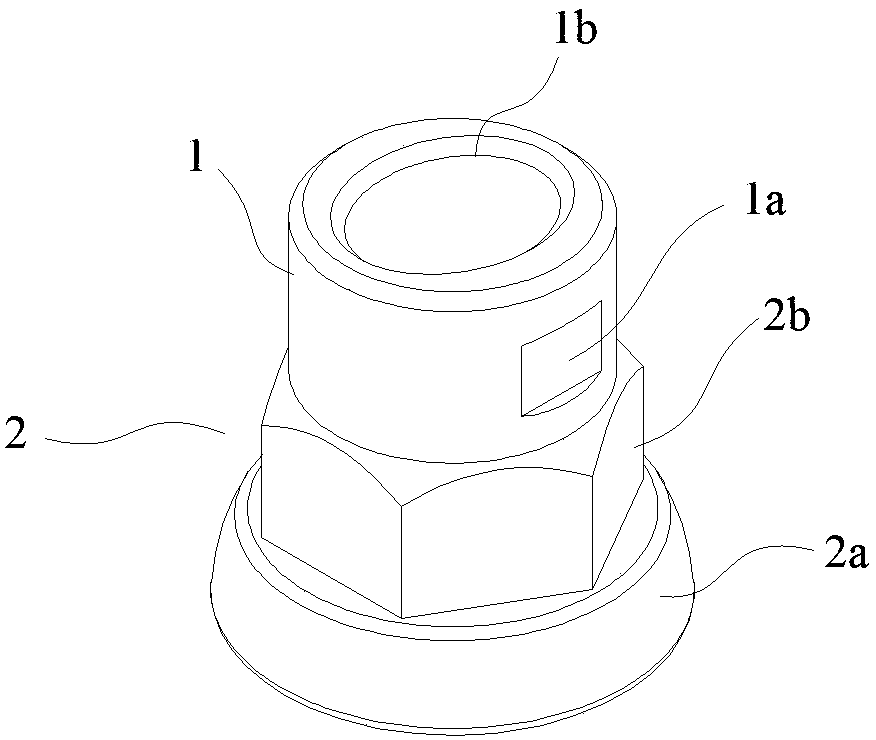

An exhaust system mounting nut

The invention discloses an exhaust system mounting nut. The exhaust system mounting nut comprises an anti-loosening end and a buffering end located under the anti-loosening end, and the buffering end and the anti-loosening end are of an integrated structure. The anti-loosening end is provided with an inner threaded hole. A through hole communicating with the inner threaded hole is formed inside the buffering end. A tightening portion and a pressing portion are arranged on the outer side face of the buffering end. The pressing portion is located below the tightening portion. The outer side face of the anti-loosening end is round and is provided with squeezing grooves symmetrically distributed around the axis of the anti-loosening end, and the inner threaded hole is oval after being squeezed. The exhaust system mounting nut aims to prevent loosening and improve the sealing performance of an exhaust manifold of an engine with a turbocharger.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD

Bearing adjusting device for medium bridge speed reducer assembly and assembling method thereof

The invention discloses a bearing adjusting device for a medium bridge speed reducer assembly and an assembling method of the bearing adjusting device. The bearing adjusting device comprises an adjusting ring located at the end of the outer ring of a bearing and a limiting flange located at the end of the inner ring of the bearing, an oil seal playing a sealing role is arranged between the adjusting ring and the limiting flange, an O-shaped ring installation groove and a thread section are arranged on the outer circumference of the adjusting ring, an O-shaped ring is arranged in the O-shaped ring installation groove, and the thread section coated with sealant is in matched connection with a thread hole in a speed reduction shell. When the adjusting ring pretightens and adjusts the bearing,the sealing performance of the bearing can be improved, and the limiting flange can axially position the bearing.

Owner:FAW JIEFANG AUTOMOTIVE CO

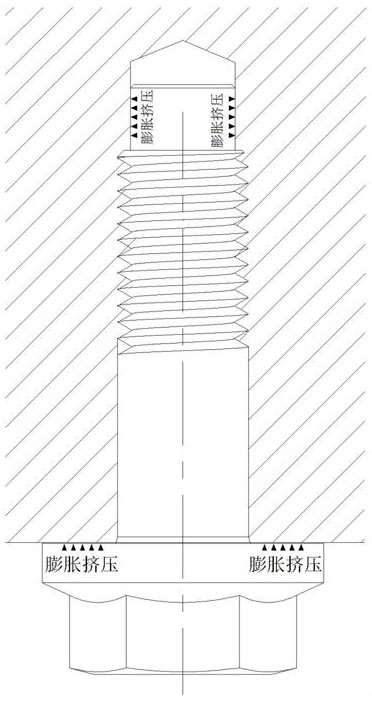

Hydraulic expansion locking bolt

The invention discloses a hydraulic expansion locking bolt. The bolt comprises a head, a flange, a rod part and a threaded part, wherein the middle part of the flange is provided with a first annularexpansion oil chamber, the outer wall of the middle part of the rod part is provided with the threaded part, a second annular expansion oil chamber is provided inside the bottom end of the rod par, amain oil chamber is opened along the bolt axis, the main oil chamber is connected to the first annular expansion oil chamber through a first oil through hole, and the main oil chamber is connected tothe second annular expansion oil chamber through a second oil through hole; the bolt head is provided with a piston rod, and the end of the piston rod is provided with a pressure screw. The hydraulicexpansion locking bolt provided by the invention compensates the pre-tightening force by designing expansion oil chambers inside the bolt, so as to achieve the purpose of enhancing the bolt connectionstrength, damping vibration and preventing loosening.

Owner:常德市中天精密工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com