Pressure test tool for floating head heat exchanger

A heat exchanger and pressure test technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems such as the difficulty in manufacturing the pressure test of the tube head of the floating head heat exchanger, and achieve safe and reliable performance and pre-tightening Good effect and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

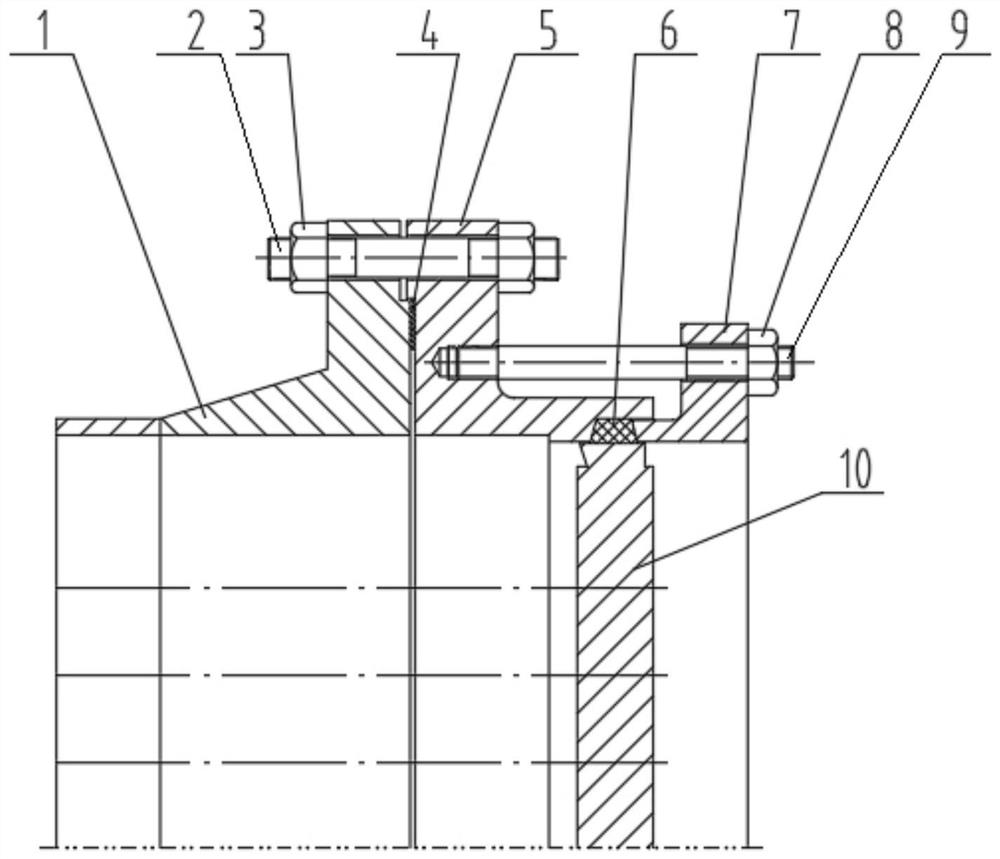

[0010] Embodiment is illustrated below in conjunction with accompanying drawing:

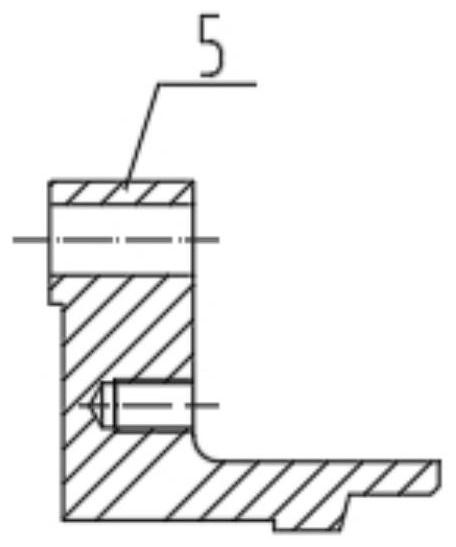

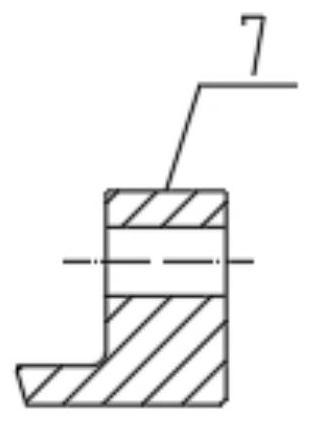

[0011] A pressure test tooling for a floating head heat exchanger, comprising: equipment flange 1, equipment stud 2, equipment nut 3, gasket 4, tooling flange 5, packing 6, gland 7, pressure test nut 8, pressure test Use bolts 9 and floating tube sheets 10; connect equipment flange 1 and tooling flange 5 through equipment studs 2 and equipment nuts 3, and connect tooling flange 5 and gland 7 through pressure test bolts 9 and pressure test nuts 8 , the equipment flange 1 and the tooling flange 5 are sealed by the gasket 4, and the floating tube sheet 10 is sealed with the tooling flange 5 and the gland 7 by the packing 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com