Highly effective pre-tighter for pre-tightened safety belt

A seat belt pre-tensioning technology, which is applied in the field of seat belt pre-tensioning devices, can solve the problems of reducing the effective effect of seat belts, high production process requirements, and increased production costs, so as to increase product adaptability and reduce production costs , Improve the effect of preload performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

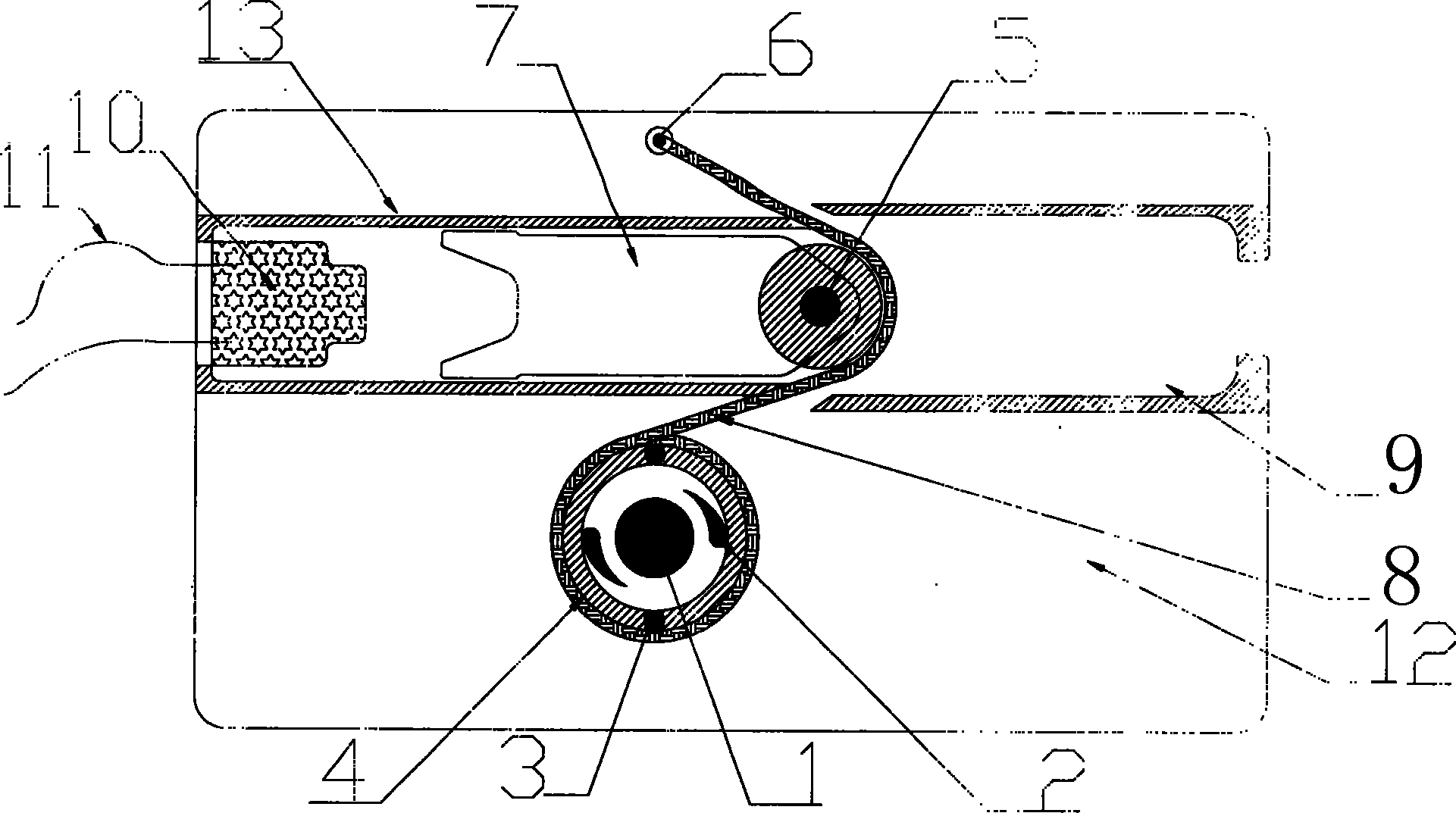

[0020] As shown in the accompanying drawings, it depicts a preferred embodiment of the present invention, in this embodiment, which depicts the usual state of a high-efficiency pretensioner for a pretensioned safety belt provided by the present invention, wherein the A fixed pin 3 is installed on the power wheel 4, and the fixed pin 3 fixes the power wheel on the base 12, and a locking pawl 2 is installed on the inner ring of the power wheel 4, and one end of the connecting rope 8 is fixed on the power wheel 4. On and around the power wheel 4 at least one turn, the end of the reel mandrel 1 is located in the power wheel 4, the locking claw 2 is located between the power wheel 4 and the reel mandrel 1, and the reel The ends of the device mandrel 1 are closely matched but not in contact with each other at ordinary times. The other end of the connecting rope 8 is fixed at the fixed point 6 on the base after bypassing the piston rod guide head 5, and the piston rod guide head 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com