Automatic prepressing device for W type elastic strips

A spring strip and pre-pressing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient operation, low efficiency, insufficient pre-pressing amount, etc., and achieve the effect of increasing the degree of automation and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below according to the drawings and embodiments.

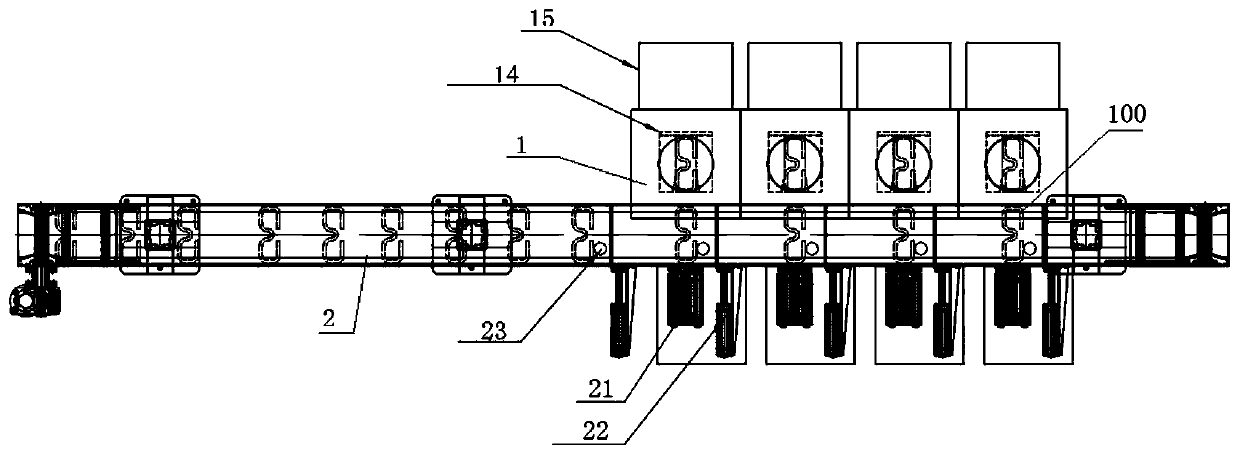

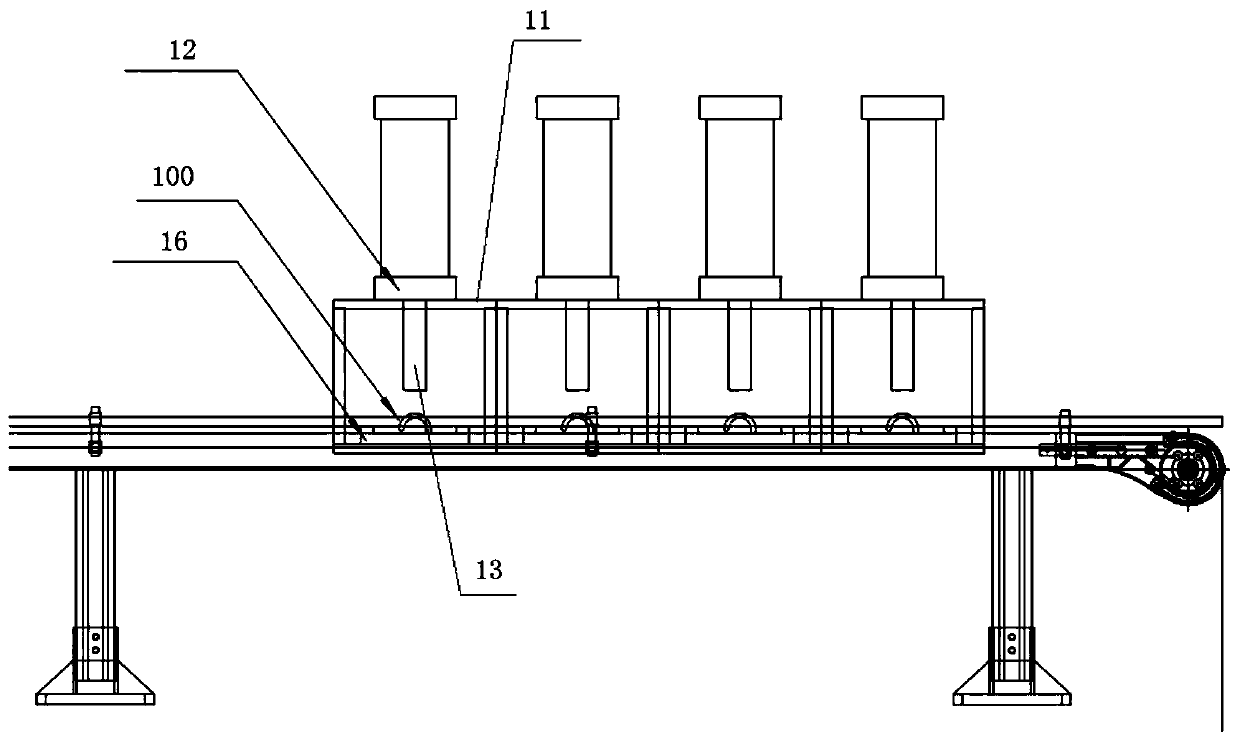

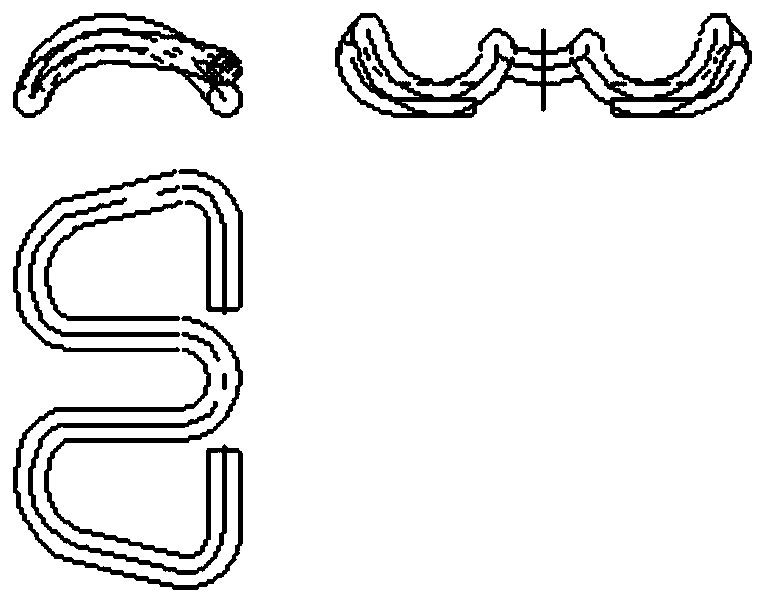

[0021] refer to Figure 1-Figure 3 According to the present invention, an automatic preloading device for W-shaped elastic strips includes a plurality of preloading mechanisms 1 and a delivery channel 2, and multiple preloading mechanisms 1 are installed side by side on the side of the delivery channel 2. The conveying channel 2 is used to convey the W-shaped elastic strip 100 and can convey the W-shaped elastic strip 100 to each of the pre-pressing mechanisms 1, and the pre-pressing mechanism 1 includes a frame 11, a hydraulic cylinder 12, and a pressure head 13. The hydraulic cylinder 12 is fixed on the top of the frame 11 , and the pressure head 13 is assembled on the bottom of the hydraulic cylinder 12 and can be pressed against the W-shaped elastic bar on the surface of the frame 11 .

[0022] Further, the conveying channel 2 is provided with a pushing cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com