Device for treating a running paper, cardboard or other fiber material web

A fiber web and paper web technology, applied in fiber raw material processing, paper, papermaking, etc., can solve the problems of unsolved web transfer, etc., and achieve the effects of small production loss, low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

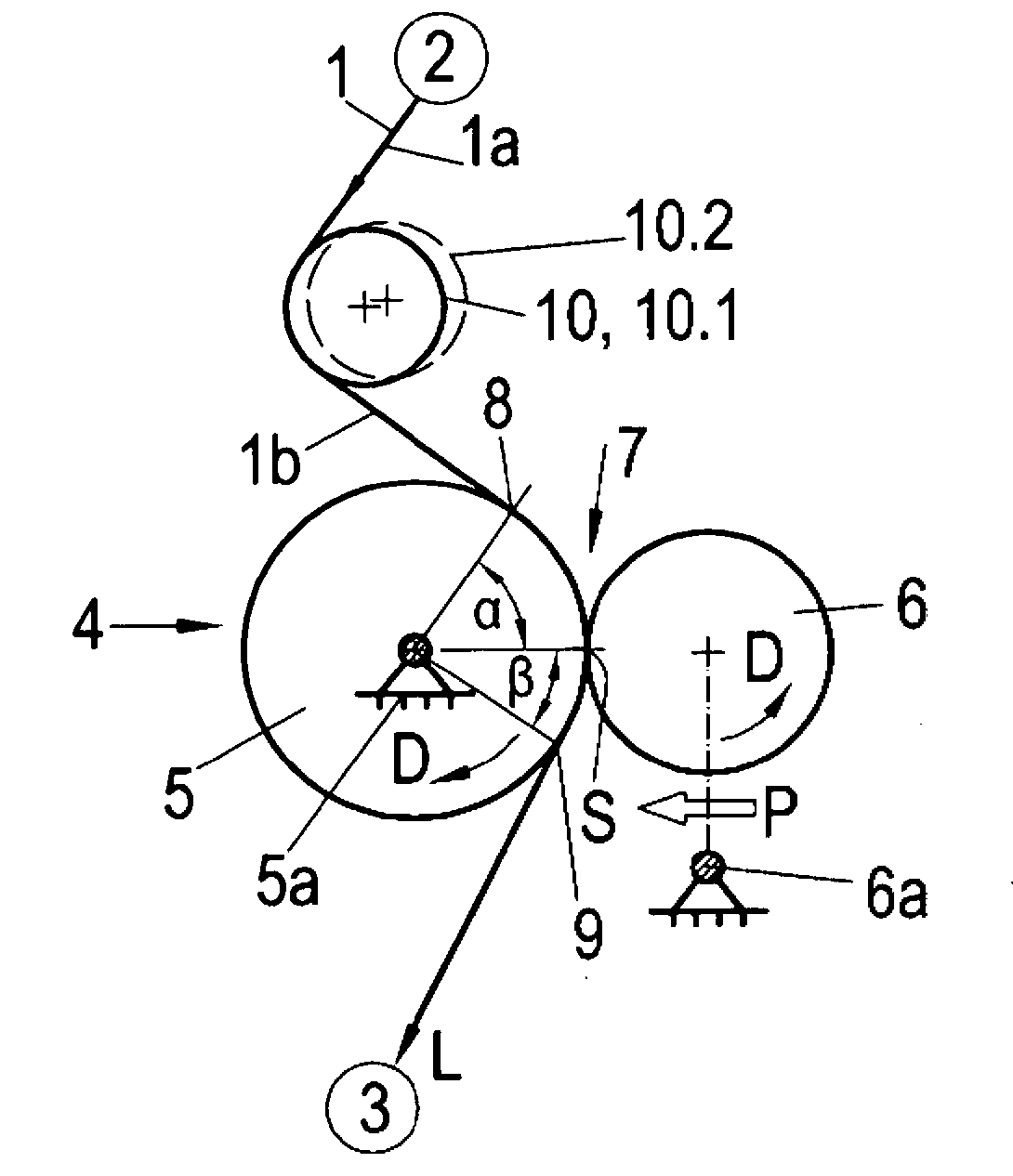

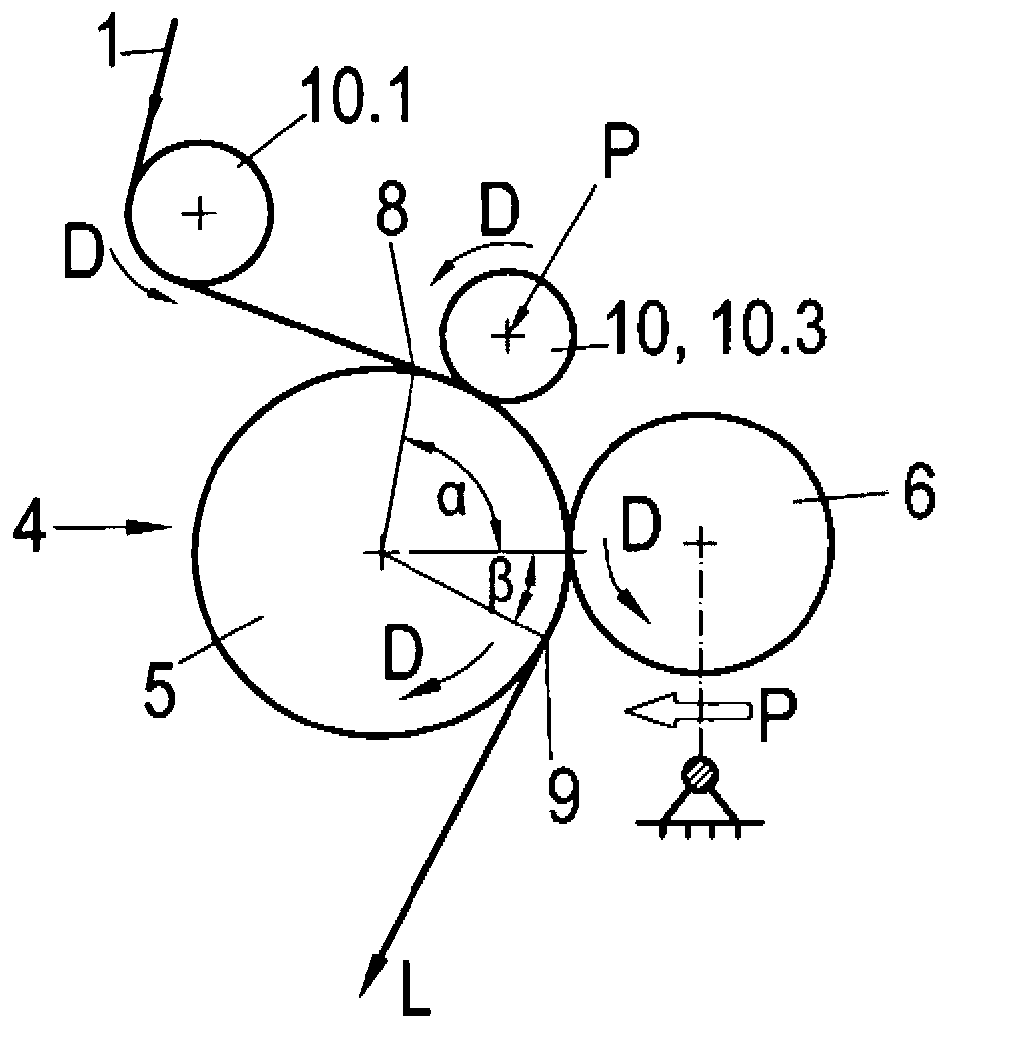

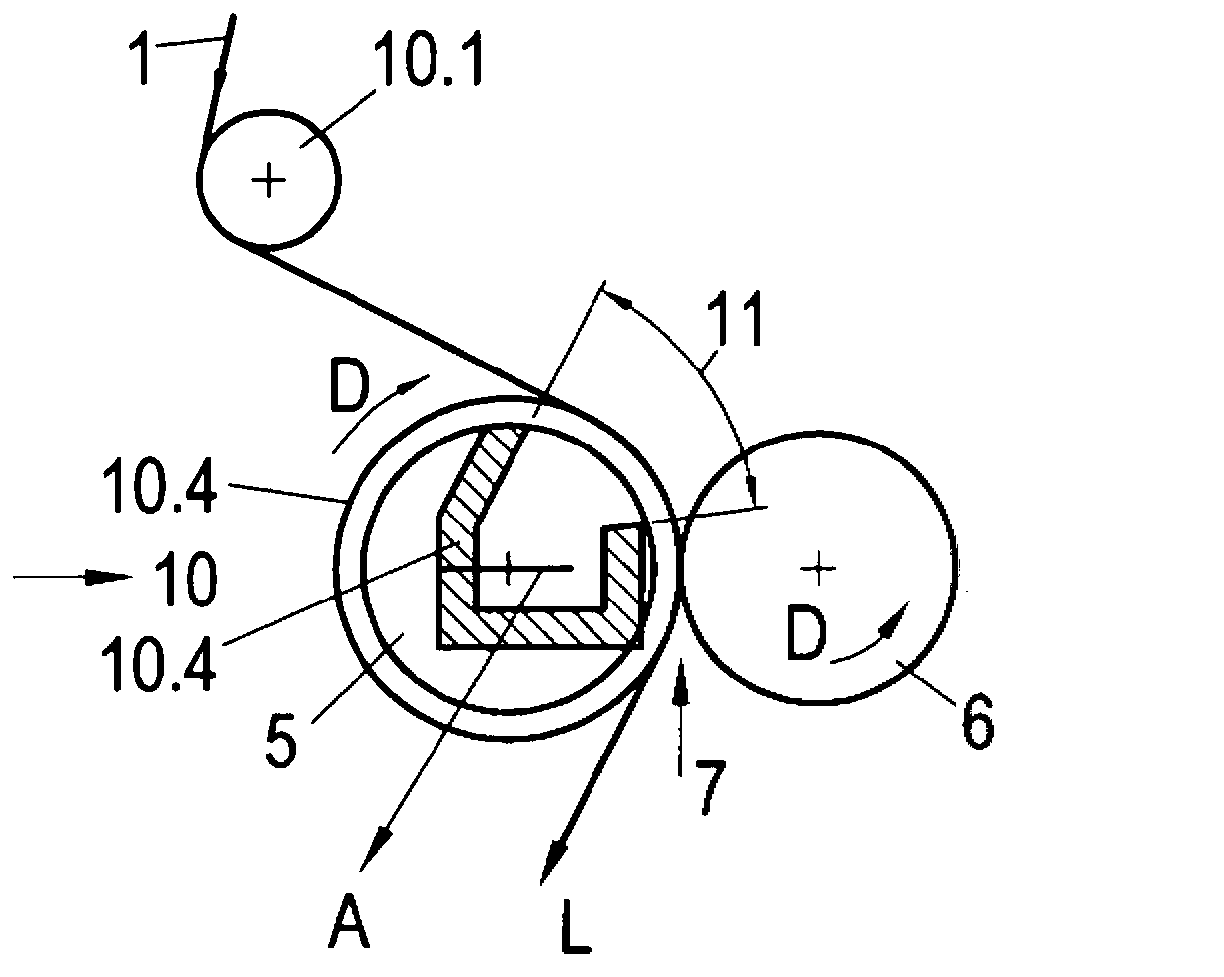

[0036] in figure 1 In the figure, a first variant of the equipment for processing continuously running paper webs, cardboard webs or other fibrous webs 1 during its manufacture and / or conditioning is shown. The equipment has a coating device 2 for coating liquid-to-paste coating medium, which is represented only as a black box, and at least one drying device 3 for drying the coated medium arranged downstream (also only in figure 1 Is only represented as a black box and for simplicity).

[0037] There is at least one traction press 4 for applying the required web tension after each processing device or various process steps not shown here. The traction press 4 is composed of a fixed (non-pivotable), that is, a driven roller 5 installed in a fixed bearing 5A and a pivotable moving roller 6, the rotating moving roller 6 is pressed by a swing bearing 6A To the fixed roller 4. The direction of rotation of the two rollers is indicated by arrow D. The pressing direction of the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com