Elastic locking component, anti-loosening nut and anti-loosening bolt nut fastener

A technology of anti-loosening nuts and elastic locks, which is applied in the direction of locking fasteners, threaded fasteners, nuts, etc., can solve the problems of inconvenient disassembly and assembly of anti-loosening structures, reduce engineering safety, and reduce the strength of fasteners. Achieve the effects of prolonging the effective clamping time, improving engineering safety and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

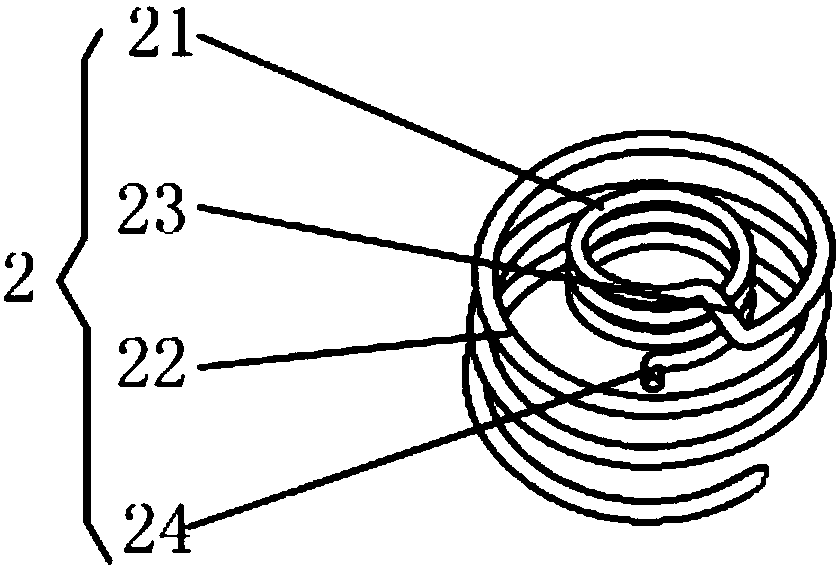

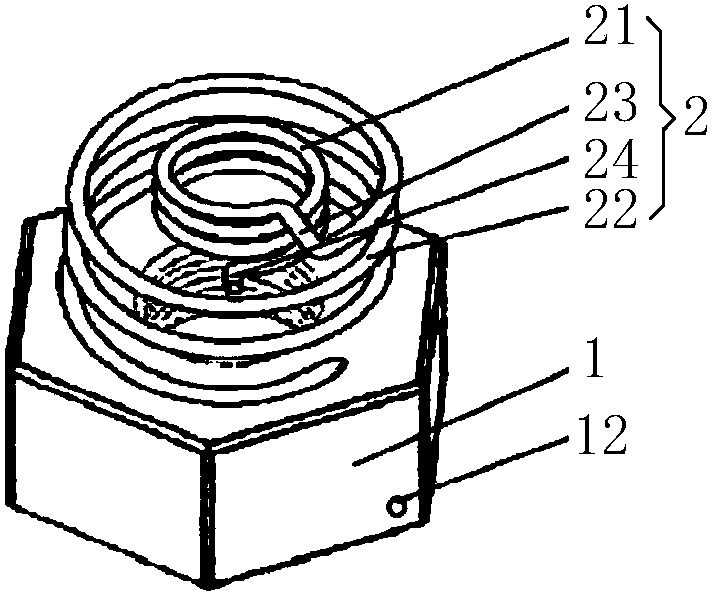

[0070] figure 2 It is a schematic diagram showing the connection structure of the nut and the elastic locking component of the first embodiment of the locknut provided by the present invention.

[0071] Such as figure 2 As shown, the locknut is used for assembling with the bolt, and it has a hexagonal nut as the nut 1 and an elastic locking part 2 .

[0072] Wherein, the elastic locking component 2 includes an inner spring 21 and an outer spring 22 sleeved on the outside of the inner spring 21 .

[0073] The axis of the inner spring 21 and the axis of the outer spring 22 are the same axis, and along the direction in which the same axis extends, the end of one end of the outer spring 22 is connected with the end of the same end of the inner spring 21 through the inner spring connection part 23, and the outer spring 22 The direction of rotation is opposite to that of the inner spring 21.

[0074] The other end of the outer spring 22 is connected to the nut 1 , and the inner...

Embodiment 2

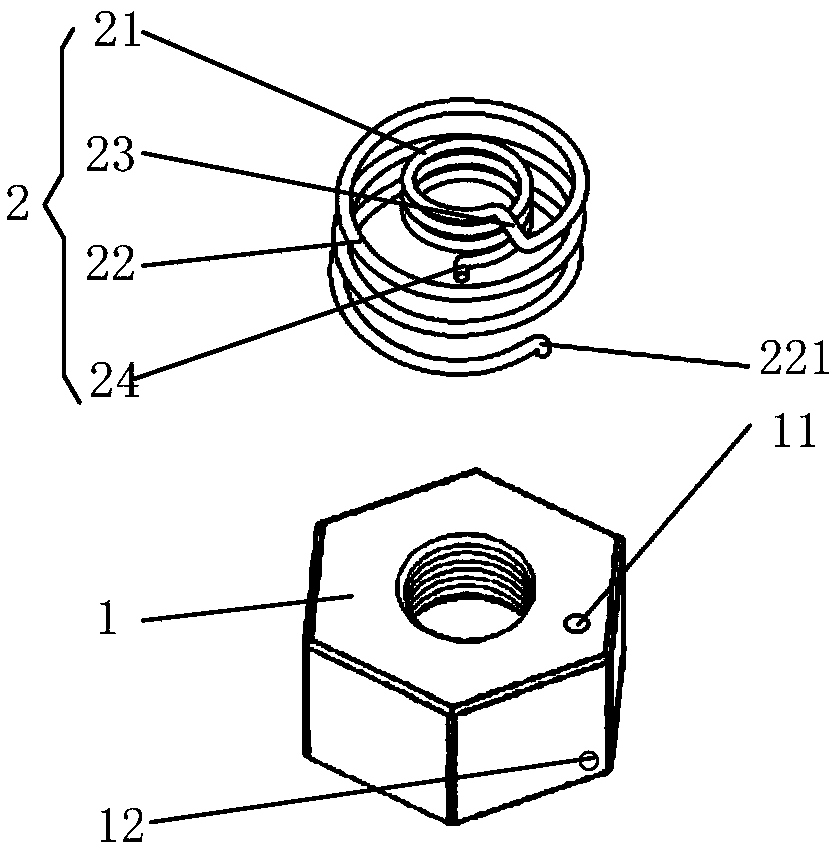

[0079] image 3 It is a schematic diagram showing the connection structure of the nut and the elastic locking component of the second embodiment of the locknut provided by the present invention.

[0080] Such as image 3 As shown, the locknut is used for assembling with the bolt, and it has a hexagonal nut as the nut 1 and an elastic locking part 2 .

[0081] Wherein, the elastic locking component 2 includes an inner spring 21 and an outer spring 22 sleeved on the outside of the inner spring 21 .

[0082] The axis of the inner spring 21 and the axis of the outer spring 22 are the same axis, and along the direction in which the same axis extends, the end of one end of the outer spring 22 is connected with the end of the same end of the inner spring 21 through the inner spring connection part 23, and the outer spring 22 The direction of rotation is opposite to that of the inner spring 21.

[0083] The other end of the outer spring 22 is connected to the nut 1 , and the inner ...

Embodiment 3

[0088] Figure 4 It is a structural schematic diagram showing the elastic locking part of the third embodiment of the locknut provided by the present invention.

[0089] Such as Figure 4 As shown, compared with the second embodiment, the structure of "further, the end of the other end of the inner spring 21 forms an inner spring toggle 24 bent toward the outside of the inner spring 21" in the second embodiment. change into:

[0090] Further, the end of the other end of the inner spring 21 extends along the tangential direction of the inner spring 21 .

[0091] Other structures are the same as those of the second embodiment.

[0092] Locknut embodiment four

[0093] Figure 5 It is a schematic diagram showing the connection structure of the nut and the elastic locking component of the fourth embodiment of the locknut provided by the present invention.

[0094] Such as Figure 5 As shown, the locknut is used for assembling with the bolt, and it has a hexagonal nut as the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com