Safety belt retractor with pre-tightening device

A technology of seat belt retractor and reel, which is applied in the directions of seat belts, belt tensioners, transportation and packaging in the car, can solve the problems of large shape of the retractor, short rewinding stroke, and difficult processing, etc. Low manufacturing cost, improved binding, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

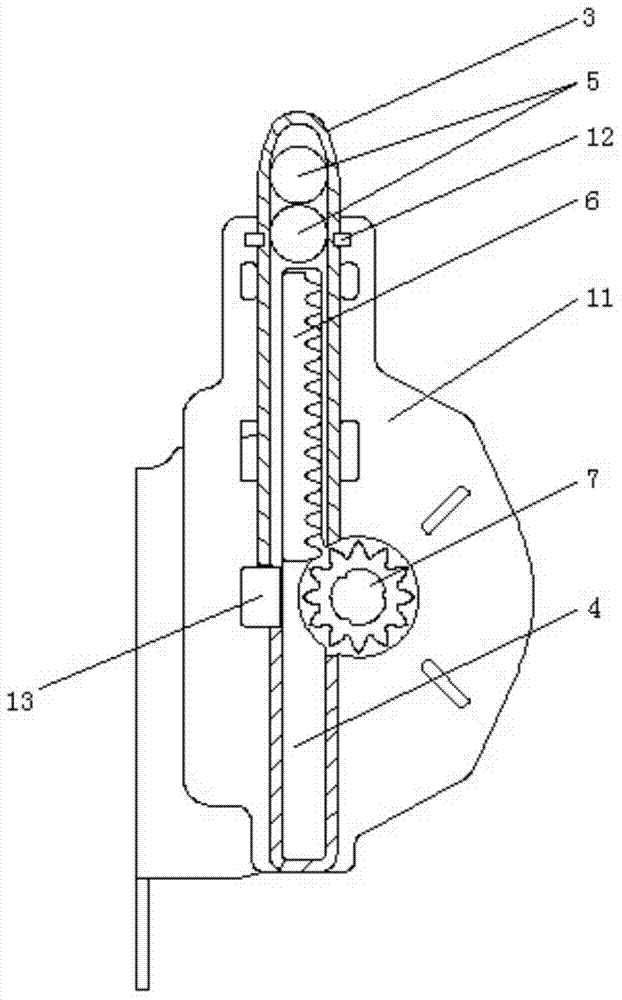

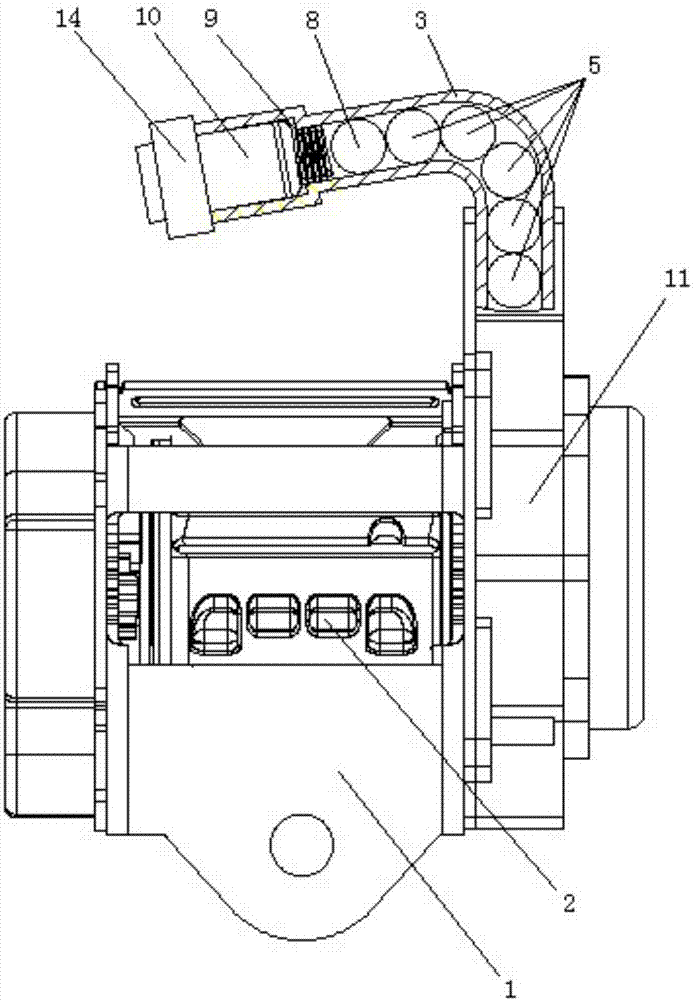

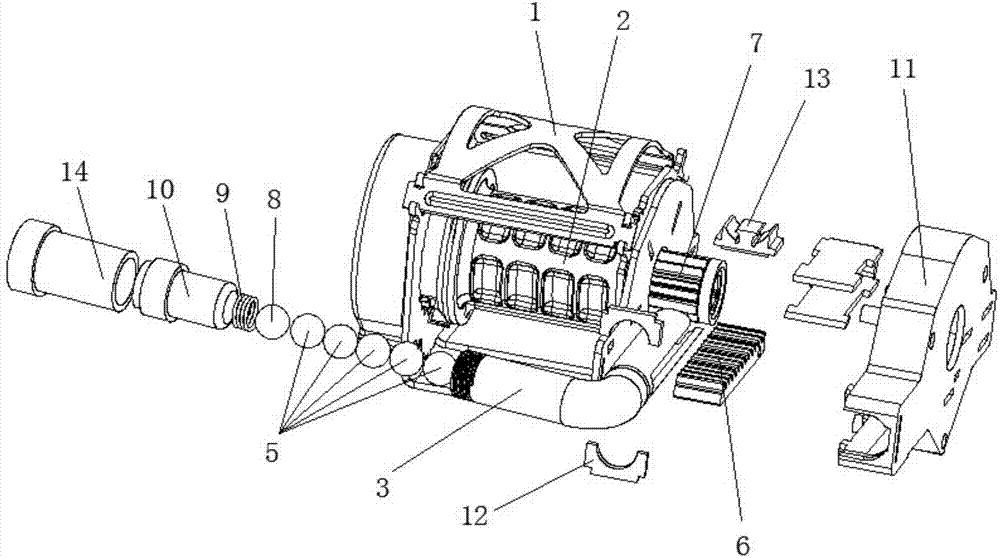

[0019] See Figure 1 to Figure 5 , the present invention includes a frame 1, a reel 2 and a pretensioning device arranged on the frame 1; 8. Spring 9, gas generator 10, and casing 11; the round tube 3 is fixedly arranged in the casing 11 after connecting with the U-shaped plate 4, and the connecting part of the round tube 3 and the U-shaped plate 4 is a straight line section. The end of the round tube 3 that is not connected with the U-shaped plate 4 is provided with a gas generator 10, and the end of the gas generator 10 extending into the round tube 3 is provided with a spring 9; The long slot 31 of the template 4 direction opening, the rack 6 is fixedly arranged in the long slot 31 by the shear pin on the cover 11, the long slot 31 and the U-shaped plate 4 form a passage for the rack 6 to descend; The sealing ball 8 and the force transmission ball group 5 are arranged in the round tube 1 and between the spring 9 and the rack 6, wherein the sealing ball 8 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com