Air tightness detection clamp

An air tightness detection and fixture technology, applied in mechanical equipment, couplings, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of reducing labor intensity, improving preloading effect, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

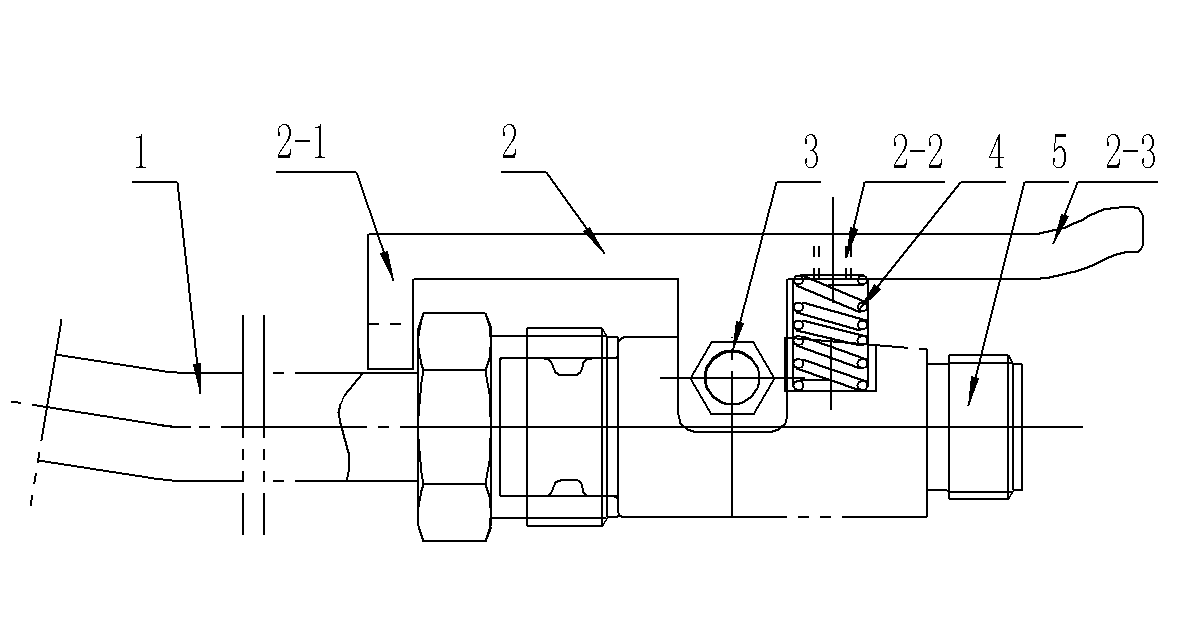

[0012] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

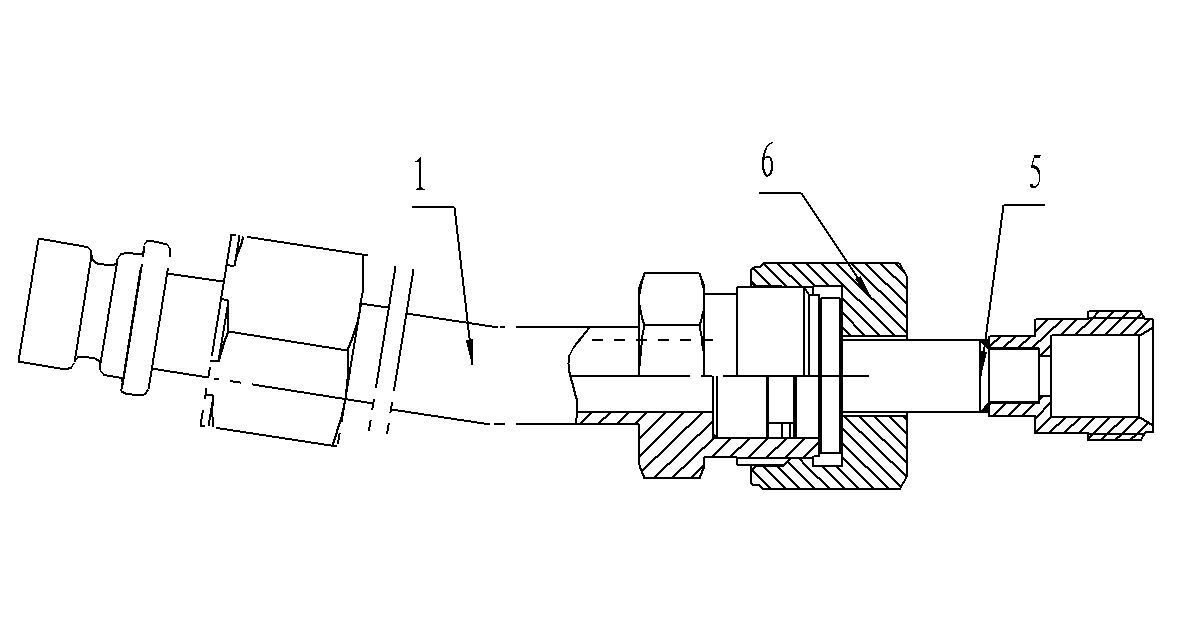

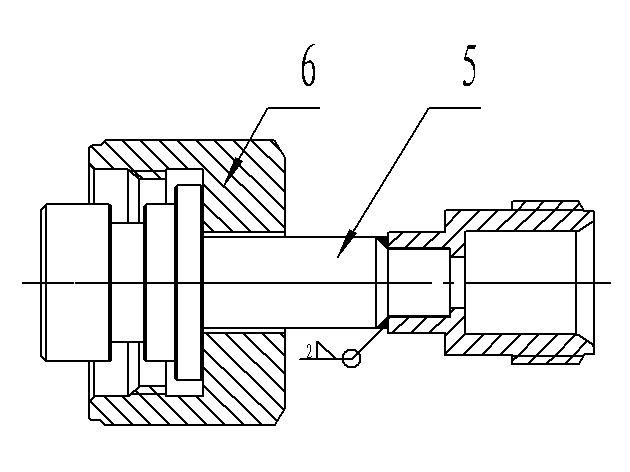

[0013] Such as image 3 , Figure 4 The shown air tightness testing fixture includes clamping part 2, hinge shaft 3, spring 4, pipe joint 5 and other components.

[0014] The air-tightness detection fixture pipe fitting 1 is equipped with an intake pipe joint 5, and a clamping part 2 is hinged on the intake pipe joint 5, and the clamping part 2 is hinged on the pipe wall of the pipe joint 5 to fix the clamping part 2. The clamping part 2 is provided with a protruding jaw part 2-1 at the front part of the hinge, and the jaw part 2-1 can be stuck on the end face of the end nut of the pipe fitting 1 to form a claw clip, and connect the pipe fitting 1 and the intake pipe The air inlet pipe joint 5 is tightly connected, and a handle part 2-2 is provided at the rear of the hinge, and a pivot pin 2-3 is provided between the hinge and the handle part 2-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com