Hydraulic expansion locking bolt

A locking bolt and hydraulic technology, applied in the direction of bolts, locking fasteners, screws, etc., can solve the problems of pre-tightening force and friction force reduction, reduction or disappearance, thread connection loosening, etc. Increased loosening torque, increased pressure, and the effect of preventing bolt loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

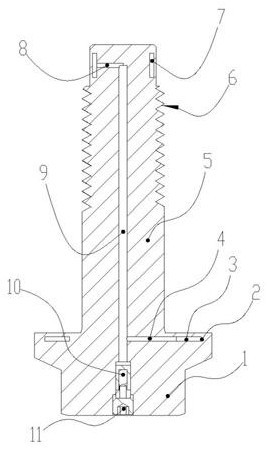

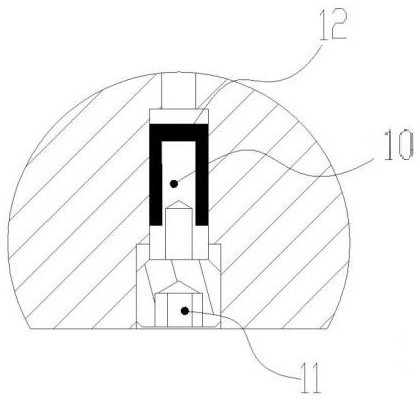

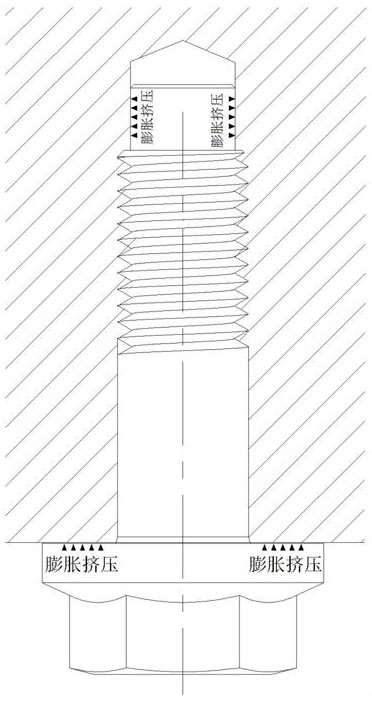

[0022] Such as figure 1 and figure 2 As shown, a hydraulic expansion locking bolt of the present invention includes a head 1, a flange 2, an expansion oil chamber 3, an oil passage hole 4, a rod part 5, a threaded part 6, an expansion oil chamber 2 7, an oil passage Hole two 8, main oil chamber 9, piston rod 10, pressure screw 11, nitrile rubber 12.

[0023] Such as figure 1 As shown, the middle part of the flange 2 is provided with an annular expansion oil chamber 1 3, the outer wall of the middle part of the rod part 5 is provided with a threaded part 6, and the inner part of the bottom end of the rod part 5 is provided with an annular expansion oil chamber 2 7; along the bolt axis A main oil chamber 9 is provided, and the main oil chamber 9 is located at the center of the bolt. The length of the main oil chamber 9 is set according to the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com