Automatic centering and locking device of numerical control slotting machine

A technology of automatic centering and locking device, applied in the direction of positioning device, clamping, supporting, etc., can solve the problem of incapable locking device and high-precision automatic centering device fusion, achieve simple and convenient switching, eliminate errors , the effect of high-precision centering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

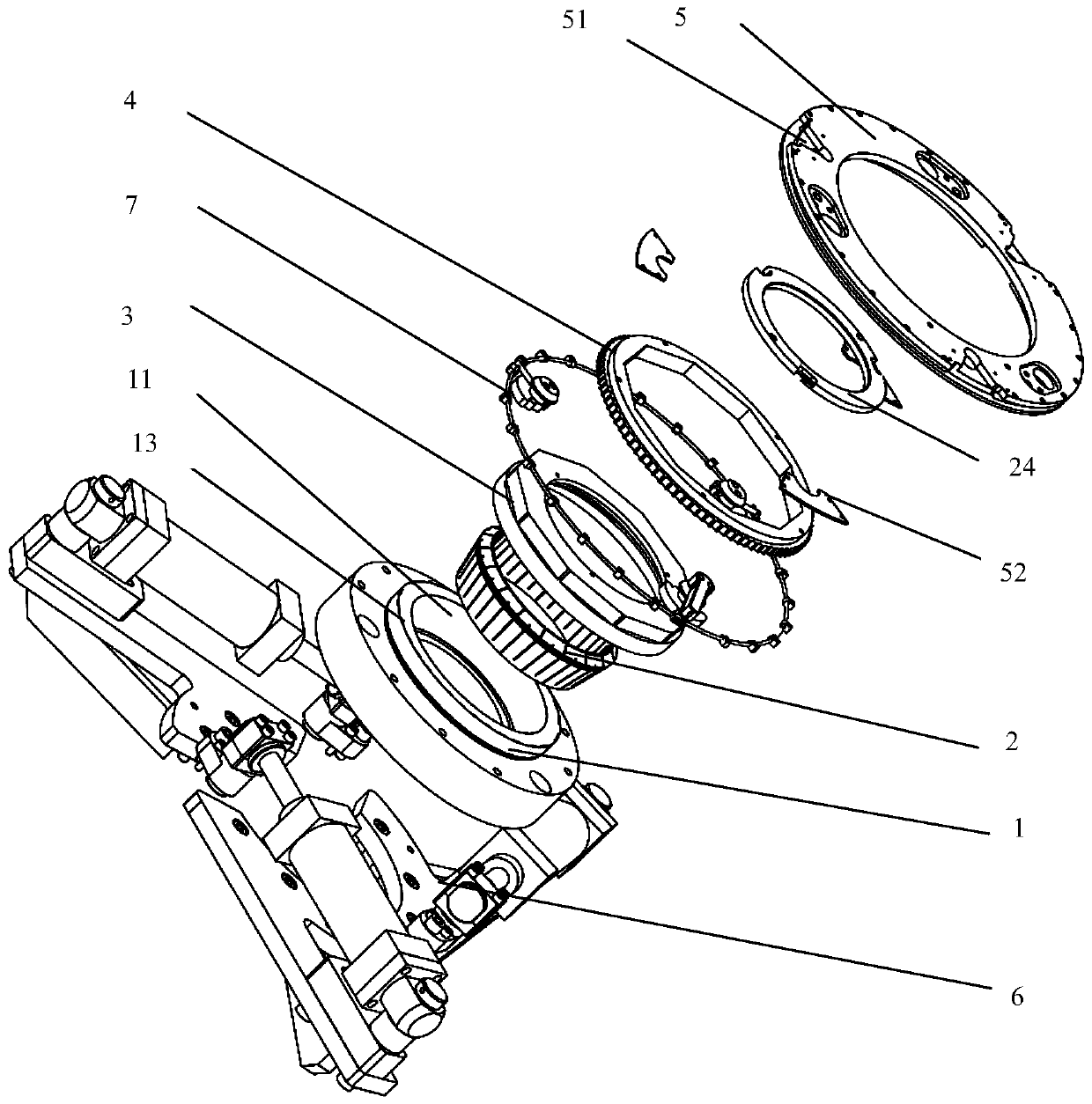

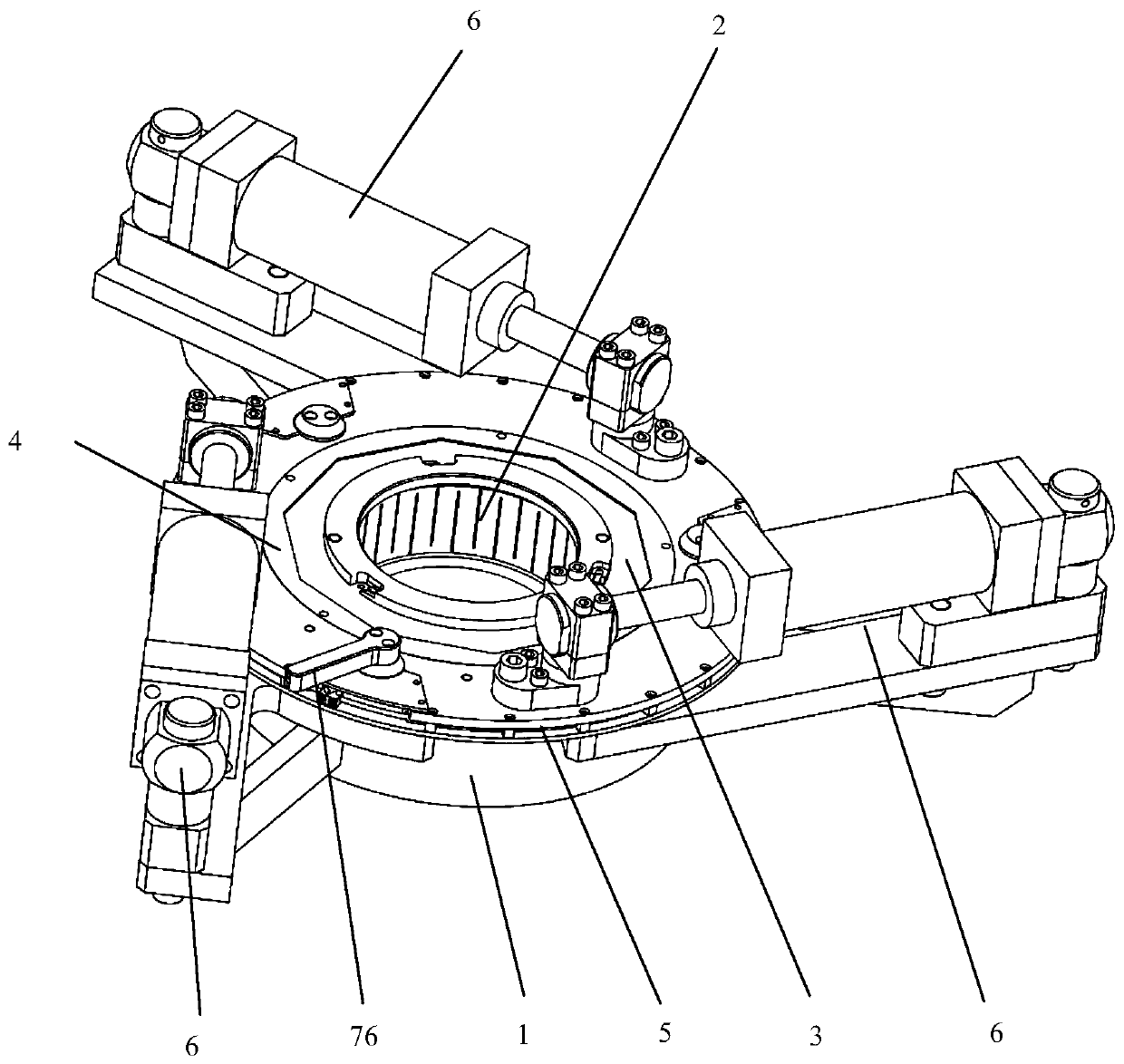

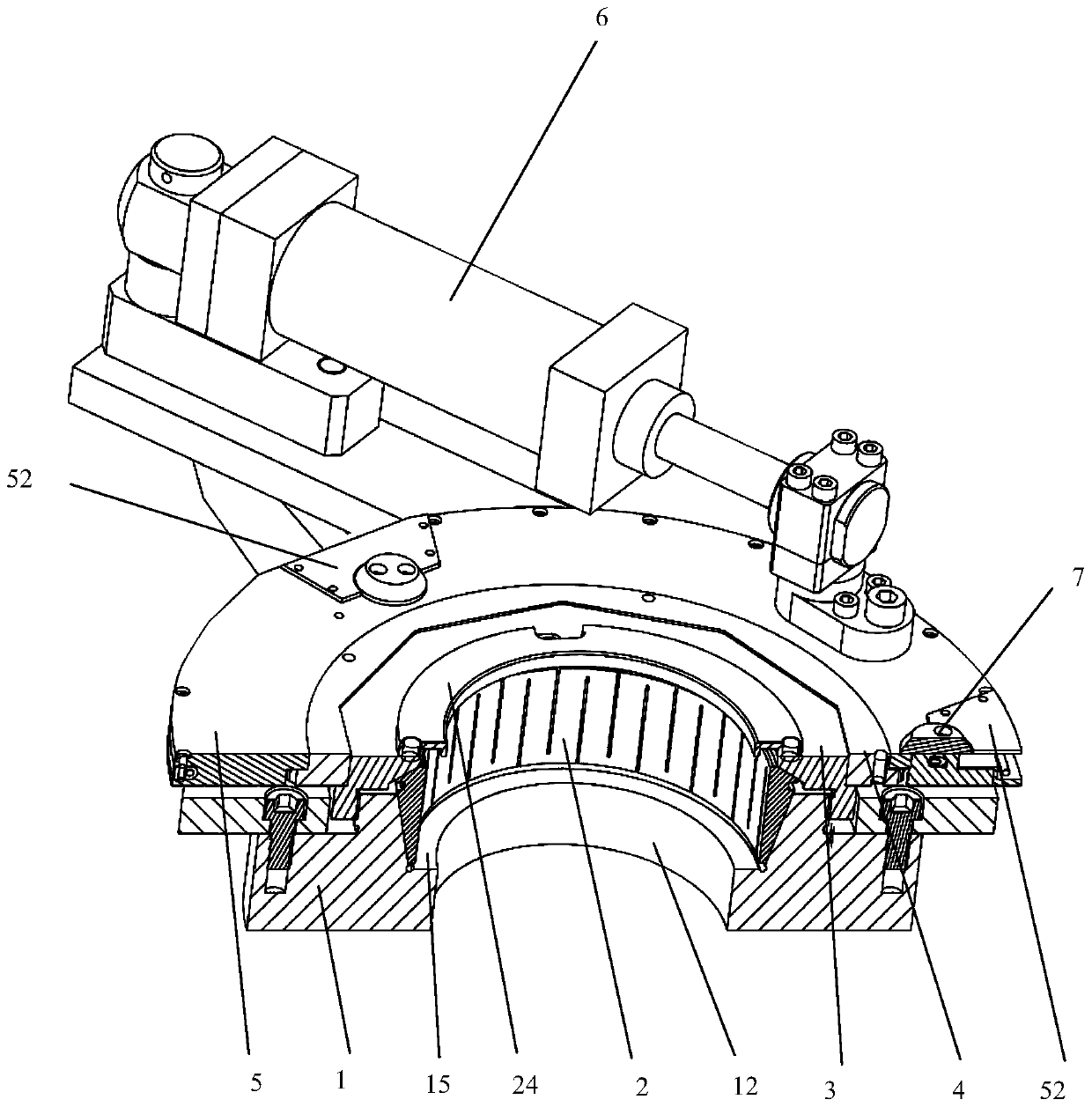

[0043] Such as figure 1 , figure 2 , image 3 with Image 6 As shown, the first preferred automatic centering locking device for CNC slotting machine is shown, including: a locking base 1, an elastic clamp 2 is arranged inside the locking base 1, and the elastic clamp 2 is tightened and clamped after moving downward. Holding the workpiece, there is a certain space in the vertical direction between the elastic clamp 2 and the locking base 1, which can be used for the elastic clamp 2 to move up and down. When the elastic clamp 2 is forced to move downward, the locking base 1 compresses the elastic clamp 2, and the elastic clamp 2 can clamp the workpiece after shrinking, and after the elastic clamp 2 puts down the workpiece, it moves upwards by its own elastic force to realize reset.

[0044] In addition, as a preferred embodiment, such as image 3 , Image 6 with Figure 11 As shown, the automatic centering locking device of the CNC slotting machine also includes: a lock ...

no. 2 example

[0057] Please continue to see figure 1 , figure 1 with Image 6 As shown, the second preferred automatic centering locking device for CNC slotting machine is shown, including: a locking base 1, the radial section of the locking base 1 is circular, and the inside of the locking base 1 is arranged along the horizontal direction Annular step 15, the inner diameter of the locking base 1 gradually increases from the annular step 15 to its upper port, the inner diameter of the locking base 1 below the annular step 15 is the same, and the inside of the locking base 1 is provided with elastic clamps 2, elastic clamps 2 Located on the upper side of the annular step 15, the elastic clamp 2 has a relative bottom end 21 and a top end 22, and the radial section of the elastic clamp 2 is circular; along the axial direction of the elastic clamp 2, the outer diameter of the elastic clamp 2 is defined by the top end 22 gradually decreases toward the bottom end 21, the outer wall of the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com