Patents

Literature

30results about How to "Increase axial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

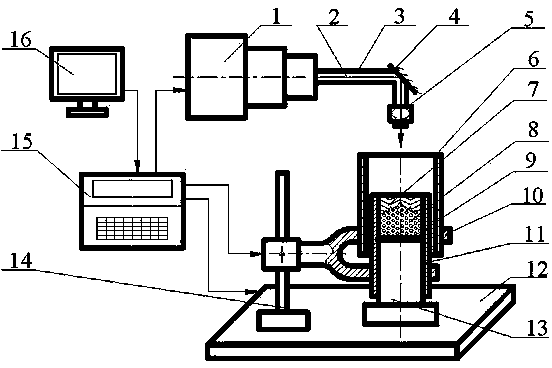

Method and device for connecting metal pipe based on laser shock wave technology

InactiveCN102225493APrecise and controllable parametersPrecisely controlled peak pressureLaser beam welding apparatusPhysicsPulse beam

The invention discloses a method and device for connecting a metal pipe based on a laser shock wave technology and belongs to the technical field of laser processing. In the invention, a black paint applied to the upper end part of a plugging rod serves as a laser energy absorption layer, and water serves as a restraint layer; a laser pulse beam subjected to parameter optimization enters the interior of a pipe fitting along the axis of the pipe fitting, so as to be irradiated on the absorption layer at the upper end part of the plugging rod through a light guide system; the absorption layer absorbs the energy of the laser so as to be gasified and ionized, thus forming high-voltage plasmas; and the high-voltage plasmas quickly dilate to form a high-amplitude shock wave, thereby promoting the quick dilatational strain of an inner pipe and causing the inner pipe to violently collide with an outer pipe, therefore the parts, which are impacted by the laser shock wave, of the two pipe fittings are plastically deformed obviously; and intensive thermal effect is produced during the collision process so that the interfaces of the collision parts of the two pipes are adhesively jointed together. The method and device provided by the invention are wide in application range, and capable of connecting metal pipe fittings different from each other in melting point, in coefficient of thermal dilation, in thermal treatment condition and in state.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

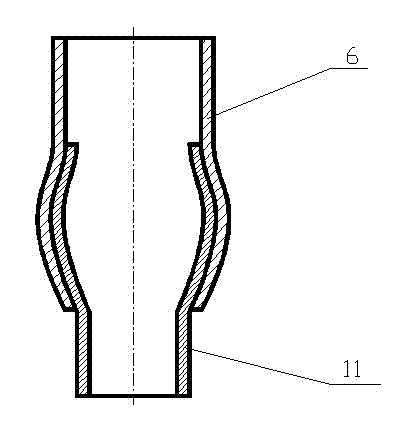

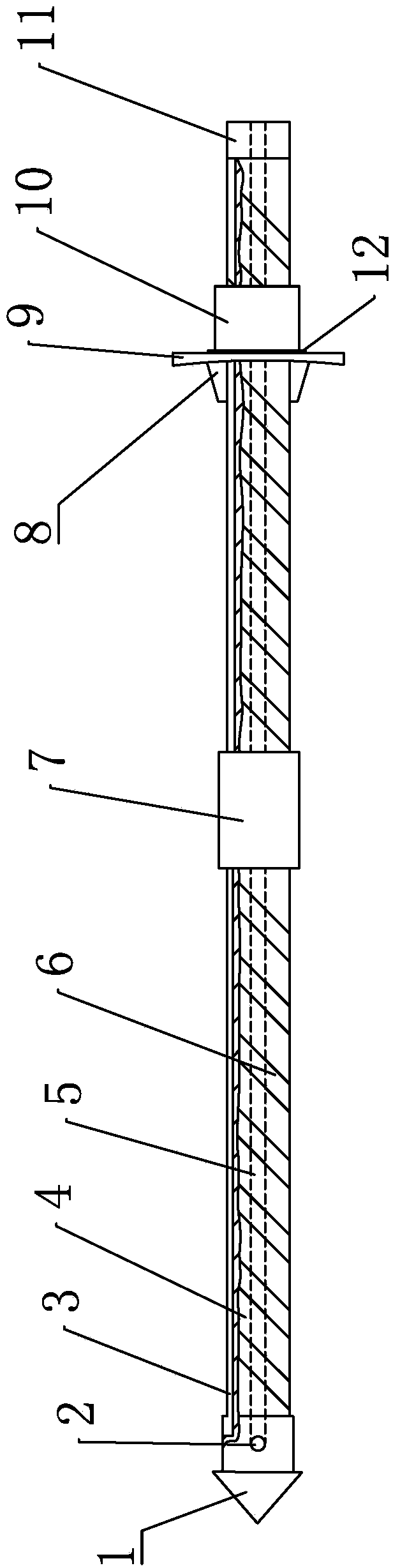

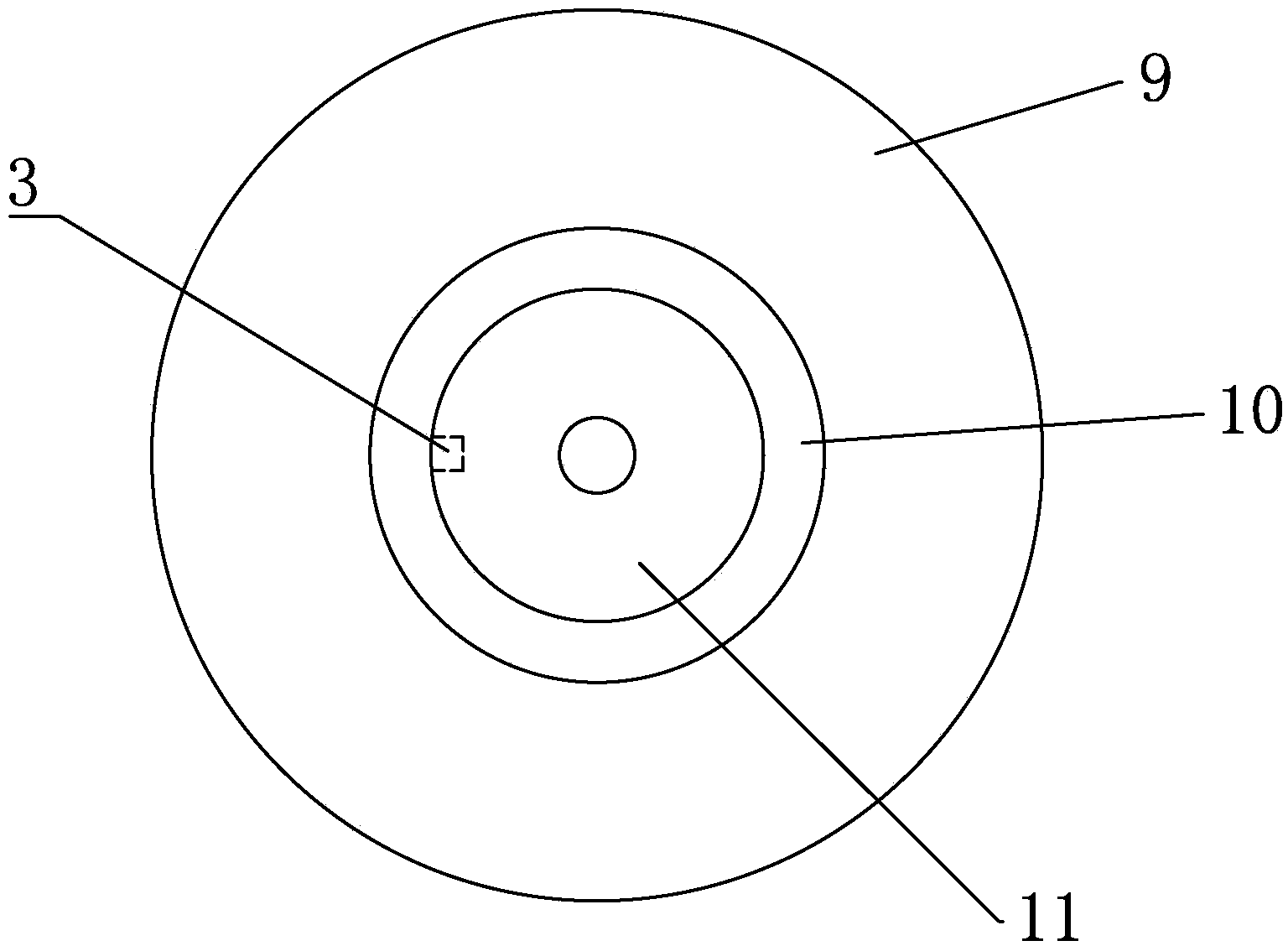

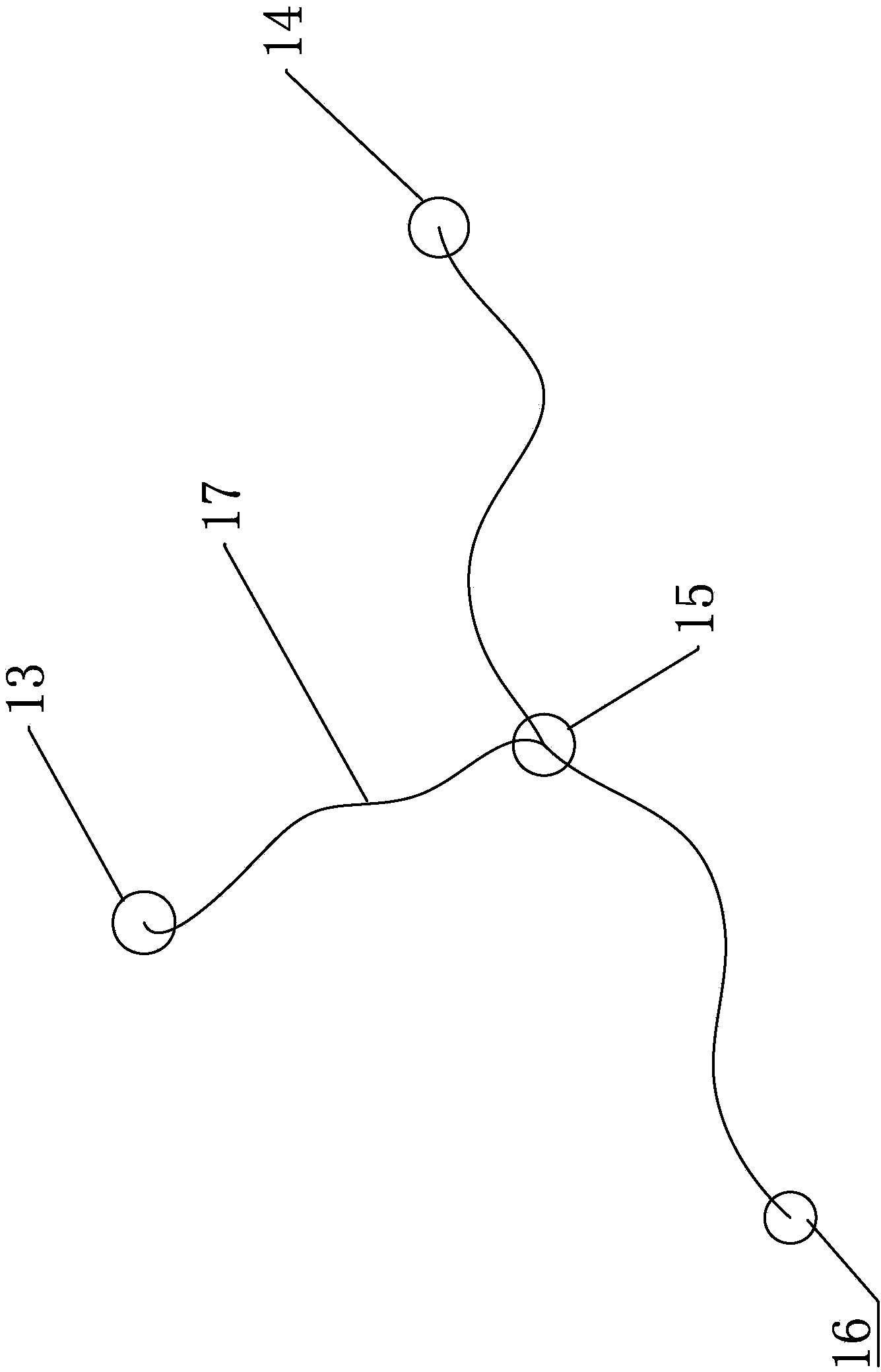

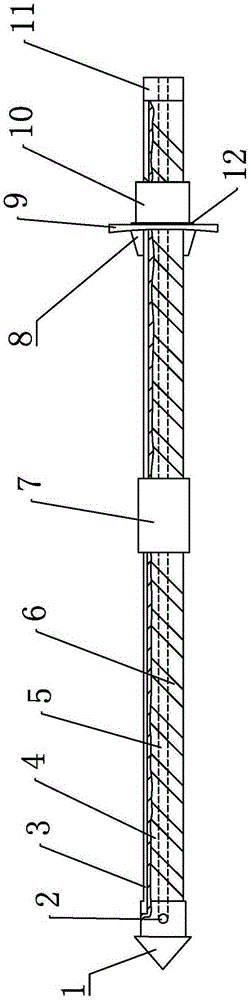

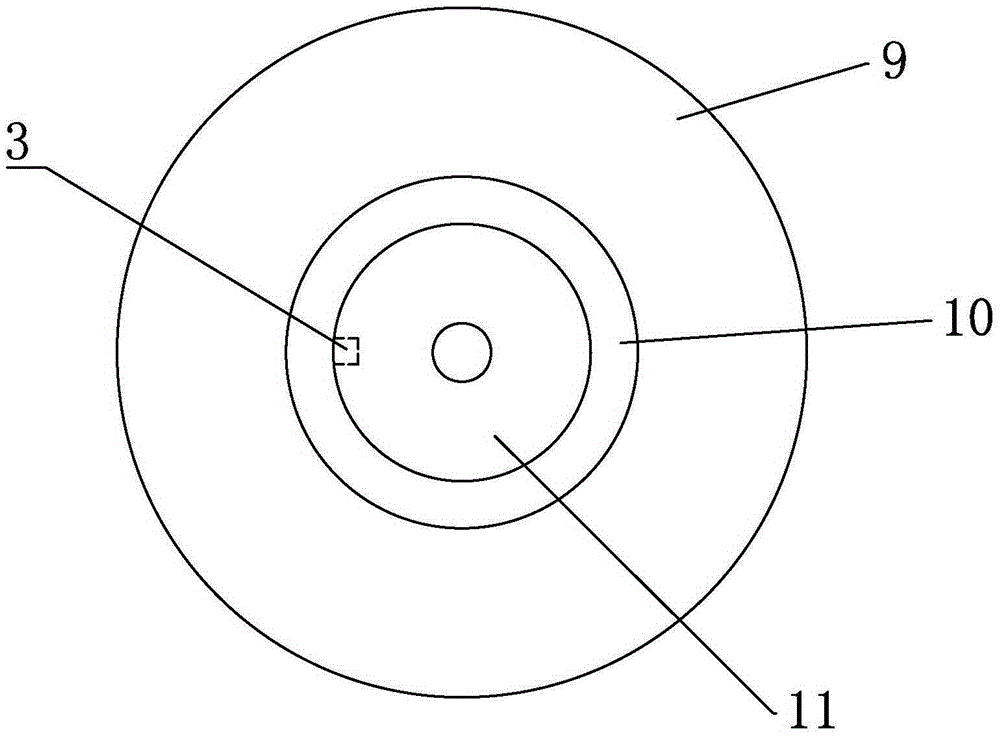

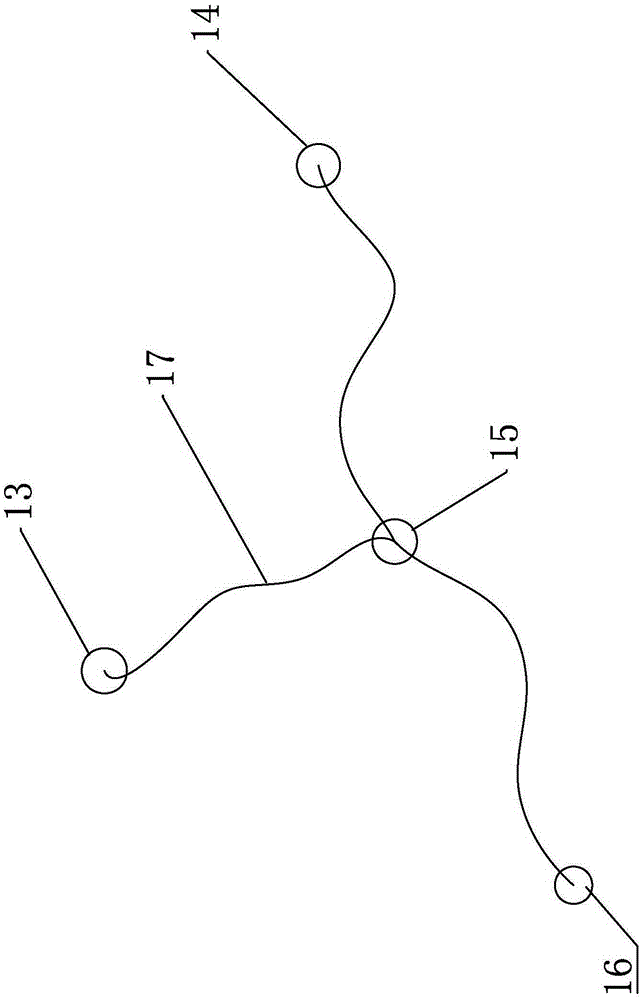

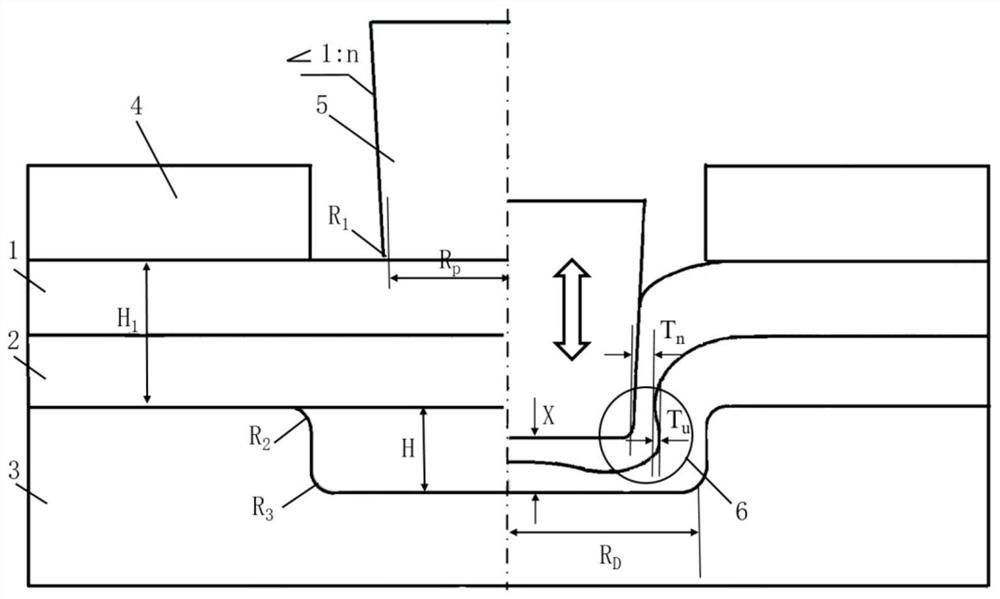

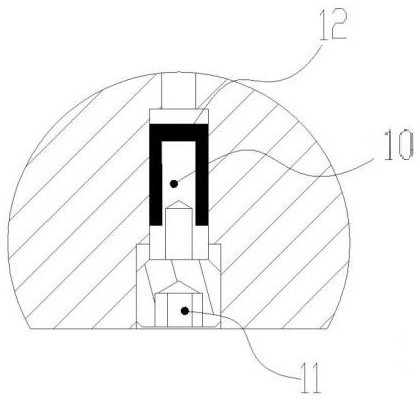

Reinforcement anchor rod and rock mass reinforcement method applying anchor rod

ActiveCN104047625AIncrease axial tensionDecrease increase reinforcement strengthAnchoring boltsSlurryEngineering

The invention relates to a reinforcement anchor rod which comprises an anchor rod body, wherein a thread tightly meshed with a rock mass is formed on the outer side surface of the anchor rod body; an axial grouting channel for grouting slurry and enabling the slurry to flow into a drilled hole of the drilled rock mass is formed in the anchor rod body; a stop plug for stopping the slurry in the drilled hole is arranged on the anchor rod body. The invention also relates to a rock mass reinforcement method applying the anchor rod. The rock mass reinforcement method comprises the steps of respectively punching the anchor rods into intersections of cracks of the rock mass and the tail ends of all the cracks, extracting air from the anchor rods at the intersections of the cracks, grouting the slurry into anchor rods at the tail ends of the cracks, and respectively grouting the slurry into rock holes in which the anchor rod bodies are positioned after the cracks are filled with the slurry so as to reinforce the whole rock mass into a whole.

Owner:JIANGSU DINGTAI ENG MATERIAL

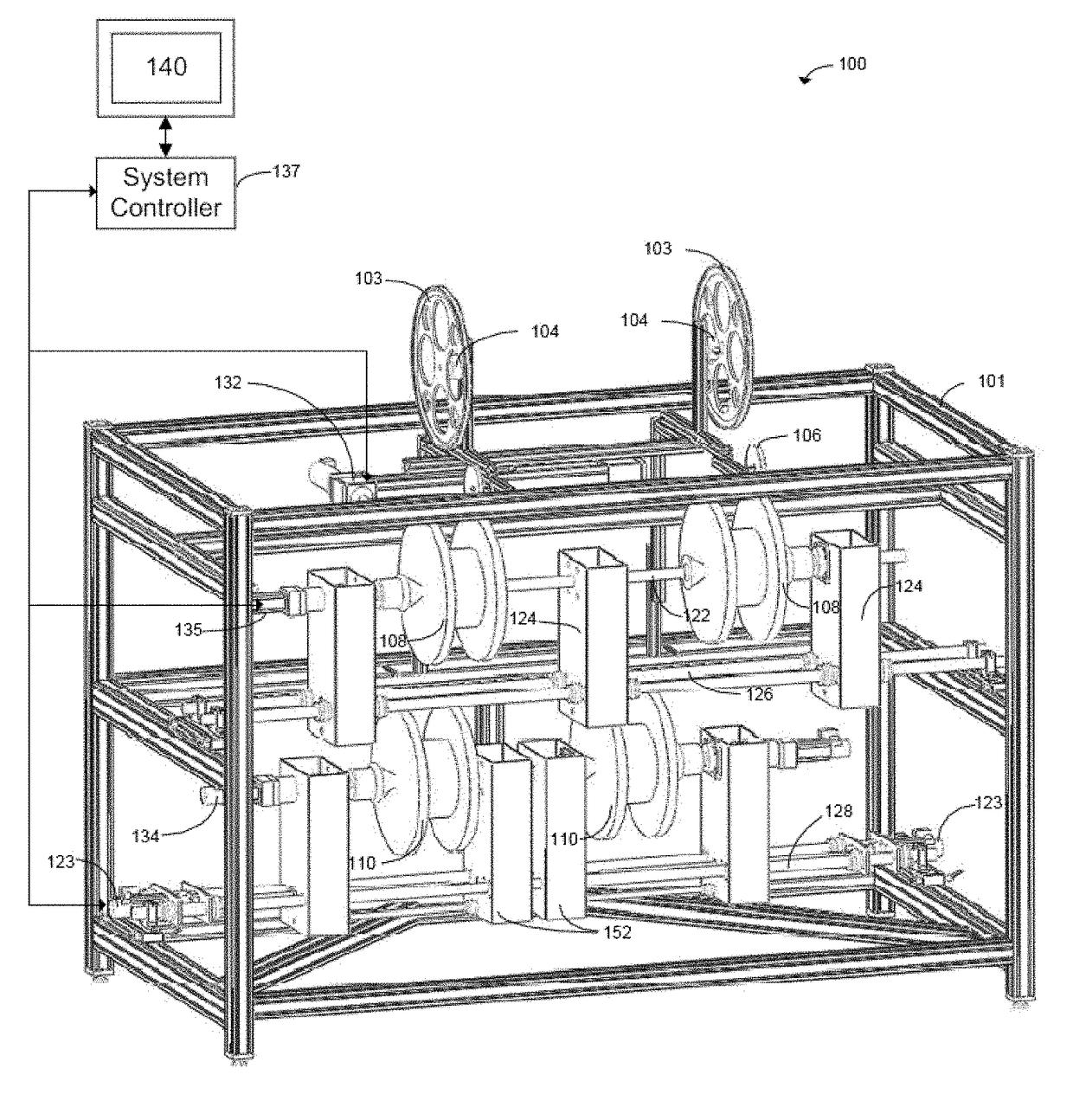

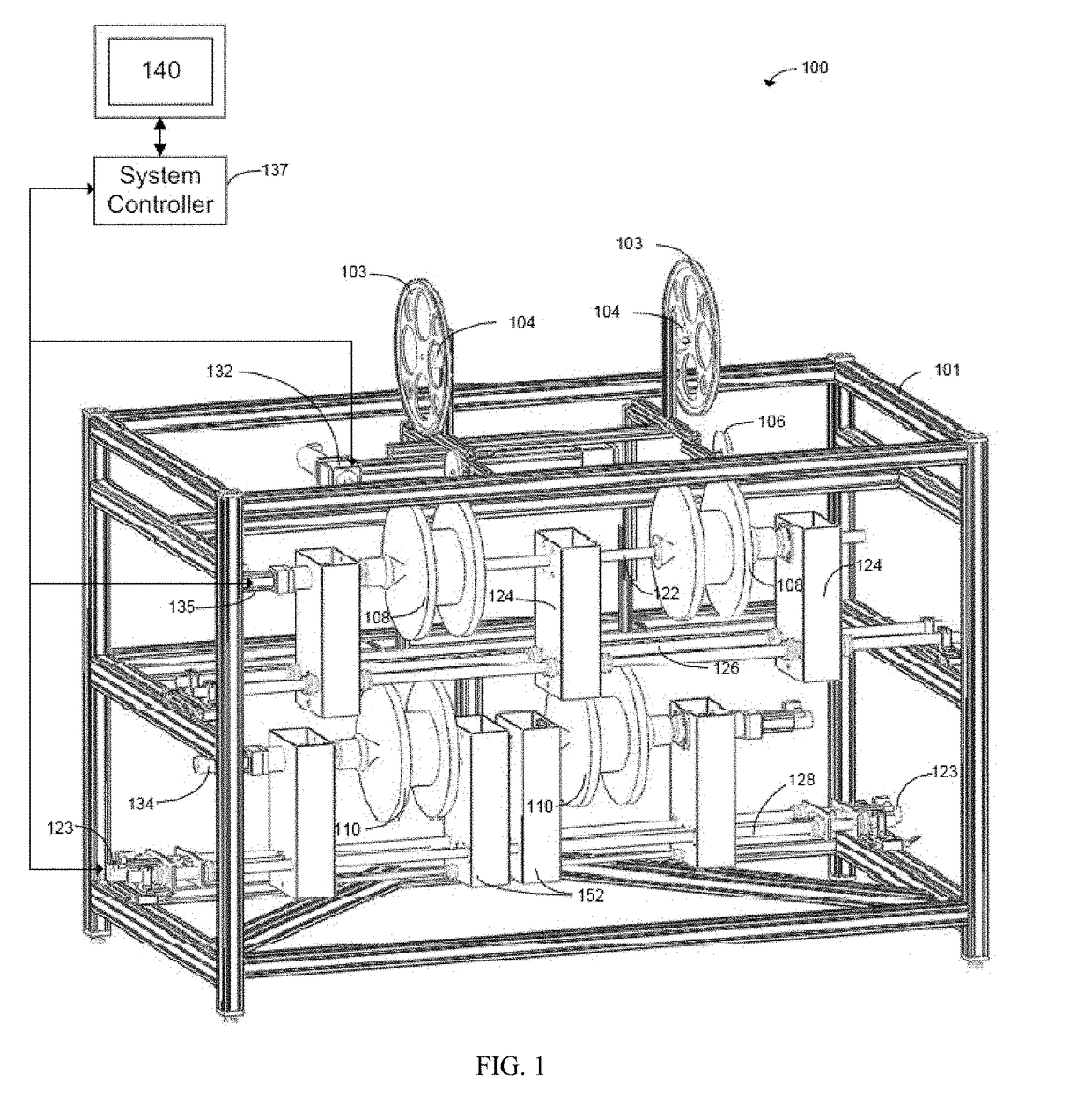

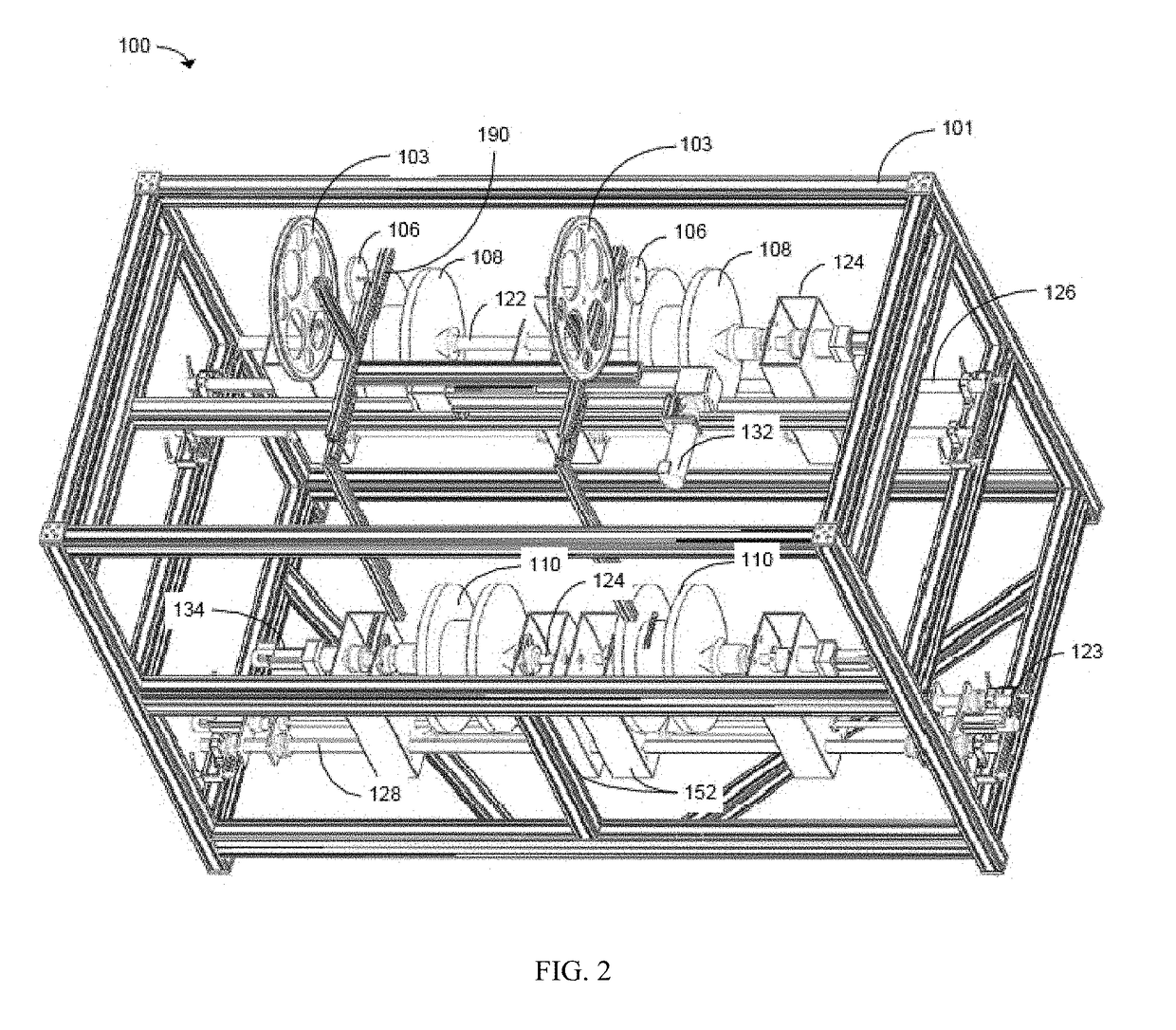

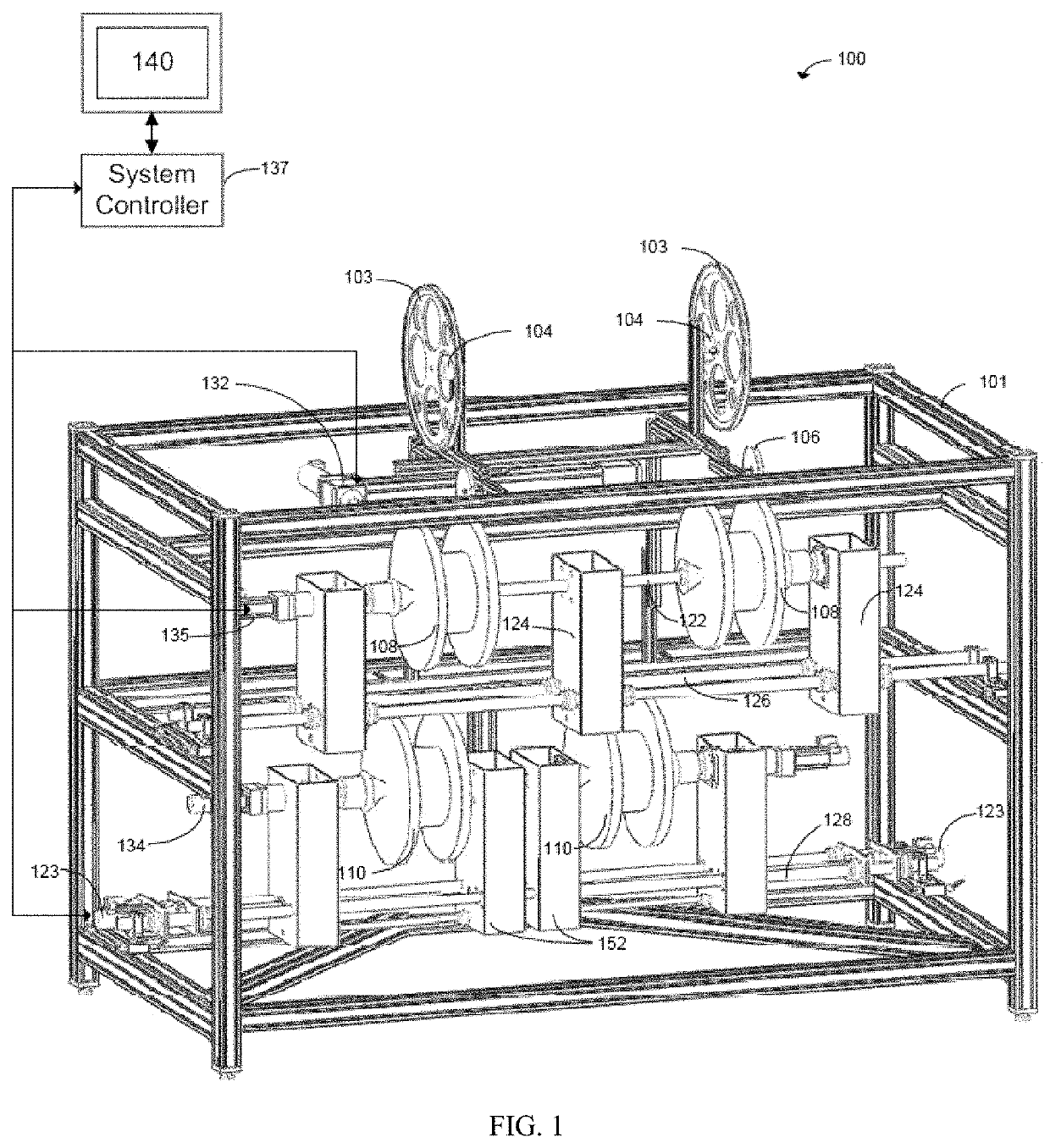

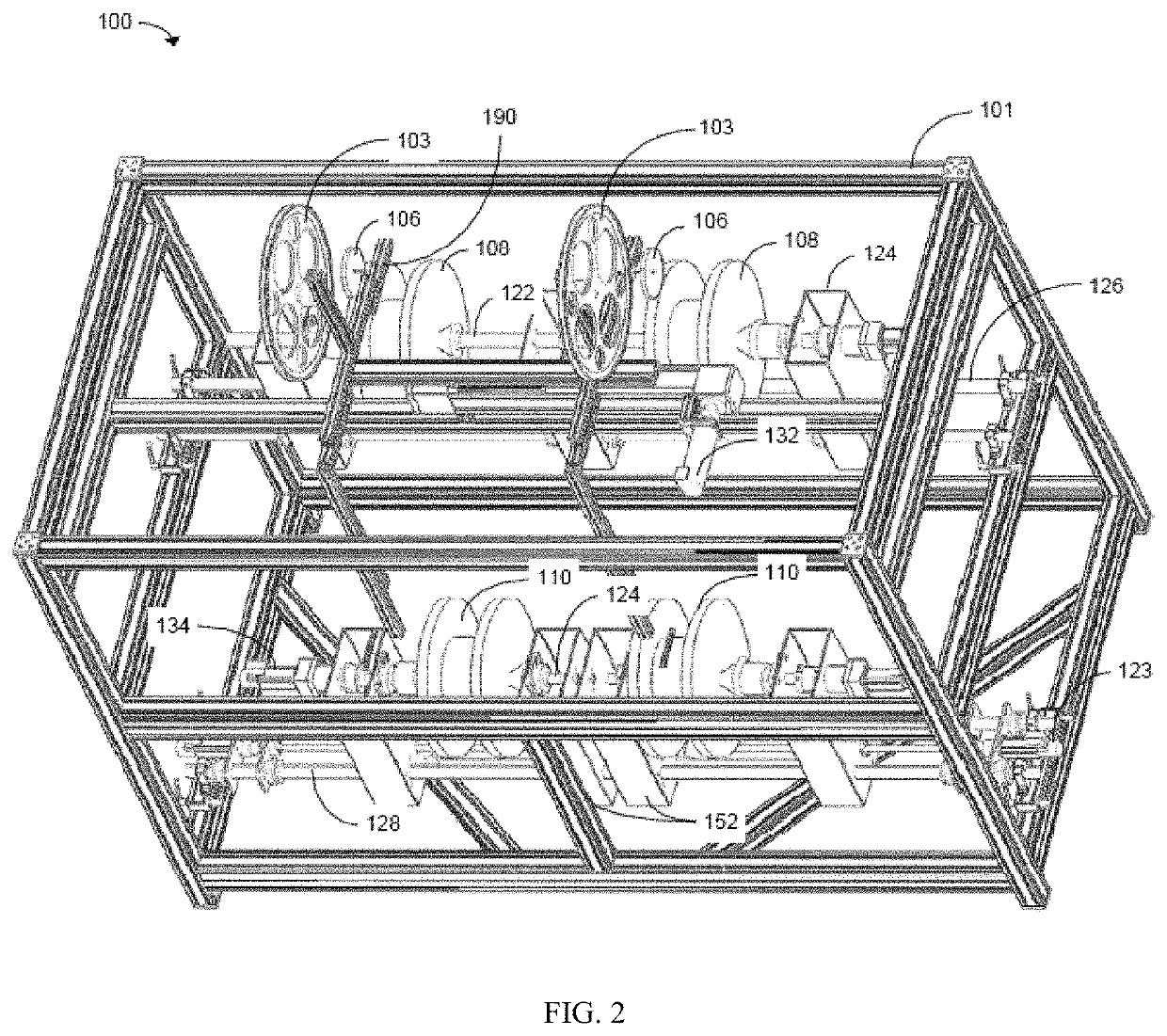

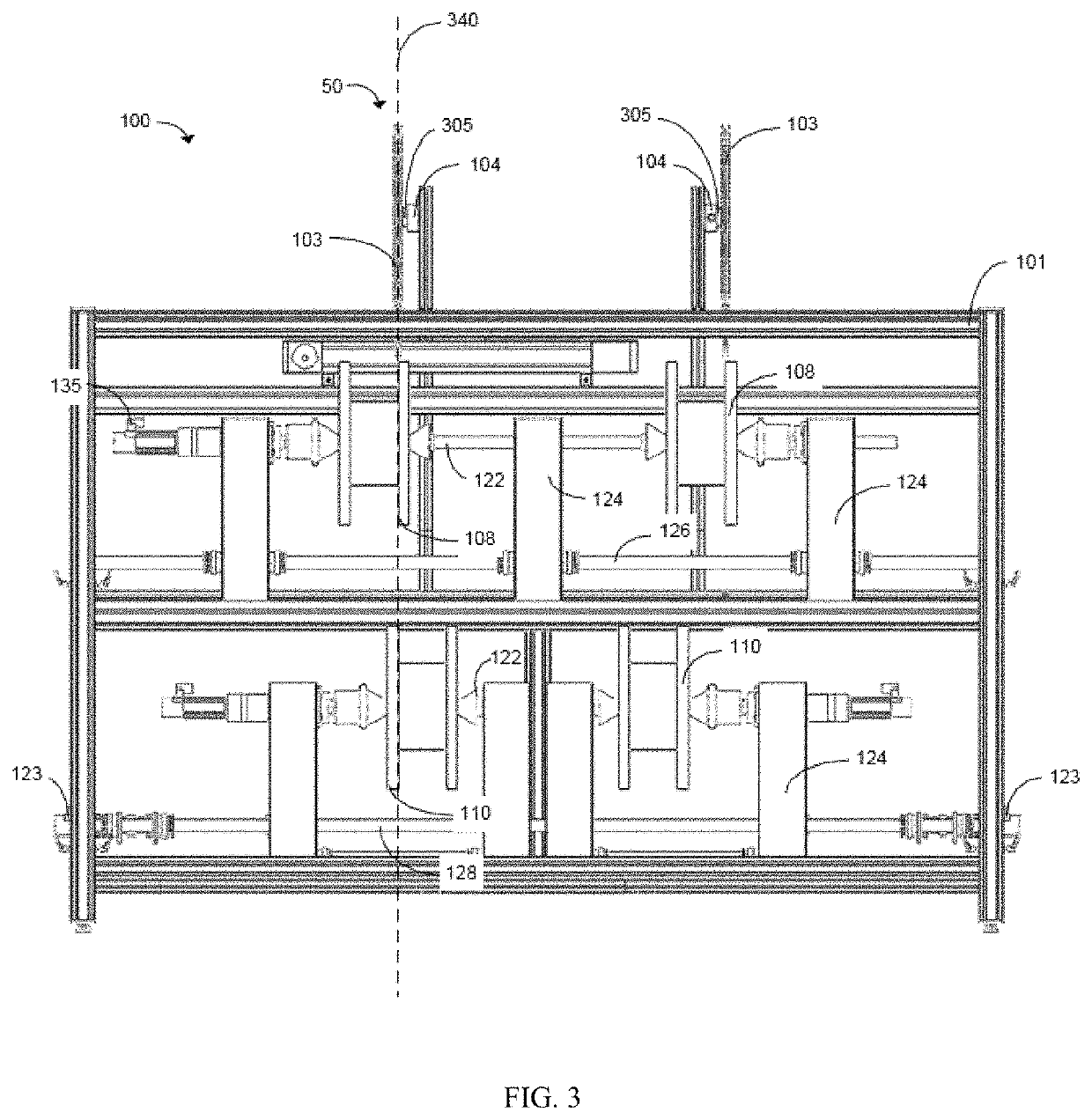

Linear media handling system and devices produced using the same

ActiveUS20180251333A1Easy to carryUseful to addressControlFilament handlingRotation velocityClosed loop

An improved system for handling delicate linear media and in particular to a method and apparatus for winding delicate linear media such as superconducting wire or tape or optical fibers onto a spool. A combination of direct closed loop control and media routing design facilitates the handling of the delicate media without causing damage. The axial tension in the linear media may be closely controlled during winding by means of feedback control loop using tension measurements to control the rotation speeds of the wind-from and wind-to spools. Further, during winding, the delicate linear media is only exposed to large radius bends with no reverse bending. Finally, output devices and features, commercial or otherwise, made possible by delicate linear media handling are revealed. This includes advanced SC devices and features.

Owner:INFINITY PHYSICS LLC

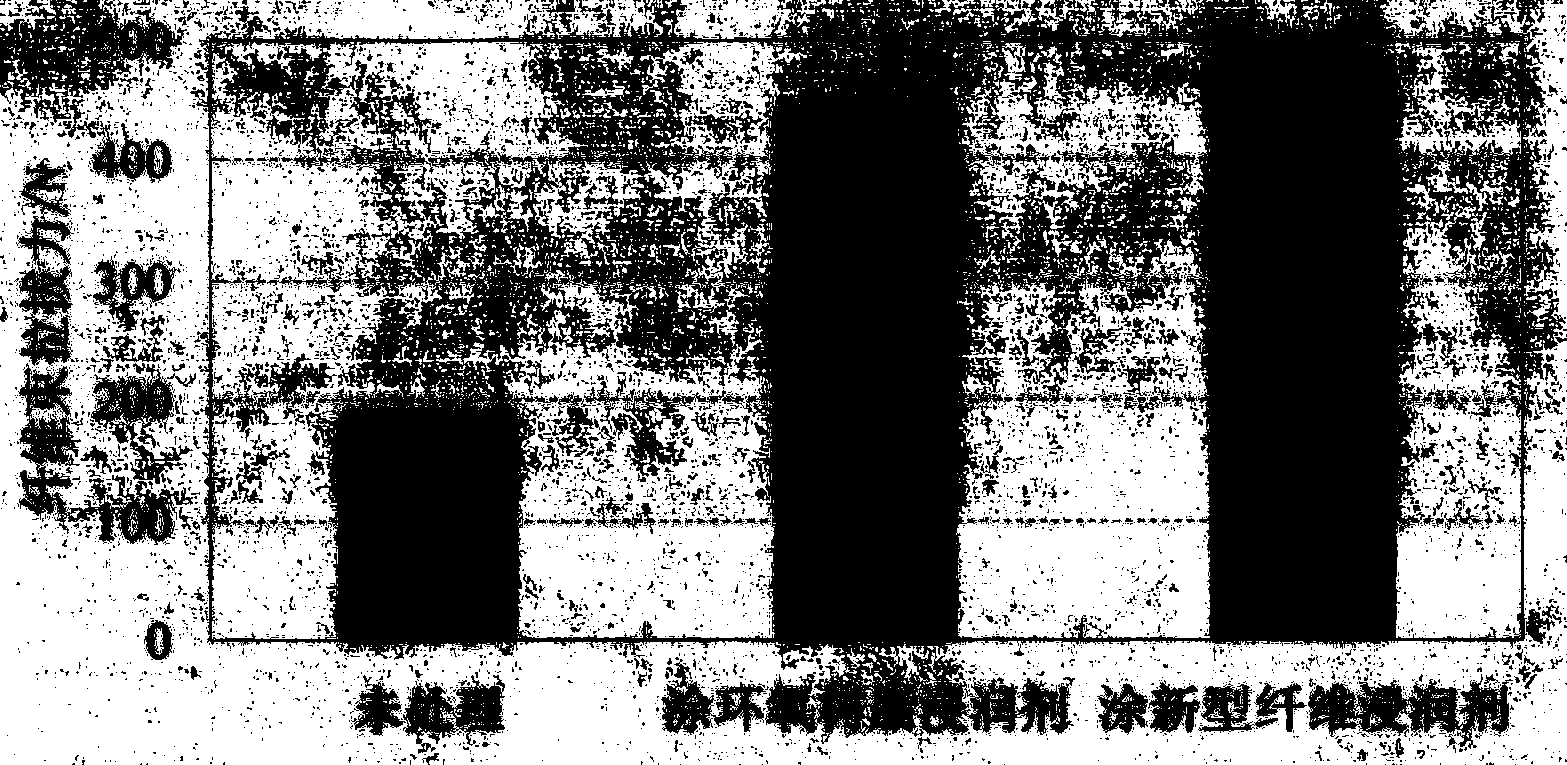

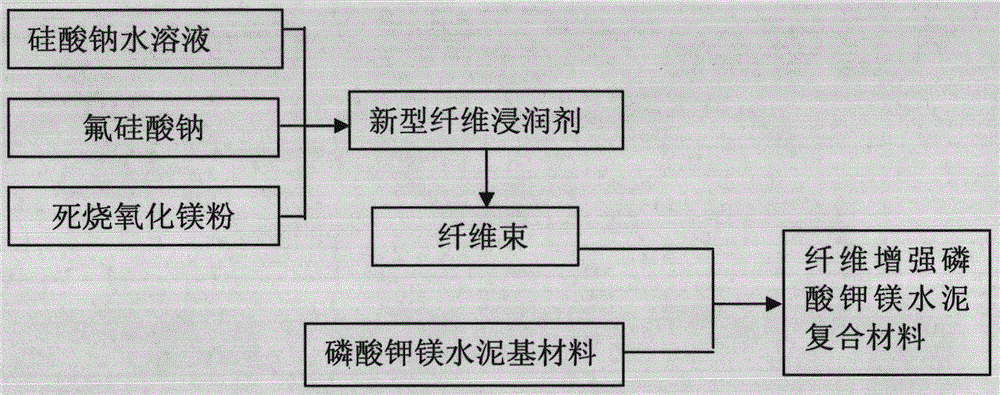

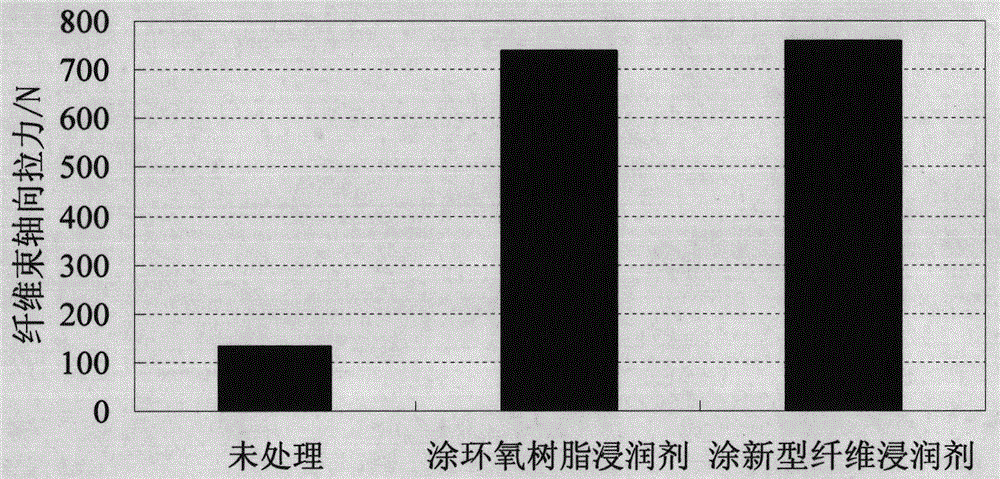

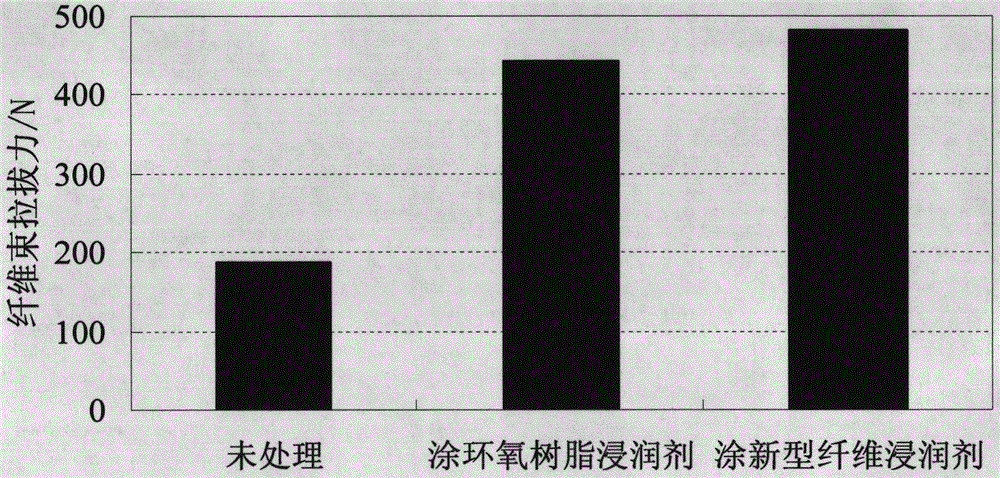

Method of improving bonding performance of fiber bundle and potassium magnesium phosphate cement-based material

The invention discloses a method of improving bonding performance of a fiber bundle and a potassium magnesium phosphate cement-based material and relates to a manufacturing technology of a fiber-reinforced potassium magnesium phosphate cement composite material. A novel fiber impregnating compound prepared by the method has characteristics such as strong permeability, quick curing, controllable curing speed, high bonding strength, acid resistance, pressure resistance and high temperature resistance. In the fiber bundle cured by the novel fiber impregnating compound, fiber filaments are bonded into an integer by a network structure of -Si-O-Si-, all fiber filaments can be stressed at the same time, and axial tension of the fiber bundle is improved by twice to three times in comparison with that of the un-treated fiber bundle. In the fiber-reinforced MPC(Magnesium Phosphate Cement)-based composite material prepared by the fiber bundle cured by the novel fiber impregnating compound, dead-burned magnesium oxide powder deposited on the surface of the fiber bundle participates in hydration reaction of an MPC base body, so that interface bonding of the fiber bundle and the MPC base body is reinforced; and pulling-drawing force of the fiber bundle is improved by 15%-40% in comparison with that of the fiber bundle treated by an epoxy resin impregnating compound. The method disclosed by the invention is simple in preparation process and convenient to use, and has cost which is only 1 / 10-1 / 6 of that of the epoxy resin fiber impregnating compounds.

Owner:YANCHENG INST OF TECH

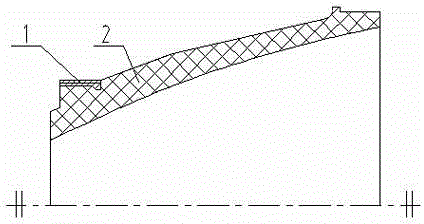

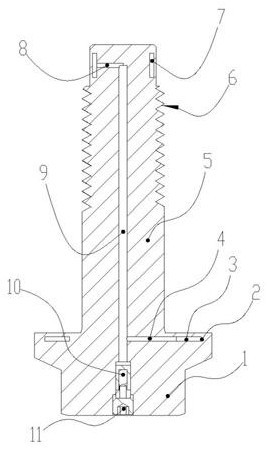

Ultrasonic pressed-in nut

The invention relates to an ultrasonic pressed-in nut which is a hollow cylinder with knurl on the external surface and thread on the internal surface, wherein the knurl is tilted, and the slope of the knurl is 25-30 degrees; a countersunk head is arranged at one end of the hollow cylinder; and a small step is arranged on the thread end part. When the ultrasonic pressed-in nut is pressed in, the ultrasonic pressed-in nut can rotate; because the knurl is tilted in a certain angle, the knurl can bear larger axial tension; and the thread end part is provided with the step which can protect the thread from being damaged.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

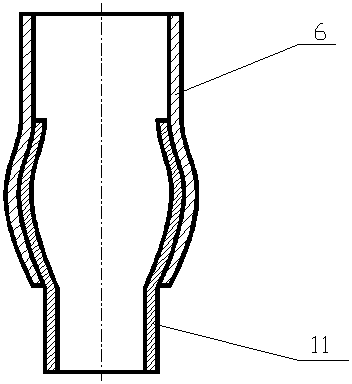

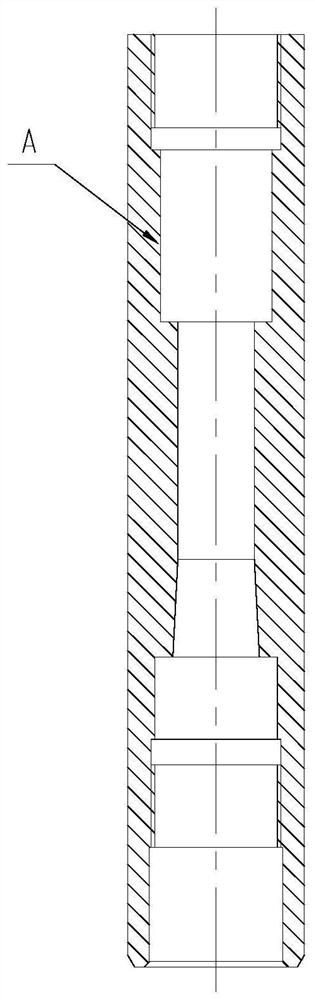

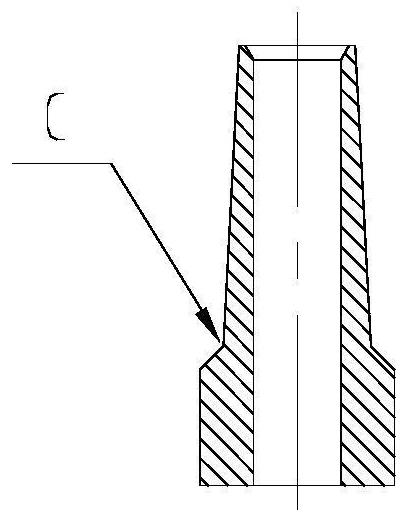

Half-and-half threaded connection structure of diffusing section of jet pipe of solid rocket engine

InactiveCN105736185AGuarantee working reliabilityEnsure structural safetyRocket engine plantsScrew threadStructural safety

The solid rocket motor nozzle diffuser pair half-thread connection structure of the present invention includes: a diffuser body and a half-thread connection pair; the half-thread connection pair is composed of a pair of half-thread connectors; the pair of half-thread connectors It is cut in half from a complete structural member with external threads and one end closed; the half-threaded connection pair is located outside the body of the diffusion section to play a connecting role. The half-thread connection structure of the nozzle diffuser of the solid rocket motor meets the basic requirements of the overall total weight within the given mass and volume range, ensures the engine's working reliability and structural safety, and solves the problem of axial rigid connection of the diffuser section. The thermal load bearing capacity of the diffusion section is improved, and the axial tension of the diffusion section is increased. The semi-thread connection structure of the nozzle diffusion section of the solid rocket motor can meet the axial force requirements of the solid rocket motor when it is working, and has high reliability.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

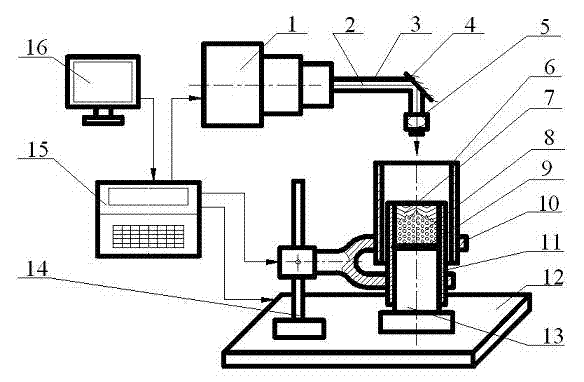

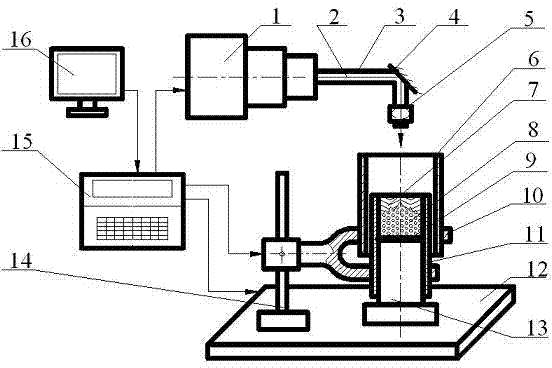

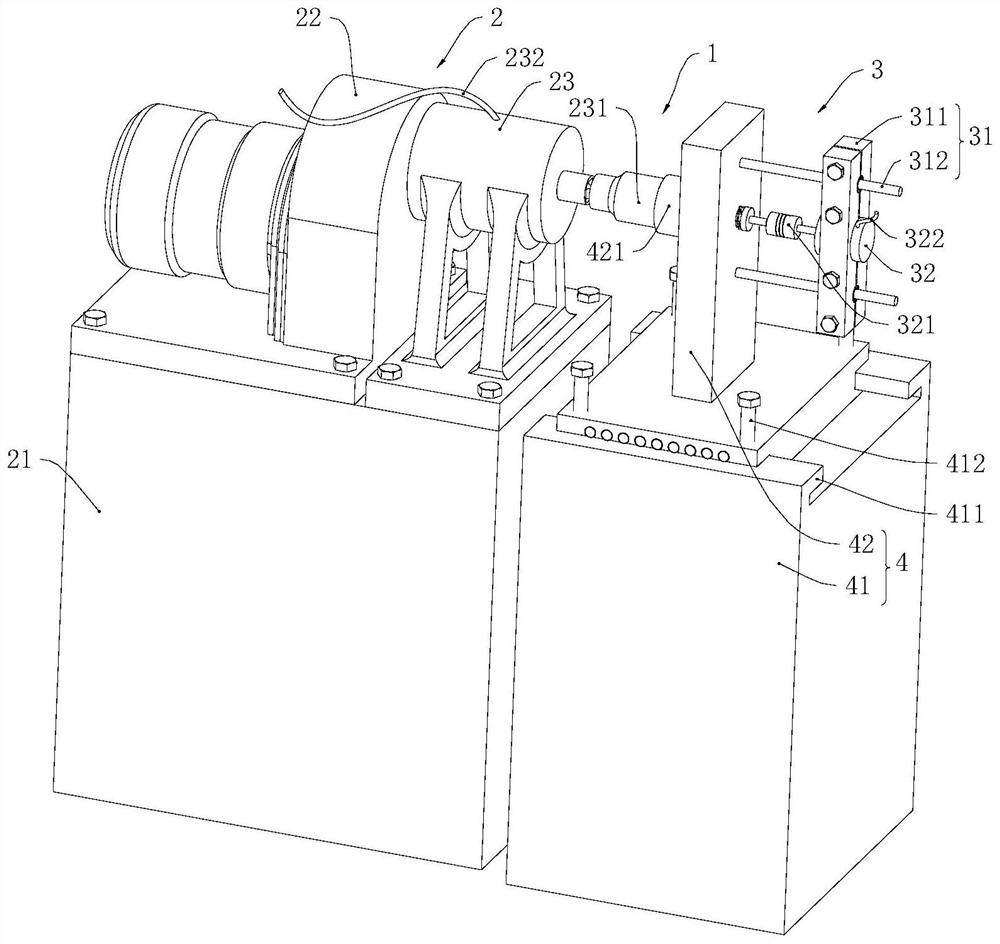

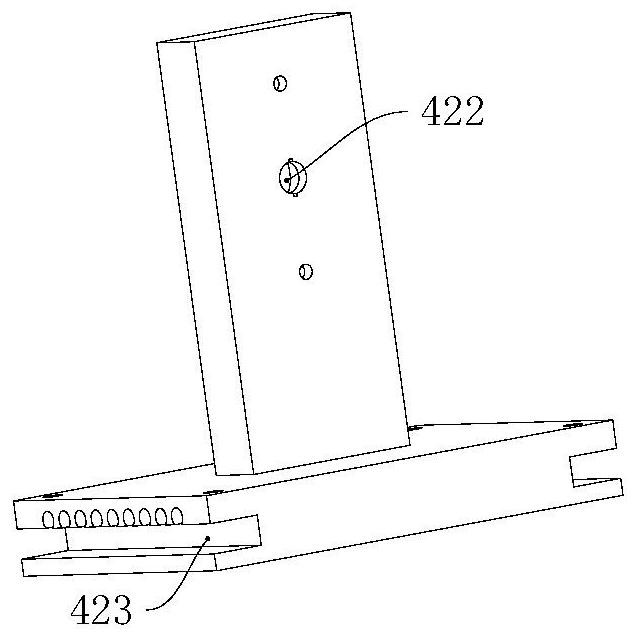

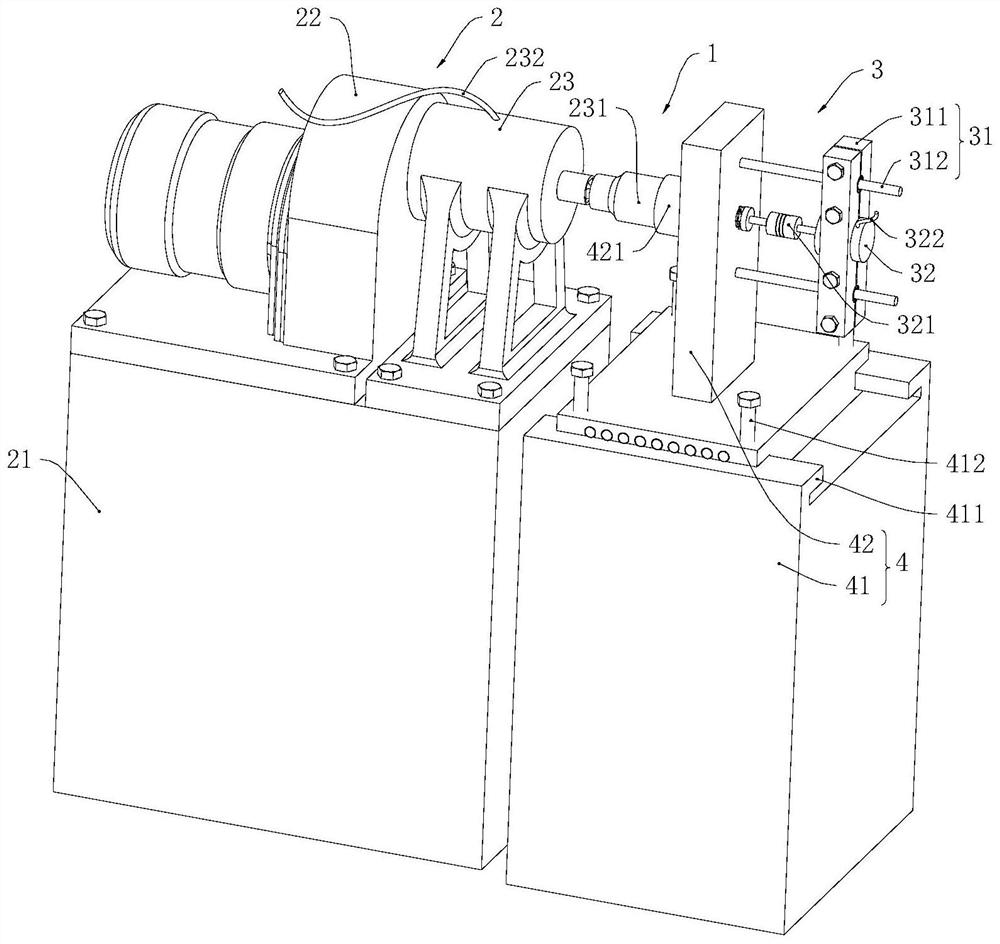

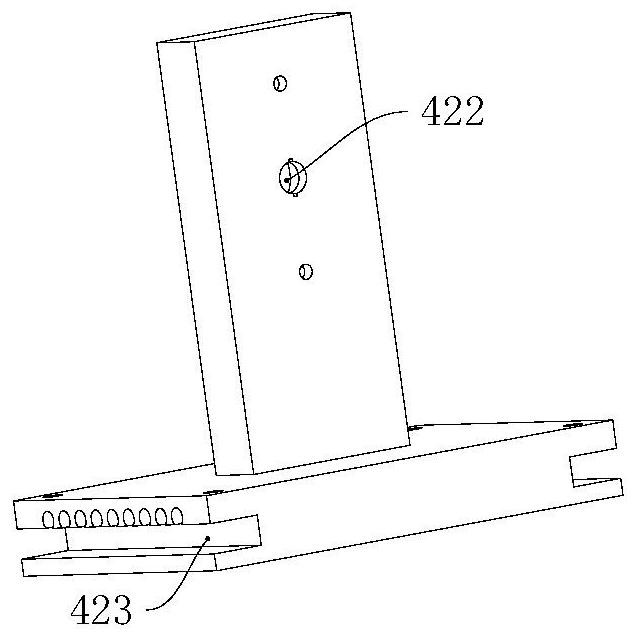

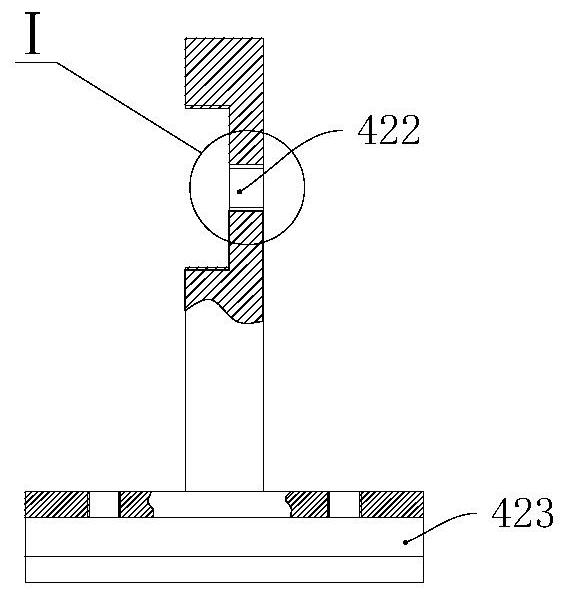

Device for testing relationship between tightening torque and angular displacement of pipe joint

ActiveCN111855181ASave human effortContinuous torque output is stableMachine part testingMeasurement of torque/twisting force while tighteningRubber ringReliable transmission

The invention discloses a device for testing the relationship between the tightening torque and the angular displacement of a pipe joint, and relates to the technical field of pipelines. The device comprises a data acquisition device, a clamping transmission assembly, a power assembly and an angular displacement measuring assembly which are respectively connected with two ends of the clamping transmission assembly. The power assembly and the angular displacement measuring assembly are in communication connection with the data acquisition device. The clamping transmission assembly comprises a clamping assembly body and a transmission assembly body. The clamping assembly body comprises a first rack and a supporting frame arranged on the first rack in a sliding and lockable mode. The transmission assembly comprises a connecting rod, a connecting seat, a conical rubber ring, a spring and a spring seat. The testing device can liberate manpower, synchronously acquire accurate data of torqueand angular displacement and ensure reliable transmission.

Owner:SOUTHWEST JIAOTONG UNIV

Linear media handling system and devices produced using the same

ActiveUS10899575B2Minimize strainStress minimizationControlFilament handlingClosed loopOutput device

An improved system for handling delicate linear media and in particular to a method and apparatus for winding delicate linear media such as superconducting wire or tape or optical fibers onto a spool. A combination of direct closed loop control and media routing design facilitates the handling of the delicate media without causing damage. The axial tension in the linear media may be closely controlled during winding by means of feedback control loop using tension measurements to control the rotation speeds of the wind-from and wind-to spools. Further, during winding, the delicate linear media is only exposed to large radius bends with no reverse bending. Finally, output devices and features, commercial or otherwise, made possible by delicate linear media handling are revealed. This includes advanced SC devices and features.

Owner:INFINITY PHYSICS LLC

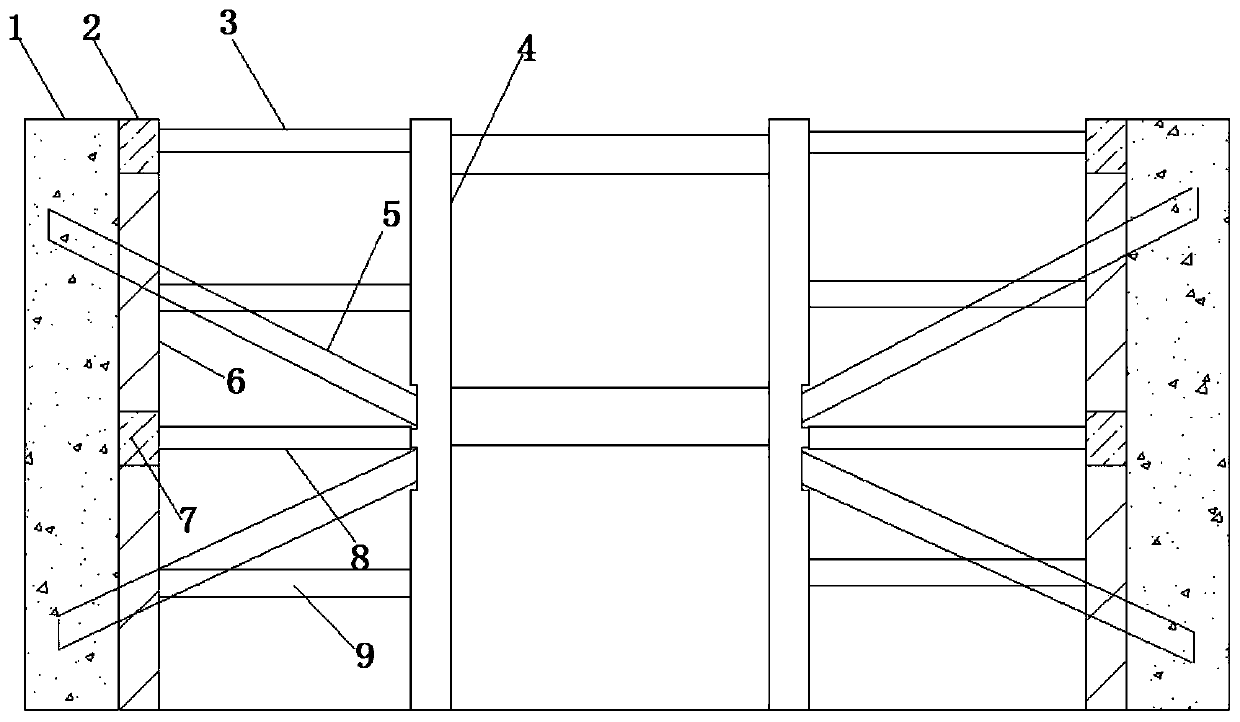

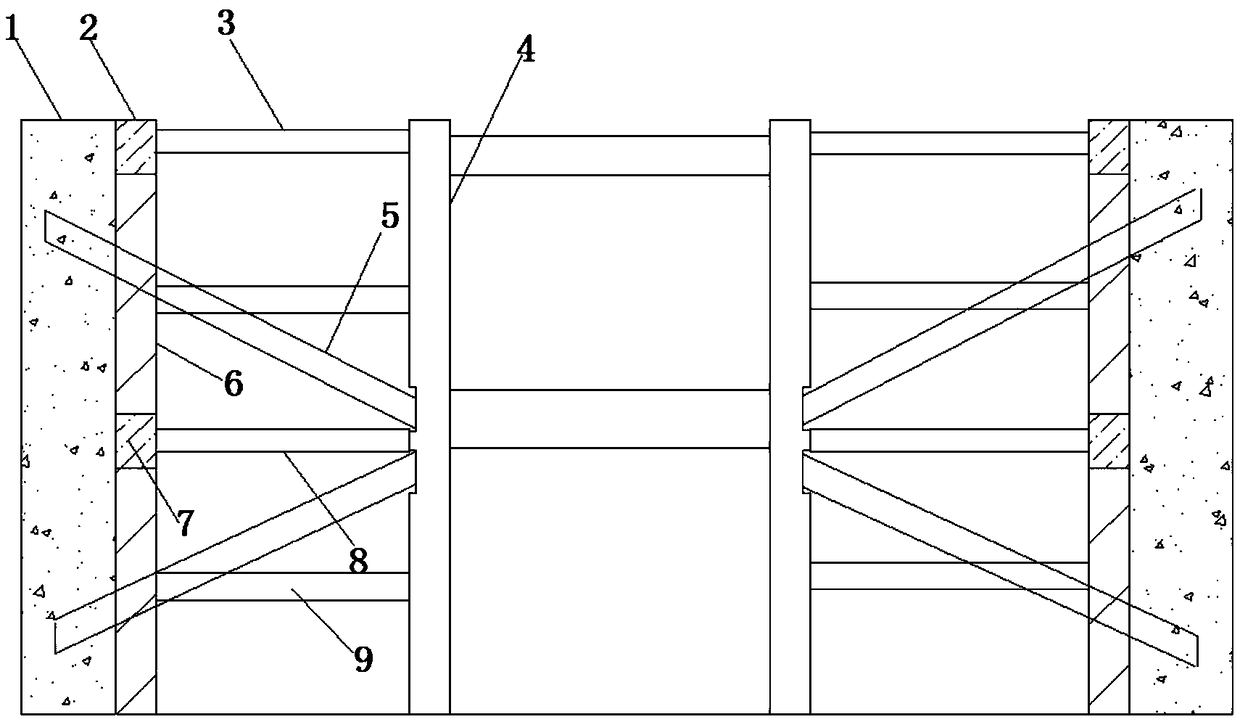

Internal and external support structure and construction method of building foundation pit

The invention provides a building foundation pit internal and external supporting structure. The building foundation pit internal and external supporting structure comprises multiple anchor rods, oneends of the multiple anchor rods are fixed in a rock-soil body, and the other ends of the multiple anchor rods are fixed on a H-shaped supporting frame; the multiple anchor rods are divided into two rows, and the two rows of anchor rods and the rock-soil body are arranged in an isosceles triangle; the upper portion and the middle portion of the H-shaped supporting frame are fixedly connected withsupporting piles arranged on the rock-soil body through upper pressing rods and lower pressing rods correspondingly; and the H-shaped supporting frame is further connected with the supporting piles through supporting rods. According to the building foundation pit internal and external supporting structure, the problems that a foundation pit supporting structure cannot be repeatedly disassembled and utilized at the present stage, so that the resource utilization rate is declined to a certain extent, and saving of the construction cost is not facilitated are solved; and in the case of the building foundation pit internal and external supporting structure, the structure is fast to construct, the construction period is short, the device is effectively protected, the use amount of the anchor rods is reduced, the raw materials are saved, and the project cost is reduced.

Owner:河南梦森建筑工程服务有限公司

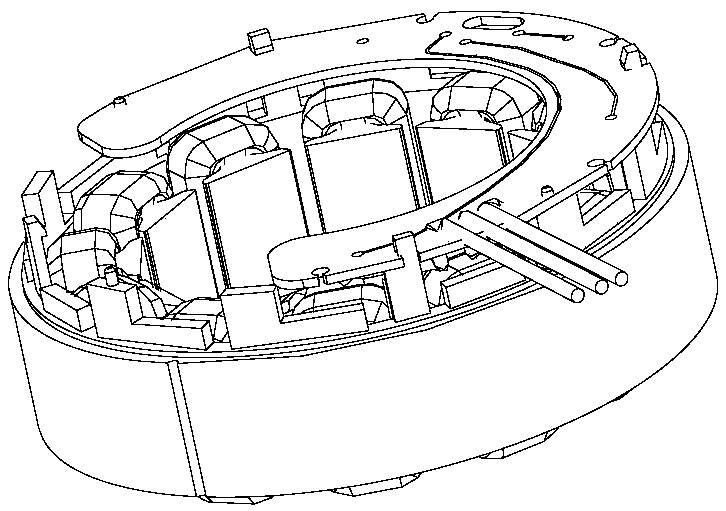

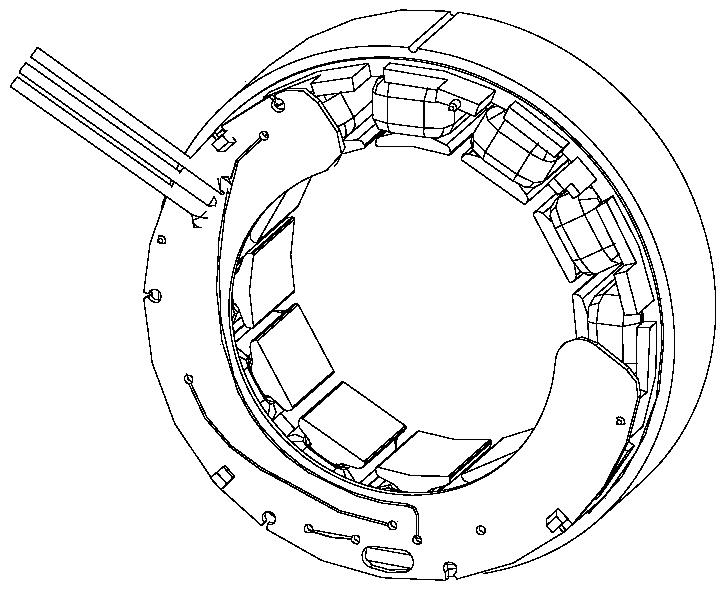

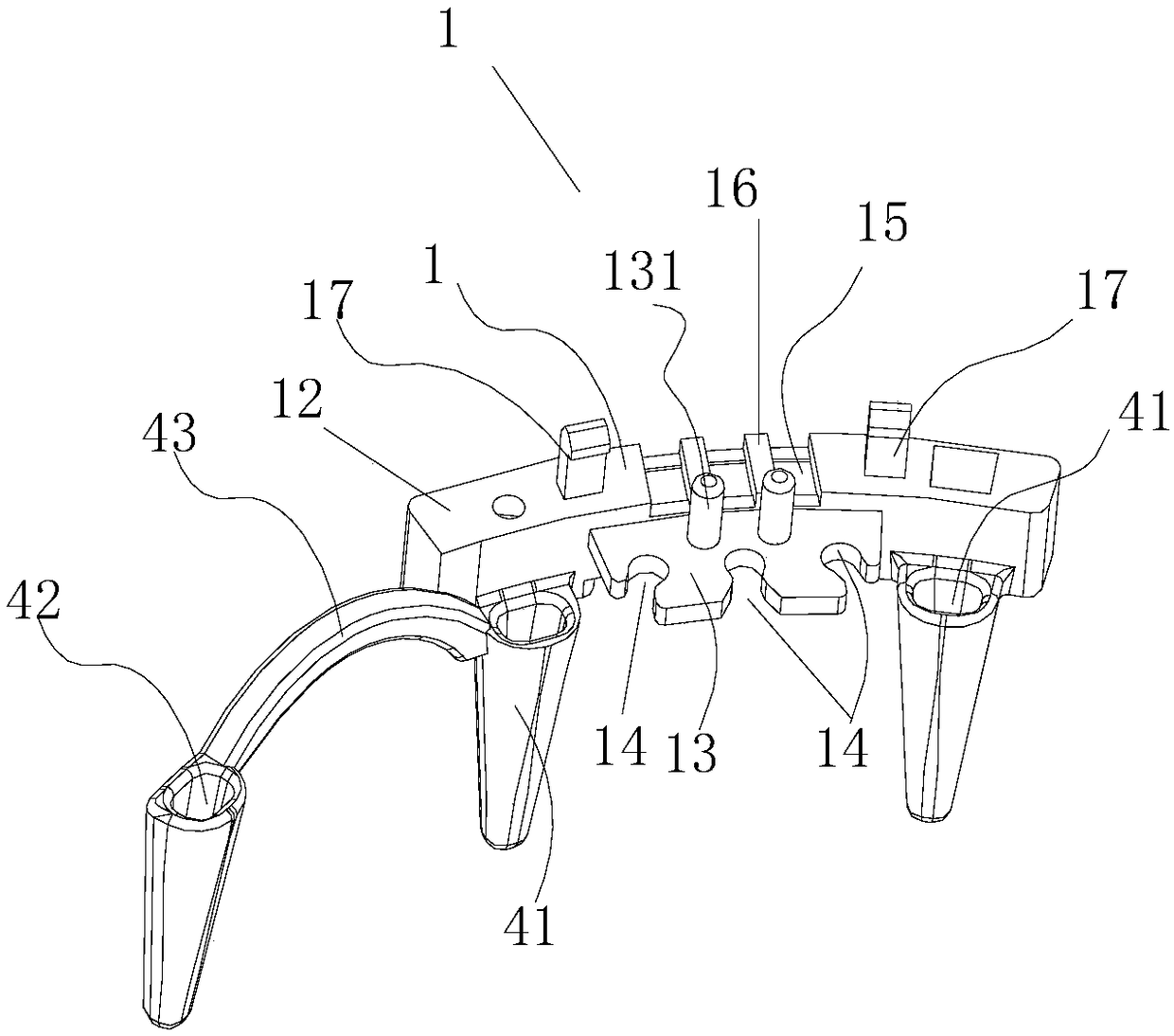

An outlet clamp assembly and an electric motor

An outlet clamp assembly and an electric motor are provided. The outlet clamp assembly comprises: a low outlet clamp (1), which can be clamped and connected to the stator frame (3), the stator frame (3) is provided with a frame protrusion (31), and the lower outlet wire clamp (1) is provided with a lower clamp groove (11) capable of being inserted and fitted with the frame protrusion (31), and thelower outlet wire clamp (1) is capable of guiding a motor power cord from a radially inner side to a radially outer side of the stator frame (3). As that outlet clamp assembly and the stator skeletoncan be effectively match without changing the existing structure of the skeleton, At the same time, the invention realizes the fixing and guiding function, eliminates the structure with the circuit board as the carrier, overcomes the problems that the circuit board as the carrier is installed, the production process and the operation are complicated, and the material cost is high, and greatly reduces the material cost and the labor cost.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

A kind of reinforced anchor rod and rock mass reinforcement method using the same

ActiveCN104047625BIncrease axial tensionDecrease increase reinforcement strengthAnchoring boltsSlurryEngineering

The invention relates to a reinforcement anchor rod which comprises an anchor rod body, wherein a thread tightly meshed with a rock mass is formed on the outer side surface of the anchor rod body; an axial grouting channel for grouting slurry and enabling the slurry to flow into a drilled hole of the drilled rock mass is formed in the anchor rod body; a stop plug for stopping the slurry in the drilled hole is arranged on the anchor rod body. The invention also relates to a rock mass reinforcement method applying the anchor rod. The rock mass reinforcement method comprises the steps of respectively punching the anchor rods into intersections of cracks of the rock mass and the tail ends of all the cracks, extracting air from the anchor rods at the intersections of the cracks, grouting the slurry into anchor rods at the tail ends of the cracks, and respectively grouting the slurry into rock holes in which the anchor rod bodies are positioned after the cracks are filled with the slurry so as to reinforce the whole rock mass into a whole.

Owner:JIANGSU DINGTAI ENG MATERIAL

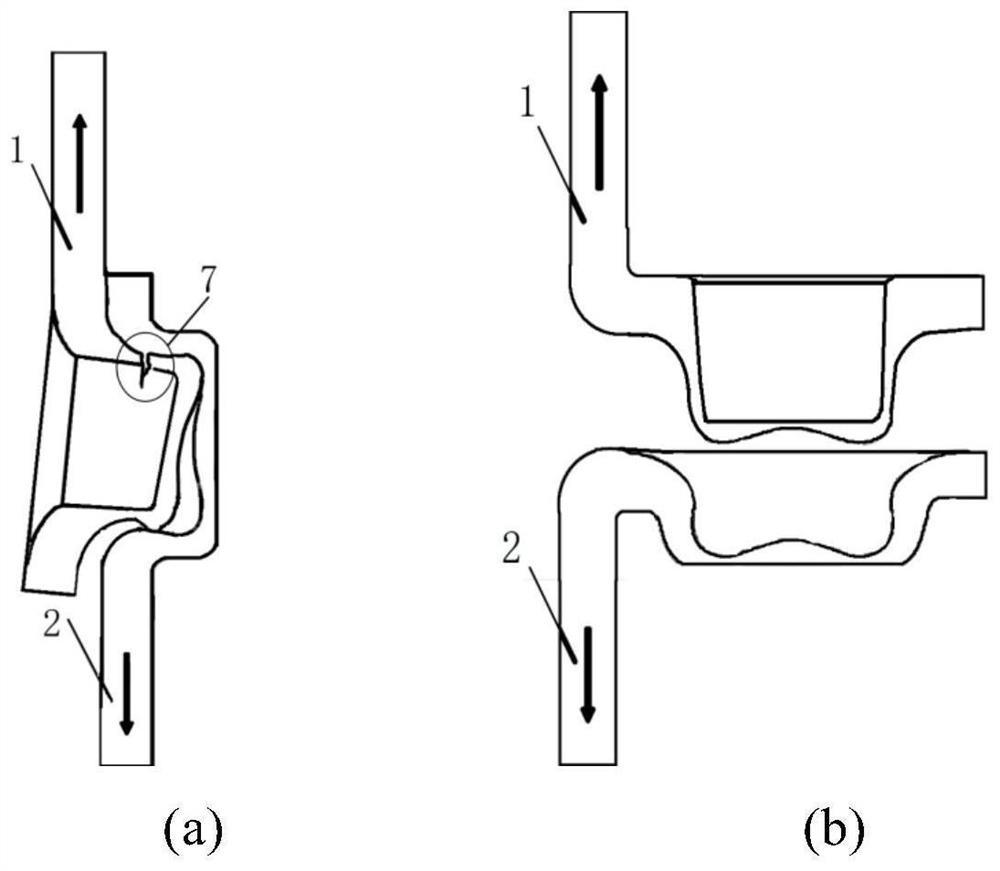

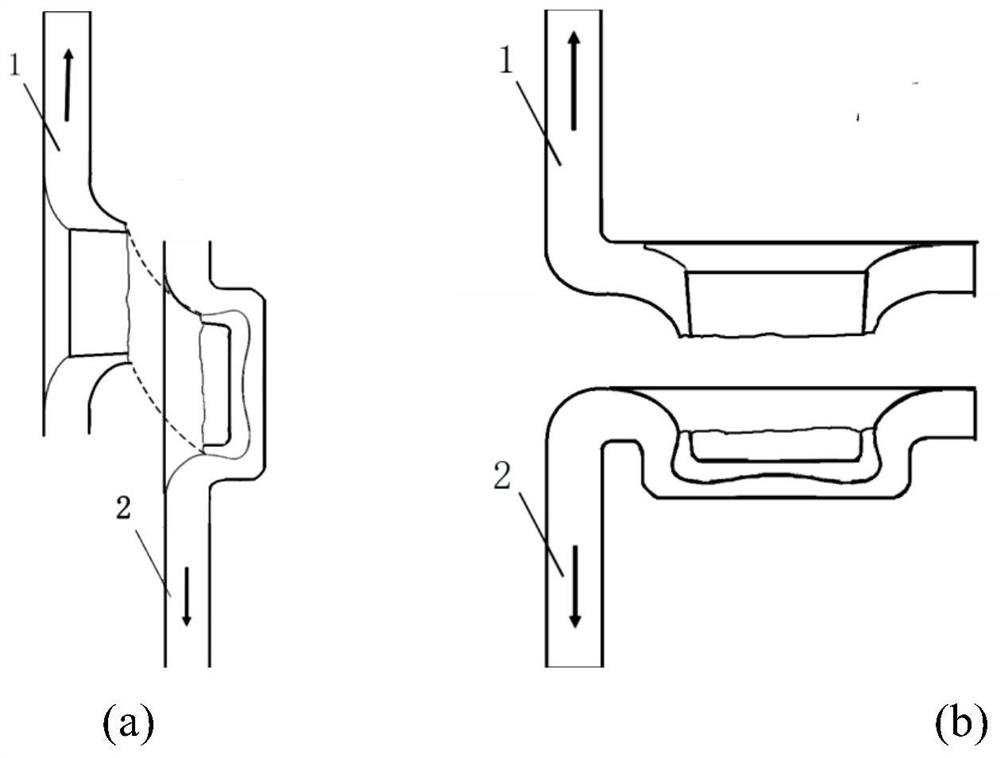

Method for enhancing rivet-free connection strength of steel-aluminum double-metal sheet through oxidation treatment

The invention provides a method for enhancing the rivet-free connection strength of a steel-aluminum double-metal sheet through oxidation treatment. The method comprises the steps that: original oxides and oil stains on to-be-compounded surfaces of a steel plate and an aluminum plate are cleaned; the to-be-compounded surface of the steel plate is subjected to oxidation treatment; the size of a punch and the size of a female die of a die are selected; and rivet-free connection is carried out, a pressurization stage and a pressure maintaining stage are completed, and demolding is performed to obtain a steel-aluminum rivet-free connection joint. Before the rivet-free connection, the to-be-compounded surface of the steel plate is subjected to oxidation treatment, so that the dissimilar plates are microcosmically engaged at the joint, friction force at the contact surface is increased, deformation tends to be synchronous, and thus the macroscopic interlocking amount is increased, the joint is restrained by a side ring surface and a bottom in the failure process, the stress concentration phenomenon is avoided, and meanwhile, the component force in a loaded direction is also reduced, the axial tension and the radial shear force required by joint failure are improved, and the connection strength of the joint is improved.

Owner:YANSHAN UNIV

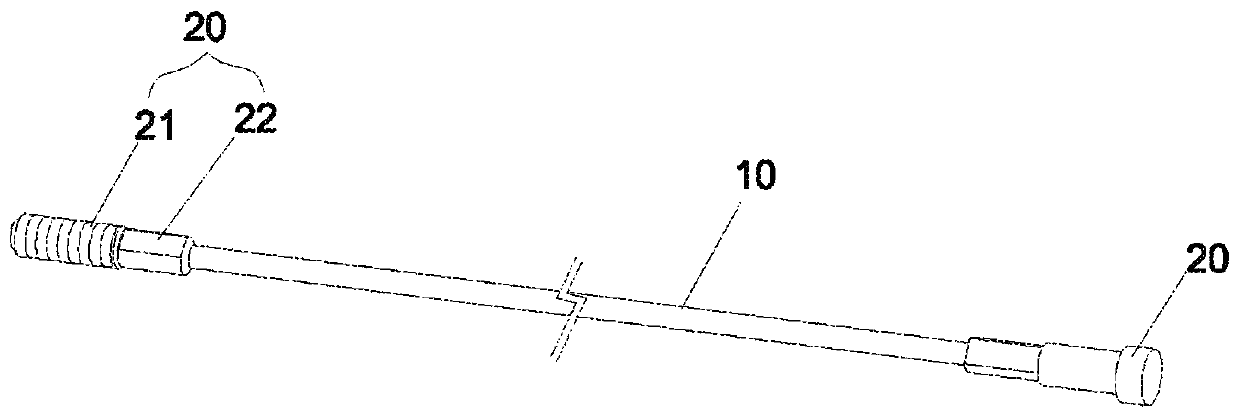

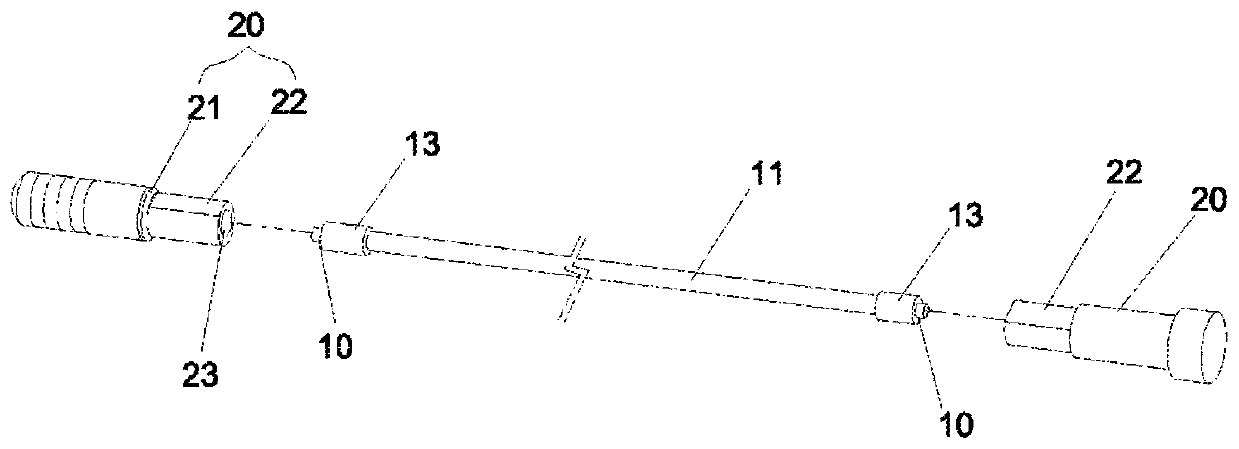

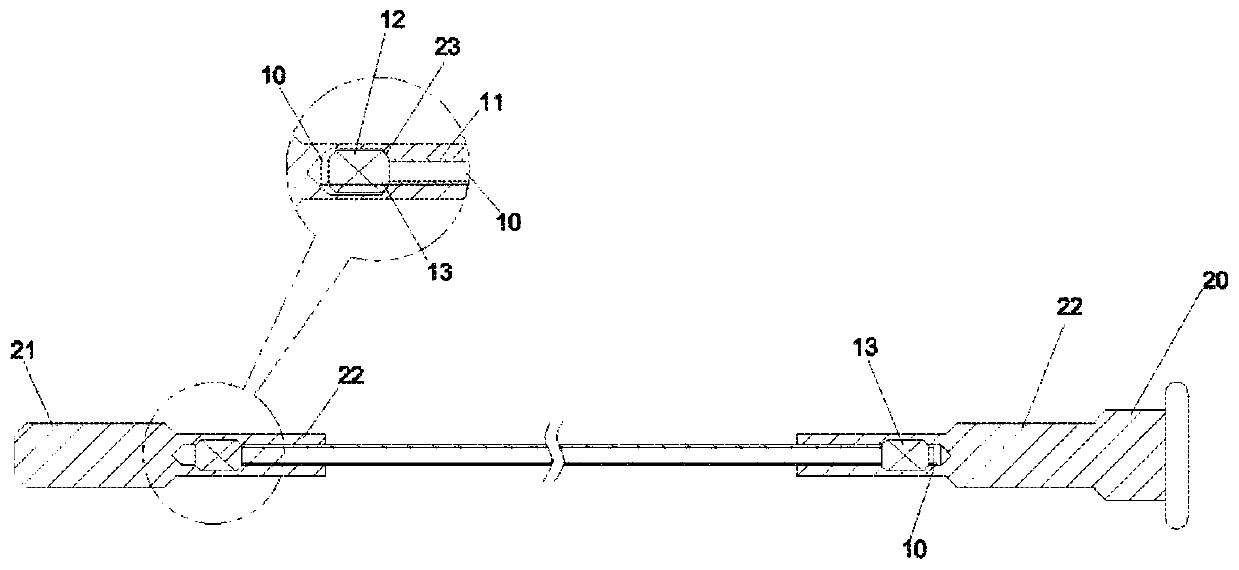

Bearing cable structure while fabricating panel

ActiveUS20180252247A1Increase service lifeExtended service lifeRivetsRopes and cables for vehicles/pulleyEngineeringSurface plate

A bearing cable structure while fabricating panel comprises a steel cable and two sets of fixing members. Each connection section of the steel cable is assembled to the corresponding antiskid ring and then assembled into the axial blind hole of each fixing member and further riveted to the screwing section of each fixing member by machine so that the fixing members are tightly connected to the outer layer of the steel cable and the steel cable and the fixing members are integrated with each other for preventing from falling off, and simultaneously the riveting of the axial blind hole may engage with the outer layer to perform double location so as to strengthen an axial pull strength of the bearing cable structure and increase service life.

Owner:LIN CHU YU +1

Building foundation pit internal and external supporting structure and construction method

InactiveCN109113070AGuarantee the quality of the projectEnsure safetyExcavationsResource utilizationEngineering

The invention provides a building foundation pit internal and external supporting structure. The building foundation pit internal and external supporting structure comprises multiple anchor rods, oneends of the multiple anchor rods are fixed in a rock-soil body, and the other ends of the multiple anchor rods are fixed on a H-shaped supporting frame; the multiple anchor rods are divided into two rows, and the two rows of anchor rods and the rock-soil body are arranged in an isosceles triangle; the upper portion and the middle portion of the H-shaped supporting frame are fixedly connected withsupporting piles arranged on the rock-soil body through upper pressing rods and lower pressing rods correspondingly; and the H-shaped supporting frame is further connected with the supporting piles through supporting rods. According to the building foundation pit internal and external supporting structure, the problems that a foundation pit supporting structure cannot be repeatedly disassembled and utilized at the present stage, so that the resource utilization rate is declined to a certain extent, and saving of the construction cost is not facilitated are solved; and in the case of the building foundation pit internal and external supporting structure, the structure is fast to construct, the construction period is short, the device is effectively protected, the use amount of the anchor rods is reduced, the raw materials are saved, and the project cost is reduced.

Owner:河南梦森建筑工程服务有限公司

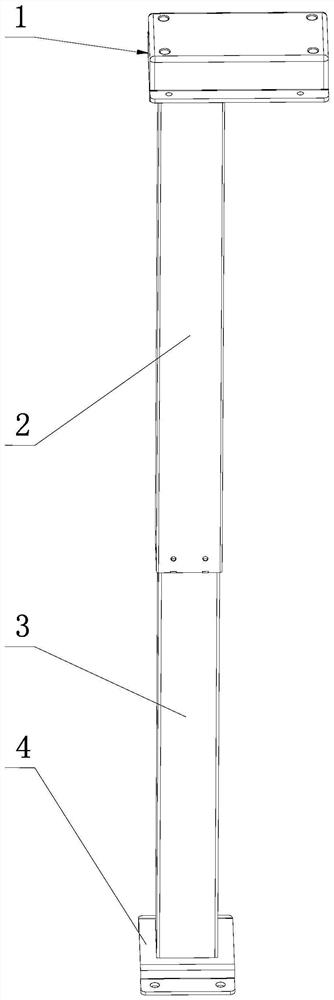

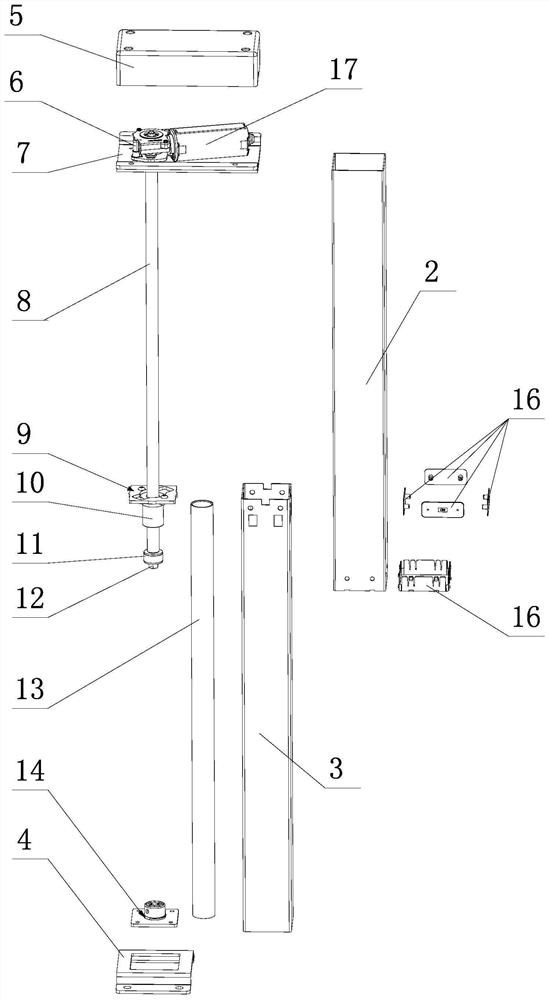

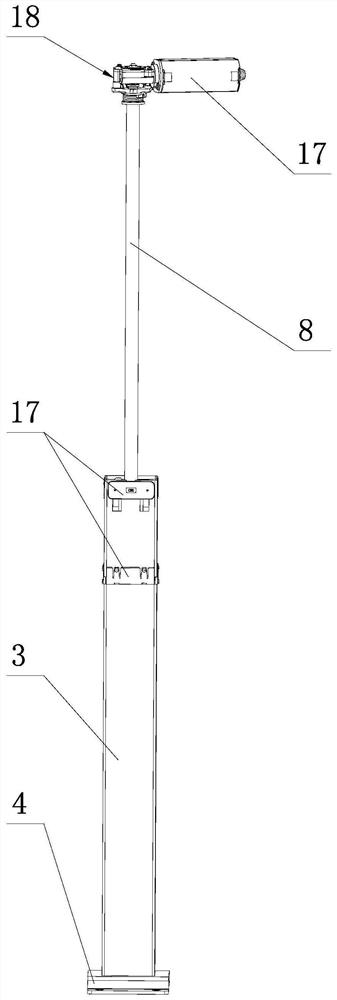

Supporting column of suspension type commodity shelf

ActiveCN113491397ASimple structureEnsure safetyFurniture partsVariable dimension cabinetsControl engineeringElectric machinery

Owner:ZHEJIANG LEGE INTELLIGENT DRIVE TECH CO LTD

Bearing cable structure

PendingCN111306203AAvoid wear and tearIncrease axial tensionBearing assemblyFlexible shaftsPull forceElectric cables

The invention discloses a bearing cable structure used during manufacturing for a panel. The bearing cable structure comprises a steel cable and two groups of fixing members. Each connection part of the steel cable is assembled onto a corresponding anti-slide ring, then assembled into an axial blind hole of each fixing member, and further connected to a screwing part of each fixing member in a riveting manner through a machine, so that the fixing members are closely connected to an outer cable layer, and the cable is mutually integrated with the fixing members to be prevented from separating off; and meanwhile, the riveting connection for the axial blind holes is capable of being combined with the outer layer, and double location is executed, so that the axial tension intensity of the bearing cable structure is increased, and the service life is prolonged.

Owner:BEIJING XINLI MACHINERY

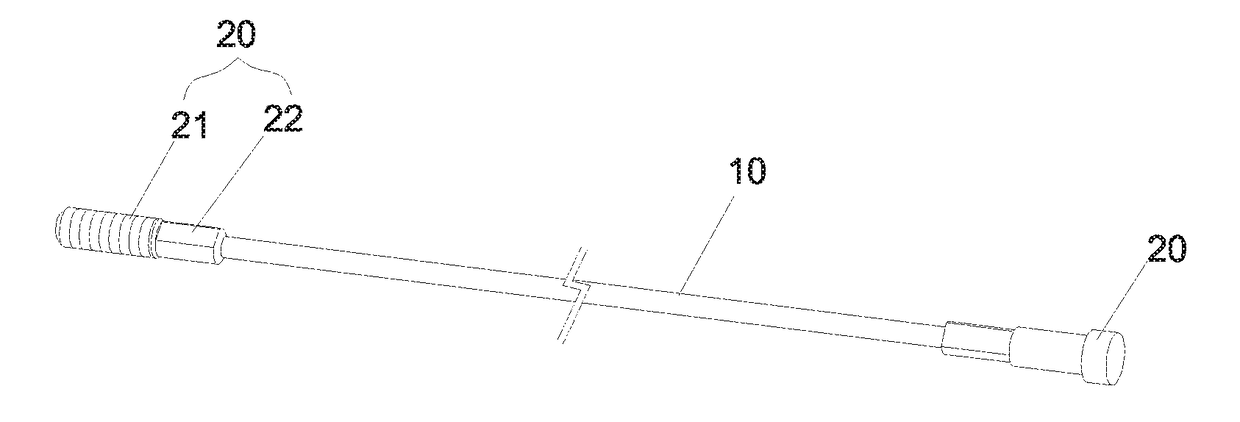

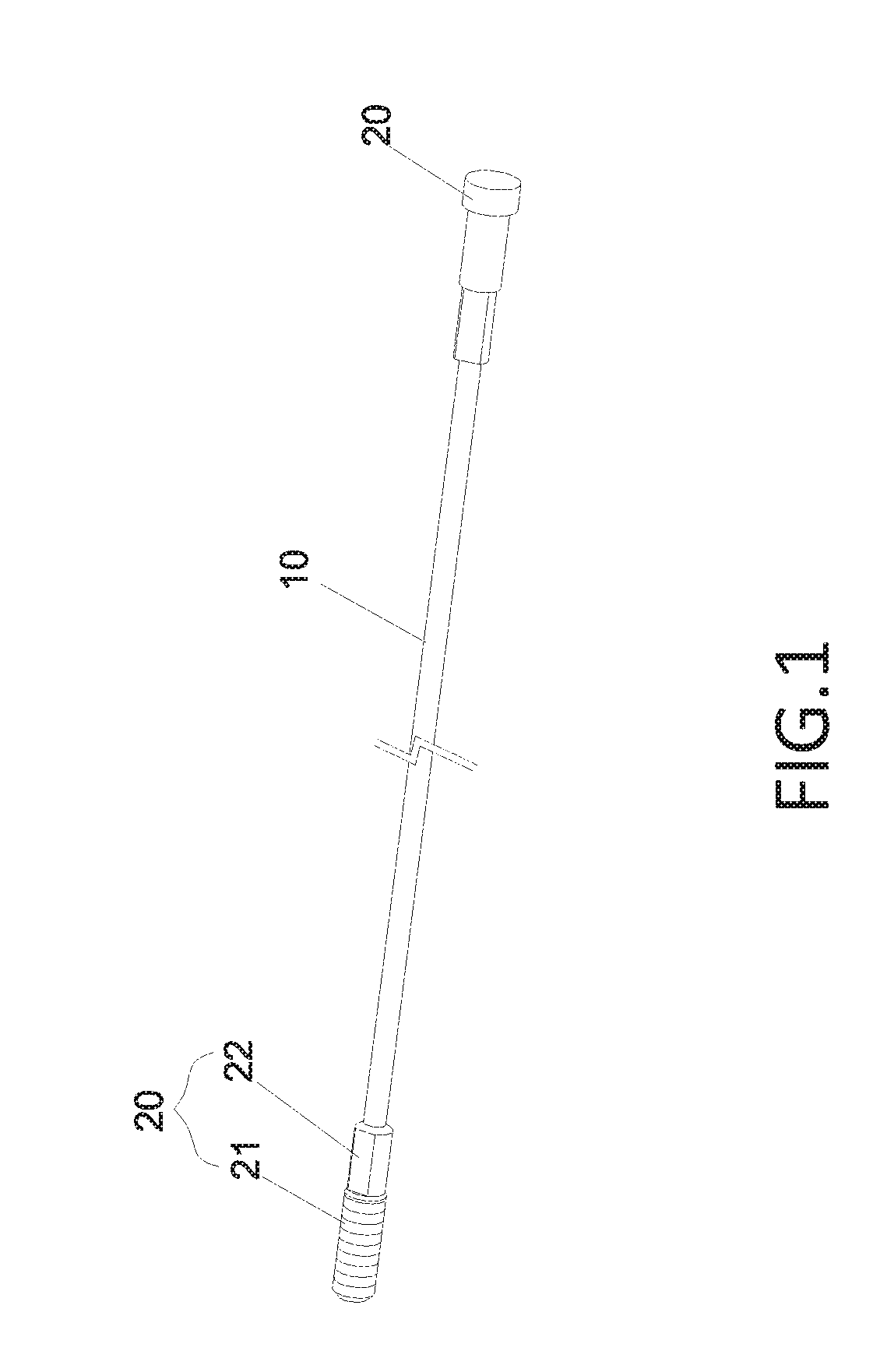

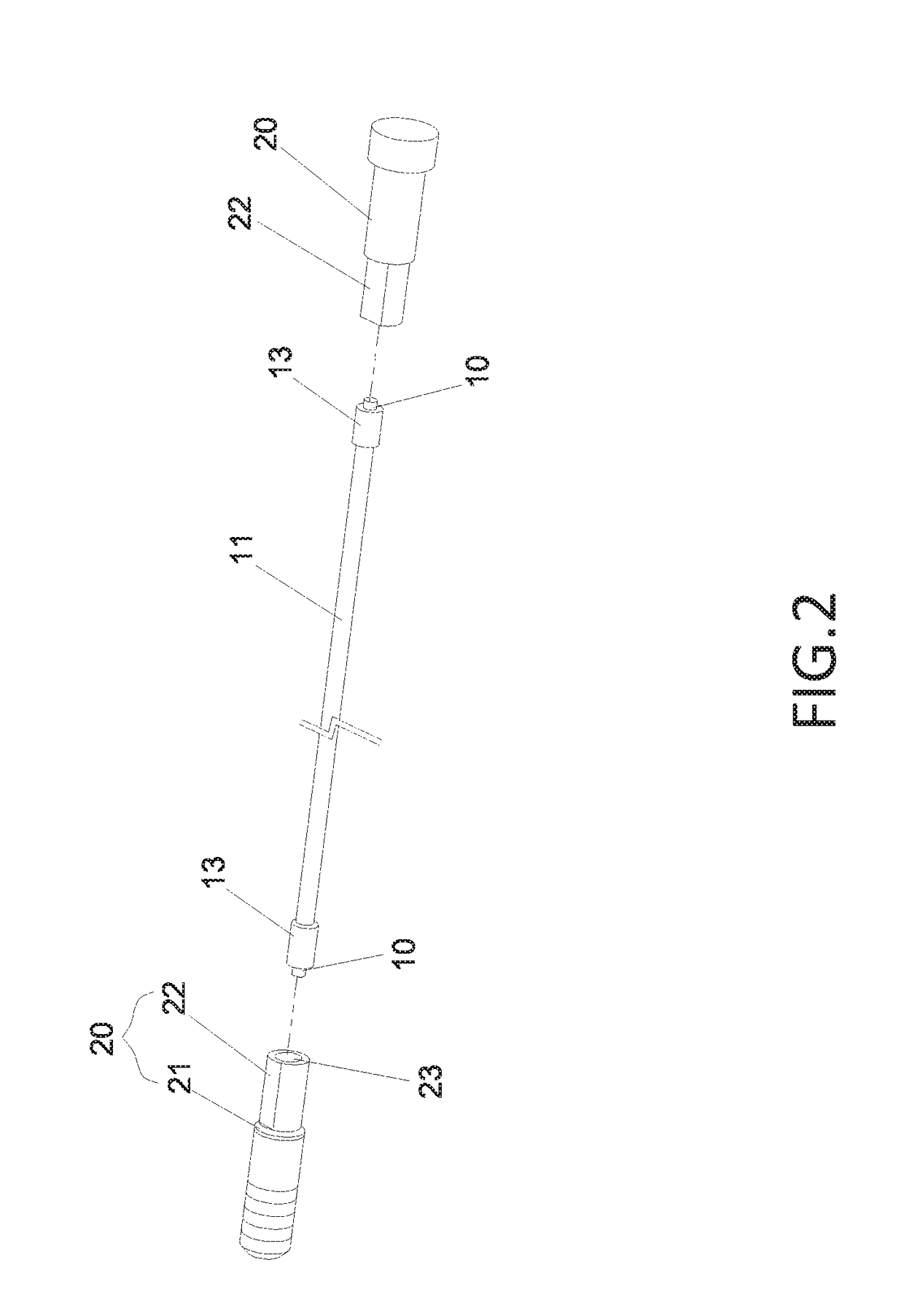

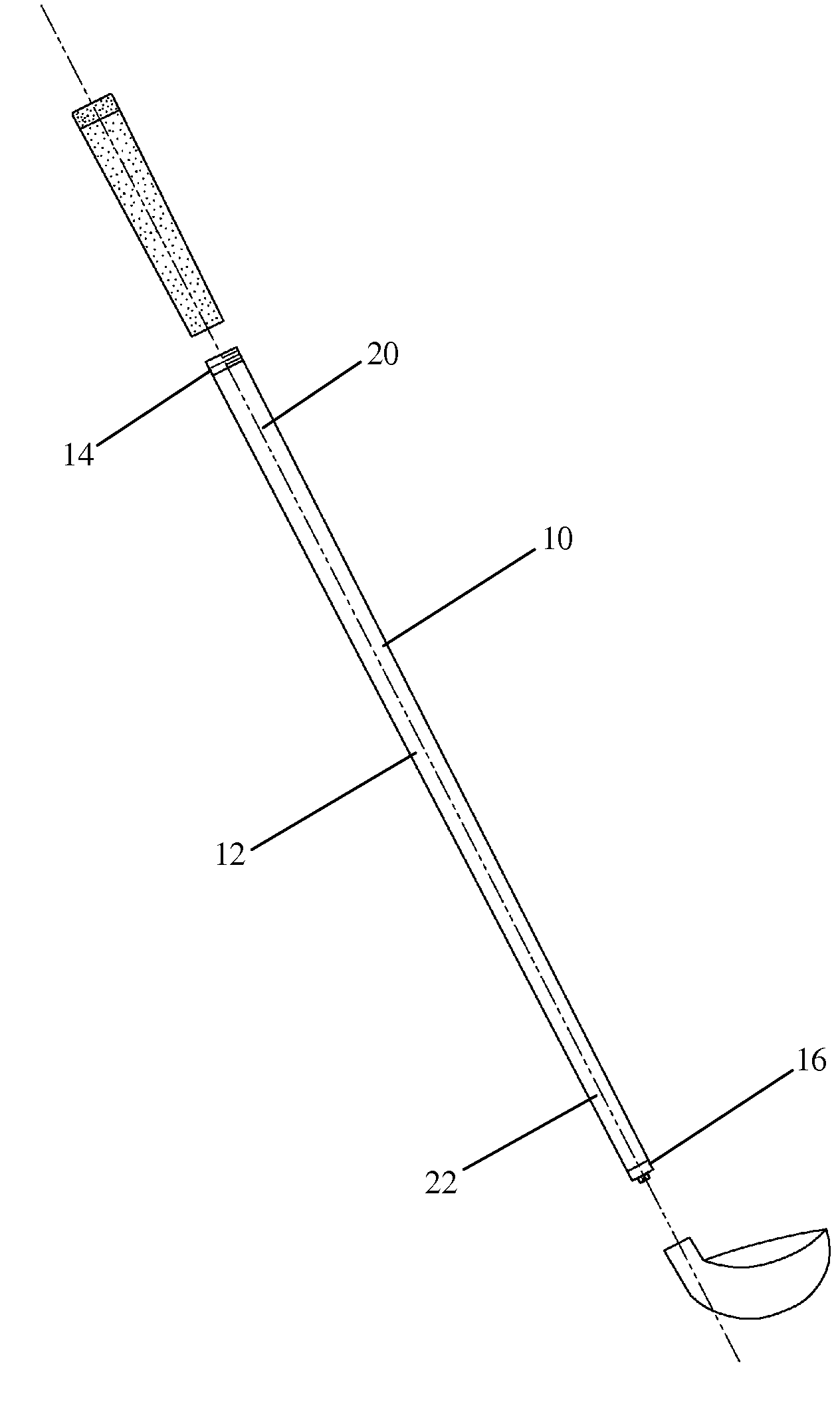

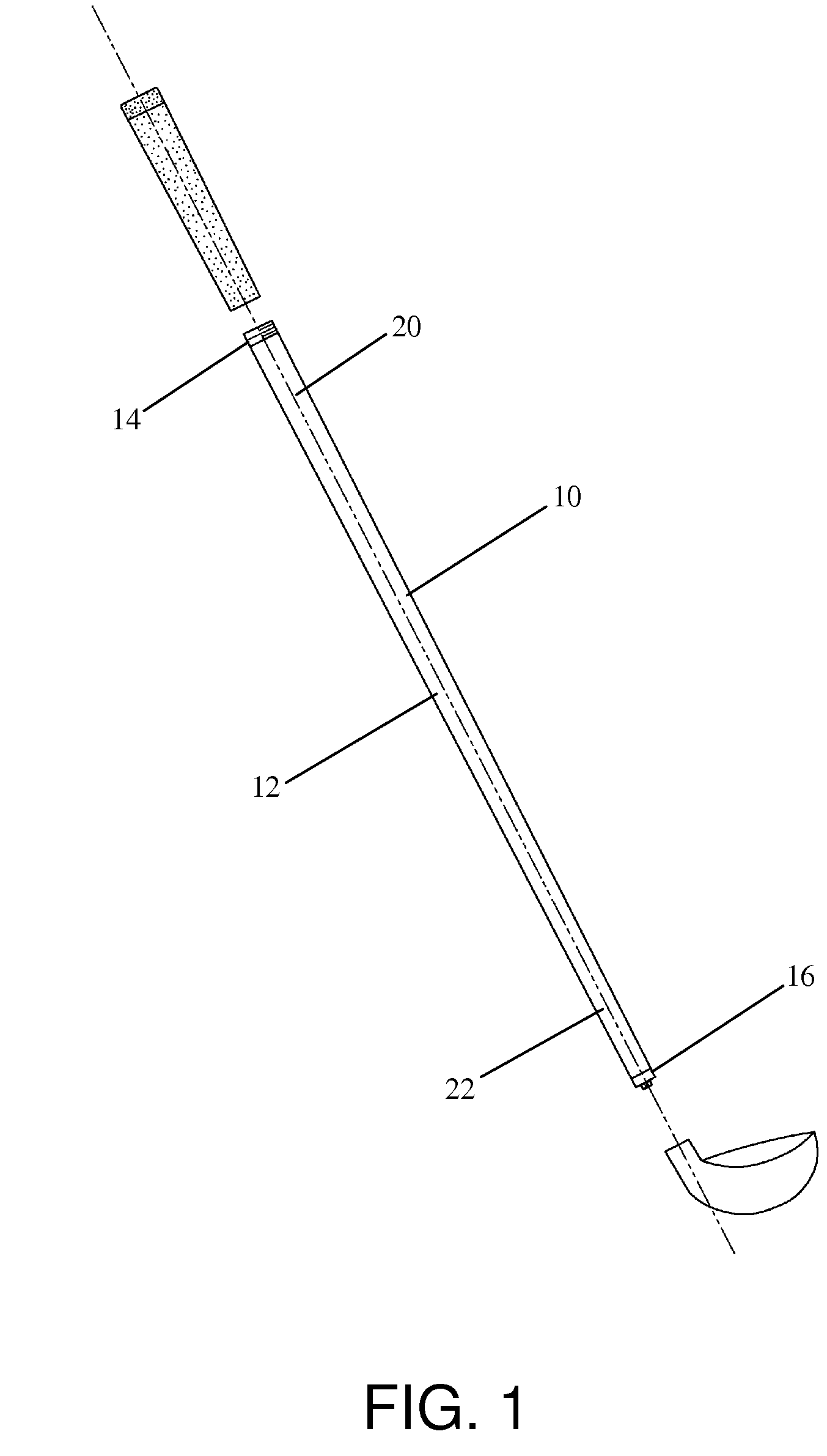

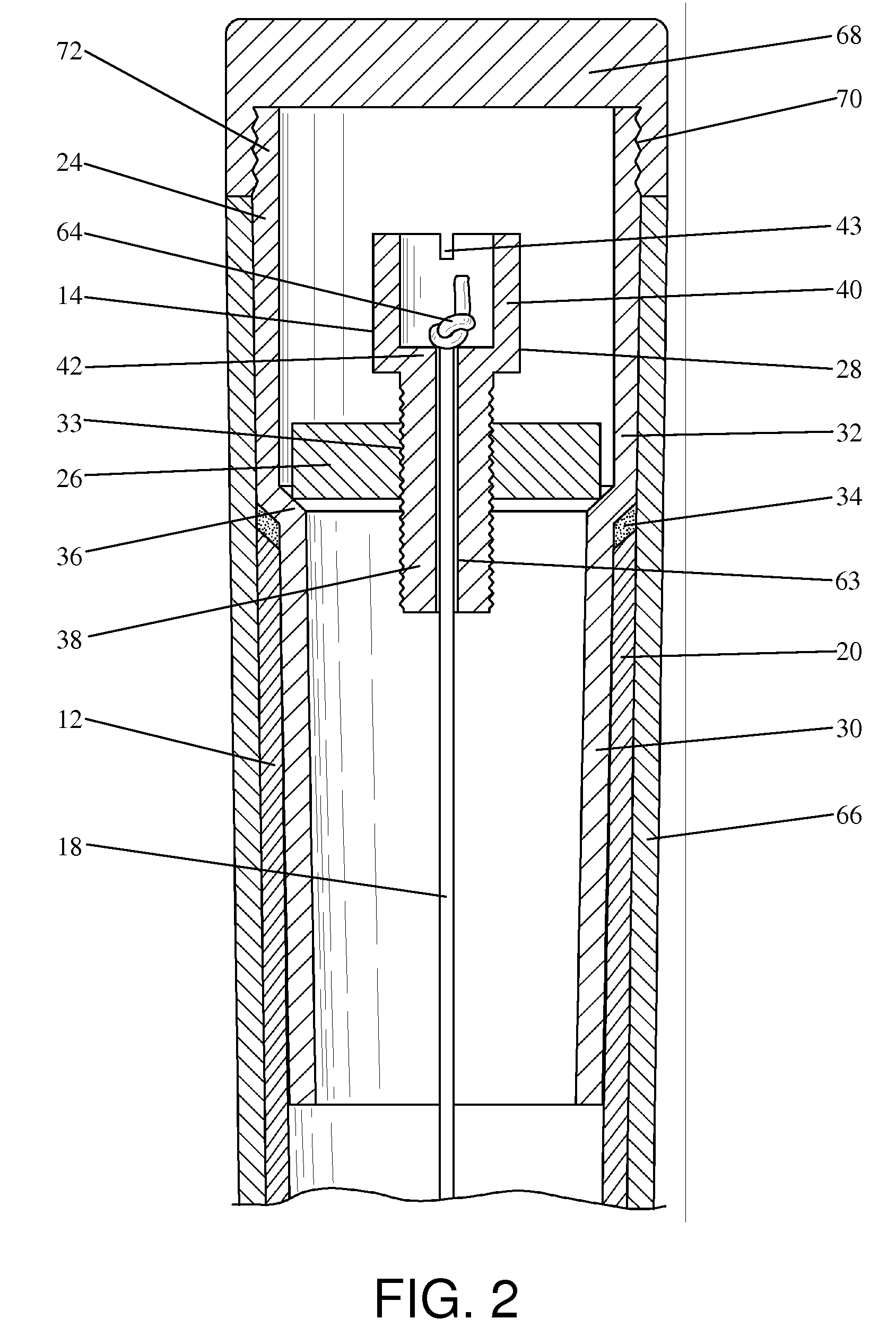

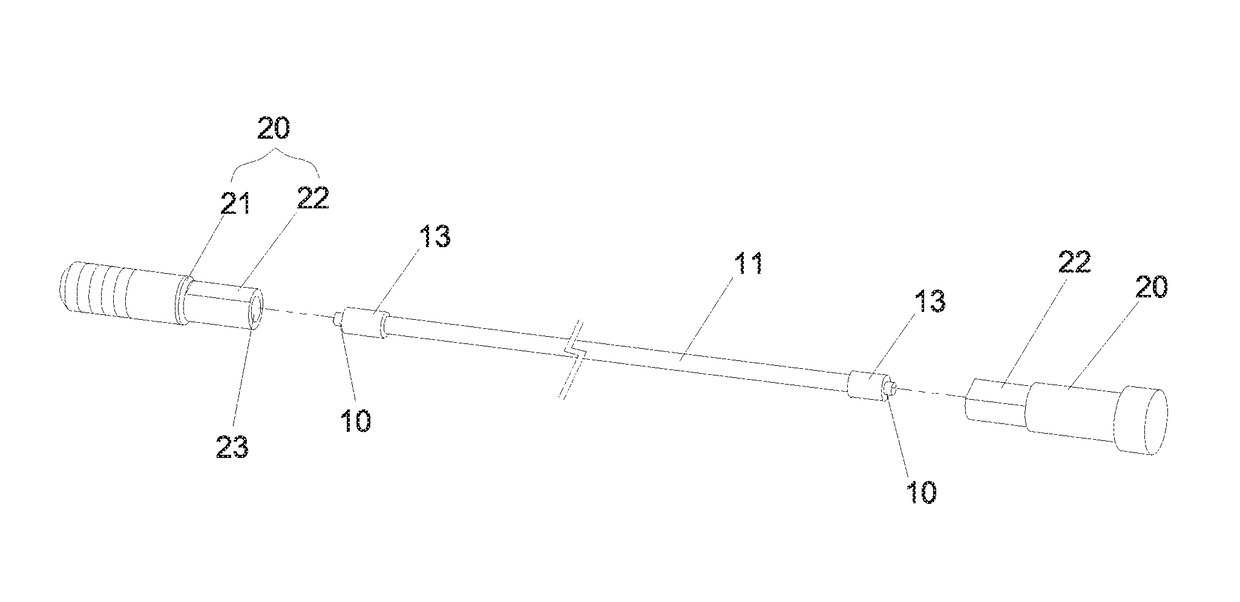

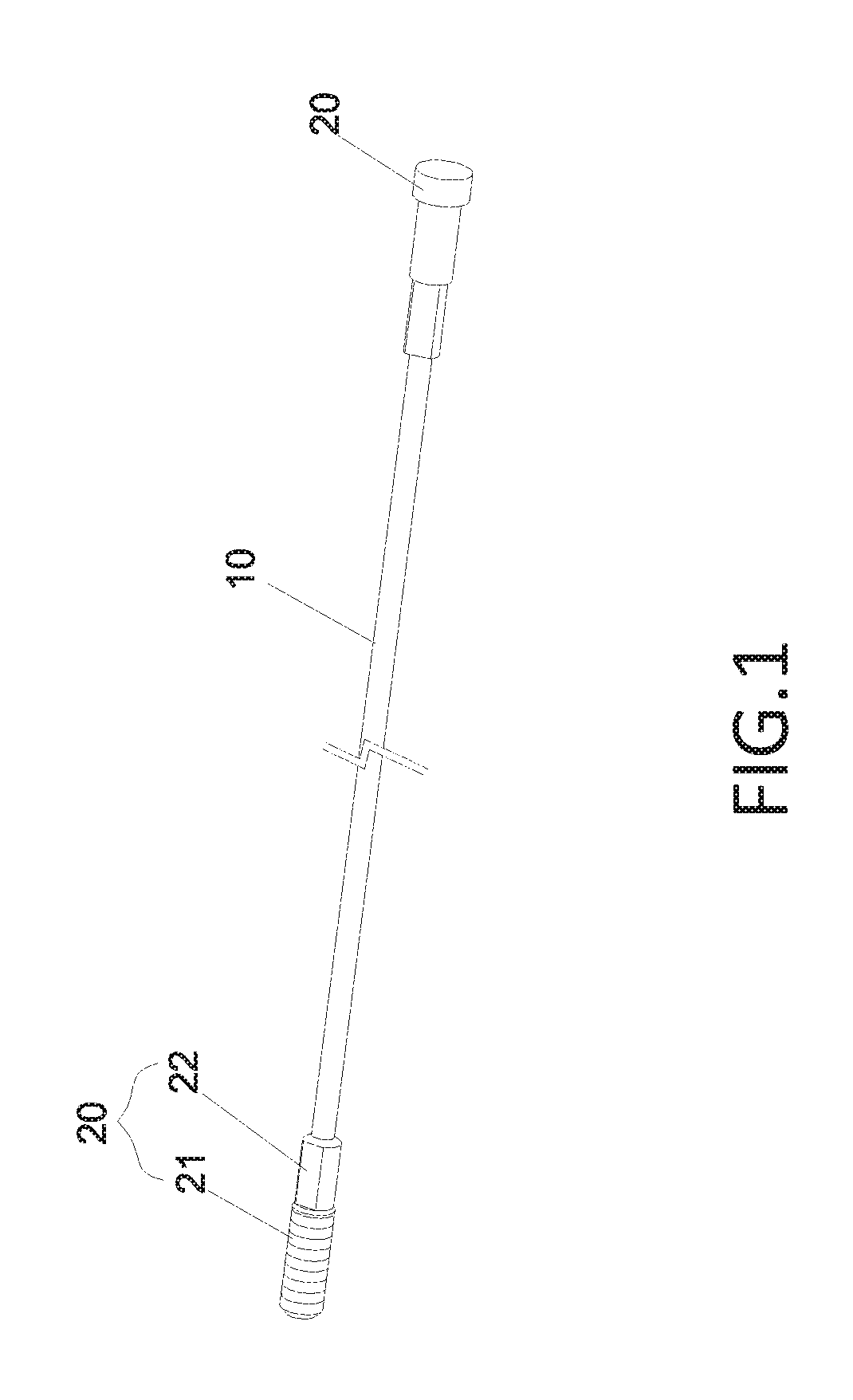

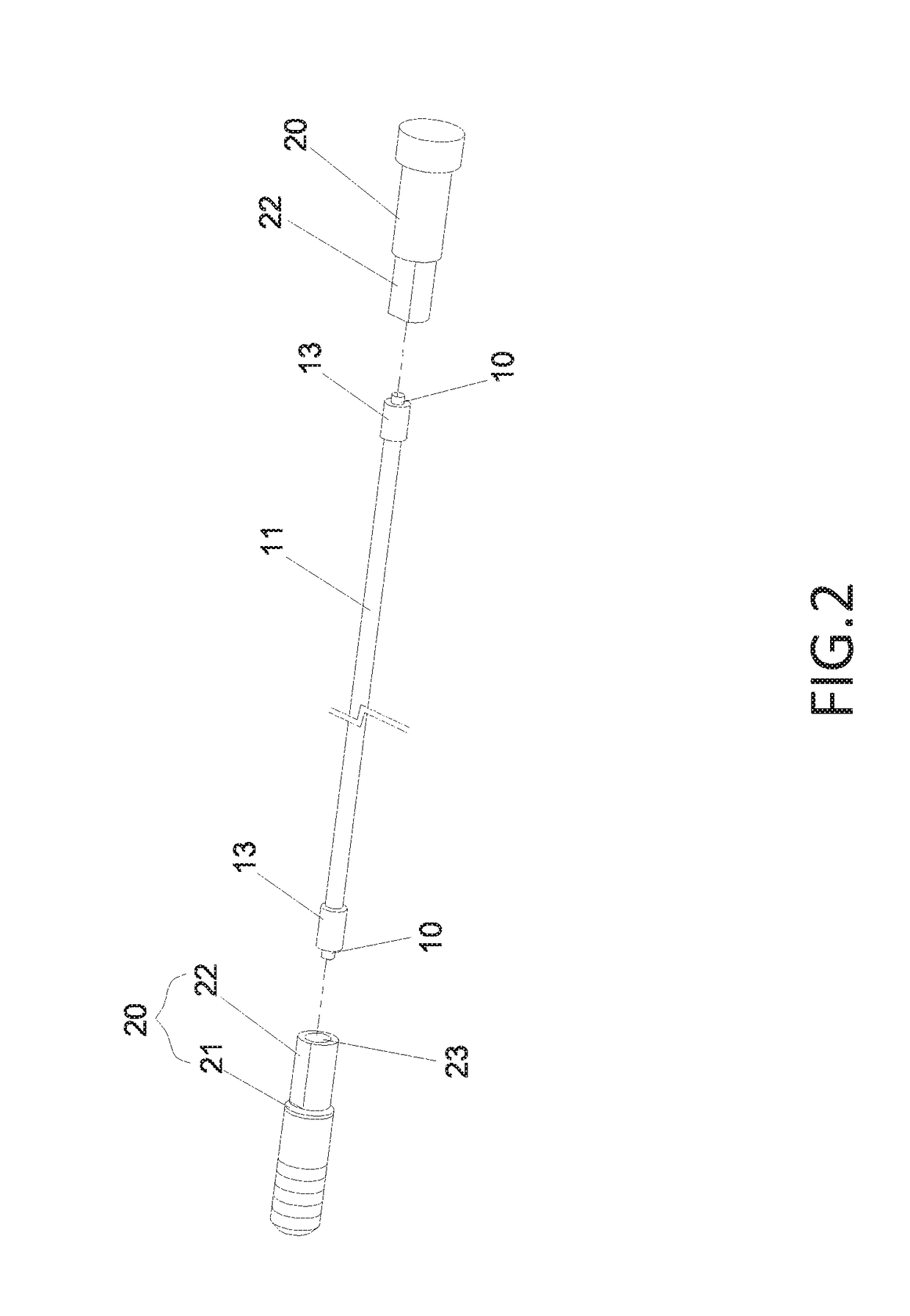

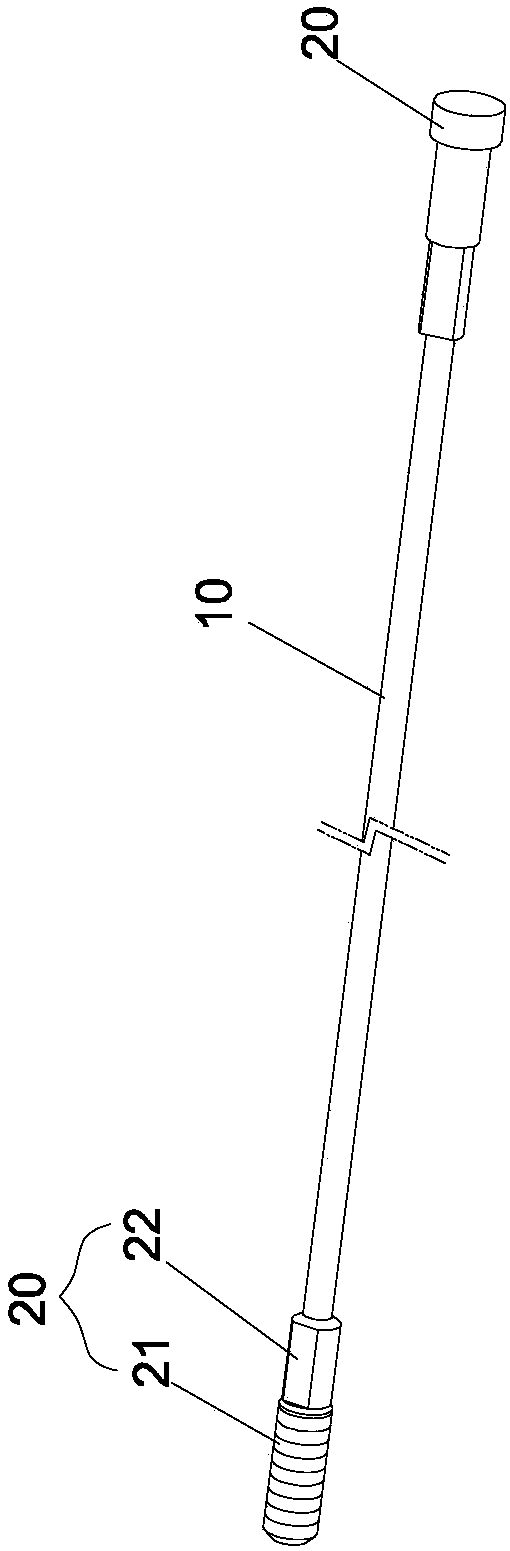

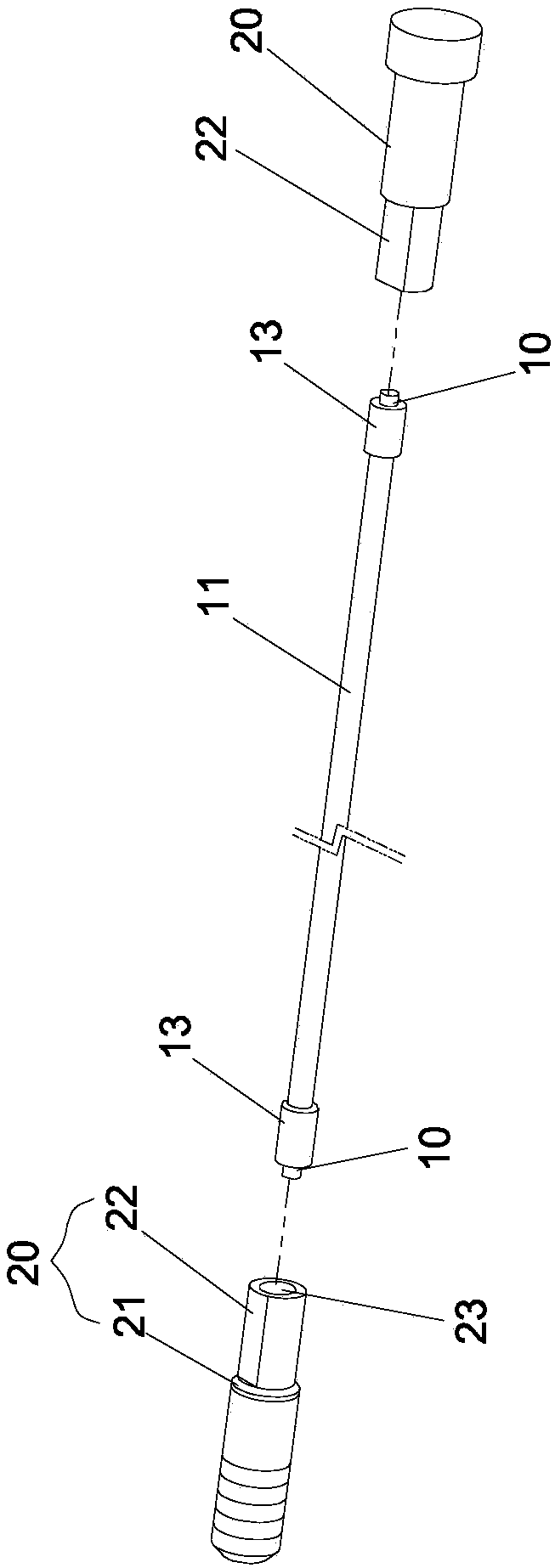

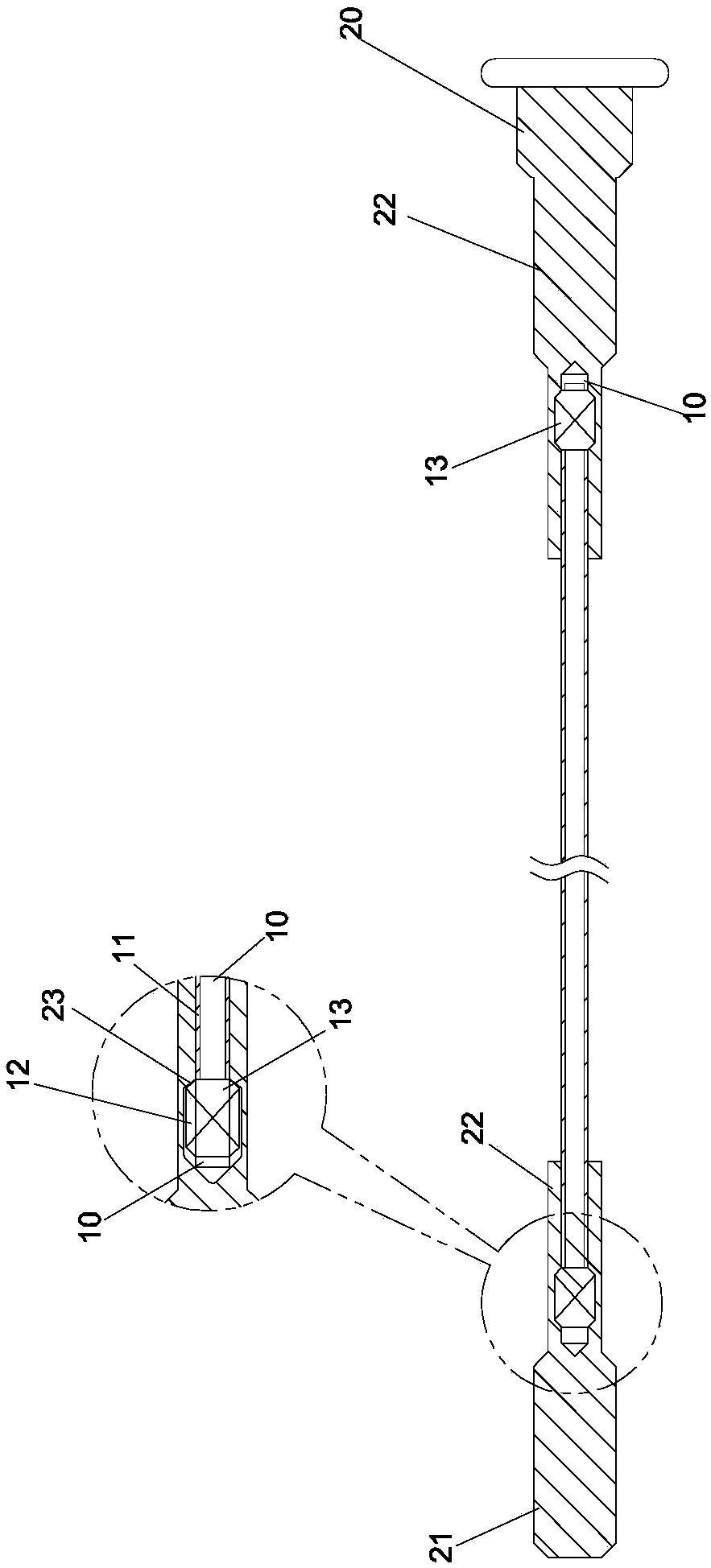

Golf club shaft with adjustable stiffness

InactiveUS20090312115A1Increase stiffnessReduce stiffnessGolf clubsRacket sportsAdjustable stiffnessEngineering

A golf club shaft having adjustable stiffness. An elongated tensioning member extends through the shaft and is mounted to both ends of the shaft. A tensioner assembly is mounted to the shaft and is connected to the tensioning member for allowing manual adjustment of the axial tension in the tensioning member, thereby allowing a technician or a user to increase or decrease the stiffness of the shaft as desired.

Owner:SIMONIS STEVEN F

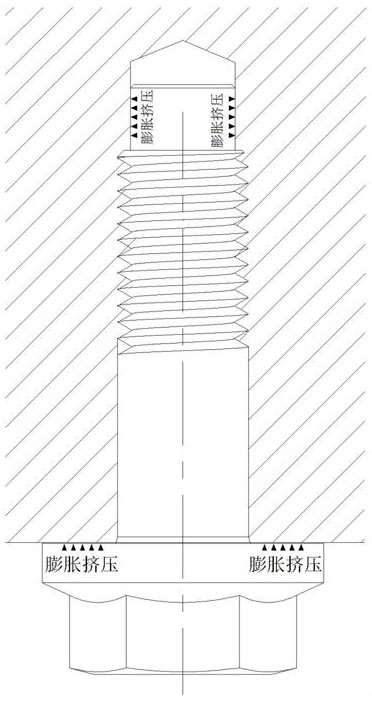

Hydraulic expansion locking bolt

The invention discloses a hydraulic expansion locking bolt. The bolt comprises a head, a flange, a rod part and a threaded part, wherein the middle part of the flange is provided with a first annularexpansion oil chamber, the outer wall of the middle part of the rod part is provided with the threaded part, a second annular expansion oil chamber is provided inside the bottom end of the rod par, amain oil chamber is opened along the bolt axis, the main oil chamber is connected to the first annular expansion oil chamber through a first oil through hole, and the main oil chamber is connected tothe second annular expansion oil chamber through a second oil through hole; the bolt head is provided with a piston rod, and the end of the piston rod is provided with a pressure screw. The hydraulicexpansion locking bolt provided by the invention compensates the pre-tightening force by designing expansion oil chambers inside the bolt, so as to achieve the purpose of enhancing the bolt connectionstrength, damping vibration and preventing loosening.

Owner:常德市中天精密工具有限公司

Bearing cable structure while fabricating panel

ActiveUS10125802B2Extended service lifeReduce tensionRivetsRopes and cables for vehicles/pulleyUltimate tensile strengthWire rope

A bearing cable structure while fabricating panel comprises a steel cable and two sets of fixing members. Each connection section of the steel cable is assembled to the corresponding antiskid ring and then assembled into the axial blind hole of each fixing member and further riveted to the screwing section of each fixing member by machine so that the fixing members are tightly connected to the outer layer of the steel cable and the steel cable and the fixing members are integrated with each other for preventing from falling off, and simultaneously the riveting of the axial blind hole may engage with the outer layer to perform double location so as to strengthen an axial pull strength of the bearing cable structure and increase service life.

Owner:LIN CHU YU +1

Bearing inhaul cable used for manufacture of panel

InactiveCN108443696ASolve wear and tearIncrease axial tensionElongated constructional elementsEngineeringUltimate tensile strength

The invention provides a bearing inhaul cable used for manufacture of a panel. The bearing inhaul cable comprises a steel cable and two groups of fixing parts. An outer layer is formed by coating thesteel cable through resin. Two side end of the steel cable are equipped with connection sections sleeved by anti-slip rings. Outer edges of the fixing parts are equipped with external thread sectionsand locking sections. A shaft hole, which is not penetrated, is arranged at the position to which one side of each locking section faces inward. The bearing inhaul cable is characterized in that the anti-slip rings are assembled on the connection sections of the steel cable and assembled into shaft holes of the fixing parts; the locking sections are riveted by a processing machinery such that thefixing parts are closely combined to the outer layer of the steel cable; and the steel cable and the two fixing parts are integrally combined and do not drop down. Accordingly, strength of the bearinginhaul cable is enhanced during manufacture of the panel. The service lifetime is prolonged.

Owner:林钜于 +1

A test device for the relationship between tightening torque and angular displacement of pipe joints

ActiveCN111855181BSave human effortContinuous torque output is stableMachine part testingMeasurement of torque/twisting force while tighteningRubber ringReliable transmission

The invention discloses a test device for the relationship between tightening torque and angular displacement of a pipe joint, relates to the technical field of pipelines, and includes: a data acquisition device, a clamping transmission component, and a power component and angular displacement respectively connected to both ends of the clamping transmission component The measuring assembly, the power assembly and the angular displacement measuring assembly are connected to the data acquisition device respectively; the clamping transmission assembly includes: a clamping assembly and a transmission assembly, and the clamping assembly includes: a first frame and a sliding A support frame on a frame; transmission components include: connecting rods, connecting seats, conical rubber rings, springs and spring seats. This test device can liberate manpower, obtain accurate data of torque and angular displacement simultaneously and ensure reliable transmission.

Owner:SOUTHWEST JIAOTONG UNIV

Method and device for connecting metal pipe based on laser shock wave technology

InactiveCN102225493BPrecisely controlled peak pressureImprove securityLaser beam welding apparatusPulse beamShock wave

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Resistance welding electrode trimming tool with spiral arc edges

PendingCN113084234AReduce vibrationImprove appearance qualityMilling cuttersMilling equipment detailsEngineeringKnife blades

The invention relates to a blade mechanism, and particularly relates to a resistance welding electrode trimming tool with spiral arc edges. The resistance welding electrode trimming tool comprises a tool apron and a blade mechanism; the blade mechanism comprises a blade; the upper end and the lower end of the blade are each provided with one edge; each edge comprises an end face forming face, an electrode cap guide face, an anti-impact chamfer and an edge rear angle face; the blade further comprises a first side face, a second side face and an installation face; and each cutting edge is a spiral arc formed by intersecting the corresponding electrode cap guide face with the first side face. According to the resistance welding electrode trimming tool, the edges are the spiral arcs, and compared with linear edge lines located on the same plane, cutting is stable, and efficiency is high; the cutting torque is small, the length of the edges participating in cutting is increased, the spiral lead angles of the spiral arcs increase the axial tension, reduce the radial force and improve the positioning stability of electrode caps; and the actual working front angle is increased through the spiral lead angles, the cutting edges are sharp, the cutting force is reduced, chip removal is facilitated, and the workpiece surface roughness is more ideal.

Owner:王瑞国

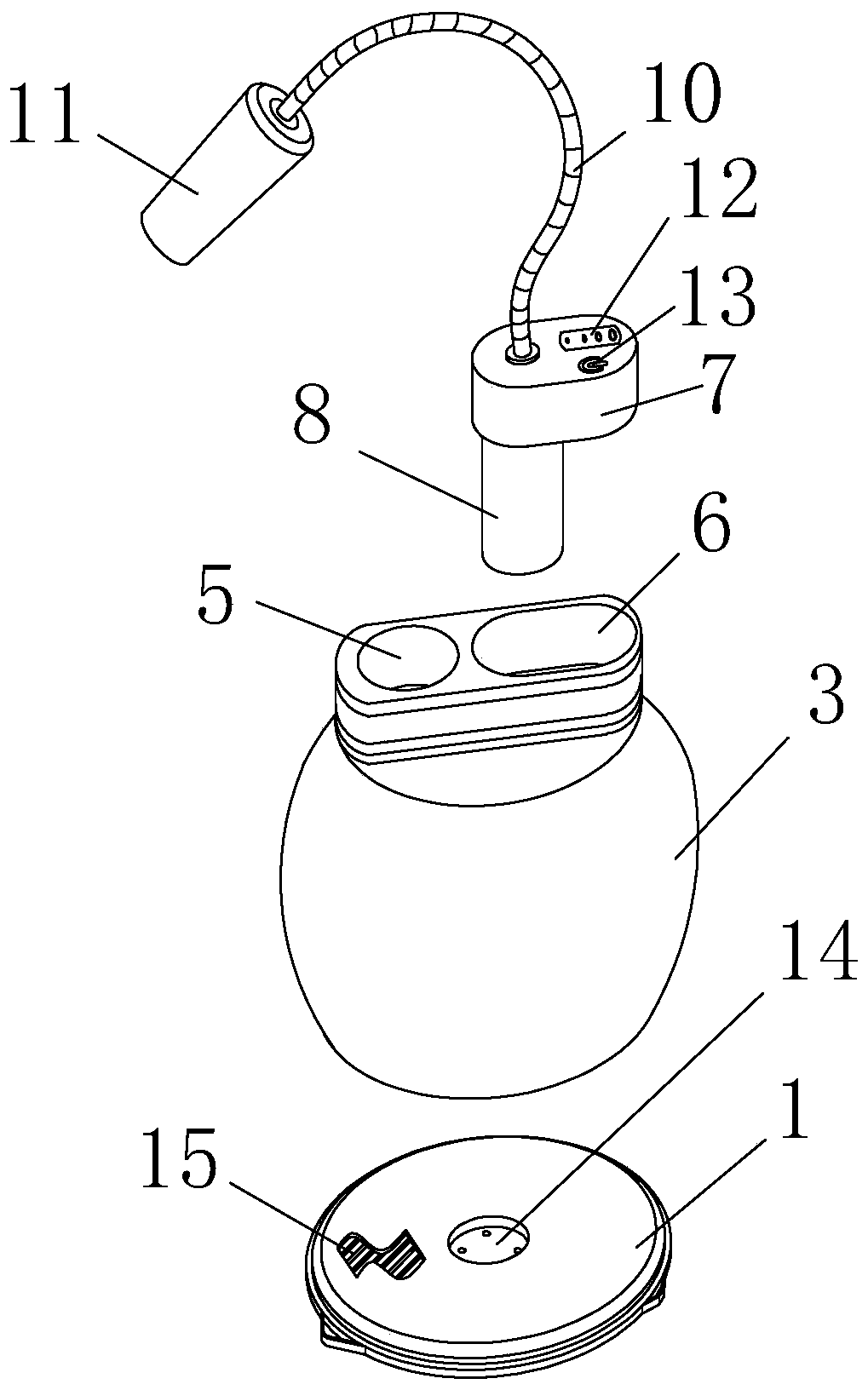

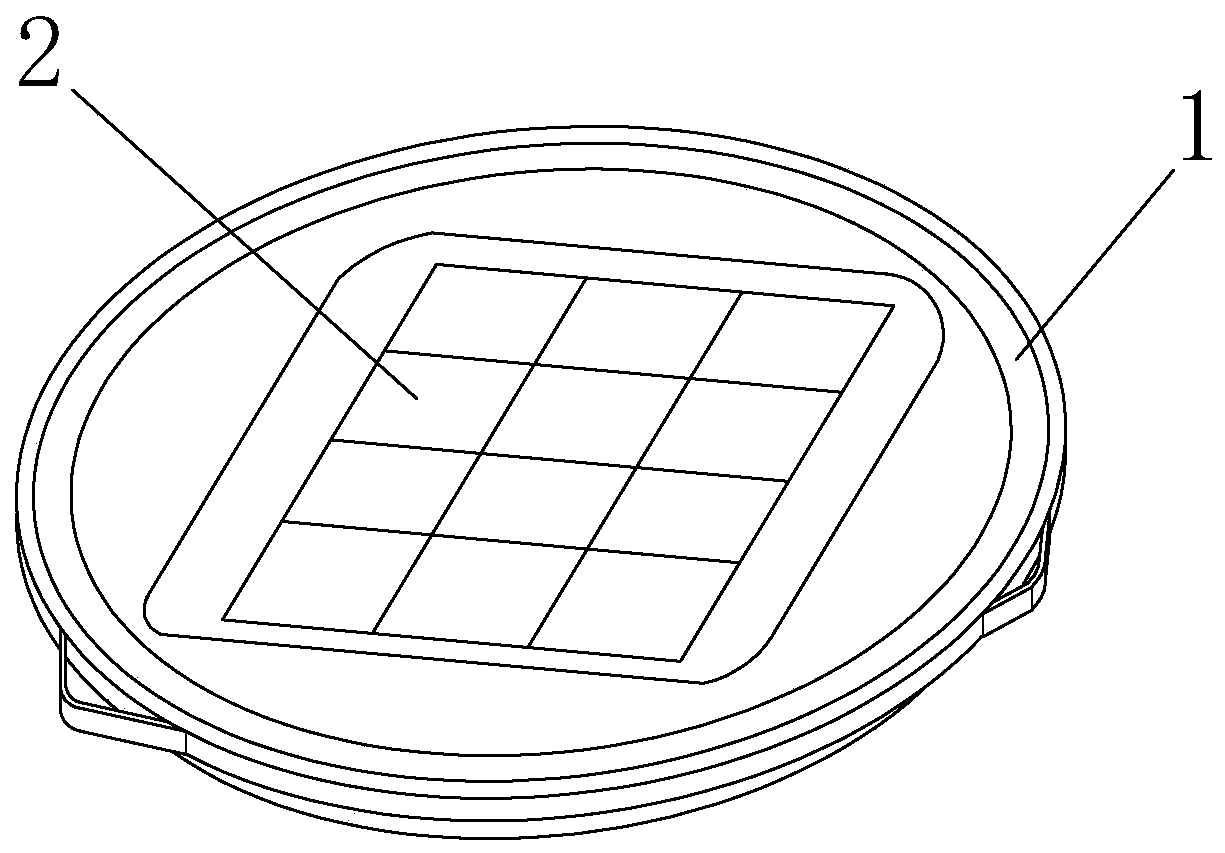

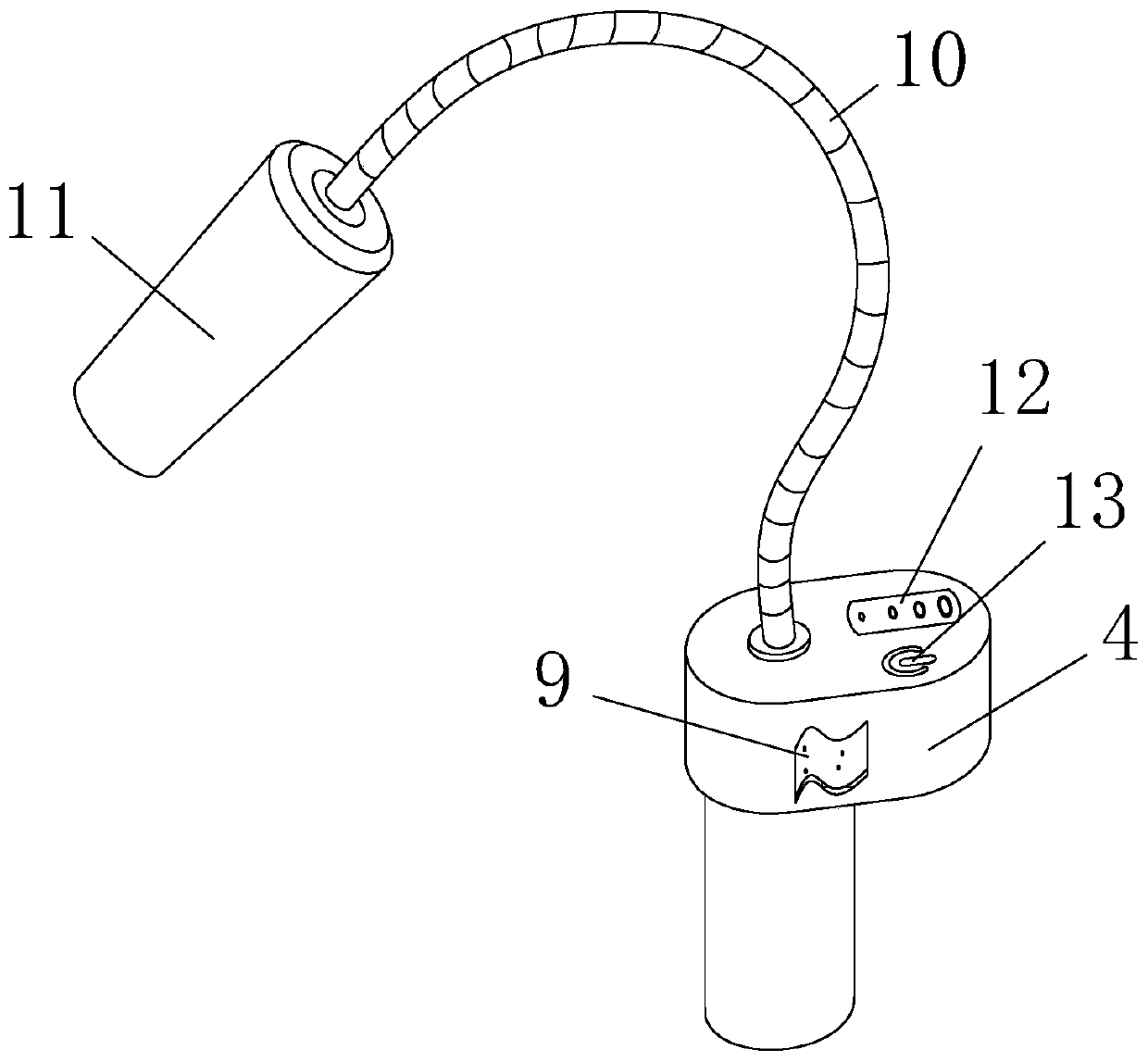

Outdoor solar lamp and control method thereof

InactiveCN111043536AIncrease axial tensionEasy to adjust directionMechanical apparatusElectric circuit arrangementsEngineeringSolar lamp

The invention discloses an outdoor solar lamp and a control method thereof. The invention belongs to the field of solar lamps, the outdoor solar lamp is characterized by comprising a lamp holder, a solar cell panel is arranged at the bottom of the lamp holder, a lampshade is connected to the top of the lamp holder in a clamped mode, a connecting seat is arranged at the top of the lampshade, a round hole is formed in the top of the connecting seat, and a strip-shaped hole located in one side of the round hole is formed in the top of the connecting base. A socket is in interference fit with theinner wall of the strip-shaped hole; a storage battery is arranged at the bottom of the socket, the bottom end of the storage battery is electrically connected with the solar cell panel, a light control module is arranged on the inner wall of the socket, an armoring wire electrically connected with the light control module is fixedly connected to the top end of the socket, and an LED lamp holder is fixedly connected to the end, away from the socket, of the armoring wire. The outdoor solar lamp has the advantages that the outdoor solar lamp is used by hand lifting, and can also be used for household lighting, meanwhile, the brightness of the outdoor solar lamp can be adjusted, and the application range is wider.

Owner:厦门亿加凌电子有限公司

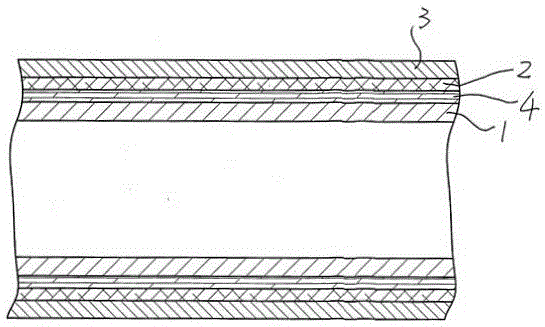

A coilable glass fiber reinforced plastic composite pipe and its preparation method

ActiveCN105952990BBendableEnough resistance to external pressureFlexible pipesTubular articlesGlass fiberPolyresin

The invention belongs to the technical field of plastic composite pipe material and discloses a coilable type glass fiber reinforced plastic composite pipe. The technical scheme of the coilable type glass fiber reinforced plastic composite pipe is that the composite pipe comprises an inner pipe layer, a reinforced layer and an outer pipe layer, wherein the reinforced layer consists of a coiled layer or a woven layer which is formed of resin-impregnated glass fiber. According to the coilable type glass fiber reinforced plastic composite pipe, the reinforced layer utilizes the resin which is mainly composed of polyether polyol mixture, dibutyl phthalate, polyurethane resin or bisphenol-A epoxy resin, K54 tertiary amine and HG-66 active silicon micro powder, so that the reinforced layer is solidified with the glass fiber to form an integral fiberglass-reinforced structure with bending property. The coilable type glass fiber reinforced plastic composite pipe has the bending property and enough anti-external-pressure property.

Owner:河北宇通特种胶管有限公司

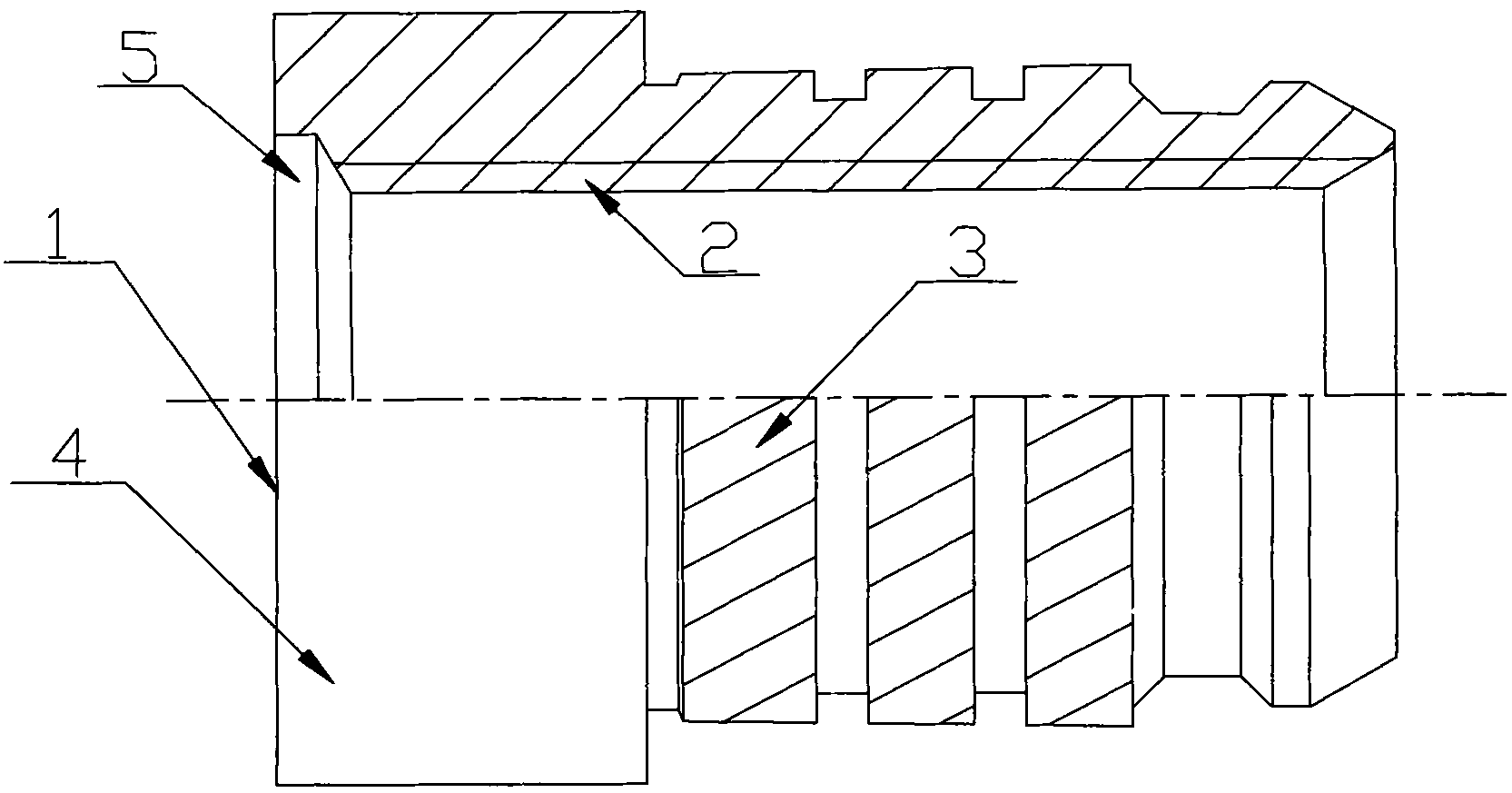

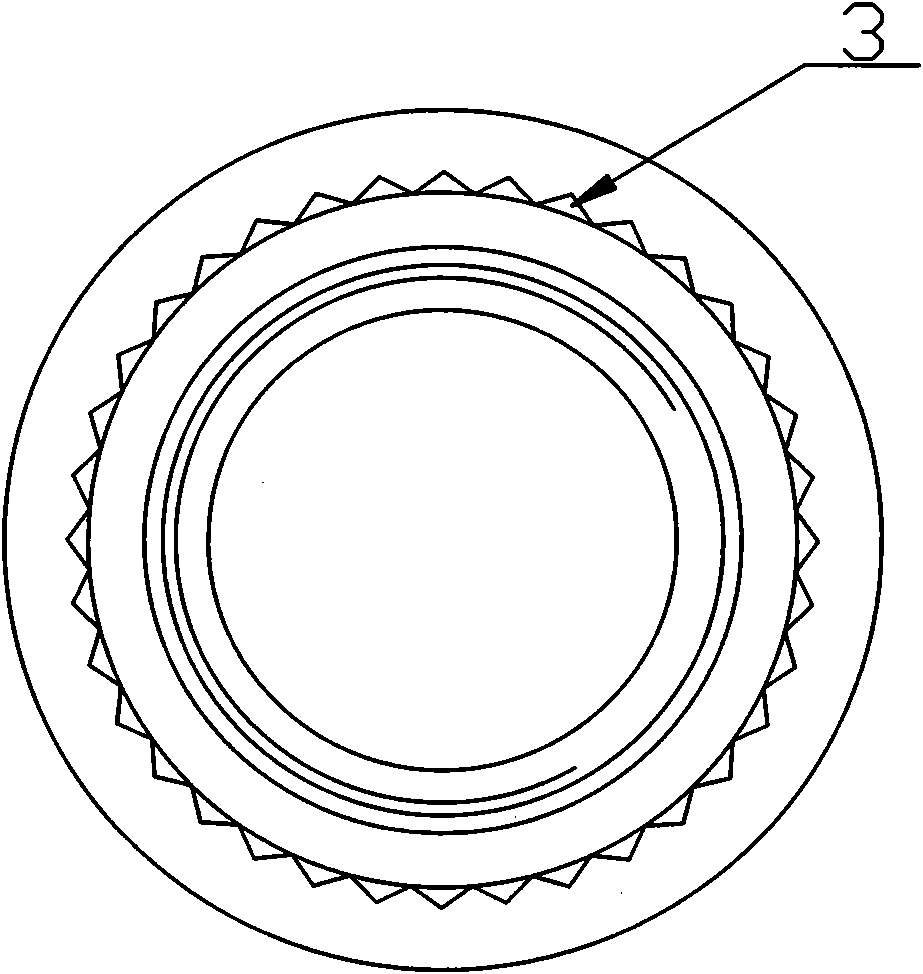

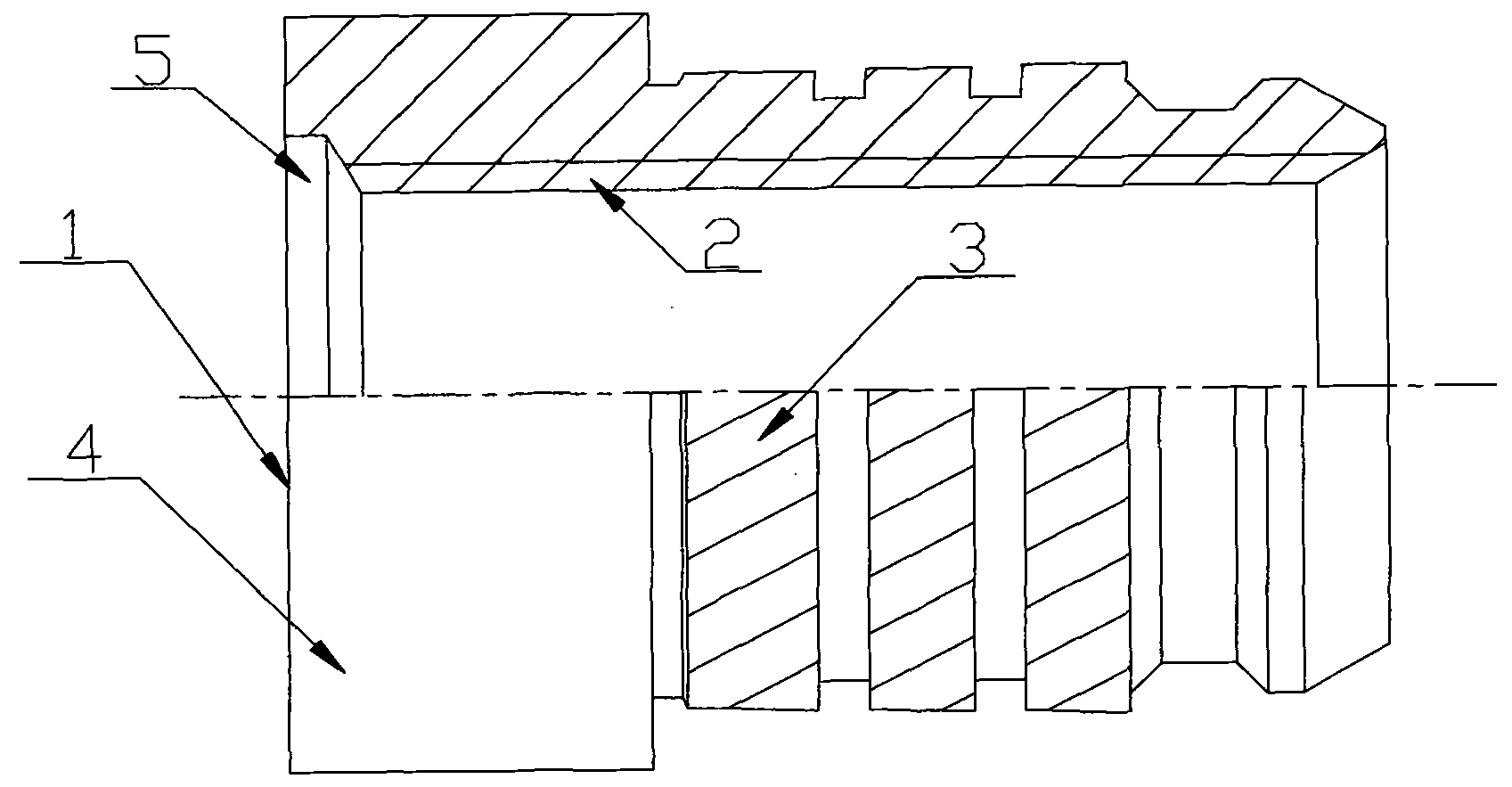

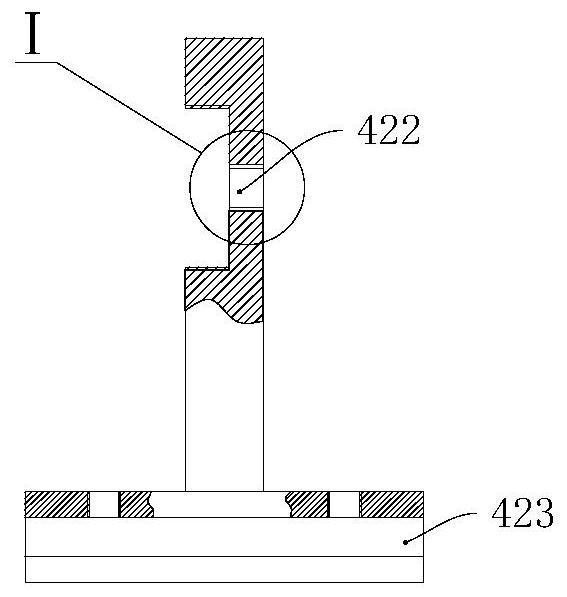

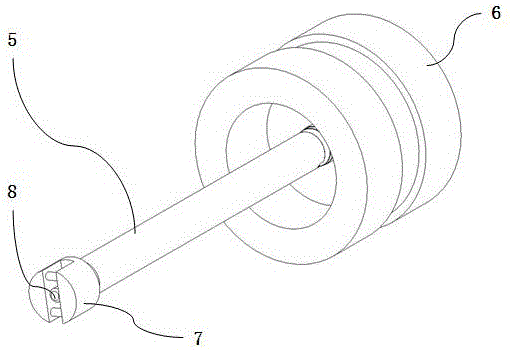

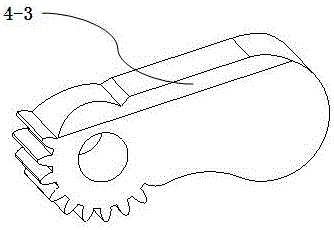

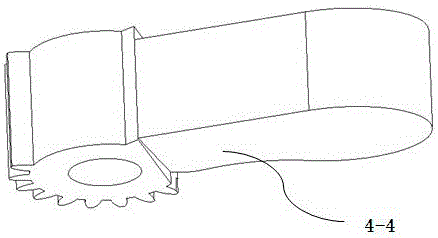

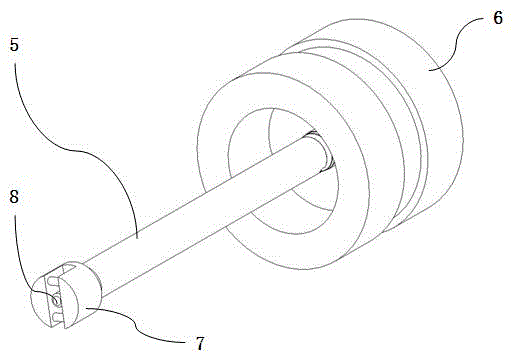

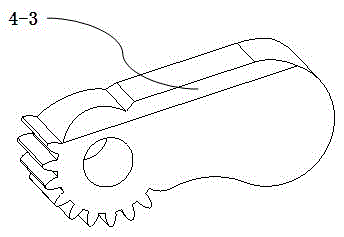

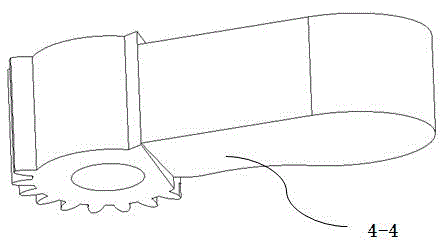

axial tensioner

ActiveCN105003590BIncrease axial tensionLoad running smoothlySpringsSprings/dampers design characteristicsRotational axisRadial position

The invention particularly relates to a centrifugal type axial strainer which is composed of a fixing sleeve, a toothed sleeve, a pin shaft and at least two centrifugal pendulums. The fixing sleeve is in a shaft sleeve shape as a whole. A toothed sleeve hole is formed in the axial center of the fixing sleeve. At least two pendulum grooves are formed in the peripheral wall of the fixing sleeve, and one end of each pendulum groove is provided with pin holes in the radial direction. At least two tooth rank grooves are formed in the outer surface of the toothed sleeve. Each centrifugal pendulum is in a long-strip shape, the corresponding pin holes are formed in one end of each centrifugal pendulum, and an engaged tooth rank is arranged on the edge of each centrifugal pendulum. The toothed sleeve is inserted in the toothed sleeve hole of the fixing sleeve, then the centrifugal pendulums are placed in the pendulum grooves of the fixing sleeve, engaged teeth of the centrifugal pendulums and the tooth rank grooves in the toothed sleeve are made to be engaged together, and finally the pin shaft is inserted in the pin holes of the fixing sleeve and the pin holes of the centrifugal pendulums, so that the fixing sleeve, the toothed sleeve and the centrifugal pendulums are combined to form a whole. The axial strainer has the beneficial effects that the axial tension force of a rotation shaft can be increased, and a load is stable in operation.

Owner:XIAMEN NANCI ELECTRONICS

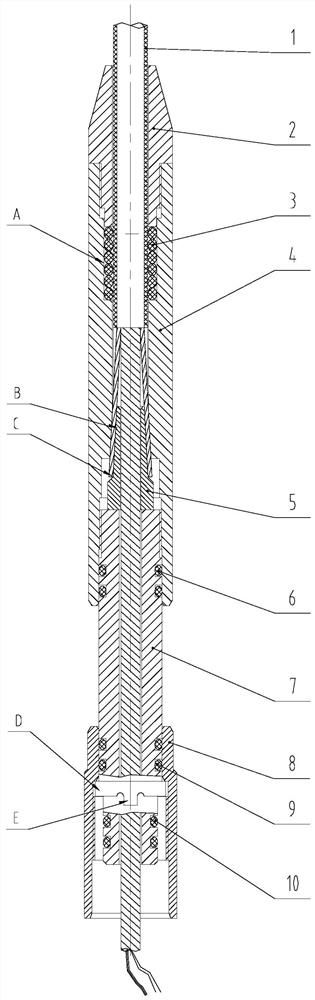

Photoelectric composite cable connector for oil well annulus test

PendingCN114171966AReasonable structural designEasy to useSecuring/insulating coupling contact membersCouplings bases/casesEngineeringMechanical engineering

The invention discloses a photoelectric composite cable connector for an oil well annulus test, and relates to the technical field of the photoelectric composite cable connector for the oil well annulus test, which is matched with a photoelectric composite cable and a spiral winding type optical fiber composite cable connector for use, and the photoelectric composite cable connector comprises an upper joint and is characterized in that the upper joint is in a pipe sleeve shape; a photoelectric composite cable penetrates through the upper connector, the minimum inner hole diameter of the upper connector is consistent with the outer diameter of the photoelectric composite cable, the upper end of the upper connector is provided with internal threads and a sealing ring groove, and the lower end of the upper connector is provided with an inner taper hole, internal threads and a sealing ring face. The photoelectric composite cable connector is reasonable in structural design and convenient to use, optical fiber welding and wire connection of a photoelectric composite cable can be achieved through the connector, large axial tension can be borne, and the problems of optical fiber welding, wire connection and fixing of the large axial tension of the photoelectric composite cable are solved.

Owner:山东希尔电缆有限公司 +1

Axial strainer

ActiveCN105003590ALow costEasy to useSpringsSprings/dampers design characteristicsRotational axisClassical mechanics

The invention particularly relates to a centrifugal type axial strainer which is composed of a fixing sleeve, a toothed sleeve, a pin shaft and at least two centrifugal pendulums. The fixing sleeve is in a shaft sleeve shape as a whole. A toothed sleeve hole is formed in the axial center of the fixing sleeve. At least two pendulum grooves are formed in the peripheral wall of the fixing sleeve, and one end of each pendulum groove is provided with pin holes in the radial direction. At least two tooth rank grooves are formed in the outer surface of the toothed sleeve. Each centrifugal pendulum is in a long-strip shape, the corresponding pin holes are formed in one end of each centrifugal pendulum, and an engaged tooth rank is arranged on the edge of each centrifugal pendulum. The toothed sleeve is inserted in the toothed sleeve hole of the fixing sleeve, then the centrifugal pendulums are placed in the pendulum grooves of the fixing sleeve, engaged teeth of the centrifugal pendulums and the tooth rank grooves in the toothed sleeve are made to be engaged together, and finally the pin shaft is inserted in the pin holes of the fixing sleeve and the pin holes of the centrifugal pendulums, so that the fixing sleeve, the toothed sleeve and the centrifugal pendulums are combined to form a whole. The axial strainer has the beneficial effects that the axial tension force of a rotation shaft can be increased, and a load is stable in operation.

Owner:CHANGTING NANCI ELECTRONICS

A method for improving the bonding performance of fiber bundles and potassium magnesium phosphate cement-based materials

The invention discloses a method of improving bonding performance of a fiber bundle and a potassium magnesium phosphate cement-based material and relates to a manufacturing technology of a fiber-reinforced potassium magnesium phosphate cement composite material. A novel fiber impregnating compound prepared by the method has characteristics such as strong permeability, quick curing, controllable curing speed, high bonding strength, acid resistance, pressure resistance and high temperature resistance. In the fiber bundle cured by the novel fiber impregnating compound, fiber filaments are bonded into an integer by a network structure of -Si-O-Si-, all fiber filaments can be stressed at the same time, and axial tension of the fiber bundle is improved by twice to three times in comparison with that of the un-treated fiber bundle. In the fiber-reinforced MPC(Magnesium Phosphate Cement)-based composite material prepared by the fiber bundle cured by the novel fiber impregnating compound, dead-burned magnesium oxide powder deposited on the surface of the fiber bundle participates in hydration reaction of an MPC base body, so that interface bonding of the fiber bundle and the MPC base body is reinforced; and pulling-drawing force of the fiber bundle is improved by 15%-40% in comparison with that of the fiber bundle treated by an epoxy resin impregnating compound. The method disclosed by the invention is simple in preparation process and convenient to use, and has cost which is only 1 / 10-1 / 6 of that of the epoxy resin fiber impregnating compounds.

Owner:YANCHENG INST OF TECH

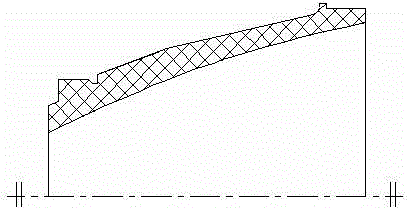

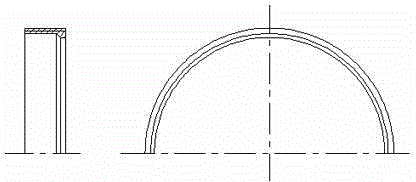

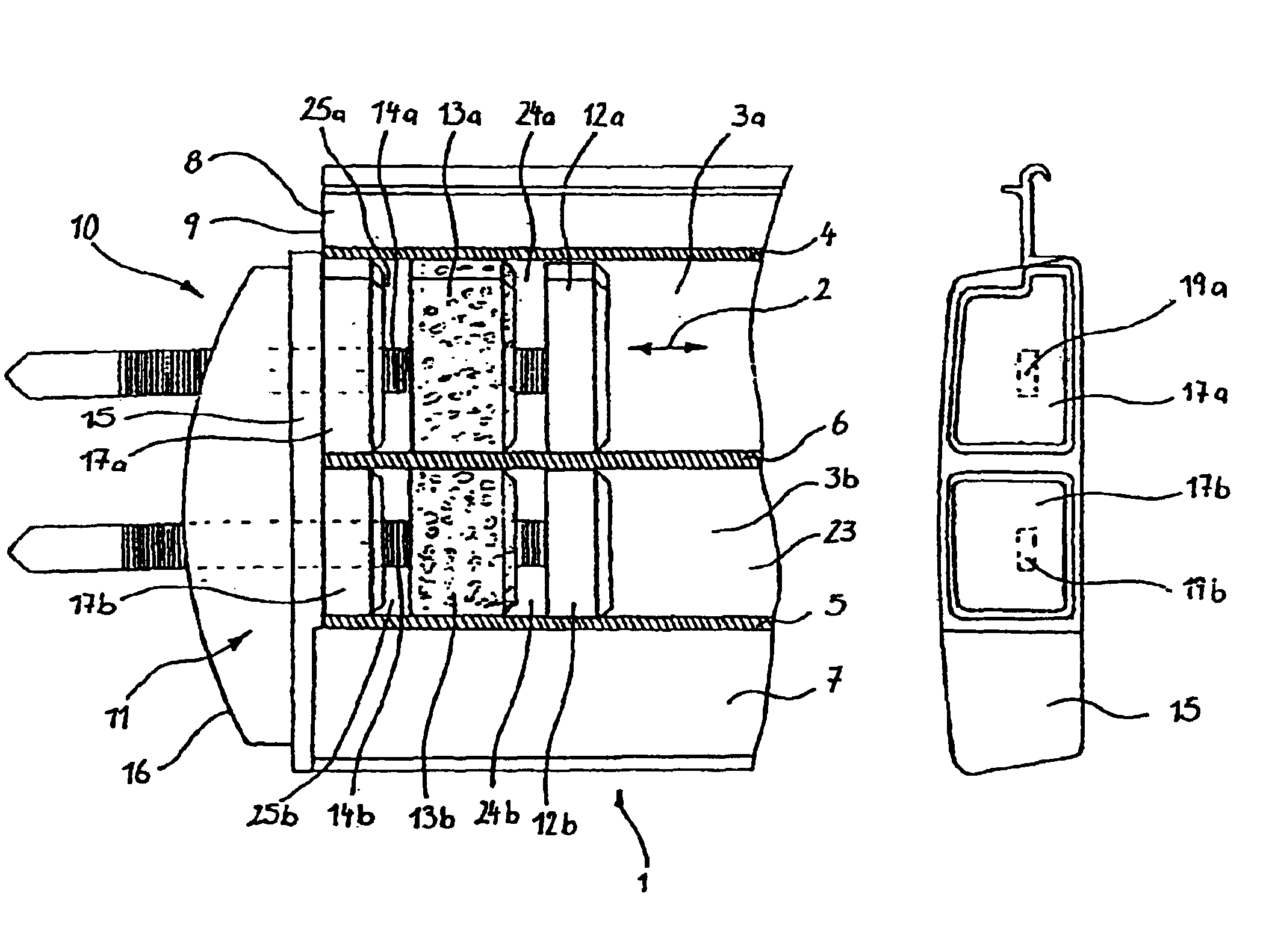

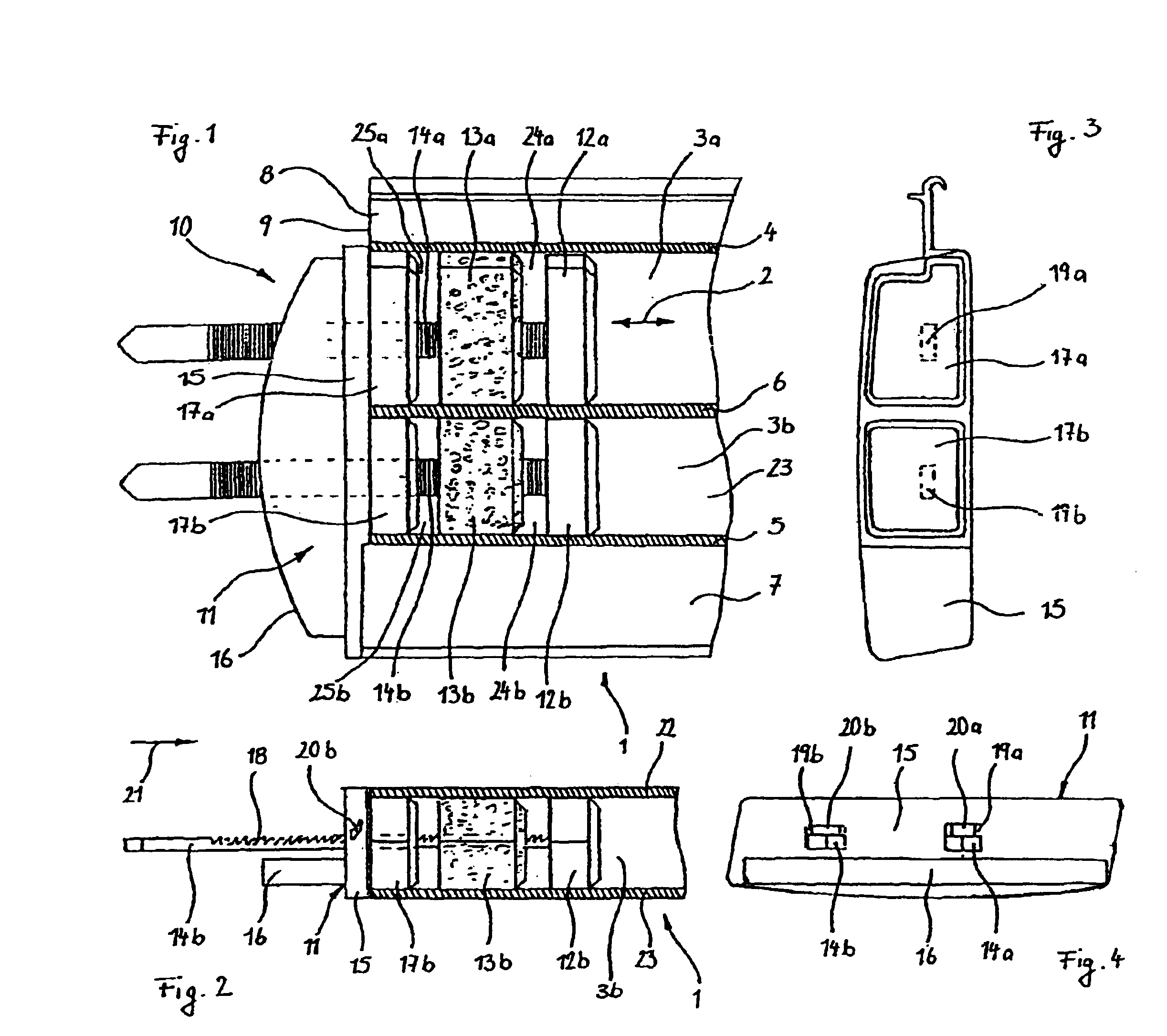

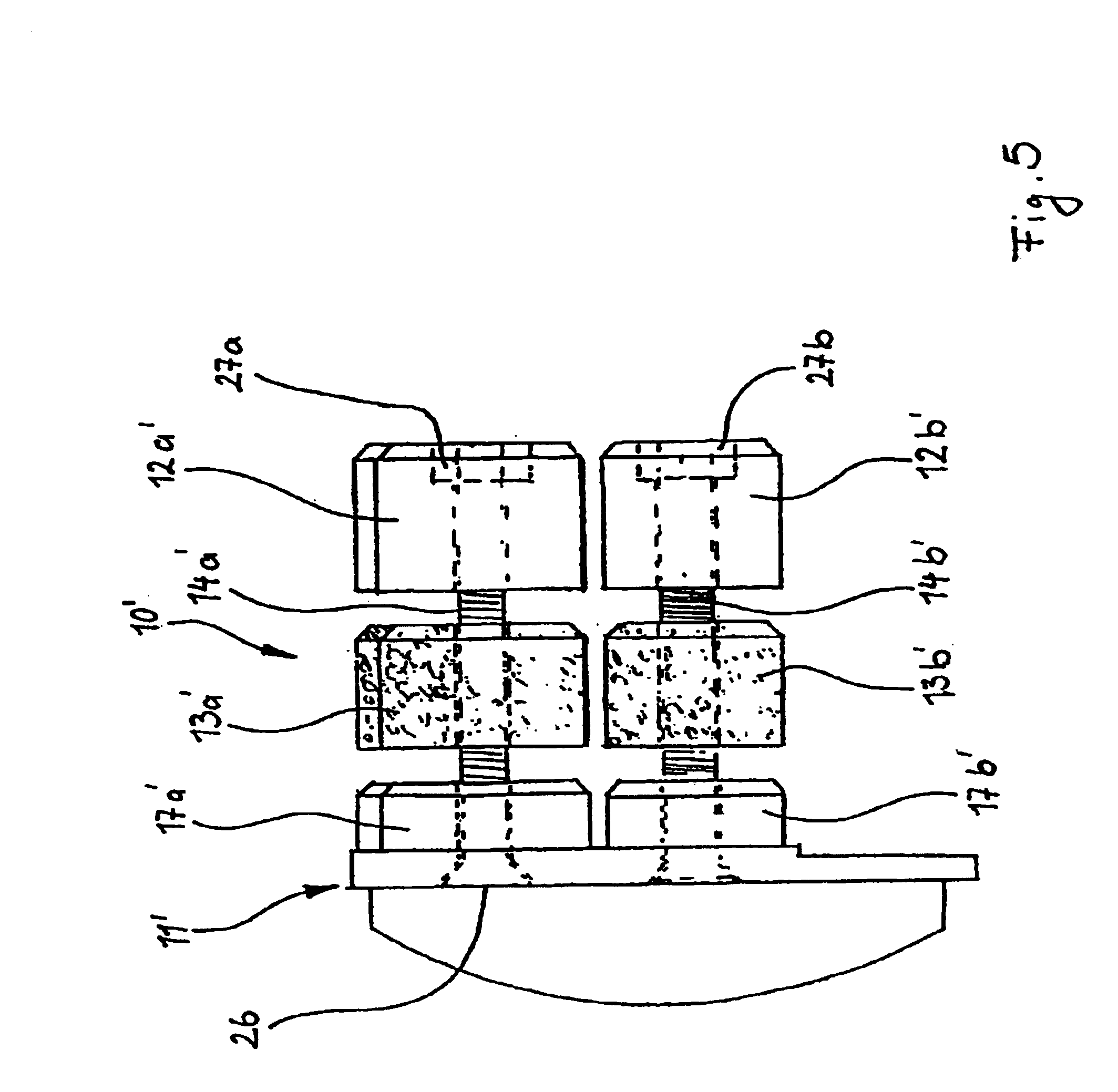

Elongated roller shutter profile made of plastic or metal for swimming pool covers

InactiveUS6910233B2Shorten the timeRemovability of the sealingBuilding roofsDoor/window protective devicesPlastic materialsMechanical engineering

An elongated roller shutter profile of plastic or metal for swimming pool covers has a water-proof closure that closes an end of at learnt one longitudinal hollow chamber of the roller shutter profile. The closure includes a cap at least partly inserted from the end into the chamber, a piston plate spaced from the cap, and a sealing body between the cap and the piston plate. The sealing body made of an elastic and / or plastic material is brought into a sealing state by clamping between the piston plate and the cap so that the sealing body expands in width and rests in a circumferentially tight manner on the inner walls of the hollow chamber.

Owner:HANS HEINZ HELGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com