Photoelectric composite cable connector for oil well annulus test

A technology for optoelectronic composite cables and connectors, which is applied in the direction of connection, coupling of optical waveguides, and components of connecting devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

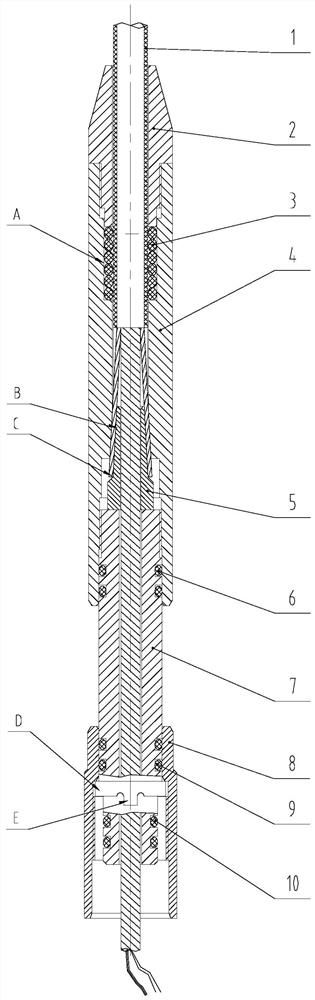

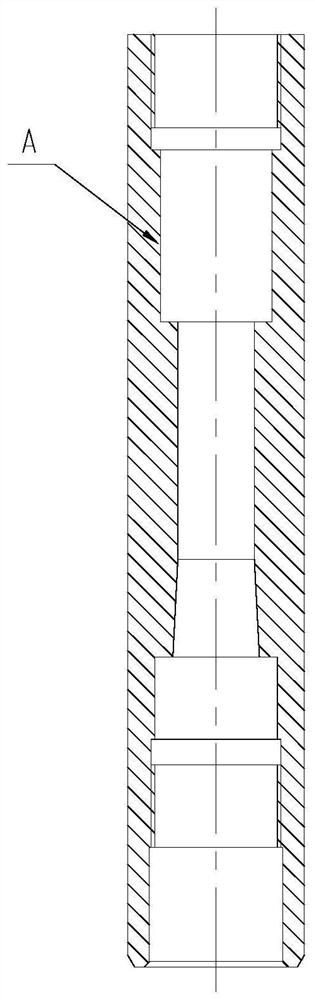

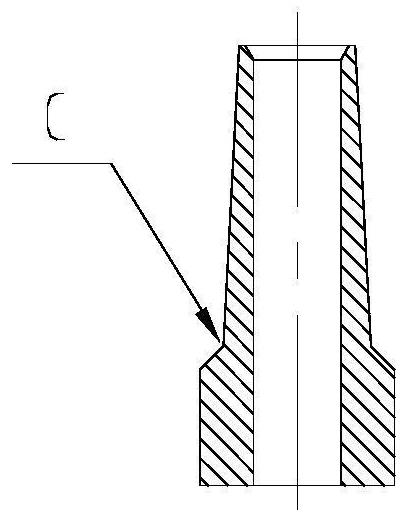

[0014] Such as Figure 1 to Figure 5 As shown, this embodiment specifically discloses a photoelectric composite cable connector for oil well annulus testing, including an upper joint 4, which is characterized in that: the upper joint 4 is in the shape of a sleeve, and the upper joint 4 passes through In the photoelectric composite cable 1, the minimum inner diameter of the upper joint 4 is consistent with the outer diameter of the photoelectric composite cable 1. The upper end of the upper joint 4 has an internal thread and a sealing ring groove A, and the lower end of the upper joint 4 has an inner taper hole, an internal thread and a sealing ring. On the ring surface, the inner tapered hole of the upper joint 4 is provided with a tapered sleeve 5, and the outer armored steel wire B of the photoelectric composite cable 1 is clamped between the inner tapered hole of the upper joint 4 and the outer tapered surface of the tapered sleeve 5, and the upper joint The lower part of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com