Device for testing relationship between tightening torque and angular displacement of pipe joint

A technology of tightening torque and testing device, which is applied in the direction of measuring torque/torsion force, measuring device, and testing of mechanical components during tightening, and can solve problems such as inaccuracy, lack of first-line operation guidance, and data dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

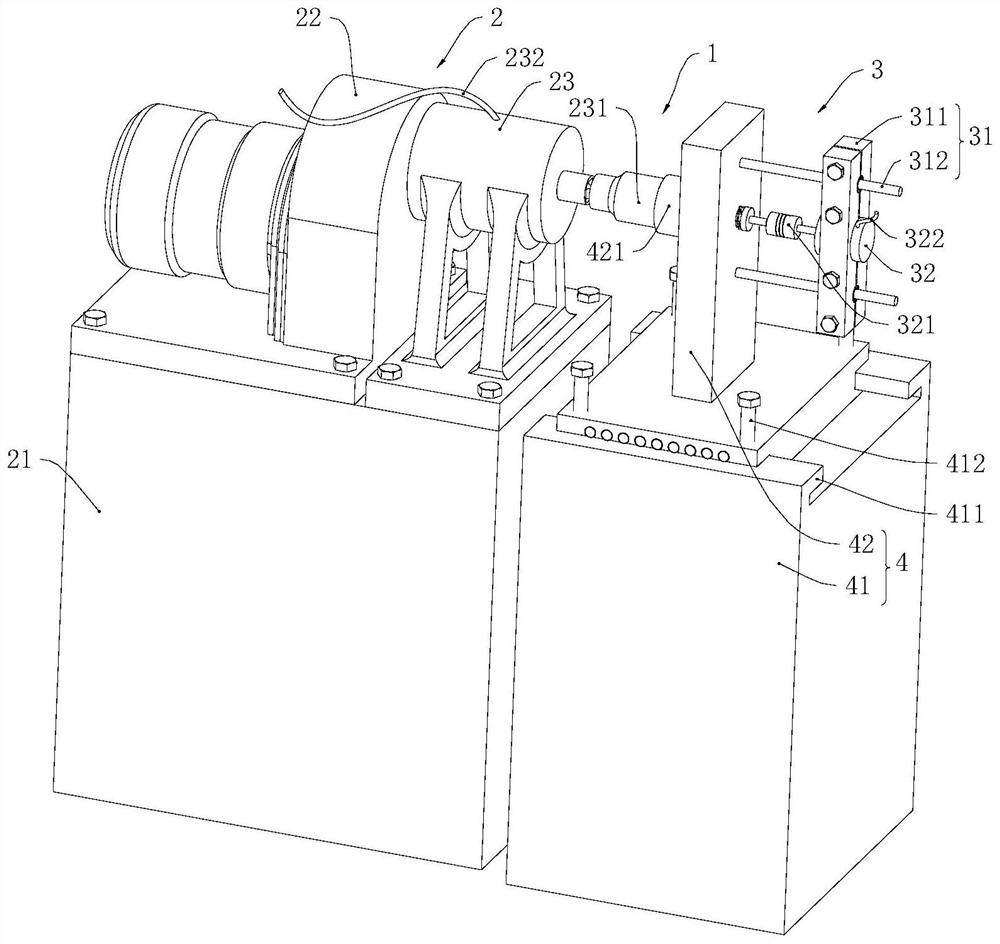

[0051] Reference figure 1 , A testing device for the relationship between the tightening torque and angular displacement of a pipe joint, comprising: a data acquisition device, a clamping transmission assembly 1, and a power assembly 2 and an angular displacement measurement assembly 3 respectively arranged at both ends of the clamping transmission assembly 1. Power assembly 2 The angular displacement measurement component 3 is respectively connected to the data acquisition device in communication. In this embodiment, the data is collected through the acquisition device, and Labview visualization software is used to realize the visualization of the collected process data;

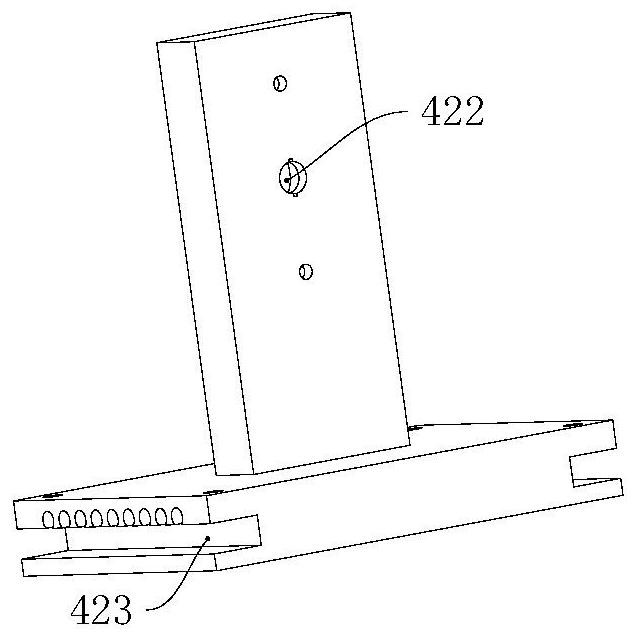

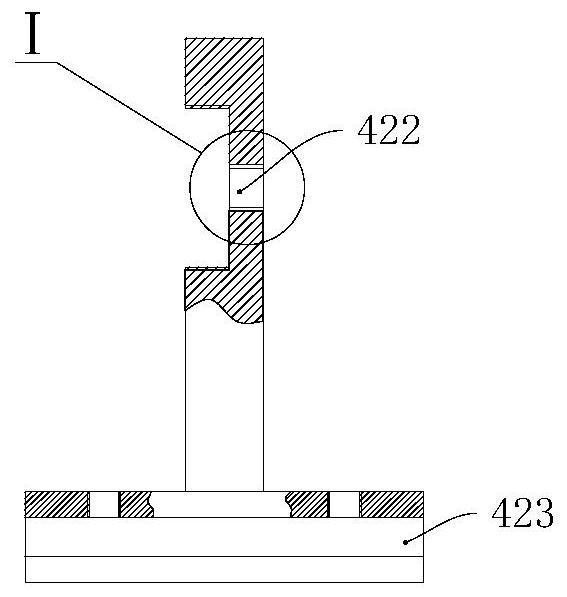

[0052] The clamping transmission assembly 1 includes a clamping assembly 4 and a transmission assembly 5, refer to figure 1 , The clamping assembly 4 includes: a first frame 41 and a support frame 42 slidably and lockably arranged on the first frame 41. In this embodiment, the support frame 42 has a T-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com