Half-and-half threaded connection structure of diffusing section of jet pipe of solid rocket engine

An engine nozzle and solid rocket technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of large space occupied by the thermal insulation layer, reducing the mass ratio of solid rocket engines, and excessive local gaps. The effect of ensuring work reliability and structural safety, solving the stress requirements of axial rigid connections, and improving thermal load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

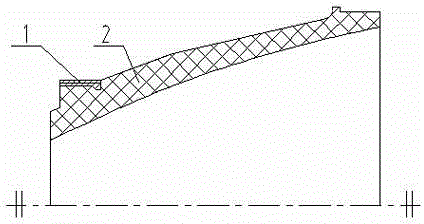

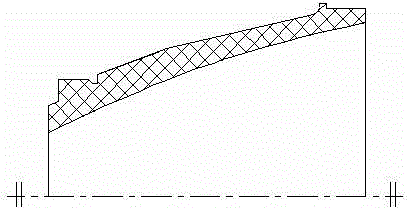

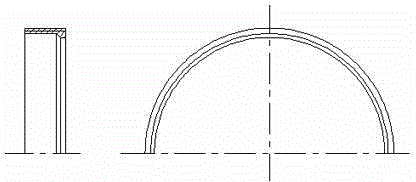

[0016] Please refer to figure 1 According to the present invention, the semi-thread connection structure for the nozzle diffuser of the solid rocket motor includes: the diffuser body 2 and the half-thread connection pair 1 located outside the diffuser body 2 for connection.

[0017] During the working process of the solid rocket motor, the diffuser body 2 mainly plays the role of resisting high-temperature gas ablation, and the pressure generated by the gas of the solid rocket motor is transmitted to the half-threaded connection pair 1 through the diffuser body 2, and the half-threaded connection pair 1 It plays the role of connecting the diffuser body 2 to ensure the reliability of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com