Method for enhancing rivet-free connection strength of steel-aluminum double-metal sheet through oxidation treatment

A technology of oxidation treatment and riveting connection, which is applied in the field of non-rivet connection of dissimilar materials, can solve the problems of reducing the axial connection strength, and achieve the effects of avoiding stress concentration, improving connection strength and reducing component force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

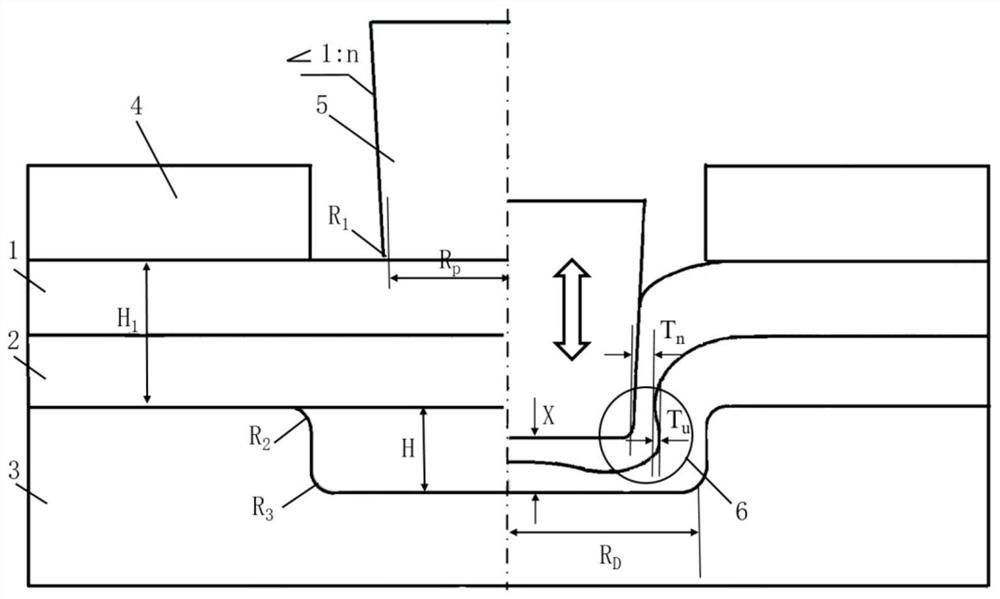

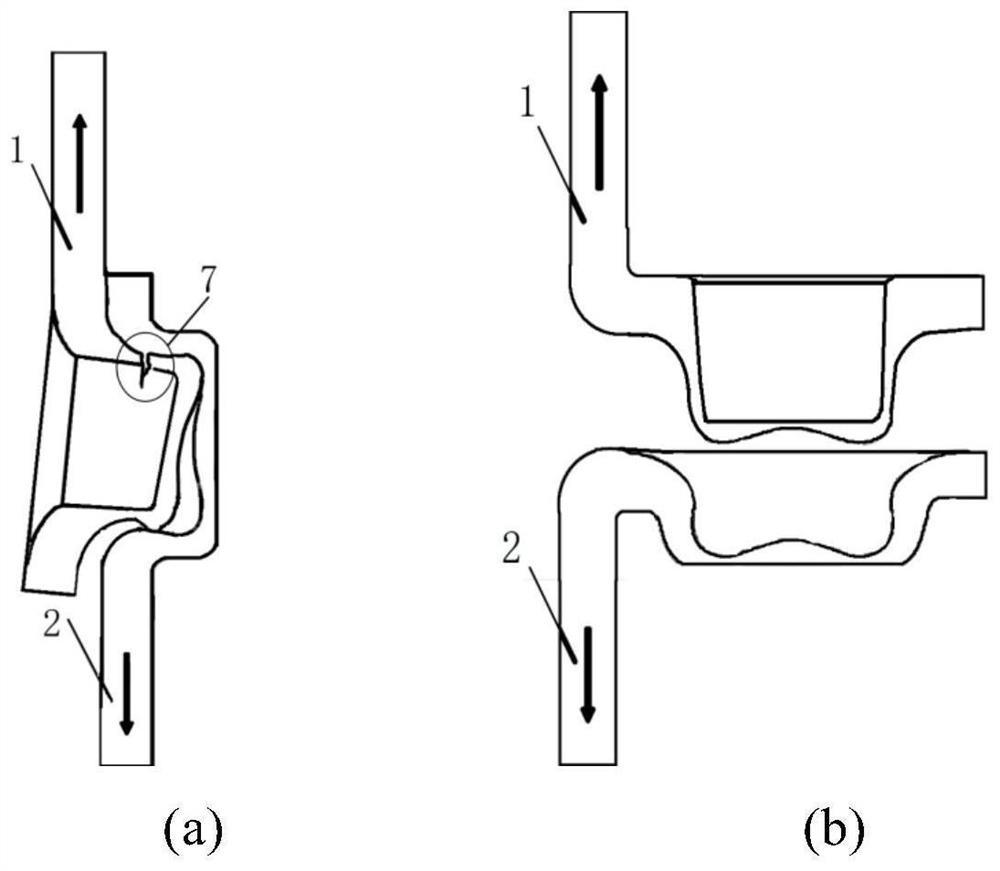

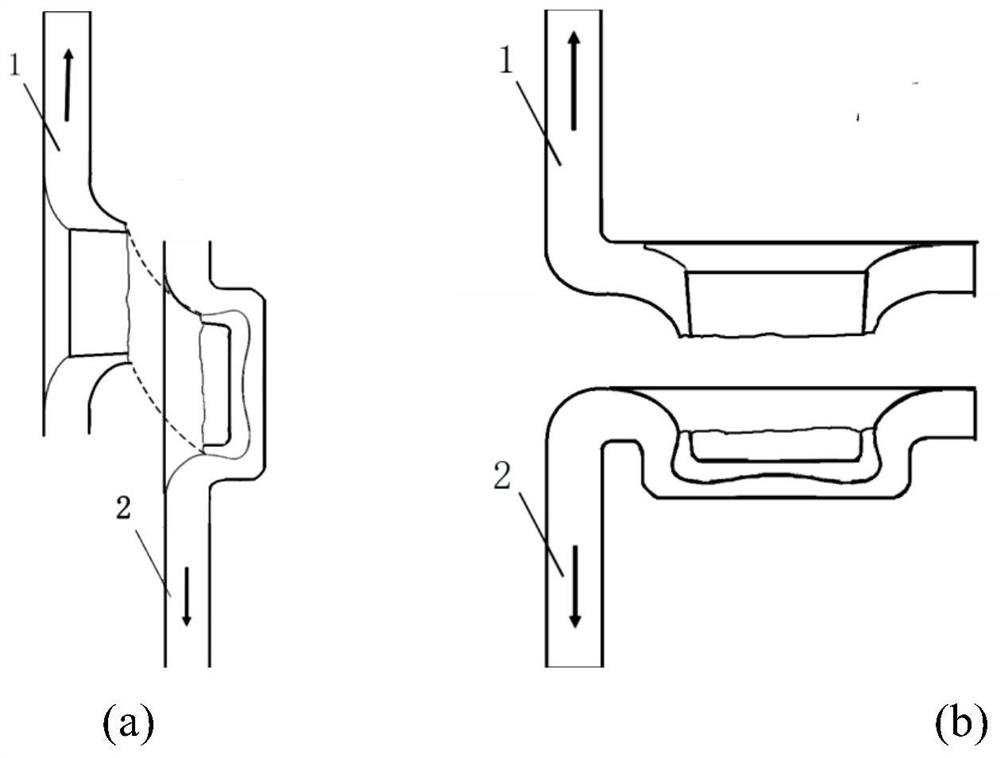

[0041] Such as Figure 1~5 , a method for enhancing the rivetless connection strength of steel-aluminum bimetal sheets through oxidation treatment, comprising:

[0042] Step S1, prepare the steel plate 2 and the aluminum plate 1 to be connected: in this embodiment, the steel plate 2 is a low carbon steel plate, the aluminum plate is an A5052 aluminum plate, the length of the steel plate 2 and the aluminum plate 1 are both 100 mm, the width is 30 mm, and the thickness is 1.5 mm;

[0043] Step S2, surface cleaning treatment: use a wire brush, sandpaper or a grinding wheel to remove the original oxide on the surface of the steel-aluminum bimetallic plate to be compounded on the aluminum plate 1 and steel plate 2, and use acetone and alcohol to wipe off the oil on the surface to be compounded, and then use a hair dryer Blow dry for later use;

[0044] Step S3, surface oxidation treatment: heating in the air, placing the clean steel plate 2 on a drying platform, using a torch to ...

Embodiment 2

[0055] Such as figure 1 with 6 Shown, a kind of oxidation treatment strengthens the method for the rivetless connection strength of steel-aluminum bimetal sheet, comprises:

[0056] Step S1, prepare the steel plate 2 and the aluminum plate 1 to be connected: in this embodiment, the steel plate 2 is a low-carbon steel plate, the aluminum plate is an A5052 aluminum plate, the length of the steel plate 2 and the aluminum plate 1 are both 100 mm, the width is 30 mm, and the thickness is 1 mm;

[0057] Step S2, surface cleaning treatment: use a wire brush, sandpaper or a grinding wheel to remove the original oxide on the surface of the steel-aluminum bimetallic plate to be compounded with the 5052 aluminum plate 1 and the low-carbon steel plate 2 obtained in step S1, and use acetone and alcohol to clean the surface to be compounded Wipe off the oil stains, and then dry them with a hair dryer for later use;

[0058] Step S3, surface oxidation treatment: heating in the air, placing...

Embodiment 3

[0063] Such as figure 1 Shown, a kind of oxidation treatment strengthens the method for the rivetless connection strength of steel-aluminum bimetal sheet, comprises:

[0064] Step S1, prepare the steel plate 2 and the aluminum plate 1 to be connected: in this embodiment, the steel plate 2 is a low-carbon steel plate, the aluminum plate is an A5052 aluminum plate, the length of the steel plate 2 and the aluminum plate 1 are both 100 mm, the width is 30 mm, and the thickness is 1 mm;

[0065] Step S2, surface cleaning treatment: use a wire brush, sandpaper or a grinding wheel to remove the original oxide on the surface of the steel-aluminum bimetallic plate to be compounded with the 5052 aluminum plate 1 and the low-carbon steel plate 2 obtained in step S1, and use acetone and alcohol to clean the surface to be compounded Wipe off the oil stains, and then dry them with a hair dryer for later use;

[0066] Step S3, surface oxidation treatment: the clean low carbon steel plate 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com