Reinforcement anchor rod and rock mass reinforcement method applying anchor rod

A bolt and rock mass technology, applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of reducing the strength of bolts, potential safety hazards, large grouting gaps, etc., to eliminate gaps and prevent potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

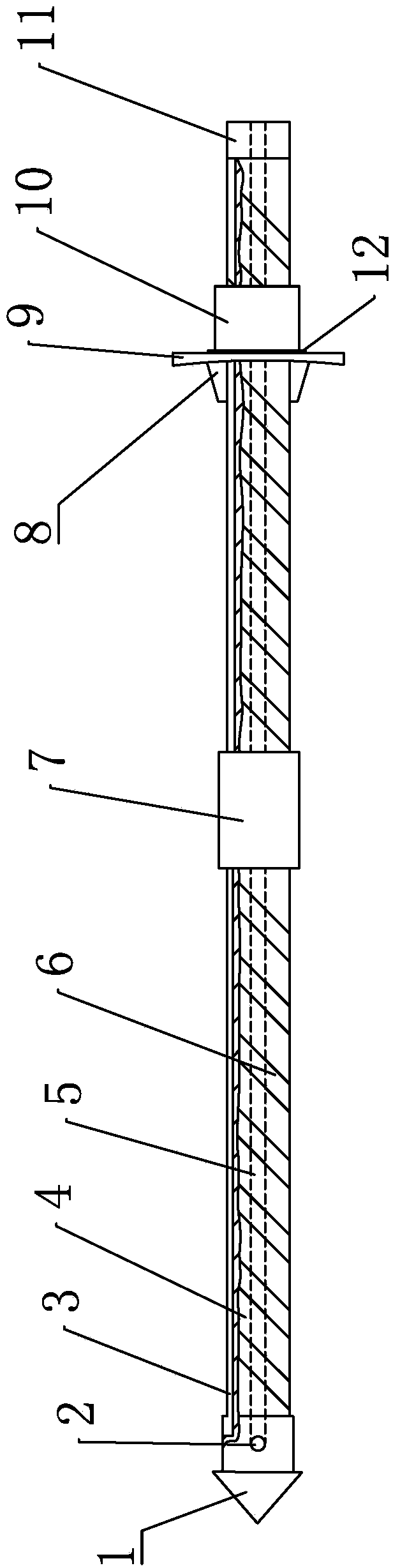

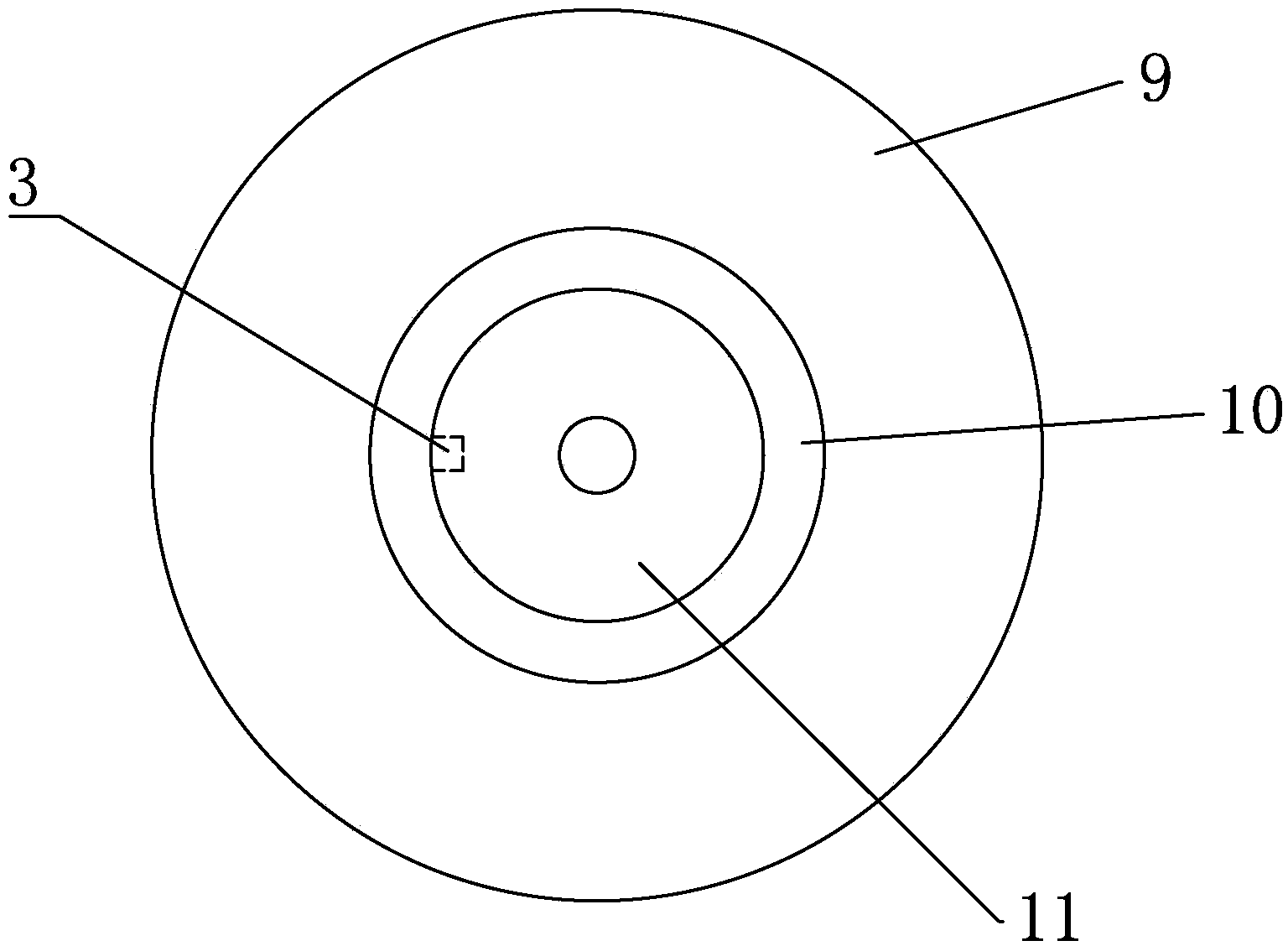

[0029] like figure 1 , figure 2 As shown, the reinforced anchor rod includes: drill bit 1, grout outlet 2, exhaust groove 3, anchor rod body 4, grouting channel 5, thread 6, coupling sleeve 7, grout plug 8, backing plate 9, nut 10. One-way valve 11, gasket 12.

[0030] The anchor body 4 is cylindrical, and its outer surface is provided with a screw thread 6 for engaging with the rock mass. The front side of the anchor body 4 is fixed with a tapered drill bit 1 for drilling. A grouting channel 5 for grouting is provided, and a grouting port 2 is provided on the rear end side wall of the drill bit 1, and the grouting port 2 communicates with the grouting channel 5 through the internal channel of the drill bit 1, and the anchor rod The outer surface of the body 4 and the drill bit 1 is provided with an exhaust groove 3 for exhausting during grouting, and the bolt body 4 is provided with a grout stopper 8 for sealing the grout in the rock hole. The rear side is provided with a...

Embodiment 2

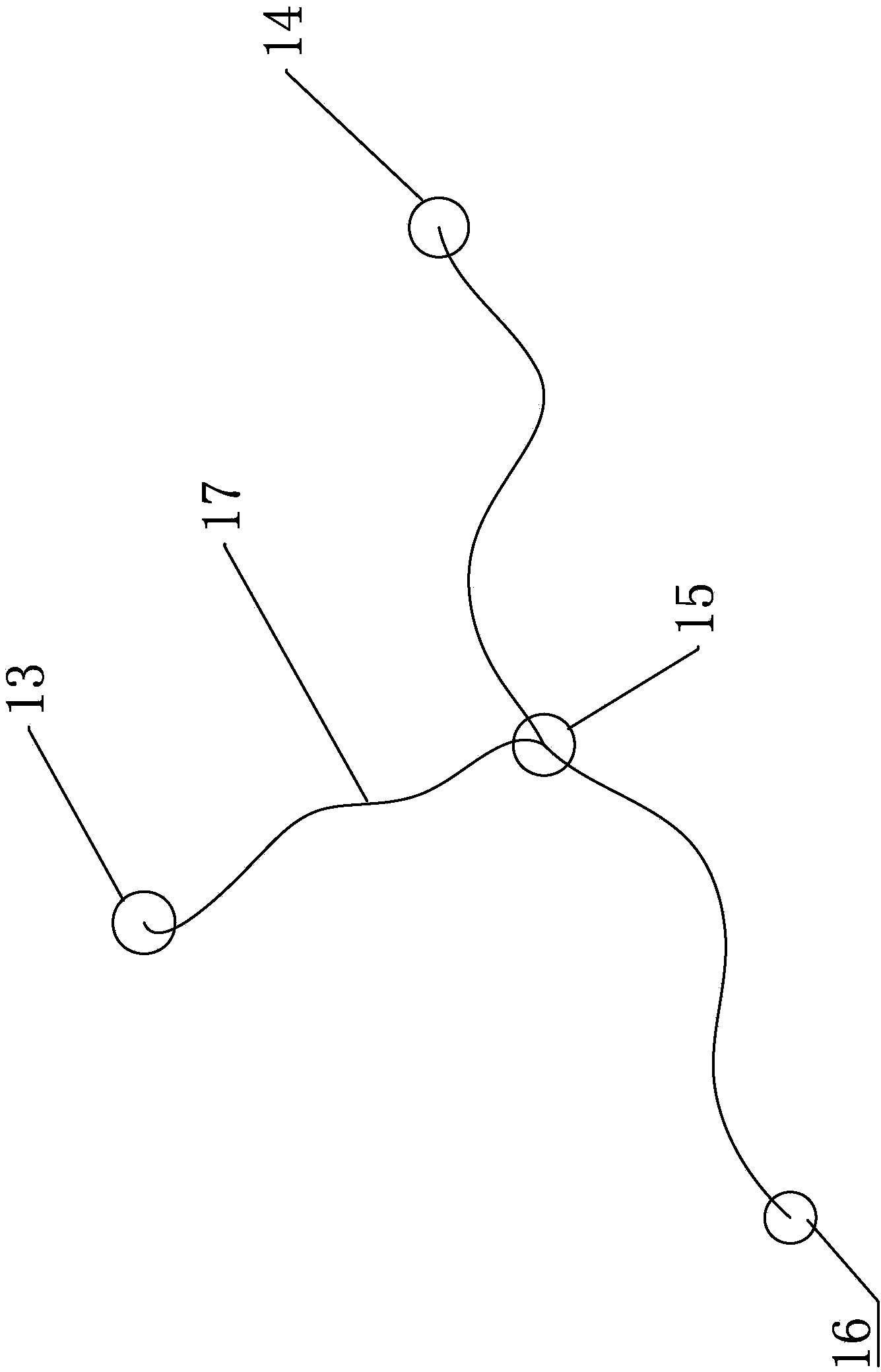

[0041] This embodiment is a rock mass reinforcement method that adopts the reinforcement bolt described in Embodiment 1; cracks generally appear on the surface or inside of the rock mass structure, and such cracks are often in the state where multiple cracks intersect, such as image 3 As shown, the three fractures intersect at one point; if the fracture 17 is located inside the rock mass, instruments such as an ultrasonic detector can be used to find out the position of the fracture or void.

[0042] Drive into the reinforcement anchor rod one 15 at the intersection of the three cracks, and drive into the reinforcement anchor rod two 13, the reinforcement anchor rod three 14, and the reinforcement anchor rod four 16 respectively at the ends of the three cracks; then install with the method in Example 1 respectively Stop grout plug 8, backing plate 9, nut 10, washer 12, if you need to lengthen the anchor rod, you can use the coupling sleeve 7; use sealing plugs to block the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com