An outlet clamp assembly and an electric motor

A technology for components and power cords, applied in the directions of electric components, windings, electrical components, etc., can solve the problems of complicated operation and high material cost, achieve high material cost, increase radial tension and axial tension, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

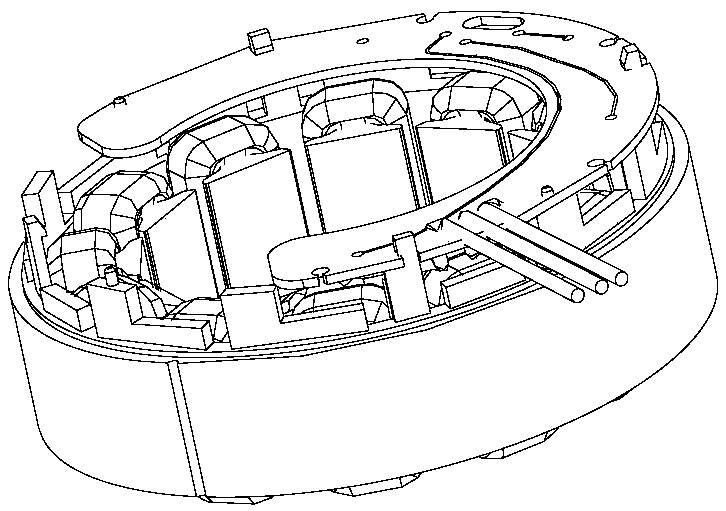

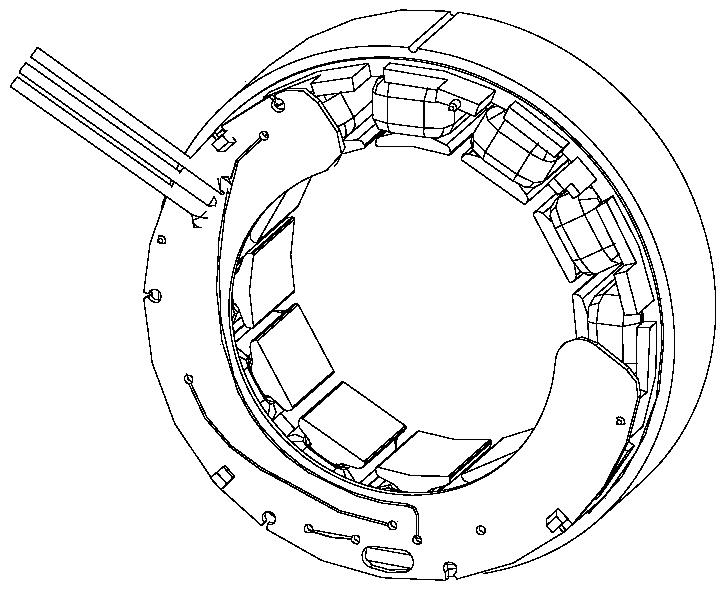

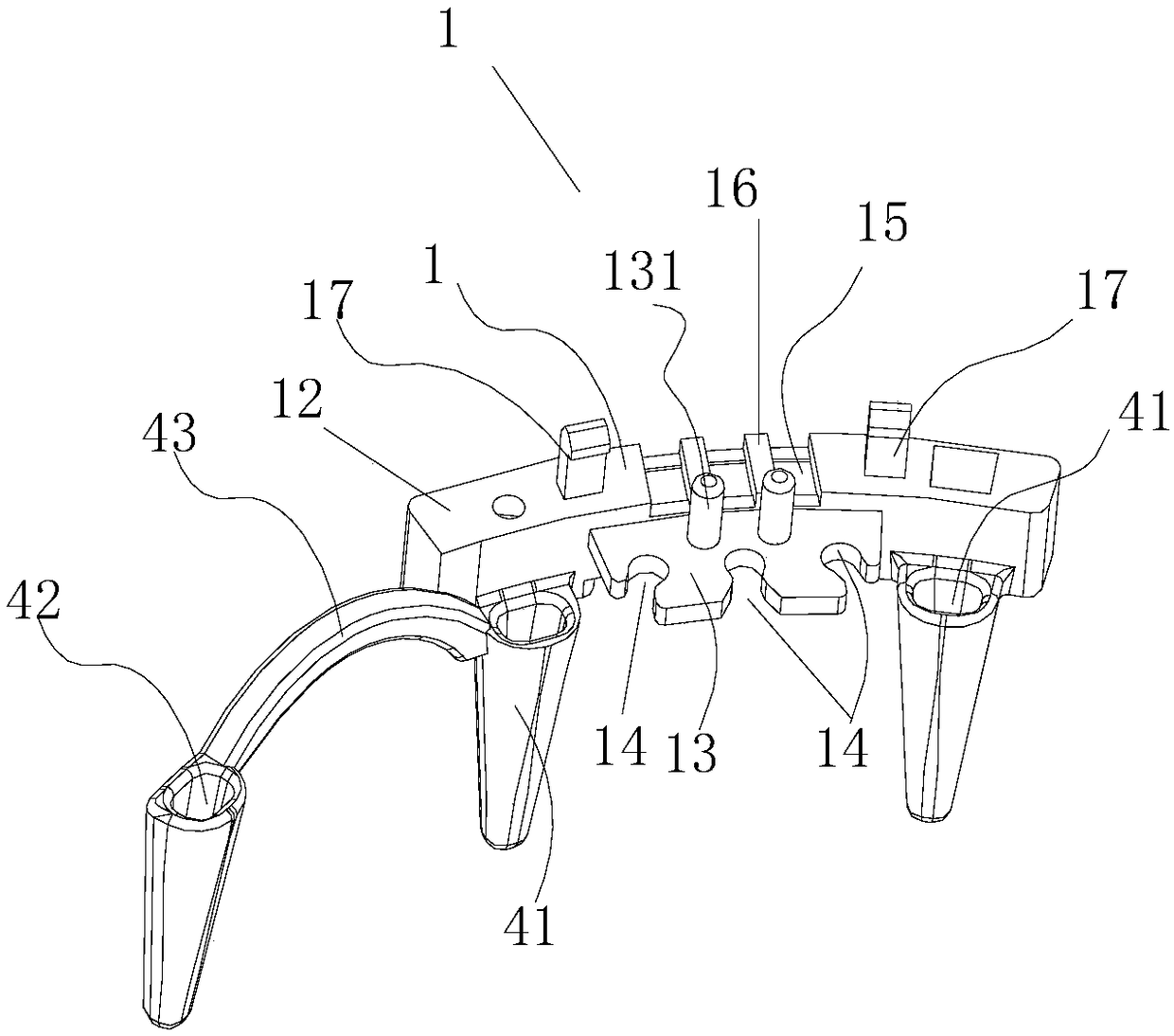

[0053] like Figure 2a-8 Shown, the present invention provides a kind of outlet guard clip assembly, and it comprises:

[0054] The lower outgoing wire protection clip 1 can be clamped and connected to the stator skeleton 3. The stator skeleton 3 has a skeleton protrusion 31, and the lower outgoing wire protection clip 1 has a The lower guard clip groove 11, and the lower outgoing wire guard 1 can guide the motor power line from the radial inner side to the radial outer side of the stator frame 3.

[0055]In the present invention, by setting the lower outgoing wire protection clip that can be clamped on the skeleton protrusion on the skeleton through the groove of the lower protective clip, the outgoing wire protection clip assembly can be effectively matched with the stator skeleton without changing the existing structure of the skeleton, and Effectively guide the motor power line on the radially inner side of the stator frame to the radially outer side, effectively realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com