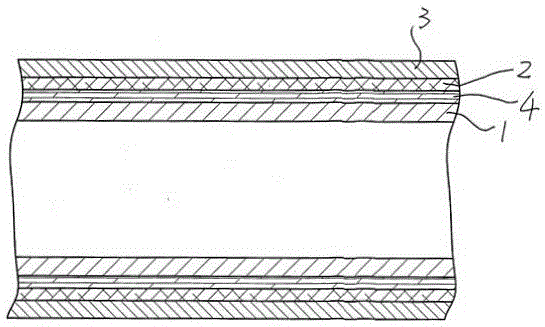

A coilable glass fiber reinforced plastic composite pipe and its preparation method

A technology of reinforced plastics and composite pipes, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of short service life of steel pipes, difficult to meet the requirements of external compressive strength, and difficult to bend, and achieve the effect of improving the axial tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、50

[0033] Embodiment 1, the polyhydroxypolyether mixture of 50 parts by weight, the dibutyl phthalate of 12.0 parts by weight, the polyurethane resin of 28.0 parts by weight, the accelerator of 3.0 parts by weight, the castor oil of 0.5 parts by weight, the castor oil of 1.4 parts by weight Parts of trimethylolpropane (TMP), 0.6 parts by weight of phosphoric acid and 4.5 parts by weight of flame retardant;

Embodiment 2、50

[0034] Embodiment 2, the polyhydroxypolyether mixture of 50 parts by weight, the dibutyl phthalate of 10.0 parts by weight, the polyurethane resin of 32.0 parts by weight, the accelerator of 2.5 parts by weight, the castor oil of 0.4 parts by weight, the castor oil of 1.3 parts by weight Parts of trimethylolpropane (TMP), 0.5 parts by weight of phosphoric acid and 4.2 parts by weight of flame retardant;

[0035] Embodiment 3, the polyhydroxypolyether mixture of 50 parts by weight, the dibutyl phthalate of 8.0 parts by weight, the polyurethane resin of 30.0 parts by weight, the accelerator of 2.0 parts by weight, the castor oil of 0.3 parts by weight, the castor oil of 1.2 parts by weight Parts of trimethylolpropane (TMP), 0.4 parts by weight of phosphoric acid and 4.0 parts by weight of flame retardant;

Embodiment 4、50

[0036] Embodiment 4, the polyhydroxypolyether mixture of 50 parts by weight, the dibutyl phthalate of 9.0 parts by weight, the polyurethane resin of 29.0 parts by weight, the accelerator of 2.5 parts by weight, the castor oil of 0.6 parts by weight, the castor oil of 1.6 parts by weight Parts of trimethylolpropane (TMP), 0.3 parts by weight of phosphoric acid and 5.0 parts by weight of flame retardant;

[0037] Embodiment 5, the bisphenol A epoxy resin of 60 weight parts, the K54 tertiary amine of 5.0 weight parts, the HG-66 active silicon micropowder of 3.0 weight parts, the epichlorohydrin of 0.6 weight parts, the curing agent of 30.0 weight parts, The oil-absorbing resin of 1.0 weight part and the toughening agent of 0.6 weight part;

[0038] Embodiment 6, the bisphenol A epoxy resin of 60 weight parts, the K54 tertiary amine of 4.5 weight parts, the HG-66 active silicon micropowder of 3.2 weight parts, the epichlorohydrin of 0.2 weight part, the curing agent of 28.0 weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com