Bearing inhaul cable used for manufacture of panel

A process and panel technology, applied in the direction of slender components, building components, etc., can solve the problems of instability, easy wear of stainless steel wires, etc., and achieve the effect of strengthening and increasing axial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable your reviewer to have a further understanding and recognition of the features and characteristics of the present invention, the following preferred embodiments are enumerated and illustrated as follows:

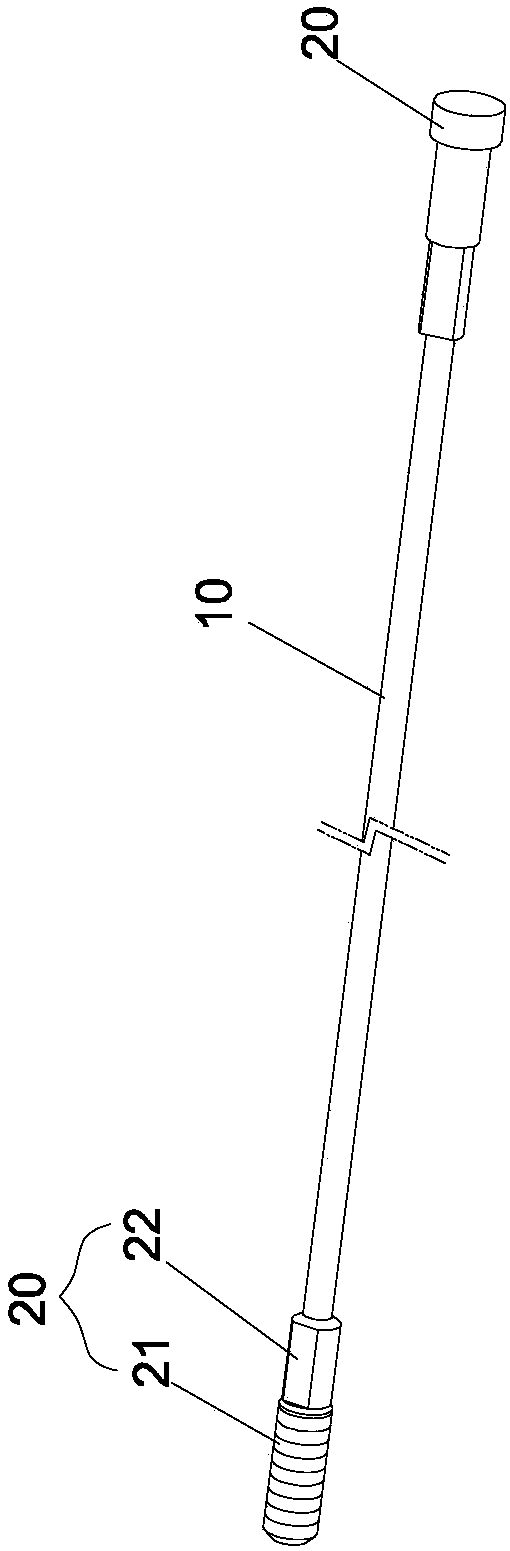

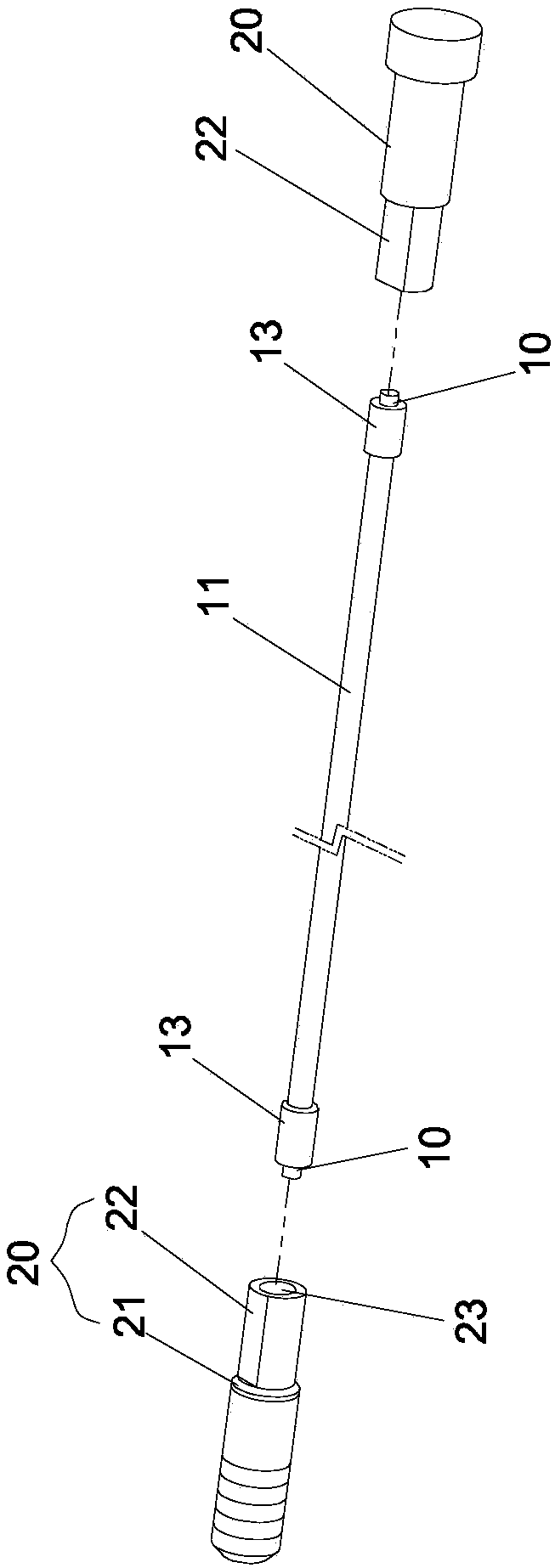

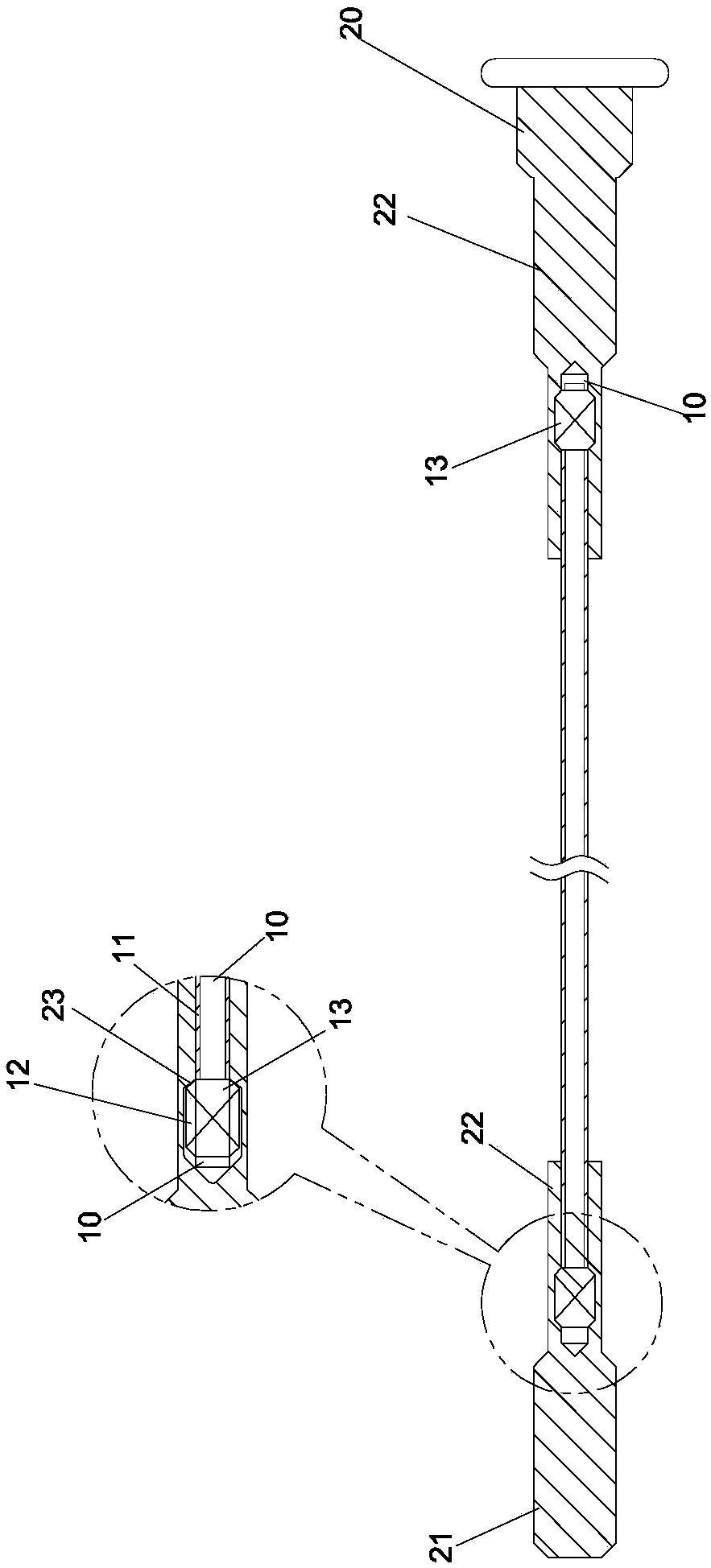

[0021] See Figure 1 to Figure 3 In the panel manufacturing process of the present invention, the load-bearing cable mainly includes a steel cable 10 and two sets of fixing members 20.

[0022] The steel cable 10 forms an outer layer 11 by coating the steel cable 10 with resin. Both ends of the steel cable 10 are reserved with connecting sections 12 that are not coated with resin. A shaft sleeve is provided on the connecting section 12 The anti-slip ring 13 is fixed, and the diameter of the anti-slip ring 13 is larger than the outer layer 11 of the steel cable 10. Among them, the steel cable 10 can be selected by multiple steel wires wound into a double shaft structure or a single shaft structure.

[0023] Secondly, the fixing member 20 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com