Bearing cable structure

A cable structure and bearing technology, applied in the field of bearing cable structure, can solve problems such as falling and affecting the panel manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

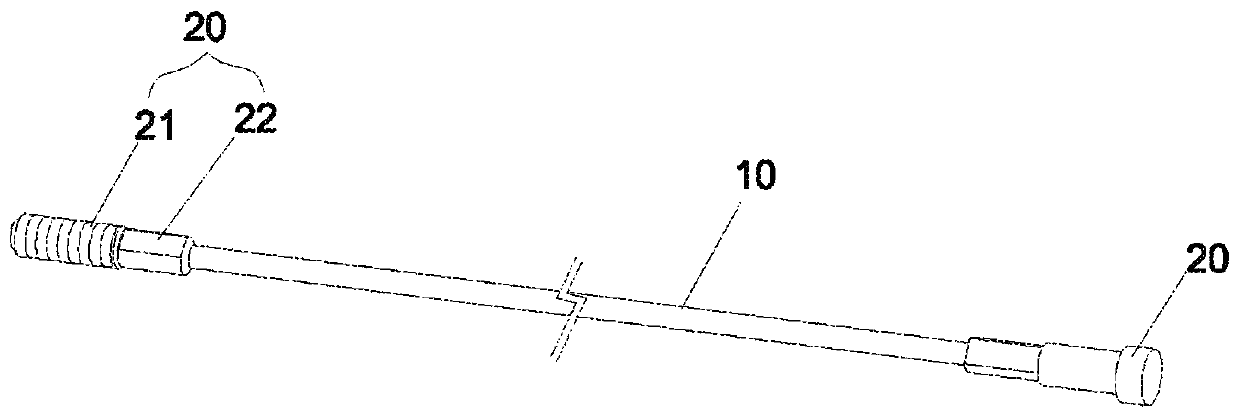

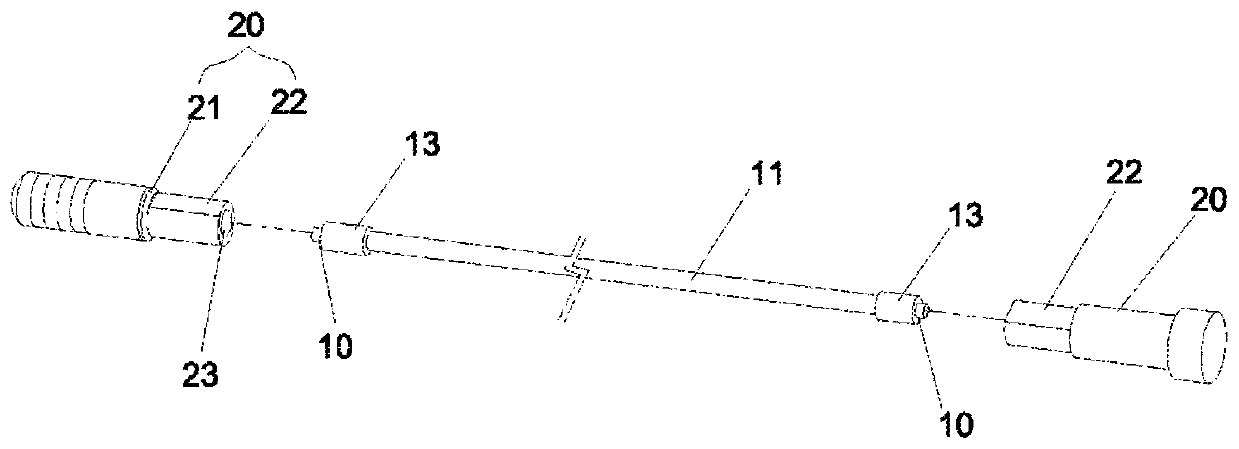

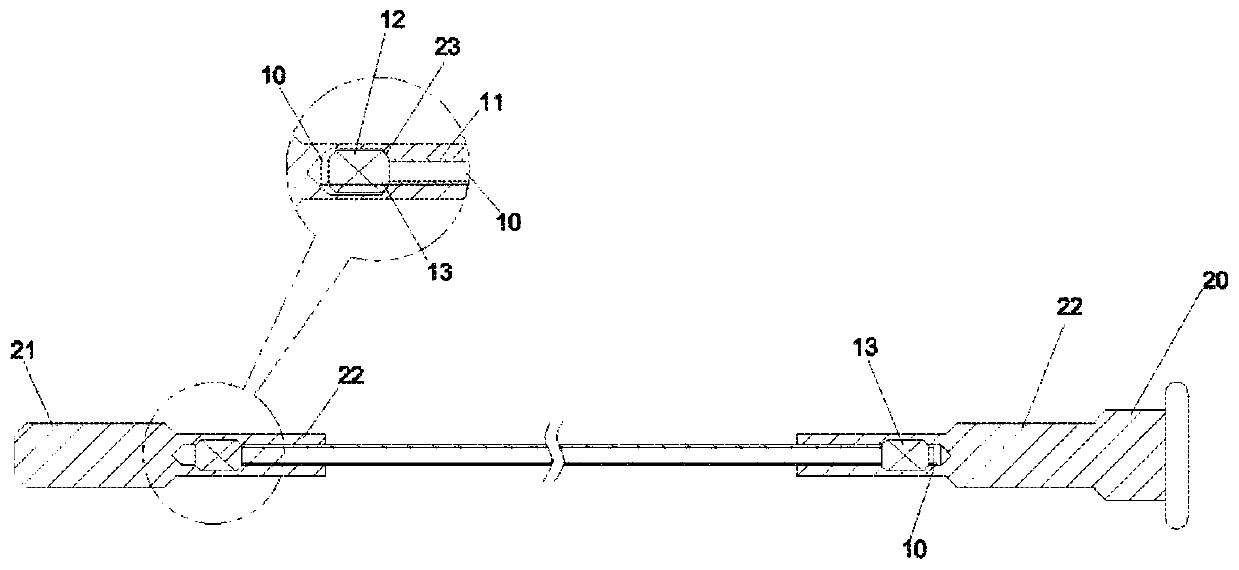

[0011] Referring now to the drawings, wherein like features and characteristics are represented by like reference numerals throughout the various drawings.

[0012] Please refer to Figure 1 to Figure 3 . like Figures 1 to 3 As shown, the bearing cable structure when manufacturing panels of the present invention may include steel cables 10 and two sets of fixing members 20 .

[0013] An outer layer 11 made of resin covers the steel cable 10 .

[0014] Two connecting portions 12 are respectively formed at both ends of the steel cable 10 not covered by the outer layer 11 . A non-slip ring 13 covers each of the two connecting parts 12 for fixing. The diameter of the anti-slip ring 13 is larger than that of the outer layer 11 . Alternatively, the steel cable 10 may be composed of multiple steel wires that are twisted around each other to form a biaxial structure or a single steel wire. shaft structure.

[0015] A threaded portion 22 is arranged on the outer edge of each fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com