Ultrasonic pressed-in nut

An ultrasonic and nut technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of small tension, easy falling off, and nut damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

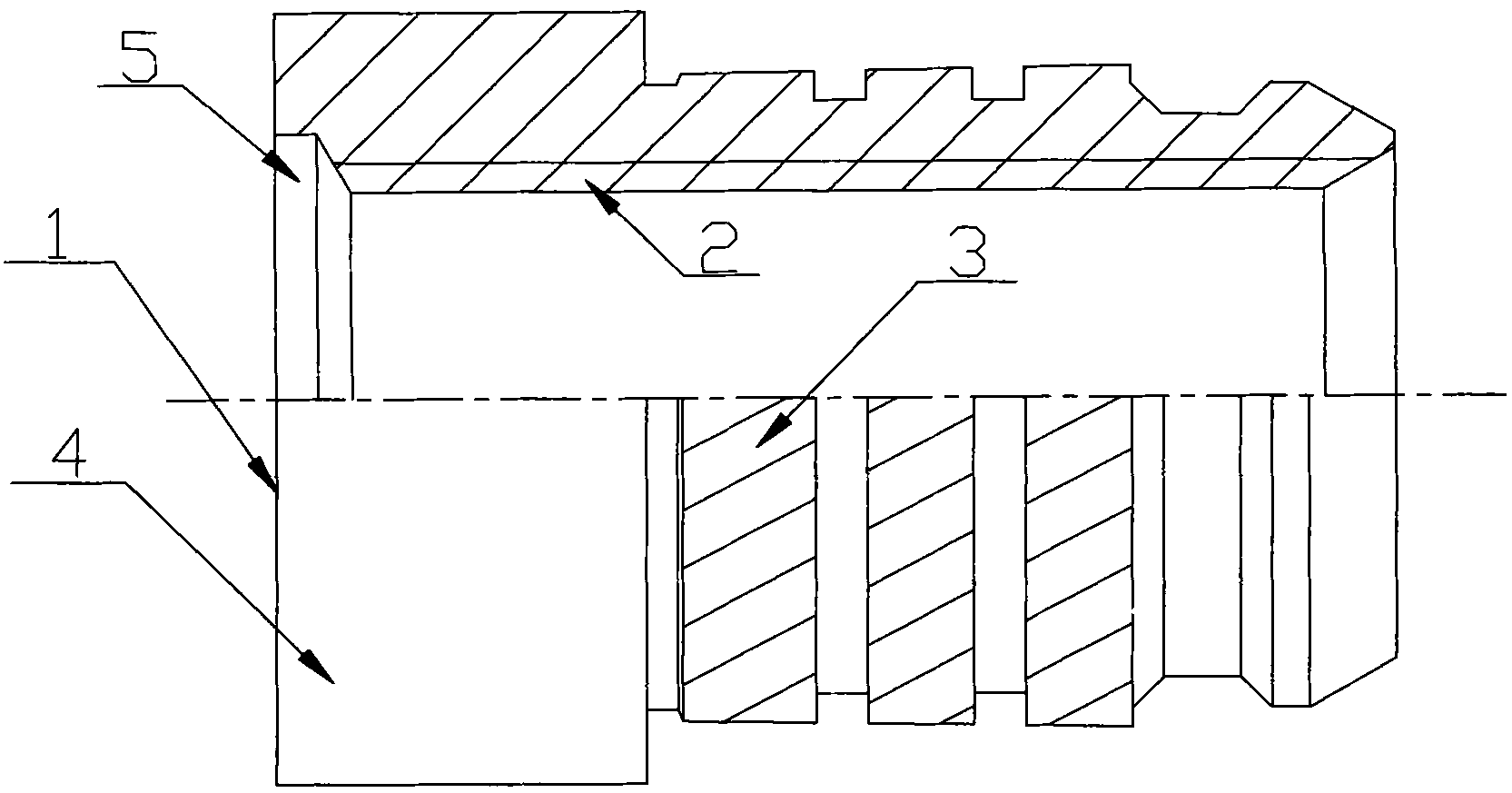

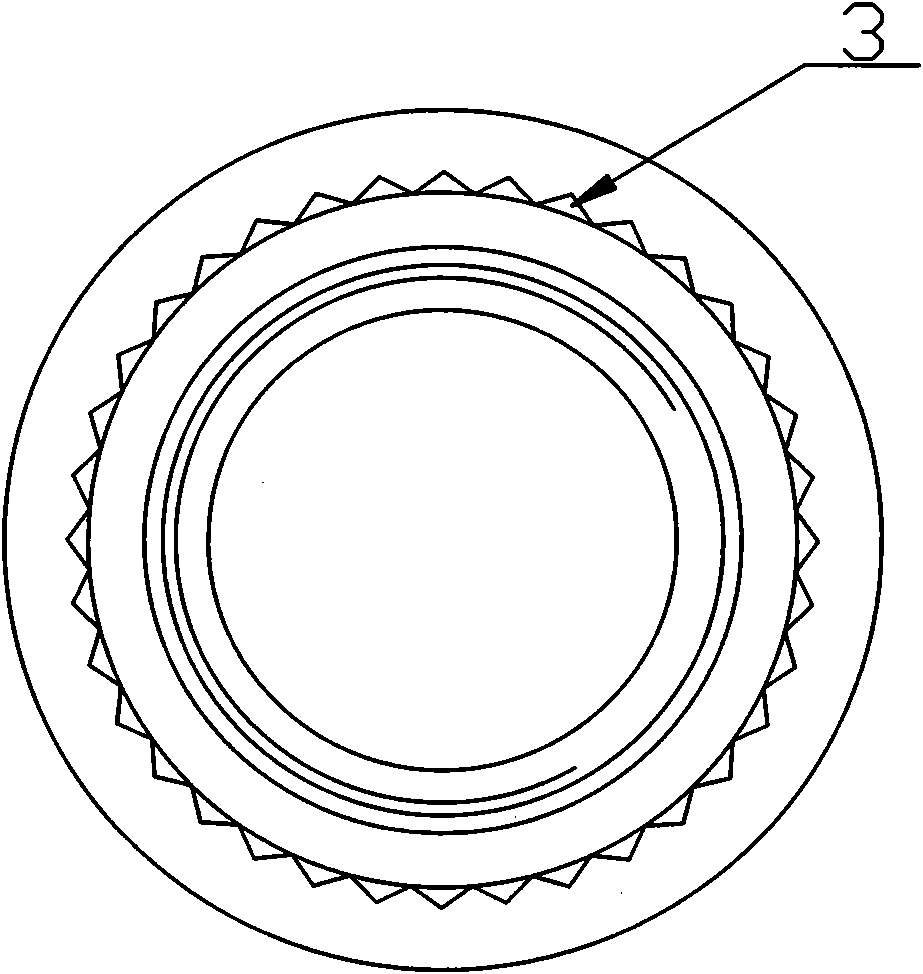

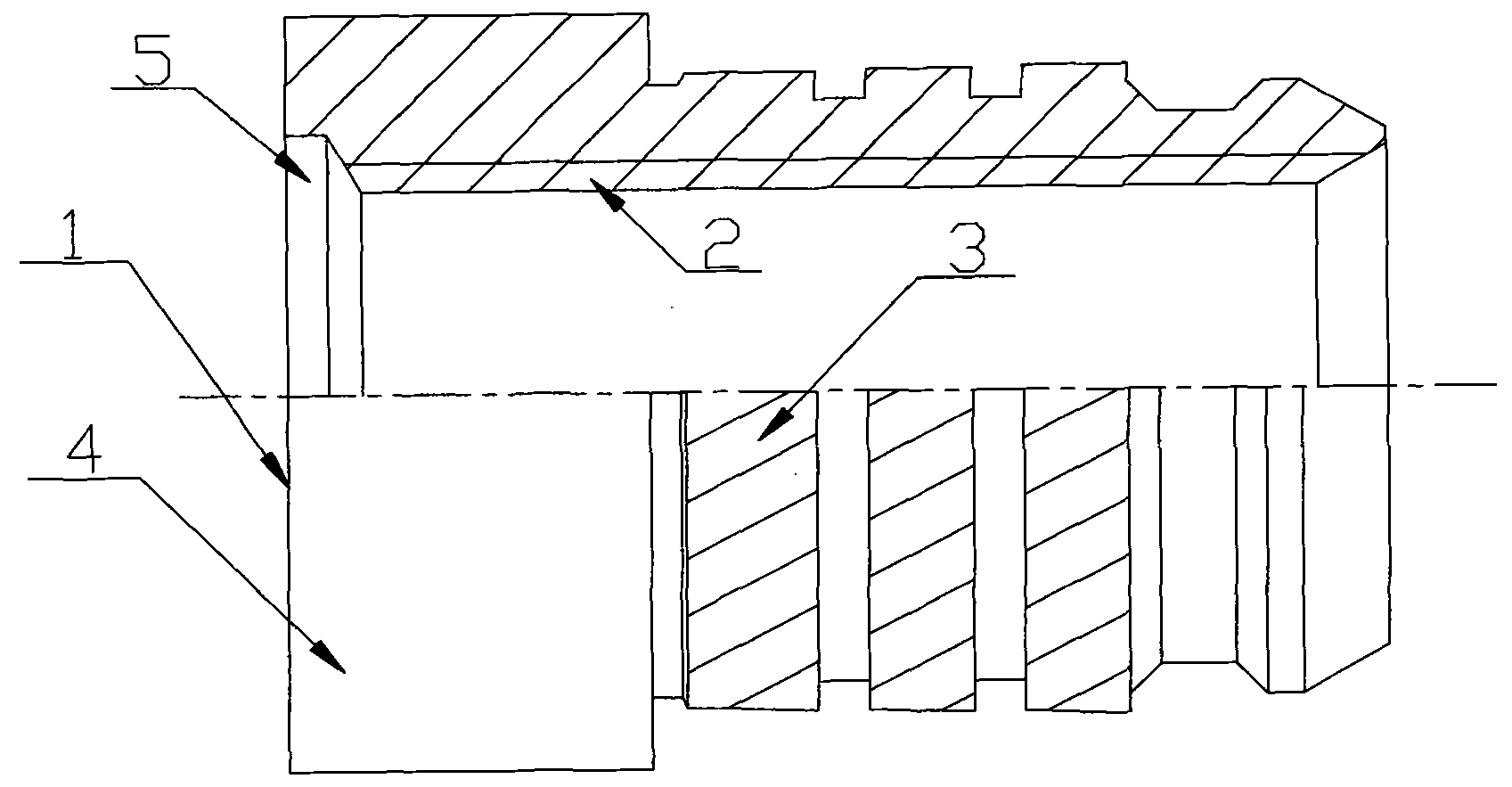

[0012] figure 1 and figure 2 Shown is an ultrasonic press-in nut, which is a hollow cylinder 1 with knurling 3 on the outer surface of the hollow cylinder 1 and threads 2 on the inner surface. The knurling 3 is inclined. The inclination of the knurling 3 is 25-30°, and the bearing force in the axial direction is greater, and it is not easy to fall off. One end of the hollow cylinder 1 has a countersunk 4, which can be placed in the countersunk hole to make the surface more smooth and not prominent. The end of the thread is provided with a small step 5, in order to protect the thread of the inner hole from being damaged.

[0013] Preheat the ultrasonic press-in nut and press it in. It can be rotated when it is pressed in. Press the countersunk 4 into the countersunk hole, and the bolt can be connected to the internal thread 2. When pressing in, the temperature control of the ultrasonic wave, the length of heating time, the speed of pressing in, the calculation of the interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com