Toothed belt pre-tightening device and method

A technology of toothed belt and toothed plate, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc. The effect of good tightening effect and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

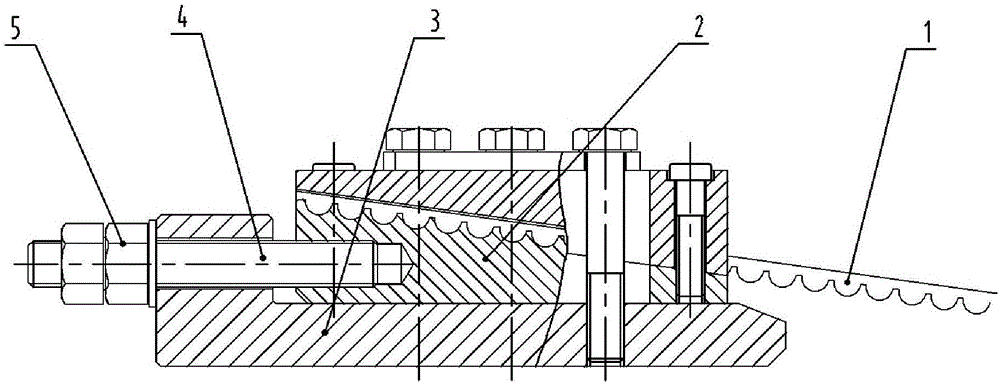

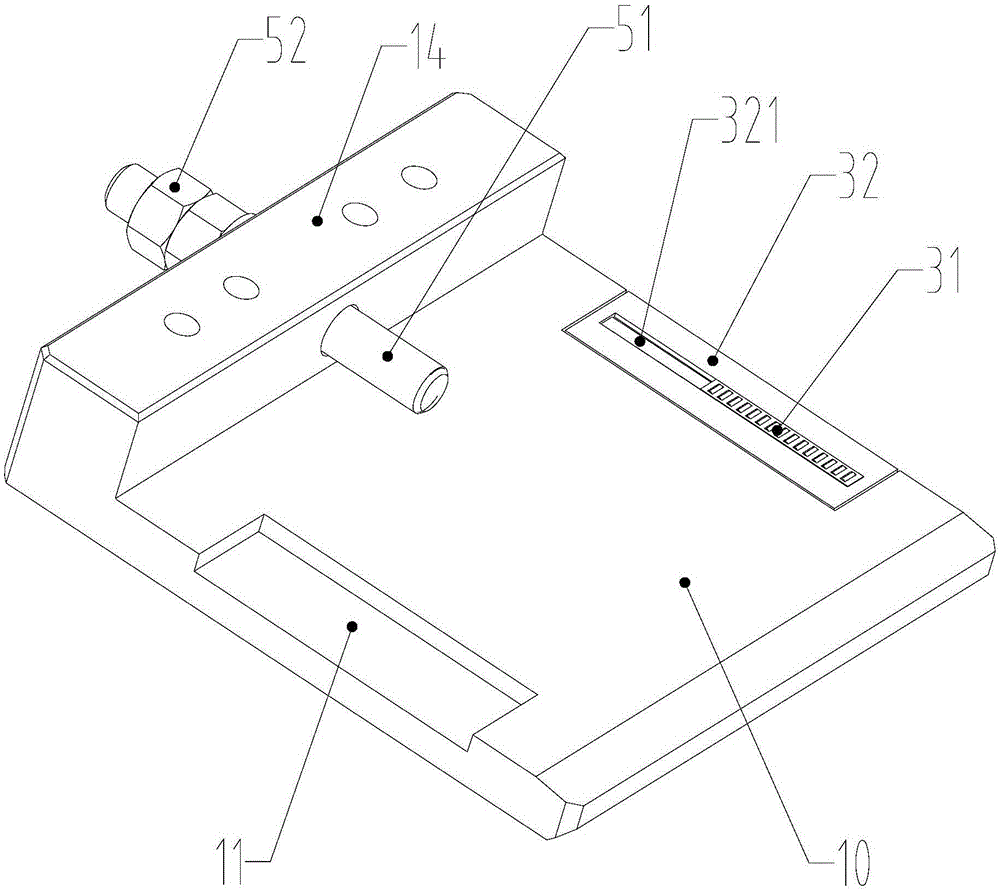

[0030] Such as figure 2 and 3 As shown, according to the first embodiment of the present invention, the toothed belt pretensioning device includes a toothed plate seat 10, a toothed plate 20, a friction reducing part, a position adjusting member 40 and the like. The tooth plate seat 10 is used to carry other components, and at least one first mounting groove 11 for carrying the friction reducing part is provided on the tooth plate seat 10. In order to ensure that the friction reducing part can be easily mounted and dismounted, the first mounting groove 11 runs through the At least one side wall of the board seat 10 is used to form a disassembly opening. The toothed plate 20 is arranged on the toothed plate seat 10 for fixing the toothed belt 60 . The friction reducing part is detachably arranged in the first installation groove 11, and has a working position in contact with the bottom surface of the toothed plate 20, and is used to support the toothed plate 20 to reduce the...

Embodiment 2

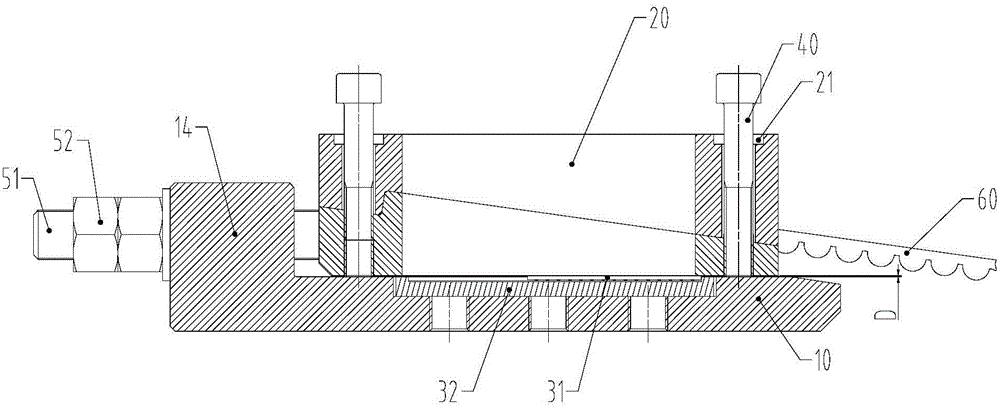

[0045] In this embodiment, except that the setting position and working method of the position adjusting member 40 are different from those in the first embodiment, the structures and working methods of other components are the same as those in the first embodiment.

[0046] Such as Figure 4 As shown, specifically, in this embodiment, the tooth plate seat 10 is provided with a second threaded hole 12 penetrating through the tooth plate seat 10 along the thickness direction of the tooth plate seat 10, and the second threaded hole 12 is connected with the first installation groove 11 connectivity. The position adjusting member 40 has a threaded rod section, which is screwed into the second threaded hole 12 and pushes up the friction reducing part, so that the friction reducing part contacts with the toothed plate 20 . In this embodiment, the position adjusting member 40 may be a common bolt or any other structure with a screw section. The anti-friction part can be a rolling a...

Embodiment 3

[0053] In this embodiment, except that the setting position and working method of the position adjusting member 40 are different from those in the first embodiment, the structures and working methods of other components are the same as those in the first embodiment.

[0054] Such as Figure 5 and 6 As shown, in this embodiment, the position adjusting member 40 has a cam segment 41 . Specific as Figure 6 As shown, the position adjustment member 40 is provided with a sleeve with an elliptical cross-sectional shape outside the screw or bolt, and the sleeve forms a cam segment 41 . It should be noted that, the cross-sectional shape of the cam segment 41 may be other shapes, as long as a height difference is generated during the rotation of the position adjusting member 40 .

[0055] In order to cooperate with this kind of position adjustment member 40, a second installation groove 13 is also provided on the gear plate seat 10, the second installation groove 13 is located below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com