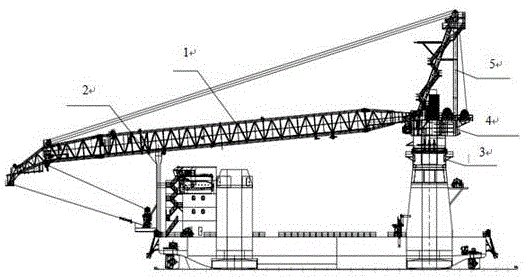

Hoisting process of full-circle slewing crane

A crane and full rotation technology, applied in cranes and other directions, can solve the problems of slow installation progress and large on-site installation workload, and achieve the effect of reducing equipment use costs, reducing installation workload, and speeding up installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Such as figure 1 As shown, the present invention discloses a hoisting process of a full-slewing crane, the steps of which are as follows:

[0021] (1) Lifting of components: Use 1600T floating crane double hooks to hang the slewing chassis and the assembly lifting lugs on the top of the herringbone frame. The four assembly lifting lugs on the slewing chassis are integrated by the Q690E high-strength plate with a thickness of 40mm at the hinge point of the slewing chassis , the weighted plate is formed, and the required components are blanked as a whole during the numerical control; the assembly lugs on the top of the herringbone frame are the luffing hinge point lugs and hinge point shafts on the top of the herringbone frame, and the original parts are used as the lifting lugs, which are safe Reliable, without additional processing; hoist the rotary chassis 4 and herringbone frame 5 components, slowly tension the hoisting wire rope, hoist the rotary chassis 4 and herrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com