Extraction tower and process for removing methanol from residual C4 of etherification reaction

A technology for post-ether C4 and extraction towers, which is applied in extraction purification/separation, liquid solution solvent extraction, organic chemistry, etc., can solve the problem of inability to meet the requirements of isooctane devices, and achieves the elimination of anti-springboard and uniform liquid flow. , Improve the effect of gas-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

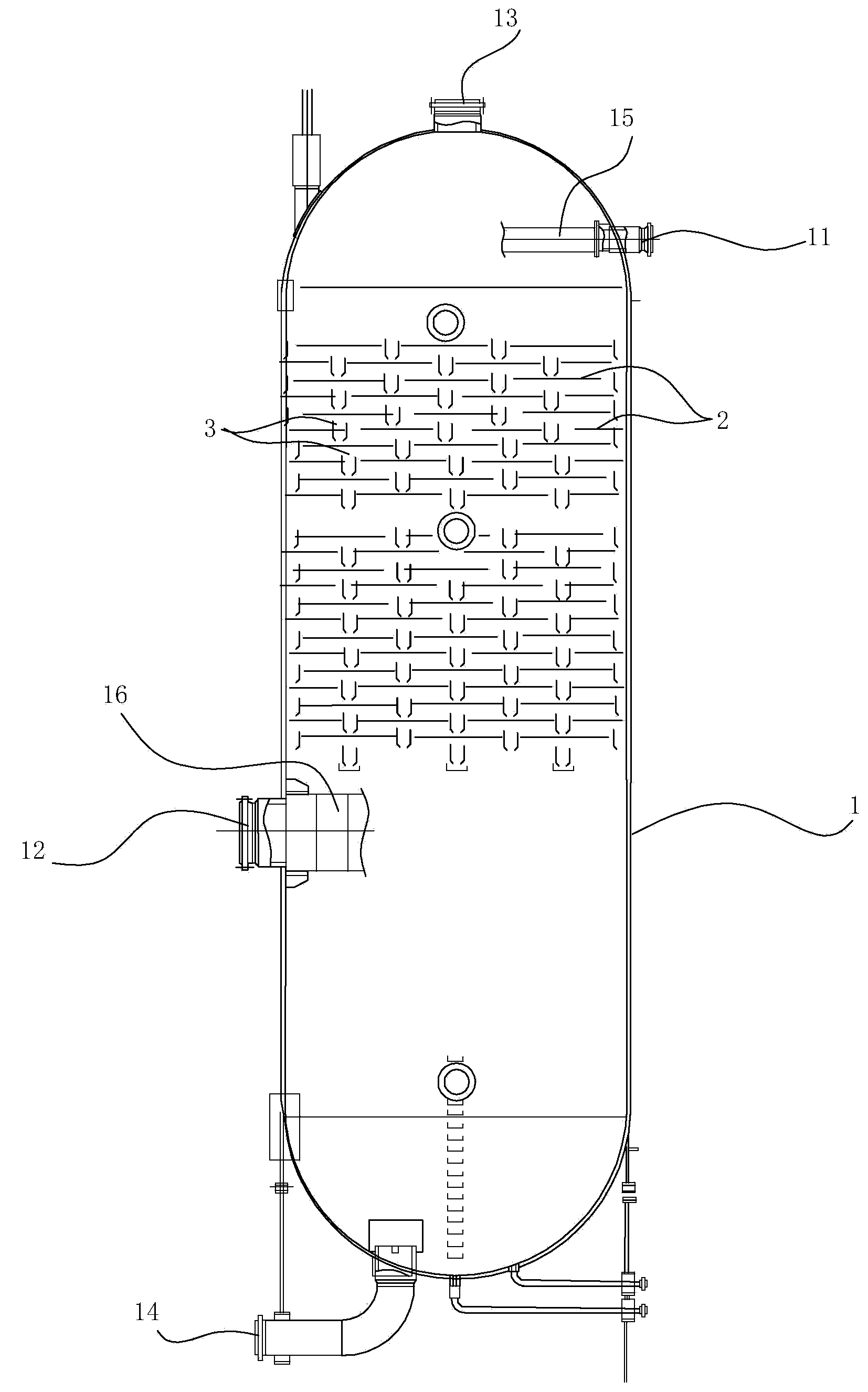

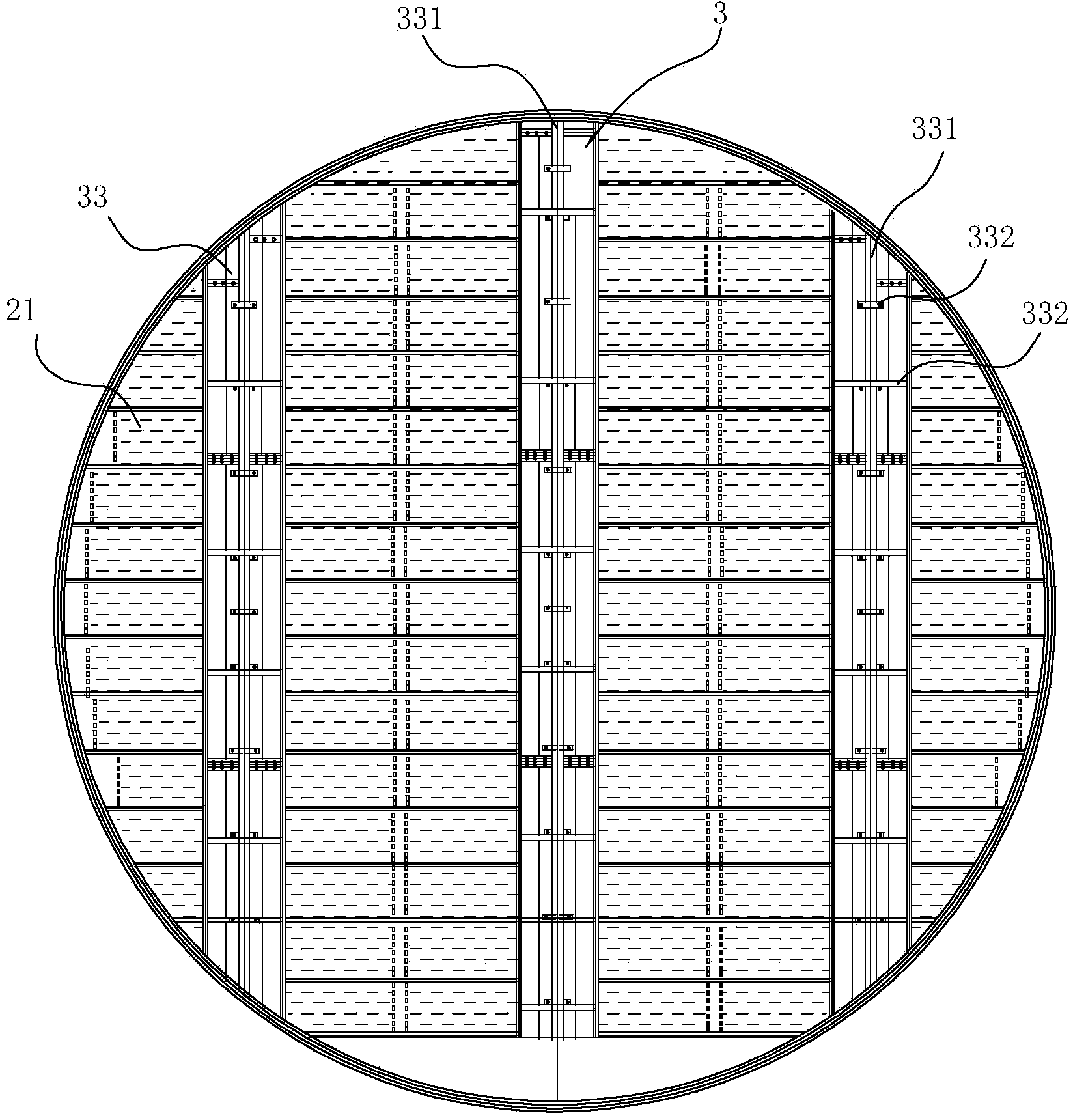

[0033] Such as Figure 1 to Figure 4 As shown, the extraction tower includes:

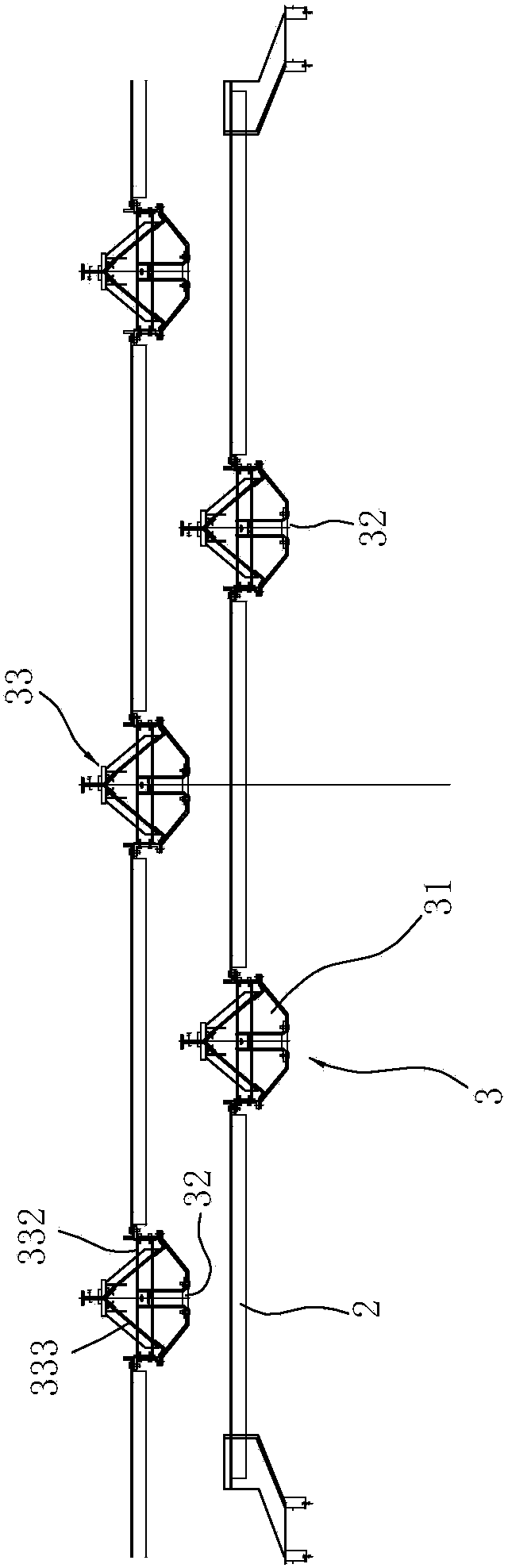

[0034] The tower body 1 adopts a conventional tower body, which is composed of a main body, an upper head and a lower head, and a plurality of support beams 3 are arranged in parallel in the tower body. These support beams are divided into multiple groups, and each group of support beams corresponds to each Layer trays 2 are arranged on the same circumferential surface.

[0035] In this embodiment, each group of supporting beams includes multiple supporting beams, and the supporting beams in two adjacent groups of supporting beams are arranged alternately up and down. Each support beam 3 is provided with a plurality of grooves 31 at intervals along the length direction of the support beam, and a liquid flow hole 32 is provided on the bottom surface of each groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com