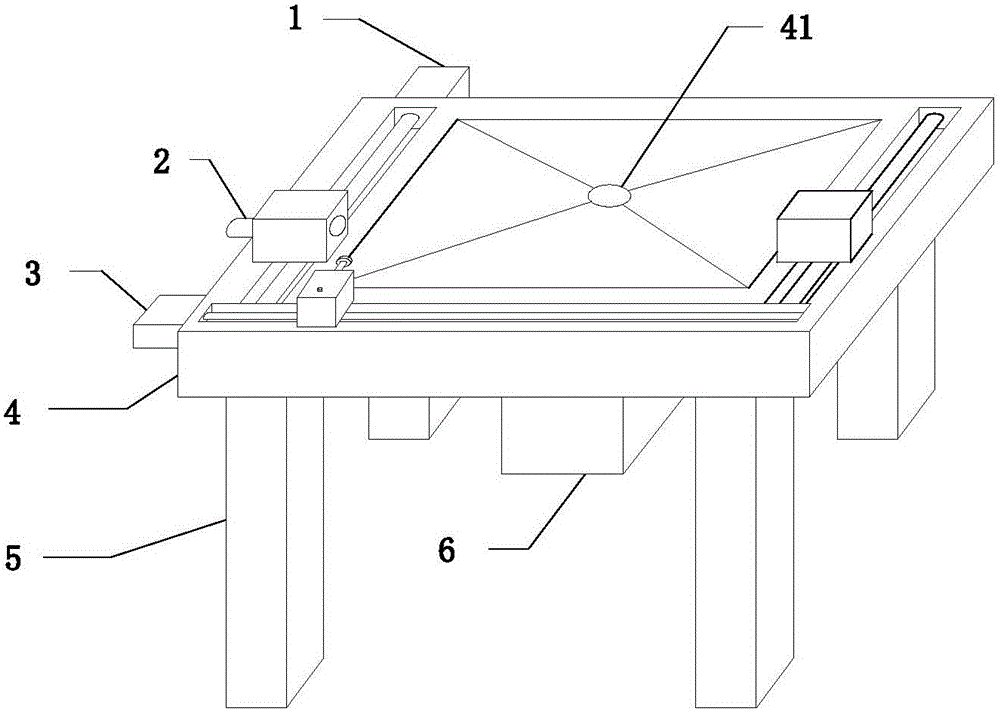

Metal pipe outer wall rust removing and cleaning equipment

A technology for cleaning equipment and metal pipes, which is applied in the field of rust removal and cleaning equipment for the outer wall of metal pipes. Good rust effect, improved rust removal efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

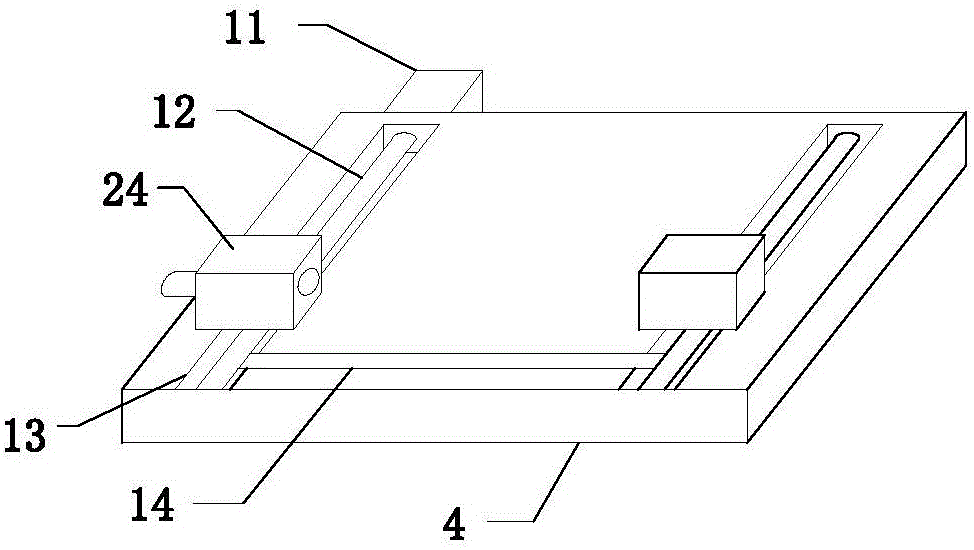

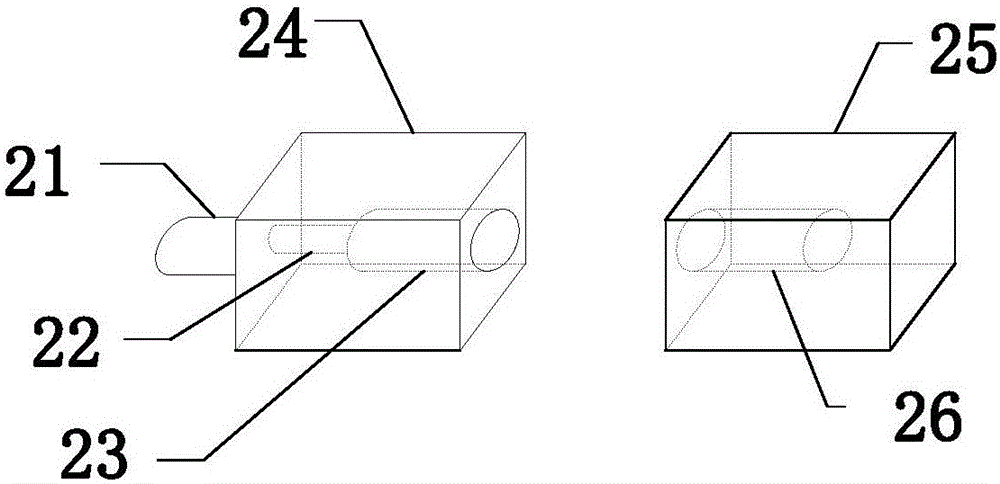

[0024] The specific embodiment: the operator runs the motor one 11, the motor one 11 drives the moving screw mandrel 12 to rotate, and the moving screw mandrel 12 rotates to drive the base one 24 and the base two 25 to move simultaneously, after moving to the required position, stop running the motor one 11, and the metal pipe is placed on the first clamp 23 and the second clamp 26, and the metal pipe is clamped. Because the present invention adds a motor one 11, a moving screw 12, a tank body 13 and a connecting rod 14, the The design solves the problem of inconvenient loading and unloading of metal pipes, which is convenient for operators to install metal pipes and reduces the installation workload.

[0025] After the metal pipe is clamped, the operator runs the motor two 21, the motor two 21 drives the drive shaft 22 to rotate, the drive shaft 22 drives the clamp one 23 to rotate, and the clamp one 23 drives the metal pipe to rotate, because the present invention adds the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com