Method for mounting large shafts in ship and ocean engineering

A marine engineering and installation method technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of long working hours, high labor intensity of workers, damage to large or heavy shaft liner bushings, etc. Achieve the effects of preventing collisions, improving quality and efficiency, and reducing installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below we further elaborate the present invention in combination with the accompanying drawings and specific embodiments in order to understand the working principle of the present invention more clearly, but the protection scope of the present invention cannot be limited by this.

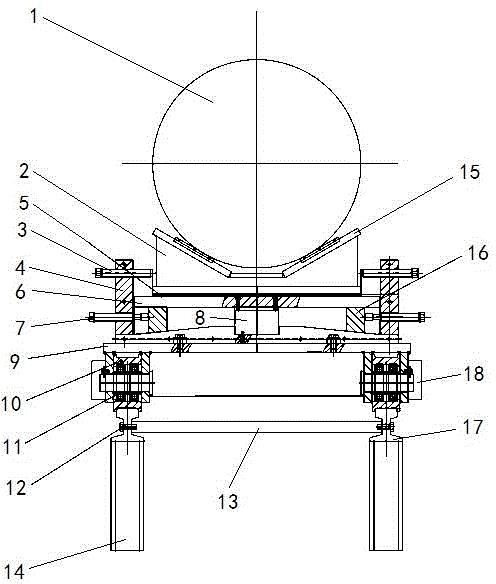

[0021] like figure 1 As shown, the present invention is a method for installing large shafts in ships and marine engineering, the purpose of which is to transport large and heavy shafts such as stern shafts to the installation location smoothly and expressly, so as to realize fast and safe installation. The auxiliary device structurally includes a V-shaped bracket 2, an adjustment frame 4, a hydraulic cylinder 8, a driving traveling mechanism 18, a roller 10 and a heavy rail 17. A V-shaped groove is arranged on the upper part of the V-shaped bracket 2, and the large-scale shafts including the stern shaft 1 are placed in the V-shaped groove. As an optimized design, the upper part of the V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com